Abstract

The aim of this work was to select an efficient impeller to be used in a stirred reactor for the enzymatic hydrolysis of sugar cane bagasse. All experiments utilized 100 g (dry weight)/l of steam-pretreated bagasse, which is utilized in Brazil for cattle feed. The process was studied with respect to the rheological behavior of the biomass hydrolysate and the enzymatic conversion of the bagasse polysaccharides. These parameters were applied to model the power required for an impeller to operate at pilot scale (100 l) using empirical correlations according to Nagata [16]. Hydrolysis experiments were carried out using a blend of cellulases, β-glucosidase, and xylanases produced in our laboratory by Trichoderma reesei RUT C30 and Aspergillus awamori. Hydrolyses were performed with an enzyme load of 10 FPU/g (dry weight) of bagasse over 36 h with periodic sampling for the measurement of viscosity and the concentration of glucose and reducing sugars. The mixture presented pseudoplastic behavior. This rheological model allowed for a performance comparison to be made between flat-blade disk (Rushton turbine) and pitched-blade (45°) impellers. The simulation showed that the pitched blade consumed tenfold less energy than the flat-blade disk turbine. The resulting sugar syrups contained 22 g/l of glucose, which corresponded to 45% cellulose conversion.

Similar content being viewed by others

Abbreviations

- du/dy :

-

Shear rate

- N :

-

Rotation (r.p.m)

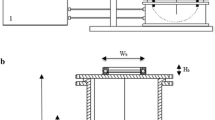

- D :

-

Impeller diameter

- H :

-

Height helpful

- T :

-

Tank diameter

- w :

-

Thickness pitched blade

- P :

-

Power

- η :

-

Apparent viscosity

- ρ :

-

Fluid density

- Θ:

-

Angle pitched blade

- g :

-

Gravitation constant

- N p :

-

Power number

- N Re :

-

Reynolds number

References

Bon EPS, Ferrara MA, Corvo ML, Vermelho AB, 317 Paiva CLA, Alencastro RB,Coelho RR (2008) Enzimas em Biotecnologia: Produção, Aplicações e Mercado.Editora Interciência, Rio de Janeiro, Brasil

Bon EPS, Gottschalk LMF, Eleutherio ECA, Ferrara MA, Ferreira-Filho EX, Silva AS, Sposina RST, Webb C, Moreira LRS, Pereira MD (2007) Composição de enzimas, uso da composição na hidrólise enzimática de material lignocelulósico, processo de produção de enzimas que degradam a fração de polissacarídeos da biomassa, processo de produção de álcool utilizando a composição de enzimas. Patent code PI0705744-0A2, Brazil

Chang MM, Chou TYC, Tsao GT (1981) Structure, pretreatment and hydrolysis of cellulose. Adv Biochem Eng Biotechnol 14:15–43. doi:10.1007/3-540-11018-6_2

Espinosa-solares T, Brito-de la fuente E, Tecante A, Medina-torres L, Tanguy PA (2002) Mixing time in rheologically evolving model fluids by hybrid dual mixing systems. Chem Eng Res Des 80(8):817–823. doi:10.1205/026387602321143345

Ferreira-leitão V, Gottschalk LMF, Ferrara MA, Nepomuceno AL, Molinari HBC, Bon EPS (2010) Biomass residues in Brazil: availability and potential uses. Waste Biomass Valor 1:65–76. doi:10.1007/s12649-010-9008-8

Fox RW, McDonald AT, Pritchard PJ (2006) Introdução à Mecânica dos Fluidos, 6th edn. LTC, Rio de Janeiro

Geddes CC, Peterson JJ, Mullinnix MT, Svoronos, SA, Shanmugan KT, Ingram LO (2010). Optimizing cellulase usage for improved mixing and rheological properties of acid-pretreated sugarcane bagasse. Bioresour Technol (in press). doi:10.1016/j.biortech.2010.07.040

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59(2):257–268

Gottschalk LMF, Oliveira RA, Bon EPS (2010) Cellulases, xylanases β-glucosidase and ferulic acid esterase produced by Trichoderma and Aspergillus act synergistically in the hydrolysis of sugarcane bagasse. Biochem Eng J 51:72–78. doi:10.1016/j.bej.2010.05.003

Green DW, Perry RH (2008) Perry’s chemical engineers’ handbook, 8th edn. McGraw-Hill, New York

Knutsen JS, Liberatore MW (2010) Rheology modification and enzyme kinetics of high solids cellulosic slurries. Energy Fuels 24:3267–3274. doi:10.1021/ef100140g

Kuzmanic B, Ljubicic N (2001) Suspension of floating solids with up-pumping pitched blade impellers mixing time and power characteristics. Chem Eng J 84(3):325–333. doi:10.1016/S1385-8947(00)00382-X

Larsson S, Palmqvist E, Hahn-hägerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant N-O (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enz Microb Technol 24:151–159. doi:10.1016/S0141-0229(98)00101-X

McCabe W, Smith J, Harriot P (2004) Unit operations of chemical engineering, 7th edn. McGraw-Hill, New York

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Nagata S (1975) Mixing: principles and applications. Kodansha Ltd and Wiley, Tokyo and New York

Oldshue JY (1983) Fluid mixing technology, 1st edn. McGraw-Hill, New York

Pimenova NV, Hanley TR (2004) Effect of corn stover concentration on rheological characteristics. Appl Biochem Biotechnol 114 (1-3):113–116. doi: 10.1385/ABAB:114:1-3:347

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure (LAP). NREL/TP-510-42618. National Renewable Energy Laboratory, Golden

Steffe JF (1996) Rheological methods in food process engineering, 2nd edn. Freeman Press, East Lansing

Stickel JJ, Knutsen JS, Liberatore MW, Luu W, Bousfield DW, Klingenberg DJ, Scott CT, Root TW, Ehrhardt MR, Monz TO (2009) Rheology measurements of a biomass slurry: an inter-laboratory study. Rheol Acta 48:1005–1015. doi:10.1007/s00397-009-0382-8

Teixeira RSS, Siqueira FG, Souza MV, Filho EXF, Bon EPS (2010) Purification and characterization studies of a thermostable β-xylanase from Aspergillus awamori. J Ind Microbiol Biotechnol (in press). doi: 10.1007/s10295-010-0751-4

Uhl VW, Gray JB (1966) Mixing: theory and practice. Academic Press, London

Viamajala S, McMillan JD, Schell DJ, Elander RT (2009) Rheology of corn stover slurries at high solids concentrations—effects of saccharification and particle size. Bioresour Technol 100(2):925–934. doi:10.1016/j.biortech.2008.06.070

Vidal JRMB, Gasparetto CA (2000) Rheological behavior of mango pulp (Mangífera indica l)—effect of insoluble solids. Ciênc Tecnol Aliment 20(2):172–175. doi:10.1590/S0101-20612000000200008

Wu J, Graham LJ, Nguyen B, Noui Mehidi MN (2006) Energy efficiency study on axial flow impellers. Chem Eng Process 45(8):625–632. doi:10.1016/j.cep.2006.01.007

Wyman CE (1994) Ethanol from lignocellulosic biomass: technology, economics, and opportunities. Bioresour Technol 50(1):3–15. doi:10.1016/0960-8524(94)90214-3

Acknowledgments

This work was supported by research and scholarship grants from the National Council for Scientific and Technological Development (CNPq) of the Brazilian Ministry of Science and Technology and by the Research and Projects Financing Agency (FINEP). Usina Vale do Rosário is gratefully acknowledged for supplying the steam-pretreated bagasse.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation at the 32nd Symposium on Biotechnology for Fuels and Chemicals.

Rights and permissions

About this article

Cite this article

Pereira, L.T.C., Pereira, L.T.C., Sposina Sobral Teixeira, R. et al. Sugarcane bagasse enzymatic hydrolysis: rheological data as criteria for impeller selection. J Ind Microbiol Biotechnol 38, 901–907 (2011). https://doi.org/10.1007/s10295-010-0857-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0857-8