Abstract

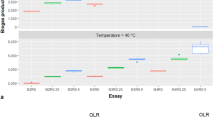

This study aimed to perform a comparative analysis of the performance of five models (Gompertz, logistic, Richards, the first-order, artificial neural networks) in predicting methane production rate from anaerobic digestion of livestock manures. The input variables were fermentation time, digestion temperature, biogas temperature, ambient temperature, pH, and specific biogas production rate. The physicochemical compositions of cow manure and sheep manure showed that volatile solid (VS) contents were close to each other in manure compositions (77.6% and 64.7%, respectively), while the potential of methane production from cow manure (673.44 mL CH4/g VS) was greater than that from sheep manure (320.32 mL CH4/g VS). The determination coefficients (R2) for logistic function, Gompertz, Richards, the first-order, and ANN models were obtained as 0.968, 0.967, 0.975, 0.825, and 0.995 for the cow manure, respectively. In case of the sheep manure, the R2 values obtained from these models were 0.976, 0.979, 0.981, 0.968 and 0.991, respectively. Although the determination coefficients of all models were in satisfactory agreement with the experimental data, the ANN model showed competitive lower RMSE values of 0.111 and 0.164 for cow and sheep manure data sets, respectively, indicating its superior performance than other models.

Similar content being viewed by others

References

Ali MM, Ndongo M, Bilal B, Yetilmezsoy K, Youm I, Bahramian M (2020) Mapping of biogas production potential from livestock manures and slaughterhouse waste: a case study for African countries. J Clean Prod 256:120499

Ali MM, Dia N, Bilal B, Ndongo M (2018) Theoretical models for prediction of methane production from anaerobic digestion: a critical review. Int J Phys Sci 13:206–216

Yetilmezsoy K, Turkdogan F, Temizel I, Gunay A (2013) Development of Ann–based models to predict biogas and methane productions in anaerobic treatment of molasses wastewater. Int J Green Energy 10:885–907

DasGhatak M, Mahanta P (2014) Comparison of kinetic models for biogas production rate from saw dust. Int J Res Eng Technol 3:248–254

Nair VV, Dhar H, Kumar S, Thalla AK, Mukherjee S, Wong JWC (2016) Artificial neural network based modeling to evaluate methane yield from biogas in a laboratory–scale anaerobic bioreactor. Biores Technol 217:90–99

Antwi P, Li J, Boadi PO, Meng J, Shi E, Deng K, Bondinuba FK (2017) Estimation of biogas and methane yields in an UASB treating potato starch processing wastewater with back propagation artificial neural network. Biores Technol 228:106–115

Xiao C, Fu Q, Liao Q, Huang Y, Xia A, Chen H, Zhu X (2020) Life cycle and economic assessments of biogas production from microalgae biomass with hydrothermal pretreatment via anaerobic digestion. Renewable Energy 151:70–78

Pramod KP, Michelle LS (2012) Impacts of temperatures on biogas production in dairy manure anaerobic digestion. Agric Biosyst Eng 4:629–630

Navickas K, Venslauskas K, Petrauskas A, Zuperka V (2013) Influence of temperature variation on biogas yield from industrial wastes and energy plants. Eng Rural Dev 13:405–410

Kheiredine B, Derbal K, Bencheikh M (2014) Effect of starting pH on the produced methane from dairy wastewater in thermophilic phase. Chem Eng Trans 38:511–516

Wang S, Jena U, Das KC (2018) Biomethane production potential of slaughterhouse waste in the United States. Energy Convers Manage 173:143–157

De Clercq D, Jalota D, Shang R, Ni K, Zhang Z, Khan A, Wen Z, Caicedo L, Yuan K (2019) Machine learning powered software for accurate prediction of biogas production: a case study on industrial–scale Chinese production data. J Clean Prod 218:390–399

Vilvert AJ, Saldeira Junior JC, Bautitz IR, Zenatti DC, Andrade MG, Hermes E (2020) Minimization of energy demand in slaughterhouses: estimated production of biogas generated from the effluent. Renew Sustain Energy Rev 120:109613

Avcioǧlu AO, Türker U (2012) Status and potential of biogas energy from animal wastes in Turkey. Renew Sustain Energy Rev 16:1557–1561

Li X, Wang Y (2017) Prediction model of biogas production for anaerobic digestion process of food waste based on LM-BP neural network and particle swarm algorithm optimization. Chinese Automation Congress (CAC) 2017:7629–7633

Tufaner F, Avsar Y, Gonullu MT (2017) Modeling of biogas production from cattle manure with co-digestion of different organic wastes using an artificial neural network. Clean Technol Environ Policy 19:2255–2264

Yang L, Lin H, Gong MY, Zhou ST (2017) Coalbed methane production forecasting based on dynamic PSO neural network model. In: 2017 13th International Conference on Natural Computation, Fuzzy Systems and Knowledge Discovery (ICNC-FSKD) 2017:948–952

Beltramo T, Klocke M, Hitzmann B (2019) Prediction of the biogas production using GA and ACO input features selection method for ANN model. Inf Process Agric 6:349–356

Sakiewicz P, Piotrowski K, Ober J, Karwot J (2020) Innovative artificial neural network approach for integrated biogas—wastewater treatment system modelling: effect of plant operating parameters on process intensification. Renew Sustain Energy Rev 124:109784

Imu NJ, Samuel DM (2014) Biogas production potential from municipal organic wastes in Dhaka City, Bangladesh. Int J Res Eng Technol 3(1):453–460

Ghatak MD, Mahanta P (2014) Comparison of kinetic models for biogas production rate from saw dust. Int J Res Eng Technol 3(7):249–254

APHA (2003) Standard test methods for direct moisture content measurement of wood and wood base materials. American Water Works Association, and Water Environment Federation, Washington

Pramanik SK, Suja FB, Porhemmat M, Pramanik BK (2019) Performance and kinetic model of a single-stage anaerobic digestion system operated at different successive operating stages for the treatment of food waste. Processes 7(600):1–16

Çetinkaya AY, Yetilmezsoy K (2019) Evaluation of anaerobic biodegradability potential and comparative kinetics of different agro-industrial substrates using a new hybrid computational coding scheme. J Clean Prod 238:117921

Ji X, Lin W, Zhang W, Yin F, Zhao X, Wang C, Liu J, Yang H, Chen Y, Liu S (2015) Evaluation of methane production features and kinetics of Bougainvillea spectabilis Willd waste under mesophilic conditions. Afr J Biotech 14:1910–1917

Strömberg S, Nistor M, Liu J (2015) Early prediction of biochemical methane potential through statistical and kinetic modelling of initial gas production. Biores Technol 176:233–241

Rorke D, Gueguim Kana E (2017) Kinetics of bioethanol production from waste sorghum leaves using Saccharomyces cerevisiae BY4743. Fermentation 3:1–10

Donoso-Bravo A, Pérez-Elvira SI, Fdz-Polanco F (2010) Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem Eng J 160:607–614

Wang D, Yang X, Tian C, Lei Z, Kobayashi N, Kobayashi M, Adachi Y, Shimizu K, Zhang Z (2019) Characteristics of ultra-fine bubble water and its trials on enhanced methane production from waste activated sludge. Biores Technol 273:63–69

Dorofki M, Elshafie AH, Jaafar O, Karim OA, Mastura S (2012) Comparison of artificial neural network activation functions abilities to simulate extreme runoff data. Int Proc Chem Biol Environ Eng 33:39–44

Vuković N, Petrović M, Miljković Z (2018) A comprehensive experimental evaluation of orthogonal polynomial expanded random vector functional link neural networks for regression. Applied Soft Computing 70:1083–1096

Rezaeianzadeh M, Stein A, Tabari H, Abghari H, Jalalkamali N, Hosseinipour EZ, Singh VP (2013) Assessment of a conceptual hydrological model and artificial neural networks for daily outflows forecasting. Int J Environ Sci Technol 10(6):1181–1192

Kurtgoz Y, Karagoz M, Deniz E (2017) Biogas engine performance estimation using ANN. Eng Sci Technol, An Int J 20:1563–1570

Jeong SH, Lee KB, Ham JH, Kim JH, Cho JY (2020) Estimation of maximum strains and loads in aircraft landing using artificial neural network. Int J Aeronaut Space Sci 21(1):117–132

Oloko-Oba MI, Taiwo AE, Ajala SO, Solomon BO, Betiku E (2018) Performance evaluation of three different–shaped bio–digesters for biogas production and optimization by artificial neural network integrated with genetic algorithm. Sustain Energy Technol Assess 26:116–124

Xu S, Chen L (2008) Novel approach for determining the optimal number of hidden layer neurons for FNN’s and its application in data mining. In: 5th International Conference on Information Technology and Applications (ICITA 2008), pp 683–686

Kuri-Morales A (2017) Closed determination of the number of neurons in the hidden layer of a multi-layered perceptron network. Soft Comput 21(3):597–609

Noor AZM, Fauadi MHFM, Jafar FA, Bakar MHA (2019) Optimal number of hidden neuron identification for sustainable manufacturing application. Int J Recent Technol Eng 8(2):2447–2453

Carpenter WC, Hoffman ME (1997) Guidelines for the selection of network architecture. Artif Intell Eng Des Anal Manuf 11(5):395–408

Kumar S, Saroj B, Meher K, Park HS (2015) Artificial neural network model for predicting methane percentage in biogas recovered from a landfill upon injection of liquid organic waste. Clean Technol Environ Policy 17:443–453

Romagnoli F, Pastare L, Sabunas A, Balina K, Blumberga D (2017) Effects of pre–treatment on Biochemical Methane Potential (BMP) testing using Baltic Sea Fucus vesiculosus feedstock. Biomass Bioenerg 105:23–31

Achinas S, Li Y, Achinas V, Euverink GJW (2018) Influence of sheep manure addition on biogas potential and methanogenic communities during cow dung digestion under mesophilic conditions. Sustain Environ Res 28(5):240–246

Im S, Petersen SO, Lee D, Kim DH (2020) Effects of storage temperature on CH4 emissions from cattle manure and subsequent biogas production potential. Waste Manage 101:35–43

Latif MA, Mehta CM, Batstone DJ (2017) Influence of low pH on continuous anaerobic digestion of waste activated sludge. Water Res 113:42–49

Cavinato C, Da Ros C, Pavan P, Bolzonella D (2017) Influence of temperature and hydraulic retention on the production of volatile fatty acids during anaerobic fermentation of cow manure and maize silage. Biores Technol 223:59–64

Lindner J, Zielonka S, Oechsner H, Lemmer A (2015) Effect of different pH-values on process parameters in two-phase anaerobic digestion of high-solid substrates. Environ Technol 36(2):198–207

Bharathiraja B, Sudharsana T, Jayamuthunagai J, Praveenkumar R, Chozhavendhan S, Iyyappan J (2018) Biogas production—a review on composition, fuel properties, feed stock and principles of anaerobic digestion. Renew Sustain Energy Rev 90:570–582

Kanat G, Saral A (2009) Estimation of biogas production rate in a thermophilic UASB reactor using artificial neural networks. Environ Model Assess 14(5):607–614

Beltramo T, Ranzan C, Hinrichs J, Hitzmann B (2016) Artificial neural network prediction of the biogas flow rate optimised with an ant colony algorithm. Biosys Eng 143:68–78

Saghouri M, Abdi R, Ebrahimi-Nik M, Rohan, A, Maysami M (2020) Modeling and optimization of biomethane production from solid-state anaerobic co-digestion of organic fraction municipal solid waste and other co-substrates. Energy Sources Part A: Recovery Util Environ Eff. https://doi.org/10.1080/15567036.2020.1767728

Almomani F (2020) Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network. Fuel 280:118573

Ware A, Power N (2017) Modelling methane production kinetics of complex poultry slaughterhouse wastes using sigmoidal growth functions. Renewable Energy 104:50–59

Altas L (2009) Inhibitory effect of heavy metals on methane–producing anaerobic granular sludge. J Hazard Mater 162:1551–1556

Li L, Kong X, Yang F, Sun Y (2012) Biogas production potential and kinetics of microwave and conventional thermal pretreatment of grass. Appl Biochem Biotechnol 166:1183–1191

Nielfa R, Cano R, Fdz-Polanco M (2015) Theoretical methane production generated by the co–digestion of organic fraction municipal solid waste and biological sludge. Biotechnol Rep 5:14–21

Moset V, Al-zohairi N, Mølle HB (2015) The impact of inoculum source, inoculum to substrate ratio and sample preservation on methane potential from different substrates. Biomass Bioenerg 8:787–800

Mahanty B, Zafar M, Park HS (2013) Characterization of co-digestion of industrial sludges for biogas production by artificial neural network and statistical regression models. Environ Technol 34(13–14):2145–2153

Acknowledgements

The authors would like to thank the providers of the livestock manures used as the substrates in this study. The authors wish to extend their special thanks to the Center of Studies and Research on Renewable Energy (CERER) for the use of measuring instruments during the experimental study.

Funding

This AILARA project has been supported by the French Embassy in Mauritania (Project Number: 2018–2019).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Preparation of the materials, collection of the experimental data, and analyses were conducted by MMA. MMA and KY coordinated and supervised the collaboration, developed the models, and analyzed the data. MMA, KY, and MB improved the theoretical and computational frameworks of the research. MN, BB, IY, and BİG contributed to the interpretation of the results and helped shape the investigation. The first draft of the manuscript was written by MMA, KY, and MB. The authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest including any financial, personal, or relationships with other people or organizations.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ali, M.M., Ndongo, M., Yetilmezsoy, K. et al. Appraisal of methane production and anaerobic fermentation kinetics of livestock manures using artificial neural networks and sinusoidal growth functions. J Mater Cycles Waste Manag 23, 301–314 (2021). https://doi.org/10.1007/s10163-020-01130-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01130-2