Abstract

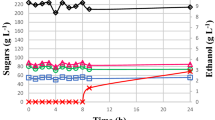

The cell viability and fermentation performance often deteriorate in fermentations of spent sulphite liquor (SSL). This investigation therefore addresses the question of how different cultivation conditions for yeast cells influence their ability to survive and boost the ethanol production capacity in an SSL-based fermentation process. The strains used as pitching agents were an industrially harvested Saccharomyces cerevisiae and commercial dry baker’s yeast. This study therefore suggests that exposure to SSL in combination with nutrients, prior to the fermentation step, is crucial for the performance of the yeast. Supplying 0.5 g/l fresh yeast cultivated under appropriate cultivation conditions may increase ethanol concentration more than 200%.

Similar content being viewed by others

References

Alkasrawi M, Rudolf A, Lidén G, Zacchi G (2006) Influence of strain and cultivation procedure on the performance of simultaneous saccharification and fermentation of steam pretreated spruce. Enzym Microbiol Technol 38:279–286

Almeida JRM, Modig T, Petersson A, Hahn-Hägerdal B, Lidén G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Barbour EA, Priest FG (1988) Some effects of Lactobacillus contamination in scotch whiskey fermentations. J Inst Brew 94:89–92

Basilio ACM, de Araujo PRL, de Morais JOF, da Silva Filho EA, de Morais MA Jr, Simoes DA (2008) Detection and identification of wild yeast contaminants of the industrial fuel ethanol fermentation process. Curr Microbiol 56:322–326

Bischoff KM, Liu S, Leathers TD, Worthington RE, Rich JO (2009) Modeling bacterial contamination of fuel ethanol fermentation. Biotechnol Bioeng 103:117–122

Delgenes JP, Moletta R, Navarro JM (1996) Effects of lignocellulose degradation products on ethanol fermentations of glucose and xylose by Saccharomyces cerevisiae, Zymomonas mobilis, Pichia stipitis, and Candida shehatae. Enzym Microbiol Technol 19:220–225

Ingledew WM (2009) Yeasts: physiology, nutrition and ethanol production. In: Ingledew WM, Kelsall DR, Austin GD, Kluhspies C (eds) The alcohol textbook, 5th edn. Nottingham University Press, Nottingham, pp 101–113

Ivorra C, Pérez-Ortìn IE, del Olmo M (1999) An inverse correlation between stress resistance and stuck fermentations in wine yeasts. A molecular study. Biotechnol Bioeng 64:668–708

Laluce C, Tognolli JO, de Oliviera KF, Souza CS, Morais MR (2009) Optimization of temperature, sugar concentration, and inoculum size to maximize ethanol production without significant decrease in yeast cell viability. Appl Microbiol Biotechnol 83:627–637

Larsson S, Reimann A, Nilvebrant N-O, Jönsson LJ (1999) Comparison of different methods for the detoxification of lignocellulose hydrolyzates of spruce. Appl Biochem Biotechnol 77:91–103

Lopez MJ, Nichols NN, Dien BS, Moreno J, Bothast RJ (2004) Isolation of microorganisms for biological detoxification of lignocellulosic hydrolysates. Appl Microbiol Biotechnol 64:125–131

Martinez A, Rodriguez ME, York SW, Preston JF, Ingram LO (2000) Effects of Ca(OH)2 treatments (“overliming”) on the composition and toxicity of bagasse hemicellulose hydrolyzates. Biotechnol Bioeng 69(5):526–536

McCaig R, Bendiak DS, Dirk S (1985) Yeast handling studies. I. Agitation of stored pitching yeast. Techn Quart Master Brew Assoc Am 22:172–176

McCaig R, Bendiak DS (1985) Yeast handling studies. II. Temperature of storage of pitching yeast. Techn Quart Master Brew Assoc Am 22:177–180

Narendranath NV, Thomas KC, Ingledew WM (2001) Effects of acetic acid and lactic acid on the growth of Saccharomyces cerevisiae in minimal media. J Indust Microbiol Biotech 26:171–177

Nilsson A, Norbeck J, Oelz R, Blomberg A, Gustafsson L (2001) Fermentative capacity after cold storage of baker’s yeast is dependent on the initial physiological state but not correlated to the levels of glycolytic enzymes. Inter J Food Microbiol 71:111–124

Olsson L, Hahn-Hägerdal B (1993) Fermentative performance of bacteria and yeast in lignocellulose hydrolysates. Process Biochem 28:249–257

Palmqvist E, Hahn-Hägerdal B, Szengyel Z, Zacchi G, Rèczey K (1997) Simultaneous detoxification and enzyme production of hemicellulose hydrolyzates obtained after steam pretreatment. Enzyme Microbiol Technol 20:286–293

Parawira W, Tekere M (2010) Biotechnological strategies to overcome inhibitors in lignocellulose hydrolysates for ethanol production: review. Crit Rev Biotechnol. doi: 10.3109/07388551003757816

Schimz K-L (1980) The effect of sulfite on the yeast Saccharomyces cerevisiae. Arch Microbiol 125:89–95

Silva CJSM, Roberto IC (2001) Improvement of xylitol production by Candida guilliermondii FTI 20037 previously adapted to rice straw hemicellulosic hydrolysate. Lett Appl Microbiol 32:248–252

Sjöström E (1981) Wood chemistry—fundamentals and applications. Academic Press, New York

Skinner AK, Leathers TD (2004) Bacterial contaminants of fuel ethanol production. J Ind Microbiol Biotechnol 31:401–408

Thomsson E, Larsson C, Albers E, Nilsson A, Fransén CJ, Gustafsson L (2003) Carbon starvation can induce energy deprivation and loss of fermentative capacity in Saccharomyces cerevisiae. Appl Environ Microbiol 69:3251–3257

Zhu JJ, Yong Q, Xu Y, Yu S-Y (2009) Comparative detoxification of vacuum evaporation/steam stripping combined with overliming on corn stover prehydrolyzate. Energy Environ Technol ICEET `09. International conference. doi: 10.1109/ICEET.2009.523

Acknowledgments

Financial support by the Kempe Foundation and the county administrative board of Västernorrland is gratefully acknowledged. Special thanks are also given to Domsjö Fabriker for their cooperation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Johansson, E., Brandberg, T. & Larsson, C. Influence of cultivation procedure for Saccharomyces cerevisiae used as pitching agent in industrial spent sulphite liquor fermentations. J Ind Microbiol Biotechnol 38, 1787–1792 (2011). https://doi.org/10.1007/s10295-011-0965-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-011-0965-0