Abstract

The concrete industry consumes a significant number of natural resources and emits hazardous gases into the atmosphere, such as carbon dioxide for cement production, which influences global warming and climate change. Therefore, many attempts have been made to develop green and eco-friendly concrete from various waste materials. Seashells are one of these waste products that accumulate on beaches and landfills, which causes environmental problems. This review assesses the usage of multiple types of seashell waste materials in concrete as a partial cement replacement. The performance of seashell powder in concrete was also evaluated in terms of fresh concrete properties, mechanical properties, durability, and other factors. According to this study, using seashells as a cement replacement improves concrete setting time, diminishes workability, and increases density due to curing age. The mechanical properties of concrete, such as compressive strength and modulus of elasticity, generally decrease as the shell content increases. However, adding admixtures and applying chemical treatment can improve concrete’s mechanical properties and durability. Nevertheless, adding up to 25% of cockle shells in concrete can reduce water permeability. Thus, it is demonstrated that using seashells in concrete as a cement replacement might have the potential to produce sustainable green building materials.

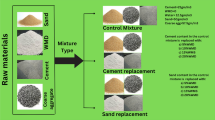

Graphical Abstract

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Copyright 2022, Elsevier)

Similar content being viewed by others

References

Hasan K, Yahaya FM, Karim A, Othman R (2021) Investigation on the properties of mortar containing palm oil fuel ash and seashell powder as partial cement replacement. Construction 1:50–61. https://doi.org/10.15282/CONSTRUCTION.V1I2.6679

Meyer C (2013) The greening of the concrete industry. Cem Concr Compos 31:601–605. https://doi.org/10.1016/j.cemconcomp.2008.12.010

McCarthy N (2014) China Used More Concrete In 3 Years Than The U.S. Used In The Entire 20th Century [Infographic]. https://www.forbes.com/sites/niallmccarthy/2014/12/05/china-used-more-concrete-in-3-years-than-the-u-s-used-in-the-entire-20th-century-infographic/?sh=6f11a3fb4131. (Accessed 14 Aug 2021)

NBSC (2022) China Cement Production-March 2022 Data–1983–2021 Historical–April Forecast. https://tradingeconomics.com/china/cement-production. (Accessed 19 Apr 2022)

Lee JC, Shafigh P, Bin MH, Lee SK (2016) Mechanical properties of high strength semi-lightweight aggregate concrete containing high volume waste materials. AIP Conf Proc 1774:030006. https://doi.org/10.1063/1.4965062

Naqi A, Jang JG (2019) Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: a review. Sustain 11:537. https://doi.org/10.3390/SU11020537

GCM (2019) Global Cement Market (Production, Consumption, Imports & Exports): Insight, Trends and Forecast (2019–2021). https://www.researchandmarkets.com/reports/4871690/global-cement-market-production-consumption. Accessed 14 Aug 2021

DATIS EXPORT (2020) Worldwide Cement Production From 2015 to 2019 | Datis Export Group. https://datis-inc.com/blog/worldwide-cement-production-from-2015-to-2019/. Accessed 14 Aug 2021

Ober JA (2018) Mineral commodity summaries 2018. Miner Commod Summ. https://doi.org/10.3133/70194932

M. Garside (2022) • U.S.: cement production 2021 | Statista. https://www.statista.com/statistics/219343/cement-production-worldwide/. Accessed 15 Apr 2022

Sonebi M, Ammar Y, Diederich P (2016) Sustainability of cement, concrete and cement replacement materials in construction. Sustain Constr Mater. https://doi.org/10.1016/B978-0-08-100370-1.00015-9

Turner LK, Collins FG (2013) Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete. Constr Build Mater 43:125–130. https://doi.org/10.1016/J.CONBUILDMAT.2013.01.023

Valipour M, Yekkalar M, Shekarchi M, Panahi S (2014) Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J Clean Prod 65:418–423. https://doi.org/10.1016/J.JCLEPRO.2013.07.055

Behera M, Bhattacharyya SK, Minocha AK et al (2014) Recycled aggregate from C&D waste & its use in concrete–a breakthrough towards sustainability in construction sector: a review. Constr Build Mater 68:501–516. https://doi.org/10.1016/J.CONBUILDMAT.2014.07.003

Suryaningrat Edwin R, Balany F, SundiPutri T et al (2019) The use of granulated copper slag as cement replacement in high-performance concrete. Int J Mater Sci Eng. https://doi.org/10.17706/ijmse.2019.7.1.20-25

Mo KH, Alengaram UJ, Jumaat MZ et al (2016) Green concrete partially comprised of farming waste residues: a review. J Clean Prod 117:122–138. https://doi.org/10.1016/J.JCLEPRO.2016.01.022

Halbiniak J, Major M (2019) The use of waste glass for cement production. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/585/1/012008

Longvinenko AA (2018) Use of rubber crumbs in cement concrete. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/327/3/032034

Silva TH, Mesquita-Guimarães J, Henriques B et al (2019) The potential use of oyster shell waste in new value-added by-product. Resour 8:13. https://doi.org/10.3390/RESOURCES8010013

Hart A (2020) Mini-review of waste shell-derived materials’ applications. Waste Manage Res 38:514–527. https://doi.org/10.1177/0734242X19897812

Martínez-García C, González-Fonteboa B, Martínez-Abella F, Carro- López D (2017) Performance of mussel shell as aggregate in plain concrete. Constr Build Mater 139:570–583. https://doi.org/10.1016/J.CONBUILDMAT.2016.09.091

Nguyen DH, Boutouil M, Sebaibi N et al (2017) Durability of pervious concrete using crushed seashells. Constr Build Mater 135:137–150. https://doi.org/10.1016/J.CONBUILDMAT.2016.12.219

FAO (2014) Globefish research programme Food and Agriculture Organization of the United Nations Products The European market for mussels Volume 115

Yoon GL, Kim BT, Kim BO, Han SH (2003) Chemical–mechanical characteristics of crushed oyster-shell. Waste Manag 23:825–834. https://doi.org/10.1016/S0956-053X(02)00159-9

Jović M, Mandić M, ŠljivićIvanović M, Smičiklas I (2019) Recent trends in application of shell waste from mariculture. Stud Mar. Doi: 10.5281/zenodo.3274471

Varhen C, Carrillo S, Ruiz G (2017) Experimental investigation of Peruvian scallop used as fine aggregate in concrete. Constr Build Mater 136:533–540. https://doi.org/10.1016/J.CONBUILDMAT.2017.01.067

Wang J, Liu E, Li L (2019) Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J Clean Prod 220:235–252. https://doi.org/10.1016/J.JCLEPRO.2019.02.122

Suarez-Riera D, Merlo A, Lavagna L et al (2021) Mechanical properties of mortar containing recycled Acanthocardia tuberculata seashells as aggregate partial replacement. Boletín la Soc Española Cerámica y Vidr 60:206–210. https://doi.org/10.1016/J.BSECV.2020.03.011

Owuamanam S, Cree D (2020) Progress of bio-calcium carbonate waste eggshell and seashell fillers in polymer composites: a review. J Compos Sci 4:70. https://doi.org/10.3390/JCS4020070

Eziefula UG, Ezeh JC, Eziefula BI (2018) Properties of seashell aggregate concrete: a review. Constr Build Mater 192:287–300. https://doi.org/10.1016/J.CONBUILDMAT.2018.10.096

Mo KH, Alengaram UJ, Jumaat MZ et al (2018) Recycling of seashell waste in concrete: a review. Constr Build Mater 162:751–764. https://doi.org/10.1016/J.CONBUILDMAT.2017.12.009

Ammari M, Ghoraishi M, AA-IJ of, 2017 undefined Sand with crushed seashells and its effect on the strength of mortar and concrete used in the United Arab Emirates. academia.edu

Soltanzadeh F, Emam-Jomeh M, Edalat-Behbahani A, Soltan-Zadeh Z (2018) Development and characterization of blended cements containing seashell powder. Constr Build Mater 161:292–304. https://doi.org/10.1016/J.CONBUILDMAT.2017.11.111

Wang J, Liu E (2020) Upcycling waste seashells with cement: Rheology and early-age properties of Portland cement paste. Resour Conserv Recycl 155:104680. https://doi.org/10.1016/J.RESCONREC.2020.104680

Bamigboye GO, Nworgu AT, Odetoyan AO et al (2021) Sustainable use of seashells as binder in concrete production: prospect and challenges. J Build Eng 34:101864. https://doi.org/10.1016/j.jobe.2020.101864

Tayeh BA, Hasaniyah MW, Zeyad AM et al (2020) Durability and mechanical properties of seashell partially-replaced cement. J Build Eng. https://doi.org/10.1016/J.JOBE.2020.101328

Rahul Rollakanti C, Prasad VSR, Poloju KK et al (2021) An experimental investigation on mechanical properties of concrete by partial replacement of cement with wood ash and fine sea shell powder. Mater Today Proc 43:1325–1330. https://doi.org/10.1016/J.MATPR.2020.09.164

Ferraz E, Gamelas JAF, Coroado J et al (2019) Recycling waste seashells to produce calcitic lime: characterization and wet slaking reactivity. Waste Biomass Valorizat 10:2397–2414. https://doi.org/10.1007/s12649-018-0232-y

Readman A (2021) Types of Shells to Find on Beaches Around the World: Facts, Chart and Pictures - Outforia. https://outforia.com/types-of-shells/. Accessed 28 Aug 2021

Ferguson (2020) Sea Shell Types. http://naplesseashellcompany.com/shell-types.html. Accessed 21 Aug 2021

Bouasria M, Khadraoui F, Benzaama MH et al (2021) Partial substitution of cement by the association of Ferronickel slags and Crepidula fornicata shells. J Build Eng 33:101587. https://doi.org/10.1016/J.JOBE.2020.101587

Zhang J, Chen H, Mu T, Pan Y (2018) Research and application of shell powder. IOP Conf Ser Earth Environ Sci 170:8–12. https://doi.org/10.1088/1755-1315/170/3/032031

Kumar K, Davim J (2021) Plant and Animal Based Composites

Tayeh BA, Hasaniyah MW, Zeyad AM, Yusuf MO (2019) Properties of concrete containing recycled seashells as cement partial replacement: a review. J Clean Prod 237:117723

Tayeh BA, Hasaniyah MW, Zeyad AM, Yusuf MO (2019) Properties of concrete containing recycled seashells as cement partial replacement: a review. J Clean Prod. https://doi.org/10.1016/J.JCLEPRO.2019.117723

Azmi M, Johari M (2013) Cockle shell ash replacement for cement and filler in concrete

Wan Mohammad WAS Bin, Othman NH, Wan Ibrahim MH, et al (2017) A review on seashells ash as partial cement replacement. In: IOP Conference Series: Materials Science and Engineering

Janiszewska K, Mazur M, Machalski M, Stolarski J (2018) From pristine aragonite to blocky calcite: Exceptional preservation and diagenesis of cephalopod nacre in porous Cretaceous limestones. PLoS ONE. https://doi.org/10.1371/JOURNAL.PONE.0208598

Sampantamit T, Ho L, Lachat C et al (2020) Aquaculture production and its environmental sustainability in Thailand: challenges and potential solutions. Sustain 12:2010. https://doi.org/10.3390/SU12052010

Trisha N (2021) Growing major cockle business | The Star. https://www.thestar.com.my/metro/metro-news/2021/06/01/growing-major-cockle-business. Accessed 28 Aug 2021

Selly K (2014) A study on Indonesian mollusk fishery and its prospect for economy. Int J Mar Sci. https://doi.org/10.5376/ijms.2014.04.0005

Nicki Holmyard (2014) EU aquaculture production to double by 2030 | SeafoodSource. https://www.seafoodsource.com/features/eu-aquaculture-production-to-double-by-2030. Accessed 16 Apr 2022

Textor C (2020) China: farmed shellfish production volume 2018 | Statista. https://www.statista.com/statistics/1128461/china-cultured-shellfish-production-volume/. Accessed 28 Aug 2021

Yulinda E, Saad M, Yusuf M (2020) A study on the economic potential of blood cockles (Anadara granosa) in Rokan Hilir, Riau Province, Indonesia. AACL Bioflux 13:1504–1510

Abinaya S, Prasanna Venkatesh S (2016) An effect on oyster shell powder’s mechanical properties in self compacting concrete. Int J Innov Res Sci Eng Technol. https://doi.org/10.15680/IJIRSET.2016.0506296

Abinaya SP S, Venkatesh SP (2016) An effect on oyster shell powder’s mechanical properties in self compacting concrete. Egin Tecnol 5:2319–2324. https://doi.org/10.15680/IJIRSET.2016.0506296

Lertwattanaruk P, Makul N, Siripattarapravat C (2012) Utilization of ground waste seashells in cement mortars for masonry and plastering. J Environ Manage 111:133–141. https://doi.org/10.1016/J.JENVMAN.2012.06.032

Tayeh BA, Hasaniyah MW, Zeyad AM et al (2020) Durability and mechanical properties of seashell partially-replaced cement. J Build Eng 31:101328. https://doi.org/10.1016/J.JOBE.2020.101328

Olivia M, Oktaviani R (2017) Properties of concrete containing ground waste cockle and clam seashells. Procedia Eng 171:658–663. https://doi.org/10.1016/J.PROENG.2017.01.404

Zeyad AM, Tayeh BA, Yusuf MO (2019) Strength and transport characteristics of volcanic pumice powder based high strength concrete. Constr Build Mater 216:314–324. https://doi.org/10.1016/j.conbuildmat.2019.05.026

Kassim U, Ong BP (2019) Performance of concrete incorporating of clam shell as partially replacement of ordinary Portland cement (OPC). J Adv Res Appl Mech 55:12–21

Ez-Zaki H, Diouri A, Kamali-Bernard S, Sassi O (2016) Composite cement mortars based on marine sediments and oyster shell powder. Mater Constr. https://doi.org/10.3989/MC.2016.01915

Kokh SN, Sokol EV, Sharygin VV (2015) Ellestadite-group minerals in combustion metamorphic rocks. Coal Peat Fires A Glob Perspect 3:543–562. https://doi.org/10.1016/B978-0-444-59509-6.00020-X

Li G, Xu X, Chen E et al (2015) Properties of cement-based bricks with oyster-shells ash. J Clean Prod 91:279–287. https://doi.org/10.1016/J.JCLEPRO.2014.12.023

Bamigboye G, Enabulele D, Odetoyan AO et al (2021) Mechanical and durability assessment of concrete containing seashells: a review. Cogent Eng. https://doi.org/10.1080/23311916.2021.1883830

Ketebu O, Farrow ST (2017) Comparative study on cementitious content of ground mollusc snail and clam shell and their mixture as an alternative to cement. Int J Eng Trends Technol 50:8–11. https://doi.org/10.14445/22315381/ijett-v50p202

Ubachukwu OA, Okafor FO (2019) Investigation of the supplementary cementitious potentials of oyster shell powder for eco-friendly and low-cost concrete. Electron J Geotech Eng 24(05):1297–1306

Talha Zaid S, Ghorpade VG, Pradesh Anantapur A, Pradesh A (2014) Experimental investigation of snail shell ash (SSA) as partial replacement of ordinary Portland cement in concrete. Int J Eng Res Technol 3:2278–3181

Olivia M, Mifshella AA, Darmayanti L (2015) Mechanical properties of seashell concrete. Procedia Eng 125:760–764. https://doi.org/10.1016/J.PROENG.2015.11.127

Wang HY, Ten KW, Lin CC, Po-Yo C (2013) Study of the material properties of fly ash added to oyster cement mortar. Constr Build Mater 41:532–537. https://doi.org/10.1016/j.conbuildmat.2012.11.021

Adeala A, Olaoye J (2019) Structural properties of snail shell ash concrete (SSAC). J Emerg Technol Innovat Res. 6(12):24–31

Sarada B, Vinayaka Murthy M, Udaya Rani V (2018) Effect on strength properties of concrete containing seashell powder as a partial substitution of fine aggregate and silica fume used as admixture. Undefined 7:689–692. https://doi.org/10.14419/IJET.V7I3.12.16455

Woon CP, Shek PN, Md. Tahir M (2014) Engineering properties of bio-inspired cement mortar containing seashell powder

Ong BP, Kassim U (2019) Performance of concrete incorporating of clam shell as partially replacement of ordinary Portland cement (OPC). J Adv Res Appl Mech J homepage 55:12–21

Olivia M, Mifshella AA, Darmayanti L (2015) Mechanical properties of seashell concrete. In: Procedia Engineering. Elsevier Ltd, pp 760–764

Etuk BR, Etuk IF, Asuquo LO (2012) Feasibility of using sea shells ash as admixtures for concrete. J Environ Sci Engin 1:121–127

Bouasria M, Khadraoui F, Benzaama MH et al (2021) Partial substitution of cement by the association of Ferronickel slags and Crepidula fornicata shells. J Build Eng. https://doi.org/10.1016/j.jobe.2020.101587

Edalat-Behbahani A, Soltanzadeh F, Emam-Jomeh M, Soltan-Zadeh Z (2021) Sustainable approaches for developing concrete and mortar using waste seashell. Eur J Environ Civ Eng 25:1874–1893. https://doi.org/10.1080/19648189.2019.1607780

Umoh AA, Ujene AO (2015) Improving the strength performance of high volume periwinkle shell ash blended cement concrete with sodium. J Civ Eng Sci Technol 6:18–22

Talha Zaid S, Ghorpade VG, Pradesh Anantapur A, Pradesh A Experimental Investigation of Snail Shell Ash (SSA) as Partial Repalacement of Ordinary Portland Cement in Concrete

Hazurina NOR, Bakar ABU, Johari M, Don MAT (2013) AWAM International Conference on Civil Engineering & Geohazard Information Zonation Potential Use of Cockle(Anadara granosa) Shell Ash as Partial Cement Replacement in Concrete. 2: 369–376

Wan Mohammad WAS Bin, Othman NH, Wan Ibrahim MH, et al (2017) A review on seashells ash as partial cement replacement. In: IOP Conference Series: Materials Science and Engineering. Institute of Physics Publishing, p 012059

Umoh AA, Ujene AO (2015) Improving the strength performance of high volume periwinkle shell ash blended cement concrete with sodium nitrate as accelerator. J Civ Eng Sci Technol 6:18–22

Jones DRH, Ashby MF (2019) Elastic moduli. Eng Mater 1:31–47. https://doi.org/10.1016/B978-0-08-102051-7.00003-8

Olusola KO (2012) Compressive strength and static modulus of elasticity of periwinkle shell ash blended cement. Int J Sustain Constr Eng Technol 3:45–55

Peow WC, Ngian SP, Tahir M (2014) Engineering properties of bio-inspired cement mortar containing seashell powder. Natl Semin Civ Eng Res SEPKA 2014:1–14

Cui Y, Gao K, Zhang P (2020) Experimental and statistical study on mechanical characteristics of geopolymer concrete. Mater 13(1651):1651. https://doi.org/10.3390/MA13071651

Thomas RJ, Peethamparan S (2015) Alkali-activated concrete: engineering properties and stress-strain behavior. Constr Build Mater 93:49–56. https://doi.org/10.1016/j.conbuildmat.2015.04.039

Yang EI, Kim MY, Park HG, Yi ST (2010) Effect of partial replacement of sand with dry oyster shell on the long-term performance of concrete. Constr Build Mater 24:758–765. https://doi.org/10.1016/j.conbuildmat.2009.10.032

Chiou IJ, Chen CH, Li YH (2014) Using oyster-shell foamed bricks to neutralize the acidity of recycled rainwater. Constr Build Mater 64:480–487. https://doi.org/10.1016/J.CONBUILDMAT.2014.04.101

Safi B, Saidi M, Daoui A et al (2015) The use of seashells as a fine aggregate (by sand substitution) in self-compacting mortar (SCM). Constr Build Mater 78:430–438. https://doi.org/10.1016/j.conbuildmat.2015.01.009

Mohanalakshmi MV, Indhu MS (2017) Developing Concrete using Sea Shell as a Fine Aggregate. IJIRST-Int J Innov Res Sci Technol 3:282–286

Panda KC, Behera S, Jena S (2020) Effect of rice husk ash on mechanical properties of concrete containing crushed seashell as fine aggregate. Mater Today Proc 32:838–843. https://doi.org/10.1016/J.MATPR.2020.04.049

Rajeswari V, Babu V, Viswasa T et al (2020) Experimental study on partial replacement of cement with fly ash and coarse aggregate with sea shells "experimental study on partial replacement of cement with fly ash and coarse aggregate with sea. Int J Mod Trends Sci Technol Shells 06:163–168

Kumar S, Suriya Kumar P, Yuvaraj P et al (2016) A partial replacement for coarse aggregate by sea shell and cement by lime in concrete. Imp J Interdiscip Res. 2:1131–1136

Tudin DZA, Rizalman AN (2020) Properties of cement mortar containing NaOH-treated crumb rubber as fine aggregate replacement. IOP Conf Ser Earth Environ Sci. https://doi.org/10.1088/1755-1315/476/1/012030

Hasnaoui A, Bourguiba A, El Mendili Y et al (2021) A preliminary investigation of a novel mortar based on alkali-activated seashell waste powder. Powder Technol 389:471–481. https://doi.org/10.1016/J.POWTEC.2021.05.069

Zhang Y, Chen D, Liang Y et al (2020) Study on engineering properties of foam concrete containing waste seashell. Constr Build Mater. https://doi.org/10.1016/J.CONBUILDMAT.2020.119896

Bamigboye GO, Okara O, Bassey DE et al (2020) The use of Senilia senilis seashells as a substitute for coarse aggregate in eco-friendly concrete. J Build Eng 32:101811. https://doi.org/10.1016/J.JOBE.2020.101811

Otunyo A, Friday I, In TI-J of ET, 2013 U (2013) Exploratory study of crushed periwinkle shell as partial replacement for fine aggregates in concrete. journals.co.za

Sainudin MS, Othman NH, Ismail NN et al (2020) Utilization of cockle shell (Anadara granosa) powder as partial replacement of fine aggregates in cement brick. Int J Integr Eng 12:161–168. https://doi.org/10.30880/IJIE.2020.12.09.019

Abdullah R (2015) Effect of temperature in calcination process of seashells Formulation of Fish Feed with Optimum Protein-bound Lysine and Methionine for African catfish fingerlings View project

Dankwah JR, Nkrumah E (2016) Recycling blends of rice husk ash and snail shells as partial replacement for Portland cement in building block production. Ghana J Technol 1:67–74

Felipe-Sesé M, Eliche-Quesada D, Corpas-Iglesias FA (2011) The use of solid residues derived from different industrial activities to obtain calcium silicates for use as insulating construction materials. Ceram Int 37:3019–3028. https://doi.org/10.1016/j.ceramint.2011.05.003

OnuohaP C, … OO-… J of I, 2017 undefined (2017) Physical and Morphological Properties of Periwinkle Shell-Filled Recycled Polypropylene Composites. researchgate.net

Ten KW, Wang HY, Shu CY, Su DS (2013) Engineering properties of controlled low-strength materials containing waste oyster shells. Constr Build Mater 46:128–133. https://doi.org/10.1016/J.CONBUILDMAT.2013.04.020

Etuk B, Etuk I, Science LA-J of E, 2012 U (2012) Feasibility of using sea shells ash as admixtures for concrete. researchgate.net

Edalat-Behbahani A, Soltanzadeh F, Emam-Jomeh M, Soltan-Zadeh Z (2019) Sustainable approaches for developing concrete and mortar using waste seashell. Eur J Environ Civil Eng 25:1874–1893. https://doi.org/10.1080/19648189.2019.1607780

Agwu OE, Akpabio JU, Akpabio MG (2020) Potentials of waste seashells as additives in drilling muds and in oil well cements. Clean Eng Technol 1:100008. https://doi.org/10.1016/j.clet.2020.100008

Samidurai V, Mahesh G, Maruthupandi M (2017) Partial replacement of cement by groudnut shell ash and sea shell powder 4. Materials used Cement. 390–397

Seesanong S, Boonchom B, Chaiseeda K, et al (2021) Conversion of Bivalve Shells to Advanced Calcium Phosphate Materials : A Simple , Rapid , Environmentally Benign, and Cost-effective Approach to Recycle Seafood Wastes. https://doi.org/10.20944/preprints202107.0007.v1

Razali MS, Khimeche K, Boudjellal A, Ramdani N (2021) Effect of newly developed sintered seashell on the microhardness properties of biocomposites. Mater Lett 291:129565. https://doi.org/10.1016/j.matlet.2021.129565

Binag ND (2016) Powdered Shell Wastes as Partial Substitute for Masonry Cement Mortar in Binder, Tiles and Bricks Production. undefined

Benjamin R. Etuk1 IFE and LOA (2012) Feasibility of Using Sea Shells Ash as Admixtures for Concrete - PDF Free Download. https://docplayer.net/45128104-Feasibility-of-using-sea-shells-ash-as-admixtures-for-concrete.html. Accessed 1 Sep 2021

Adewuyi AP, Franklin SO, Ibrahim KA (2015) Utilization of mollusc shells for concrete production for sustainable environment. Int J Sci Eng Res 6:201–208

Afolayan JO, Wilson UN, Zaphaniah B (2019) Effect of sisal fibre on partially replaced cement with Periwinkles Shell Ash (PSA) concrete. J Appl Sci Environ Manag 23:715. https://doi.org/10.4314/jasem.v23i4.22

Acknowledgements

The authors would like to acknowledge Universiti Malaysia Pahang (UMP) (Grant Number: RDU192308) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Ethics approval statement

Hereby, I, consciously assure that for the manuscript “A review of the mechanical properties and durability of concrete containing recycled seashells as a partial cement replacement” the following is fulfilled: this material is the authors’ own original work, which has not been previously published elsewhere. The paper is not currently being considered for publication elsewhere. This research does not include any human being or animal. The results are appropriately placed in the context of prior and existing research. All sources used are properly disclosed (correct citation). Literally copying of text must be indicated as such by using quotation marks and giving proper references. All authors have been personally and actively involved in substantial work leading to the paper and will take public responsibility for its content.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hasan, K., Karim, A., Islam, M.T. et al. A review of the mechanical properties and durability of concrete containing recycled seashells as a partial cement replacement. J Mater Cycles Waste Manag 25, 3192–3216 (2023). https://doi.org/10.1007/s10163-023-01795-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01795-5