Abstract

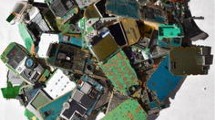

Knowing the metal content of electronic waste is essential to evaluate metal recovery. Lack of a standard method for digestion of precious metals from electronic waste has resulted in difficulty in comparison to the efficiency of recovery. In this study, different precious metal digestion methods and economic value of precious metals from different types of waste printed circuit boards in different fraction sizes, including computer printed circuit boards, mobile phone printed circuit boards, television printed circuit boards, fax machine printed circuit boards, copy machine printed circuit boards, and central processing unit were examined. The optimal digestion method using aqua regia, hydrogen peroxide, hydrofluoric acid, and boric acid was adopted. The precious metal content was analyzed to answer what precious metals and types of printed circuit boards is preference. The results presented the following order of total value of precious metals (\(\sum {W_{ti} \Pr_{ti} }\)): central processing unit > Mobile phone > Copy > Fax > Computer > Television. Among the precious metals, gold and palladium were, respectively, attributed to the highest value distribution. The average values of the precious (gold and palladium) and all of the metals of electronic waste are about 19 and 21 times higher than the average cost of the world’s top ten mines.

Similar content being viewed by others

References

Pariatamby A, Victor D (2013) Policy trends of e-waste management in Asia. J Mater Cycles Waste 15(4):411–419

Habuer NJ, Moriguchi Y (2017) Resource-availability scenario analysis for formal and informal recycling of end-of-life electrical and electronic equipment in China. J Mater Cycles Waste 19(2):599–611

Ghodrat M, Rhamdani MA, Khaliq A, Brroks G, Samali B (2018) Thermodynamic analysis of metals recycling out of waste printed circuit board through secondary copper smelting. J Mater Cycles Waste 20(1):386–401

Rudnik E, Pierzynka M, Handzlik P (2016) Ammoniacal leaching and recovery of copper from alloyed low-grade e-waste. J Mater Cycles Waste 18(2):318–328

EPA (United States Environmental Protection Agency) (2004). The life cycle of a mobile phone, Solid waste and emergency response. (accessed 20 March 2010)

Holgersson S, Steenari BM, Bjorkman M, Cullbrand K (2018) Analysis of the metal content of small-size Waste Electric and Electronic Equipment (WEEE) printed circuit boards—part 1: Internet routers, mobile phones and smartphones. Resour Conserv Recy 133:300–308

Garlapati VK (2016) E-waste in India and developed countries: Management, recycling, business and biotechnological initiatives. Renew Sust Energ Rev 54:874–881

Singh M, Thind PS, John S (2018) An analysis on e-waste generation in Chandigarh: quantification, disposal pattern and future predictions. J Mater Cycles Waste 20(3):1625–1637

Tanskanen P (2013) Management and recycling of electronic waste. Acta Mater 61(3):1001–1011

Jiang P, Song YX, Chen BQ, Harney M, Korzenski MB (2014) Environmentally benign solution for recycling electronic waste using the principles of green chemistry. Adv Mat Res 878:406–412

Korte F, Spiteller M, Coulston F (2000) The cyanide leaching gold recovery process is a nonsustainable technology with unacceptable impacts on ecosystems and humans: The disaster in Romania. Ecotox Environ Safe 46(3):241–245

Zhu P, Yang YZ, Chen Y, Qian GR, Liu Q (2018) Influence factors of determining optimal organic solvents for swelling cured brominated epoxy resins to delaminate waste printed circuit boards. J Mater Cycles Waste 20(1):245–253

Adie GU, Sun L, Zeng X, Zheng L, Osibanjo O, Li J (2017) Examining the evolution of metals utilized in printed circuit boards. Environ Technol 38(13–14):1696–1701

Dangton J, Leepowpanth Q (2014) A study of gold recovery from E-waste by bioleaching using Chromobacterium violaceum. Appl Mech Mater 548–549:280–283

Fogarasi S, Imre-Lucaci F, Egedy A, Imre-Lucaci A, Ilea P (2015) Eco-friendly copper recovery process from waste printed circuit boards using Fe3+/Fe2+ redox system. Waste Manage 40:136–143

Natarajan G, Ting YP (2014) Pretreatment of e-waste and mutation of alkali-tolerant cyanogenic bacteria promote gold biorecovery. Bioresource Technol 152:80–85

Xiang Y, Wu P, Zhu N, Zhang T, Liu W, Wu J, Li P (2010) Bioleaching of copper from waste printed circuit boards by bacterial consortium enriched from acid mine drainage. J Hazard Mater 184(1):812–818

Arshadi M, Mousavi SM, Rasoulnia P (2016) Enhancement of simultaneous gold and copper recovery from discarded mobile phone PCBs using Bacillus megaterium: RSM based optimization of effective factors and evaluation of their interactions. Waste Manage 57:158–167

Arshadi M, Mousavi SM (2015) Enhancement of simultaneous gold and copper extraction from computer printed circuit boards using Bacillus megaterium. Bioresource Technol 175:315–324

Kavitha AV (2014) Extraction of preious metals from E-waste. Int J Chem Pharm Sci 147–150

Yamane LH, Moraes VTD, Epinosa DCR, Tenorio AS (2011) Recycling of WEEE: Characterization of spent printed circuit boards from mobile phones and computers. Waste Manage 31(12):2553–2558

Ilyas S, Lee JC, Kim BS (2014) Bioremoval of heavy metals from recycling industry electronic waste by a consortium of moderate thermophiles: process development and optimization. J Clean Prod 70:194–202

Yang Y, Chen S, Li S, Chen M, Chen H, Liu B (2014) Bioleaching waste printed circuit boards by Acidithiobacillus ferrooxidans and its kinetics aspect. J Biotechnol 173:24–30

Shah MB, Tipre DR, Purohit MS, Dave SR (2015) Development of two-step process for enhanced biorecovery of Cu-Zn-Ni from computer printed circuit boards. J Biosci Bioeng 120(2):167–73

Bazargan A, Bwegendaho D, Baford J, Mckay G (2014) Printed circuit board waste as a source for high purity porous silica. Sep Purif Technol 136:88–93

Das AK, Chakraborty R, Mde G, Cervera ML, Goswami D (2001) ICP-MS multielement determination in fly ash after microwave-assisted digestion of samples. Talanta 54(5):975–981

Imre-Lucaci F, Fogarasi S, Ilea P, Tamasan M (2012) Copper recovery from real samples of WPCBs by anodic dissolution. Environ Eng Manag J 11:1439–1444

Das S, Ting YP (2017) Evaluation of wet digestion methods for quantification of metal content in electronic scrap material. Resources 6(4):64

Arshadi M, Yaghmaei S, Mousavi SM (2018) Content evaluation of different waste PCBs to enhance basic metals recycling. Resour Conserv Recy 139:298–306

Lee H, Mishra B (2018) Selective recovery and separation of copper and iron from fine materials of electronic waste processing. Miner Eng 123:1–7

Ghosh B, Ghosh MK, Parhi P, Mukherjee PS, Mishra BK (2015) Waste Printed Circuit Boards recycling: an extensive assessment of current status. J Clean Prod 94(Suupplement C):5–19

Robinson BH (2009) E-waste: An assessment of global production and environmental impacts. Sci Total Environ 408(2):183–191

Basov V (2015) The world’s highest grade gold mines. www. Mining.com

Tuncuk A, Stazi V, Ackil A, Yazici EY, Deveci H (2012) Aqueous metal recovery techniques from e-scrap: Hydrometallurgy in recycling. Miner Eng 25(1):28–37

Metalary (15 January 2020). www.Metalary.com.

Basov V (2017) These 10 mines have the world's most valuable ore

Van Schaik A (2010) Reuter MA (2010) Dynamic modelling of E-waste recycling system performance based on product design. Miner Eng 23(3):192–210

Inc S (1999) Chapter 7: Basic of X-ray Diffraction: www.scintag.com. p: 1–25

Acknowledgements

This project has been conducted by the deputy of research and technology of Sharif University of Technology (Award Number QA: 970713) and Iran's National Elites Foundation (Award Number: 7000/ 9036). The authors are thankful to Pars Charkhesh Asia company for supplying the PCBs.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arshadi, M., Yaghmaei, S. & Esmaeili, A. Evaluating the optimal digestion method and value distribution of precious metals from different waste printed circuit boards. J Mater Cycles Waste Manag 22, 1690–1698 (2020). https://doi.org/10.1007/s10163-020-01043-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01043-0