Abstract

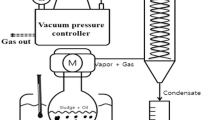

This study was performed to investigate the possibility of utilizing sewage sludge as a fuel. The drying characteristics of sewage sludge were examined by using vacuum evaporation and fry-drying technology in a batch-type rotary evaporator. In addition, the optimal drying conditions of sludge in the vacuum evaporator were investigated in terms of the vacuum pressure, temperature, and oil dosage ratio, etc. Experimental results showed that the moisture content in the sludge decreased with increases in oil/sewage sludge ratio and temperature. Dried sludge fuel (SDF) product could be obtained with on average less than 5% moisture content and a lower heating value of more than 4000 kcal/kg. Considering energy efficiency, we suggest that the optimal operating condition for drying sludge is −450 mmHg of vacuum, a temperature of 100°C, a drying time of 90 min, and a sludge/oil ratio of 1:1. The SDF product was shaped as granules and fluff-type particles. Evaluated from the perspective of the energy balance and economic considerations, this sludge drying system with vacuum fry drying could be used for effective sludge treatment and the production of SDF.

Similar content being viewed by others

References

Environmental Statistics Yearbook (2008) Ministry of environment of Korea

Romdhana MH, Hamasaiid A, Ladevie B, Lecomte D (2009) Energy valorization of industrial biomass: using a batch frying process for sewage sludge. Biores Technol 100:3740–3744

Vaxelaire J, Bongiovanni JM, Mousques P, Puiggali JR (2000) Thermal drying of residual sludge. Water Res 34:4318–4323

Lee SK, Park KT, Kim YH, Park BC, Seo BM (2009) Drying of sewage sludge using vacuum evaporation and immersion frying technology. ISWA/APESB 2009 World Congress, Lisbon, 12–15 October

Garayo J, Moreira R (2002) Vacuum frying of potato chips. J Food Eng 55:181–191

Silva DP, Rudolph V, Taranto OP (2005) The drying of sewage sludge by immersion frying. Brazilian J Chem Eng 22(2):271–276

Peregrina C, Arlabosse P, Lecomte D, Rudolph V (2006) Heat and mass transfer during fry-drying of sewage sludge. Dry Technol 24:797–818

APHA/AWWA/WEF (1995) Standard methods for the examination of water and wastewater, 19th edn. American Public Health Association, Washington, DC

Chun WP, Lee KW (2004) Sludge drying characteristics on combined system of contact dryer and fluidized bed dryer. In: Proceeding of the 14th International Drying Symposium, São Paulo, 22–25 August, B. pp 1055–1061

Vaxelaire J, Cezac P (2004) Moisture distribution in activated sludges: a review. Water Res 38:2215–2230

Ohm TI, Chae JS, Kim JE, Kim HK (2009) Study on the characteristics of evaporative drying in immersed hot oil for summer and winter sewage sludge. J Korea Soc Waste Manag 26:78–85

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, KT., Lim, BR. & Lee, SK. Drying characteristics of sewage sludge using vacuum evaporation and frying. J Mater Cycles Waste Manag 12, 235–239 (2010). https://doi.org/10.1007/s10163-010-0293-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-010-0293-x