Abstract

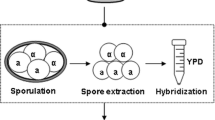

Genome shuffling is a powerful strategy for rapid engineering of microbial strains for desirable industrial phenotypes. Here we improved the thermotolerance and ethanol tolerance of an industrial yeast strain SM-3 by genome shuffling while simultaneously enhancing the ethanol productivity. The starting population was generated by protoplast ultraviolet irradiation and then subjected for the recursive protoplast fusion. The positive colonies from the library, created by fusing the inactivated protoplasts were screened for growth at 35, 40, 45, 50 and 55°C on YPD-agar plates containing different concentrations of ethanol. Characterization of all mutants and wild-type strain in the shake-flask indicated the compatibility of three phenotypes of thermotolerance, ethanol tolerance and ethanol yields enhancement. After three rounds of genome shuffling, the best performing strain, F34, which could grow on plate cultures up to 55°C, was obtained. It was found capable of completely utilizing 20% (w/v) glucose at 45–48°C, producing 9.95% (w/v) ethanol, and tolerating 25% (v/v) ethanol stress.

Similar content being viewed by others

References

Abdel-fattah WH, Fadil M, Nigam P, Banat IM (2000) Isolation of thermotolerant ethanologenic yeasts and use of selected strains in industrial scale fermentation in an Egyptian distillery. Biotechnol Bioeng 68:531–535. doi:10.1002/(SICI)1097-0290(20000605)68:5<531::AID-BIT7>3.0.CO;2-Y

Aristidou A, Penttila M (2000) Metabolic engineering applications to renewable resource utilization. Curr Opin Biotechnol 11:187–198. doi:10.1016/S0958-1669(00)00085-9

Bai FW, Anderson WA, Moo-Young M (2008) Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol Adv 26:89–105. doi:10.1016/j.biotechadv.2007.09.002

Balakumar S, Arasaratnam V, Balasubramaniam K (2001) Isolation and improvement of a thermotolerant Saccharomyces cerevisiae strain. World J Microbiol Biotechnol 17:739–746. doi:10.1023/A:1012952809273

Banat IM, Nigam P, Singh D, Merchant R, McHale AP (1998) Ethanol production at elevated temperatures and alcohol concentrations: a review; part-I yeast in general. World J Microbiol Biotechnol 14:809–821. doi:10.1023/A:1008802704374

Beltran G, Novo M, Guillamon JM, Mas A, Rozes N (2008) Effect of fermentation temperature and culture media on the yeast lipid composition and wine volatile compounds. Int J Food Microbiol 121:169–177. doi:10.1016/j.ijfoodmicro.2007.11.030

Dai MH, Copley SD (2004) Genome shuffling improves degradation of the anthropogenic pesticide pentachlorophenol by Sphingobium chlorophenolicum ATCC 39723. Appl Environ Microbiol 70:2391–2397. doi:10.1128/AEM.70.4.2391-2397.2004

D’Amore T, Celotto G, Russell I, Stewart GG (1989) Selection and optimization of yeast suitable for ethanol production at 40°C. Enzyme Microb Technol 11:411–416. doi:10.1016/0141-0229(89)90135-X

Edgardo A, Carolina P, Manuel R, Juanita F, Jaime B (2008) Selection of thermotolerant yeast strains Saccharomyces cerevisiae for bioethanol production. Enzyme Microb Technol 43:120–123. doi:10.1016/j.enzmictec.2008.02.007

Ezeronye OU, Okerentugba PO (2001) Optimum conditions for yeast protoplast release and regeneration in Saccharomyces cerevisiae and Candida tropicalis using gut enzymes of the giant African snail Achatina achatina. Lett Appl Microbiol 32:190–193. doi:10.1046/j.1472-765x.2001.00885.x

Farahnak F, Seki T, Ryu DDY, Ogrydziak D (1986) Construction of a lactose-assimilating and high-ethanol-producing yeast by protoplast fusion. Appl Environ Microbiol 51:362–367

Gera R, Dhamija SS, Gera T, Dalel S (1997) Intergeneric ethanol producing hybrids of thermotolerant Kluyveromyces and non-thermotolerant Saccharomyces cerevisiae. Biotechnol Lett 19:189–193. doi:10.1023/A:1018380818454

Hida H, Yamada T, Yamada Y (2007) Genome shuffling of Streptomyces sp. U121 for improved production of hydroxycitric acid. Appl Microbiol Biotechnol 73:1387–1393. doi:10.1007/s00253-006-0613-1

Jeffries TW, Jin YS (2000) Ethanol and thermotolerance in the bioconversion of xylose by yeasts. Adv Appl Microbiol 47:221–268. doi:10.1016/S0065-2164(00)47006-1

Jin C, Han N, Wu X, Pan J, Zeng Y, Zhu M (2005) Isolation and characterization of a highly thermotolerant mutant of Saccharomyces cerevisiae. Ann Microbiol 55:57–61

Kida K, Morimura S, Sonoda Y (1992) Repeated batch fermentation process using a thermotolerant flocculating yeast constructed by protoplast fusion. J Ferment Bioeng 74:169–173. doi:10.1016/0922-338X(92)90078-9

Kim IS, Moon HY, Yun HS, Jin I (2006) Heat shock causes oxidative stress and induces a variety of cell rescue proteins in Saccharomyces cerevisiae KNU5377. J Microbiol 44:492–501

Kiransree N, Sridhar M, Venkateswar Rao L (2000) Characterisation of thermotolerant, ethanol tolerant fermentative Saccharomyces cerevisiae for ethanol production. Bioprocess Eng 22:243–246. doi:10.1007/PL00009114

KiranSree N, Sridhar M, Suresh K, Banat IM, Venkateswar Rao L (2000) Isolation of thermotolerant, osmotolerant, flocculating Saccharomyces cerevisiae for ethanol production. Bioresour Technol 72:43–46. doi:10.1016/S0960-8524(99)90097-4

Laopaiboon L, Thanonkeo P, Jaisil P, Laopaiboon P (2007) Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J Microbiol Biotechnol 23:1497–1150. doi:10.1007/s11274-007-9383-x

Lei Y, Pei X, Lei T, Wang YH, Feng Y (2008) Genome shuffling enhanced l-lactic acid production by improving glucose tolerance of Lactobacillus rhamnosus. J Biotechnol 134:154–159. doi:10.1016/j.jbiotec.2008.01.008

Matmati N, Morpurgo G, Babudri N, Marini A (2002) The influence of colonial organization on thermotolerance and thermoresistance in Saccharomyces cerevisiae. J Basic Microbiol 42:345–354. doi:10.1002/1521-4028(200210)42:5<345::AID-JOBM345>3.0.CO;2-F

Michel GPF, Starka J (1986) Effect of ethanol and heat stresses on the protein pattern of Zymomonas mobilis. J Bacteriol 165:1040–1042

Morimura S, Ling ZY, Kida K (1997) Ethanol production by repeated batch fermentation at high temperature in a molasses medium containing a high concentration of total sugar by a thermotolerant flocculating yeast with improved salt-tolerance. J Ferment Bioeng 83:271–274. doi:10.1016/S0922-338X(97)80991-9

Patnaik R, Louie S, Gavrilovic V, Perry K, Stemmer WP, Ryan CM et al (2002) Genome shuffling of Lactobacillus for improved acid tolerance. Nat Biotechnol 20:707–712. doi:10.1038/nbt0702-707

Petri R, Schmidt-Danner C (2004) Dealing with complexity: evolutionary engineering and genome shuffling. Curr Opin Biotechnol 15:298–304. doi:10.1016/j.copbio.2004.05.005

Rajoka MI, Ferhan M, Khalid AM (2005) Kinetics and thermodynamics of ethanol production by a thermotolerant mutant of Saccharomyces cerevisiae in a microprocessor- controlled bioreactor. Lett Appl Microbiol 40:316–321. doi:10.1111/j.1472-765X.2005.01663.x

Sridhar M, KiranSree N, Venkateswar Rao L (2002) Effect of UV radiation on thermotolerance, ethanol tolerance and osmotolerance of Saccharomyces cerevisiae VS1 and VS3 strains. Bioresour Technol 83:199–202. doi:10.1016/S0960-8524(01)00221-8

Stephanopoulos G (2002) Metabolic engineering by genome shuffling. Nat Biotechnol 20:666–668. doi:10.1038/nbt0702-666

Torija MJ, Beltran G, Novo M, Poblet M, Guillamon JM, Mas A et al (2003) Effects of fermentation temperature and Saccharomyces species on the cell fatty acid composition and presence of volatile compounds in wine. Int J Food Microbiol 85:127–136. doi:10.1016/S0168-1605(02)00506-8

Ueno R, Urano N, Kimura S (2002) Effect of temperature and cell density on ethanol fermentation by a thermotolerant aquatic yeast strain isolated from a hot spring environment. Fish Sci 68:571–578. doi:10.1046/j.1444-2906.2002.00463.x

Vianna CR, Silva CLC, Neves MJ, Rosa CA (2008) Saccharomyces cerevisiae strains from traditional fermentations of Brazilian cachaca: trehalose metabolism, heat and ethanol resistance. Antonie Van Leeuwenhoek 93(1–2):205–217. doi:10.1007/s10482-007-9194-y

Wang C, Shi D, Gong G (2008) Microorganisms in Daqu: a starter culture of Chinese Maotai-flavor liquor. World J Microbiol Biotechnol 24:2183–2190. doi:10.1007/s11274-008-9728-0

Wang YH, Li Y, Pei XL, Yu L, Feng Y (2007) Genome-shuffling improved acid tolerance and l-lactic acid volumetric productivity in Lactobacillus rhamnosus. J Biotechnol 129:510–515. doi:10.1016/j.jbiotec.2007.01.011

Wheals AE, Basso LC, Alves DMG, Amorim HV (1999) Fuel ethanol after 25 years. Trends Biotechnol 17:482–486. doi:10.1016/S0167-7799(99)01384-0

You KM, Rosenfield CL, Knipple DC (2003) Ethanol tolerance in the yeast Saccharomyces cerevisiae is dependent on cellular oleic acid content. Appl Environ Microbiol 69:1499–1503. doi:10.1128/AEM.69.3.1499-1503.2003

Zaldivar J, Nielsen J, Olsson L (2001) Fuel ethanol production from lignocellulose: a challenge for metabolic engineering and process integration. Appl Microbiol Biotechnol 56:17–34. doi:10.1007/s002530100624

Acknowledgments

This study was financially supported by the grants (No.20776115; No.20576100) of Natural Science Foundation of China (NSFC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Dj., Wang, Cl. & Wang, Km. Genome shuffling to improve thermotolerance, ethanol tolerance and ethanol productivity of Saccharomyces cerevisiae . J Ind Microbiol Biotechnol 36, 139–147 (2009). https://doi.org/10.1007/s10295-008-0481-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0481-z