Abstract

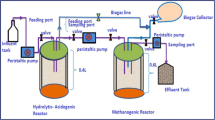

This study was carried out to optimize the working conditions hydrolytic–acidogenic step of the two stage anaerobic sequencing batch reactor (ASBR) system during anaerobic co-digestion of tannery wastewater (TWW) and tannery solid waste (TSW) under mesophilic temperature (38 ± 2 °C) for enhanced acidification products. For this purposes four laboratory scale digesters with 0.4 L working volume performed in semi-continuous mode operation were used. Four mixing ratios of substrate (100:0, 75:25, 50:50, 25:75) at hydraulic retention time (HRT) of 5, 3 and 1 days and equivalent organic loading rate (OLR) were examined to assess the effect of each operating parameter on process performance of hydrolytic–acidogenic step in the two stage ASBR. The optimized operating conditions obtained in this study for enhanced performance of hydrolytic–acidogenic step were substrate mixing ratio of 50:50, HRT of 5 days, OLR of 1.20 gCOD/L/day and pH of 6.2. The degree of acidification and hydrolysis (%) achieved in the reactor operated at those optimized parameters were 36.55% and 54.8%, respectively. In general anaerobic co-digestion of TWW with TSW is more important than using TWW alone for enhanced acidification products. This is because of the positive synergistic effects of the TSW in terms of well-balanced nutrients and an appropriate C:N ratio.

Similar content being viewed by others

References

Das M, Dixit S, Yadav A, Dwivedi PD (2015) Toxic hazards of leather industry and technologies to combat threat: a review. J Clean Prod 87:39–49

Bosnic M, Buljan J (2000) Pollutants in Tannery Effluents, United Nations industrial development Organization (UNIDO)-US/RAS/92/120

Rameshraja D, Sresh S (2011) Treatment of tannery waste water by various oxidation and combined process. Int J Environ Resour 5(2):349–360

Leather Industry Development Institute (LIDI) and United Nation Development Program (UNDP) (2010) Proceeding of National workshop on enhancing the Ethiopian Leather Industry and its Market Competitiveness. Adama, Ethiopia

Zupancic GD, Jemec A (2010) Anaerobic digestion of tannery waste; Semi-continuous and anaerobic sequencing batch reactor processes. Biores Technol 101:26–33

Seyoum L, Fassil A, Gunnel D (2003) Characterization of tannery wastewater and assessment of downstream pollution profiles along Modjo river in Ethiopia. Ethiopian J Biol Sci 2(2):116–157

Kameswari KSB, Kalyanaraman C, Umamaheswari B, Thanasekaran K (2014) Enhancement of biogas generation during co-digestion of tannery solid wastes through optimization of mix proportions of substrates. Clean Techn Environ Policy 16:1067–1080

Di Maria F, Sordi A, Cirulli G, Gigliotti G, Massaccesi L, Cucina M (2014) Co treatment of fruit and vegetable waste in sludge digesters. An analysis of the relationship among bio-methane generation, process stability and digestate phytotoxicity. Waste Manag 34:1603–1608

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic co digestion of sewage sludge and organic fraction of municipal solid wastes. Adv Environ Res 7:609–616

Mshandete A, Kivaisi A, Rubindamayugi M, Mattiasson B (2004) Anaerobic batch co-digestion of sisal pulp and fish wastes. Biores Technol 95(1):19–24

Mata-Alvarez J, Macé S, Llabrés P (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour Technol 74:3–16

Andualem M, Seyoum L (2016) Anaerobic co-treatment of tannery wastewater and cattle dung for biogas production using a pilot scale anaerobic sequencing batch reactor (ASBR). Int J Sci Eng Res 7(6):2229–5518

Sri Bala KK, Chitra K, Thanasekaran K (2015) Optimization of organic load for co-digestion of tannery solid waste in semi-continuous mode of operation. Clean Tech Environ Policy 17:693–706

Thangamani A, Rajakumar S, Ramanujam RA (2010) Anaerobic co-digestion of hazardous tannery solid waste and primary sludge: biodegradation kinetics and metabolite analysis. Clean Tech Environ Policy 12:517–524

Rivero M, Solera R, Perez M (2014) Anaerobic mesophilic co-digestion of sewage sludge with glycerol: Enhanced biohydrogen production. Int J Hydrogen Energy 39:2481–2488

Kacprzac A, Krystek L, Ledakowicz S (2010) Co-digestion of agricultural and industrial wastes. Chem Pap 64:127–131

El-Mashad HM, Zhang R (2010) Biogas production from co-digestion of dairy manure and food waste. Biores Technol 101(11):4021–4028

Azaizeh H, Jadoun J (2010) Co-digestion of Olive Mill Wastewater and Swine Manure Using Up-Flow Anaerobic Sludge Blanket Reactor for Biogas Production. J Water Resour Protect 2:314–321

Maranon E, Castrillon L, Quiroga G, Fernandez-Nava Y, Gomez L, Garcia MM (2012) Co-digestion of cattle manure with food waste and sludge to increase biogas production. Waste Manag 32(10):1821–1825

Comino E, Riggio VA, Rosso M (2012) Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresour Technology 114:46–53

Lay CH, Sen B, Chen CC, Wu JH, Lee SC (2013) Co fermentation of water hyacinth and beverage waste water in powder and pellet form for hydrogen production. Bioresour Tecnology. 135:610–615

Minale M, Worku T (2014) Anaerobic co-digestion of sanitary wastewater and kitchen solid waste for biogas and fertilizer production under ambient temperature: waste generated from condominium house. Int J Environ Sci Technol 11:509–516

Zhikai Z, Guangyi Z, Wangliang L, Chunxing L, Guangwen X (2016) Enhanced biogas production from sorghum stem by co-digestion with cow manure. Int J Hydrogen Energy 41:9153–9158

Parawira W, Read JS, Mattiasson B, Björnsson L (2008) Energy production from agricultural residues: High methane yields in pilot-scale two-stage anaerobic digestion. Biomass Bioenergy 32:44–50

Bochmann G, Montgomery L (2013) Storage and pre-treatment of substrates for biogas production. In: Wellinger A, Murphy JD, Baxter D (eds) The biogas handbook. Wood head Publishing, Oxford, pp 95–96

Browne JD, Murphy JD(2104). The impact of increasing organic loading in two phase digestion of food waste. Renew Energy 71:69–76

Massanet-Nicolau J, Dinsdale R, Guwy A, Shipley G(2105). Utilising bio-hydrogen to increase methane production, energy yields and process efficiency via two stage anaerobic digestion of grass. Bioresour Technol 189:379–383

EEPA (2003) Provisional standards for industrial pollution control in Ethiopia. In: Prepared under the ecologically sustainable industrial development (ESID) project-US/ETH/99/068/ Ehiopia, EPA/UNIDO, Addis Ababa

Seyoum L, Fassil A, Gumaelius L, Dalhammar G (2004) Biological nitrogen and organic matter removal from tannery wastewater in pilot plant operations in Ethiopia. Appl Microbiol Biotechnol 66:333–339

Berhe S, Leta S (2018) Anaerobic co-digestion of tannery waste water and tannery solid waste using two stage anaerobic sequencing batch reactor: focus on performances of methanogenic step. J Mat Cycles Waste Manag 20:1468. https://doi.org/10.1007/s10163-018-0706-9

APHA (American Public Health Association), AWWA (American Water Works Association), WEF (Water Enviroment Federation) (2012) Standard methods for the examination of water and wastewater, 22nd edn. Washington DC

Ahn YH (2006) Sustainable nitrogen elimination biotechnologies: a review. Process Biochem 41(8):1709–1721

Demirer GN, Chen S (2004) Effect of retention time and organic loading rate on anaerobic acidification and biogasification of dairy manure. J Chem Technol Biotechnol 79:1381–1387

Amulya K, Reddy MV, Venkata MS (2014) Acidogenic spent wash valorization through poly hydroxyalkanoate (PHA) synthesis coupled with fermentative bio hydrogen production. Bioresour Technol 158:336–342

Yilmaz V, Demirer GN (2007) Improved anaerobic acidification of unscreened dairy manure. Environ Eng Sci 25:309–318

Shi XS, Yuan XZ, Wang YP, Zeng SJ, Qiu YL, Guo RB, Wang LS (2014) Modeling of the methane production and pH value during the anaerobic co-digestion of dairy manure and spent mushroom substrate. Biochem Eng J 244:258–263

Dobre P, Nicolae F, Matei F (2014) Main factors affecting biogas production—an overview. Roman Biotechnol Lett 19:3

Horiuchi J, Shimizu T, Kanno T, Kobayashi M (1999) Dynamic behaviour in response to pH shift during anaerobic acidogenesis with a chemostat culture. Biotechnol Tech 13:155–157

Lim SJ, Kim BJ, Jeong CM, Choi JDR, Ahn YH, Chang HN (2008) Anaerobic organic acid production of food waste in once-a-day feeding and drawing-off bioreactor. Bioresour Technol 99(16):7866–7874

Ucisik AS, Henze M (2008) Biological hydrolysis and acidification of sludge under anaerobic conditions: the effect of sludge type and origin on the production and composition of volatile fatty acids. Water Res 42:3729–3738

De La Rubia MA, Raposo F, Rincón B, Borja R (2009) Evaluation of the hydrolytic–acidogenic step of a two-stage mesophilic anaerobic digestion process of sunflower oil cake. Biores Technol 100:4133–4138

Jianguo J, Yujing Z, Kaimin L, Quan W, Changxiu G, Menglu L (2013) Volatile fatty acids production from food waste: effects of pH, temperature, and organic loading rate. Biores Technol 143:525–530

Gaoqiang S, Mingxin H, Zhiguo Y, Shuying W, Yongzhen P (2013) Hydrolysis, acidification and dewaterability of waste activated sludge under alkaline conditions: combined effects of NaOH and Ca(OH)2. Biores Technol 136:237–243

Nguyen D, Zhang X, Jiang Z, Audet A, Paice MG, Renaud S, Tsang A (2008) Bleaching of kraft pulp by a commercial lipase: accessory enzymes degrade hexenuronic acids. Enzym Microb Technol 43:130–136

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99:4044–4064

Bouallagui H, Torrijos M, Godon JJ, Moletta R, Ben Cheikh R, Touhami Y, Delgenes JP, Hamdi M (2004) Two-phases anaerobic digestion of fruits and vegetable wastes: bioreactors performance. Biochem Eng J 21:193–197

Yu H, Fang H (2000) Thermophilic acidification of dairy wastewater. Appl Microbiol Biotechnol 54:439–444

Guerrero L, Omil F, Méndez R, Lema JM (1999) Anaerobic hydrolysis and acidogenesis of waste waters from food industries with high content of organic solids and protein. Water Res 33(15):3281–3329

Orozco AM, Nizami AS, Murphy JD, Groom E (2013) Optimizing the thermophilic hydrolysis of grass silage in a two-phase anaerobic digestion system. Bioresour Technol 143:117–125

Acknowledgements

The authors acknowledge Center for Environmental Science College of Natural Science Addis Ababa University for financial support as well as provision of laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Berhe, S., Leta, S. Anaerobic co-digestion of tannery wastes using two stage anaerobic sequencing batch reactor: focus on process performance of hydrolytic–acidogenic step. J Mater Cycles Waste Manag 21, 666–677 (2019). https://doi.org/10.1007/s10163-019-00837-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-019-00837-1