Abstract

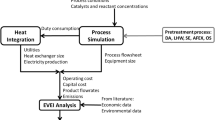

Sugarcane bagasse is used as a fuel in conventional bioethanol production, providing heat and power for the plant; therefore, the amount of surplus bagasse available for use as raw material for second generation bioethanol production is related to the energy consumption of the bioethanol production process. Pentoses and lignin, byproducts of the second generation bioethanol production process, may be used as fuels, increasing the amount of surplus bagasse. In this work, simulations of the integrated bioethanol production process from sugarcane, surplus bagasse and trash were carried out. Selected pre-treatment methods followed, or not, by a delignification step were evaluated. The amount of lignocellulosic materials available for hydrolysis in each configuration was calculated assuming that 50% of sugarcane trash is recovered from the field. An economic risk analysis was carried out; the best results for the integrated first and second generation ethanol production process were obtained for steam explosion pretreatment, high solids loading for hydrolysis and 24–48 h hydrolysis. The second generation ethanol production process must be improved (e.g., decreasing required investment, improving yields and developing pentose fermentation to ethanol) in order for the integrated process to be more economically competitive.

Similar content being viewed by others

References

Balat M, Balat H, Öz C (2008) Progress in bioethanol processing. Prog Energy Combust Sci 34:551–573

Brasil (2010) Ministry of Development, Industry and Foreign Trade. Available from http://www.mdic.gov.br. Accessed on March 20, 2010

Carrasco C, Baudel HM, Sendelius J, Modig T, Roslander C, Galbe M, Hahn-Hägerdal B, Zacchi G, Lidén G (2010) SO2-catalyzed steam pretreatment and fermentation of enzymatically hydrolyzed sugarcane bagasse. Enzyme Microb Technol 46:64–73

CEPEA—Center for Advanced Studies on Applied Economics (2010) Available from http://www.cepea.usp.br. Accessed February 20, 2010

Chen JCP, Chou CC (1993) Cane sugar handbook: a manual for cane sugar manufacturers and their chemists. Wiley, London

Demirbaş A (2001) Relationships between lignin contents and heating values of Biomass. Energy Convers Manag 42:183–188

Dias MOS, Ensinas AV, Nebra SA, Maciel Filho R, Rossell CEV, Maciel MRW (2009) Production of bioethanol and other bio-based materials from sugarcane bagasse: integration to conventional bioethanol production process. Chem Eng Res Des 87:1206–1216

Dias MOS, Ensinas AV, Modesto M, Nebra SA, Maciel Filho R, Rossell CEV (2009) Energy efficiency in anhydrous bioethanol production from sugarcane. Part 1: Process simulation and thermal integration. Proc ECOS 2009:425–436

Dias MOS, Maciel Filho R, Rossell CEV (2007) Efficient cooling of fermentation vats in ethanol production—Part 1. Sugar J 70:11–17

Dodić S, Popov S, Dodić J, Ranković J, Zavargo Z, Mučibabić RJ (2009) Bioethanol production from thick juice as intermediate of sugar beet processing. Biomass Bioenergy 33:822–827

Ensinas AV, Nebra SA, Lozano MA, Serra LM (2007) Analysis of process steam demand reduction and electricity generation in sugar and ethanol production from sugarcane. Energy Convers Manag 48:2978–2987

Franceschin G, Zamboni A, Bezzo F, Bertucco A (2008) Ethanol from corn: a technical and economical assessment based on different scenarios. Chem Eng Res Des 86:488–498

Garcia DR (2009) Determination of kinetics data of the pretreatment of sugarcane bagasse with alkaline hydrogen peroxide and subsequent enzymatic hydrolysis. MSc Dissertation. School of Chemical Engineering, University of Campinas (in Portuguese). Available from http://cutter.unicamp.br/document/?code=000442925. Accessed March 29, 2010

Goldemberg J (2007) Ethanol for a sustainable energy future. Science 315:808–810

Hassuani SJ, Leal MRLV, Macedo IC (eds) (2005) Biomass power generation—sugarcane bagasse and trash. CTC and PNUD, Piracicaba

Hoch PM, Espinosa J (2008) Conceptual design and simulation tools applied to the evolutionary optimization of a bioethanol purification plant. Ind Eng Chem Res 47:7381–7389

Intelligen, Inc. (2009) SuperPro Designer, v. 7.5

JBEI (2010) Corn Stover to Ethanol Model. Available from http://www.econ.jbei.org. Accessed March 29, 2010

Kuo C-H, Lee C-K (2009) Enhanced enzymatic hydrolysis of sugarcane bagasse by N-methylmorpholine-N-oxide pretreatment. Bioresour Technol 100:866–871

Larson ED, Williams RH, Leal MRLV (2001) A review of biomass integrated-gasifier/gas turbine combined cycle technology and its application in sugarcane industries, with an analysis for Cuba. Energy Sustain Dev 5(1):54–76

Maas RHW, Bakker RR, Boersma AR, Bisschops I, Pels JR, de Jong E, Weusthuis RA, Reith H (2008) Pilot-scale conversion of lime-treated wheat straw into bioethanol: quality assessment of bioethanol and valorization of side streams by anaerobic digestion and combustion. Biotechnol Biofuels 1:14. doi:10.1186/1754-6834-1-14

Macedo IC, Seabra JEA, Silva JEAR (2008) Green house gases emissions in the production and use of ethanol from sugarcane in Brazil: the 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 32(7):582–595

Martín C, González Y, Fernández T, Thomsen AB (2006) Investigation of cellulose convertibility and ethanolic fermentation of sugarcane bagasse pretreated by wet oxidation and steam explosion. J Chem Technol Biotechnol 81:1669–1677

Mesa L, González E, Ruiz E, Romero I, Cara C, Felissia F, Castro E (2010) Preliminary evaluation of organosolv pre-treatment of sugar cane bagasse for glucose production: application of 23 experimental design. Appl Energy 87:109–114

Novozymes (2009) Enabling cost efficient enzymatic hydrolysis for biomass-to-ethanol conversion. In: 7th Global clean technology conference, New York. Available from http://www.novozymes.com/en/MainStructure/Investor/Events+and+presentations/Presentations. Accessed March 29, 2010

Pandey A, Soccol CR, Nigam P, Soccol VT (2000) Biotechnological potential of agro-industrial residues. I: Sugarcane Bagasse. Bioresour Technol 74:69–80

Pfeffer M, Wukovits W, Beckmann G, Friedl A (2007) Analysis and decrease of the energy demand of bioethanol-production by process integration. Appl Therm Eng 27:2657–2664

Rabelo SC, Maciel Filho R, Costa AC (2008) A comparison between lime and alkaline hydrogen peroxide pretreatments of sugarcane bagasse for ethanol production. Appl Biochem Biotechnol 148:45–58

Rabelo SC, Garzón Fuentes LL, Garcia DR, Maciel Filho R, Costa AC (2009) Influence of biomass concentration increase in the pretreatment stage of sugarcane bagasse in the enzymatic hydrolysis profile. XXV Congreso Colombiano de Ingeniería Química, Medellín

Rao K, Chelikani S, Relue P, Varanasi S (2008) A novel technique that enables efficient conduct of simultaneous isomerization and fermentation (SIF) of xylose. Appl Biochem Biotechnol 146:101–117

Rosgaard L, Pedersen S, Meyer AS (2007) Comparison of different pretreatment strategies for enzymatic hydrolysis of wheat and barley straw. Appl Biochem Biotechnol 143:284–296

Saxena RC, Adhikari DK, Goyal HB (2009) Biomass-based energy fuel through biochemical routes: a review. Renew Sustain Energy Rev 13:167–178

Sánchez ÓJ, Cardona CA (2008) Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour Technol 99:5270–5295

Seabra JEA, Tao L, Chum HL, Macedo IC (2010) A techno-economic evaluation of the effects of centralized cellulosic ethanol and co-products refinery options with sugarcane mill clustering. Biomass Bioenergy 34:1065–1078

Silverstein RA, Chen Y, Sharma-Shivappa RR, Boyette MD, Osborne J (2007) A comparison of chemical pretreatment methods for improving saccharification of cotton stalks. Bioresour Technol 98:3000–3011

Soccol CR et al (2009) Bioethanol from lignocelluloses: status and perspectives in Brazil. Bioresour Technol 101:4820–4825

Srinivasan S (2009) The food v. fuel debate: a nuanced view of incentive structures. Renewable Energy 34:950–954

UDOP (Union of Biofuel Producers) (2010) Available from http://www.udop.com.br/index.php?item=cana. Accessed February 20, 2010

Walter A, Ensinas AV (2010) Combined production of second-generation biofuels and electricity from sugarcane residues. Energy 35:874–879

Acknowledgments

The authors would like to thank Dedini Indústrias de Base S/A for supplying investment data.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation at the 32nd Symposium on Biotechnology for Fuels and Chemicals.

Rights and permissions

About this article

Cite this article

Dias, M.O.S., da Cunha, M.P., Maciel Filho, R. et al. Simulation of integrated first and second generation bioethanol production from sugarcane: comparison between different biomass pretreatment methods. J Ind Microbiol Biotechnol 38, 955–966 (2011). https://doi.org/10.1007/s10295-010-0867-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0867-6