Abstract

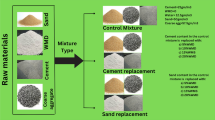

China has played a dominant role in global electrolytic manganese metal (EMM) production, accounting for over 98 % of the total world capacity since 2008. However, with the rapid development of the EMM industry and depletion of mineral ores, electrolytic manganese solid waste (EMSW) is piling up, so more large-scale landfills are needed. The environmental problems generated by EMSW pose severe threats to soil and ground water, and have become the hot issues in society. The aim is to consume and recycle EMSW, and the primary route is to make autoclaved bricks. However, less attention has been given to the procedure and strength-forming mechanism of EMSW bricks, not to mention the production line of the brick. On the basis of physical and chemical property analysis, the pretreatment process of EMSW was indispensable to solidify/stabilize the heavy metals, such as Mn, Zn, Cd, Pb, etc.. This paper expatiated on the procedure of making EMSW autoclaved bricks, analyzed in detail the strength formed by different cementitious materials with cement properties, and introduced the practical engineering of EMSW autoclaved bricks. The results showed that the pretreatment process with quicklime was effective in solidifying/stabilizing the heavy metals. The compressive strength of EMSW bricks reached 10.05 MPa when quicklime 9 % (w/w) added. Cement may be an ideal cementitious material to create EMSW bricks of high strength in experiments and on the production line. Quicklime and cement used simultaneously produced a lower strength than that when adding cement alone because the gypsum from EMSW and an alkali could generate deleterious effects, e.g., expansion or burst. In the production line of EMSW bricks, an appropriate mix proportion to make high-quality autoclaved bricks was determined: EMSW 30–40 %, cement 10–20 %, and aggregates 40–60 %. The low content of heavy metals tested by toxicity leaching may deduce that the EMSW autoclaved bricks have low environmental risk. However, long-term environmental risk evaluation will be needed, requiring more tests and leaching modeling. Employing EMSW to make high-quality autoclaved bricks may be a promising waste-to-resource strategy.

Similar content being viewed by others

References

Duan N, Dan Z-G, Song D-N (2011) Current status and directions for development of cleaner production technology of electrolytic manganese metal industry in China (in Chinese). J Environ Eng Tech 1:75–81

Duan N, Wang F, Zhou CB, Zhu C, Yu H (2010) Analysis of pollution materials generated from electrolytic manganese industries in China. Res Cons Recyc 54:506–511. doi:10.1016/j.resconrec.2009.10.007

Duan N, Dan ZG, Wang F, Pan CX, Zhou C, Jiang L (2011) Electrolytic manganese metal industry experience based China’s new model for cleaner production promotion. J Clean Prod 19:2082–2087. doi:10.1016/j.jclepro.2011.06.024

Feng Y, Chen YX, Liu F, Bao X (2006) Studies on replacement of gypsum by manganese slag as retarder in cement manufacture (in Chinese). Mod Chem Ind 26:57–60

Lan J-Q (2005) How to exploit and use the “Dregs” produced from EMM-the rich selenium as fine fertilizer (in Chinese). China’s Man Ind 23:27–30

Lan J-Q (2006) A test to corn production with fertilizer of Mn-dreg (in Chinese). China’s Man Ind 24:43–45

Qiao D, Qian JS, Wang QZ, Dang Y, Zhang H, Zeng D (2010) Utilization of sulfate-rich solid wastes in rural road construction in the Three Gorges Reservoir. Res Cons Recyc 54:1368–1376. doi:10.1016/j.resconrec.2010.05.013

Xu FG (2001) Experimental research on application of Mn-slag to roadbed backfill (in Chinese). China’s Man Ind 19:1–3

Hu CY, Yu HB (2010) Preparation of ceramic tiles using electrolytic manganese residue (in Chinese). Bull Chinese Ceram Soc 29:112–116

Wang Y (2010) Research of utilizing electrolytic manganese residue for high pressure steam brick (in Chinese). Concrete 125–128. doi:10.3969/j.issn.1002-3550.2010.10.042

Peng T, Xu L, Chen H (2010) Preparation and characterization of high specific surface area Mn3O4 from electrolytic manganese residue. Cent Eur J Chem 8:1059–1068. doi:10.2478/s11532-010-0081-4

Wang Y (2010) Pilot test on use of manganese slag and hilly sand in autoclaved brick (in Chinese). Brick Tile 8–11

Özverdİ A, Erdem M (2010) Environmental risk assessment and stabilization/solidification of zinc extraction residue: I. Environmental risk assessment. Hydrometallurgy 100:103–109. doi:10.1016/j.hydromet.2009.10.011

Peng DJ, Hu N, Peng QJ, Chen Y, Zhao W, Chen L (2006) Study on the leaching toxicity and safe disposal of manganese sulphate waste residue (in Chinese). Tech Equip Environ Pollut Control 7:100–102

Zhao F-Q, Zhao J, Liu H-J (2009) Autoclaved brick from low-silicon tailings. Constr Build Mater 23:538–541. doi:10.1016/j.conbuildmat.2007.10.013

Cicek T, Tanrıverdi M (2007) Lime based steam autoclaved fly ash bricks. Constr Build Mater 21:1295–1300. doi:10.1016/j.conbuildmat.2006.01.005

Oti JE, Kinuthia JM, Bai J (2009) Compressive strength and microstructural analysis of unfired clay masonry bricks. Eng Geol 109:230–240. doi:10.1016/j.enggeo.2009.08.010

Dermatas D, Dadachov M, Mirabito M, Meng X (2003) Strength development of solidified/stabilized organic waste and optimum treatment design. J Air Waste Man Assoc 53:1363–1372. doi:10.1080/10473289.2003.10466302

Ubbriaco P, Tasselli F (1998) A study of the hydration of lime-pozzolan binders. J Therm Anal Calorim 52:1047–1054

Chen QY, Tyrer M, Hills CD, Yang XM, Carey P (2009) Immobilisation of heavy metal in cement-based solidification/stabilisation: A review. Waste Manage (Oxford) 29:390–403. doi:10.1016/j.wasman.2008.01.019

Odler I, Zhang H (1996) Investigations on high SO3 portland clinkers and cements I. Clinker synthesis and cement preparation. Cem Concr Res 26:1307–1313. doi:10.1016/0008-8846(96)00128-7

Scrivener KL, Damidot D, Famy C (1999) Possible mechanisms of expansion of concrete exposed to elevated temperatures during curing (also known as DEF) and implications for avoidance of field problems. Cem Concr Aggre 21:93–101. doi:10.1520/CCA10513J

Glasser FP, Kindness A, Stronach SA (1999) Stability and solubility relationships in AFm phases: part I. Chloride, sulfate and hydroxide. Cem Concr Res 29:861–866

Ma ZC, Wang L, Ji GJ (2010) Effect of ettringite crystallization inhibitors on performance of sulphoaluminate cement. J Build Mater 13:395–397. doi:10.3969/j.issn.1007-9629.2010.03.025

Chen YF (2005) Study on autoclaving limes and brick using copper tailing. Dissertation, Hohai University

O’Farrell M, Wild S, Sabir BB (2001) Pore size distribution and compressive strength of waste clay brick mortar. Cem Concr Compos 23:81–91. doi:10.1016/S0958-9465(00)00070-6

Acknowledgments

The authors appreciate the basic research fund of CRAES and Shandong Hengyuan Waste Utilization Co., Ltd. for the manufacturing device support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, B., Zhou, Cb. & Duan, N. Recycling of electrolytic manganese solid waste in autoclaved bricks preparation in China. J Mater Cycles Waste Manag 16, 258–269 (2014). https://doi.org/10.1007/s10163-013-0181-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-013-0181-2