Abstract

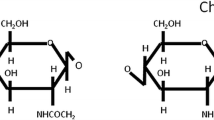

The polysaccharide chitin (CHIT), extracted mainly from exoskeletons of crustaceans, can be obtained from shrimp fishery waste. It is the source of an important biopolymer, chitosan (CHITS) that presents a wide range of applications, such as the treatment of effluents containing heavy metals and dyes, and in several bioremediation processes. In this context, this work evaluated the chitosan production from two shrimp residues, the whole cephalothorax (CPTx) and the carapace (CRP, the exoskeleton from the cephalothorax), of the commercially exploited shrimp Xiphopenaeus kroyeri, to identify which of the two sources is more advantageous. Starting from standard masses of CPTx and CRP residues, the production of 3.12 times more CHITS from CRP, compared to CPTx, is demonstrated. The results are extremely important since both residues were submitted to the same physicochemical processes, requiring the same chemical reagents. Therefore, there is a significant reduction in the quantity of reagents when extracting CHITS from CRP, representing a great economic and environmental advantage.

Similar content being viewed by others

References

Gillett R (2008) Global study of shrimp fisheries. FAO Fisheries Technical Paper No. 475, Rome, FAO. p 331

Bondad-Reantaso MG, Subasinghe RP, Josupeit H et al (2012) The role of crustacean fisheries and aquaculture in global food security: past, present and future. J Invertebr Pathol 110:158–165

Food and Agriculture Organization of the United Nations (2019) Fishery and Acquaculture Country Profites. The Federative Republic of Brazil. Part I: Overview and main indicators. FAO. http://www.fao.org/fishery/facp/bra/en#pageSection1. Accessed 21 May 2021

Cavalheiro JMO, de Souza EO, Bora PS (2007) Utilization of shrimp industry waste in the formulation of tilapia (Oreochromis niloticus Linnaeus) feed. Bioresour Technol 98:602–606

Kandra P, Challa MM, Kalangi Padma Jyothi H (2012) Efficient use of shrimp waste: present and future trends. Appl Microbiol Biotechnol 93:17–29. https://doi.org/10.1007/s00253-011-3651-2

Miranda Castro SP, Lizarraga Pauli EG (2012) Is chitosan a new panacea? Areas of application. Complex World Polysacch. https://doi.org/10.5772/51200

Vakili M, Rafatullah M, Salamatinia B et al (2014) Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: a review. Carbohydr Polym 113:115–130

Patil AG, Poornachandra S, Gumageri R et al (2017) Chitosan composites reinforced with nanostructured waste fly ash. J Mater Cycles Waste Manag 19:870–883. https://doi.org/10.1007/s10163-016-0488-x

Estevinho BN, Rocha F, Santos L, Alves A (2013) Microencapsulation with chitosan by spray drying for industry applications—a review. Trends Food Sci Technol 31:138–155. https://doi.org/10.1016/j.tifs.2013.04.001

Hamed I, Özogul F, Regenstein JM (2016) Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): a review. Trends Food Sci Technol 48:40–50

Shoji R, Miyazaki T, Niinou T et al (2004) Recovery of gold by chicken egg shell membrane-conjugated chitosan beads. J Mater Cycles Waste Manag 6:142–146. https://doi.org/10.1007/s10163-003-0112-8

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174. https://doi.org/10.3390/md13031133

Bhat P, Pawaskar G-M, Raval R et al (2019) Expression of Bacillus licheniformis chitin deacetylase in E. coli pLysS: sustainable production, purification and characterisation. Int J Biol Macromol 131:1008–1013. https://doi.org/10.1016/j.ijbiomac.2019.03.144

Antonino RSCMDQ, Fook BRPL, Lima VADO et al (2017) Preparation and characterization of chitosan obtained from shells of shrimp (Litopenaeus vannamei Boone). Mar Drugs 15:1–12. https://doi.org/10.3390/md15050141

Hossain MS, Iqbal A (2014) Production and characterization of chitosan from shrimp waste M. J Bangladesh Agril Univ 12:153–160

Ibrahim HM, Salama MF, El-Banna HA (1999) Shrimp’s waste: Chemical composition, nutritional value and utilization. Food Nahrung 43:418–423

Gómez-Ríos D, Barrera-Zapata R, Ríos-Estepa R (2017) Comparison of process technologies for chitosan production from shrimp shell waste: a techno-economic approach using Aspen Plus®. Food Bioprod Process 103:49–57. https://doi.org/10.1016/j.fbp.2017.02.010

Danarto YC, Distantina S, Purwanto A, et al (2016) Optimizing deacetylation process for chitosan production from green mussel (perna viridis) shell. In: AIP conference proceedings. AIP Publishing, p 30028

Patria A (2013) Production and characterization of chitosan from shrimp shells waste. AACL BIOFLUX 6:339–344

Philibert T, Lee BH, Fabien N (2017) Current status and new perspectives on chitin and chitosan as functional biopolymers. Appl Biochem Biotechnol 181:1314–1337. https://doi.org/10.1007/s12010-016-2286-2

Santos VP, Maia P, de Alencar NS et al (2019) Recovery of chitin and chitosan from shrimp waste with microwave technique and versatile application. Arq Inst Biol (Sao Paulo) 86:1–7. https://doi.org/10.1590/1808-1657000982018

Hossain MS, Iqbal A (2014) Production and characterization of chitosan from shrimp waste. J Bangladesh Agric Univ 12:153–160. https://doi.org/10.3329/jbau.v12i1.21405

Baxter A, Dillon M, Anthony Taylor KD, Roberts GAF (1992) Improved method for i.r. determination of the degree of N-acetylation of chitosan. Int J Biol Macromol 14:166–169. https://doi.org/10.1016/S0141-8130(05)80007-8

Sivashankari PR, Prabaharan M (2017) Deacetylation modification techniques of chitin and chitosan. In: Jennings JA, Bumgardner JD (eds) Chitosan based biomaterials volume 1 fundamentals. Woodhead Publishing, Sawston, Cambridge, pp 117–133

Wijesena RN, Tissera N, Kannangara YY et al (2015) A method for top down preparation of chitosan nanoparticles and nanofibers. Carbohydr Polym 117:731–738. https://doi.org/10.1016/j.carbpol.2014.10.055

Goy RC, de Britto D, Assis OBG (2009) A review of the antimicrobial activity of chitosan. Polímeros 19:241–247

Baskar D, Sampath Kumar TS (2009) Effect of deacetylation time on the preparation, properties and swelling behavior of chitosan films. Carbohydr Polym 78:767–772. https://doi.org/10.1016/j.carbpol.2009.06.013

Abdou ES, Nagy KSA, Elsabee MZ (2008) Extraction and characterization of chitin and chitosan from local sources. Bioresour Technol 99:1359–1367. https://doi.org/10.1016/j.biortech.2007.01.051

Tan TS, Chin HY, Tsai ML, Liu CL (2015) Structural alterations, pore generation, and deacetylation of α- and β-chitin submitted to steam explosion. Carbohydr Polym 122:321–328. https://doi.org/10.1016/j.carbpol.2015.01.016

Ishii D, Ohashi C, Hayashi H (2014) Facile enhancement of the deacetylation degree of chitosan by hydrothermal treatment in an imidazolium-based ionic liquid. Green Chem 16:1764–1767

Acknowledgements

The authors thank Wilson Orsini (Centro Universitario UNISAGRADO) for Technical support. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. William Santana thanks São Paulo Research Foundation—FAPESP for financial support (Grant # BIOTA 2013/01201-0), the National Council for Scientific and Technological Development—CNPq [Grant PQ #315185/2020-1] and the Fundação Cearense de Apoio ao Desenvolvimento Científico e Tecnológico (6647309/2017). Samples were transported in compliance with the Brazilian state and federal environmental laws (permanent license for collection of Zoological Material MMA/ICMBio/SISBIO number 37356-1 to WS). Angela Kinoshita thanks the National Council for Scientific and Technological Development—CNPq [Grant PQ #309186/2020-0]. Edilson M Pinto tanks National Council for Scientific and Technologica Delevopment - CNPq [Grant 481340/2013-0].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wegner, L., Kinoshita, A., de Paiva, F.F.G. et al. Only carapace or the entire cephalothorax: which is best to obtain chitosan from shrimp fishery waste?. J Mater Cycles Waste Manag 23, 1831–1837 (2021). https://doi.org/10.1007/s10163-021-01254-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01254-z