Abstract

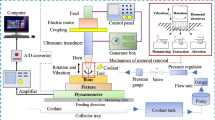

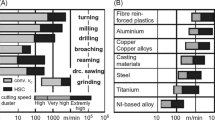

Control of the thermal and physical damage during skull base grinding is of great importance. We assess the effects of bur material (3 materials), angle of the bur (10 angles), bur diameter (10 diameters), gas coolant (4 coolants), and grinding time (10 times) to evaluate the role of operating variables in thermal and physical damage during skull bone grinding. After validation of finite element analysis (FEA) results with experimental data, the temperature in the grinding site and axial force are calculated using FEA. The use of a diamond bur leads to at least 24.48 and 12.9% reduction in thermal and physical damage, respectively. A change in angle of the bur from 0º to 90º leads to a 19.76–31.62 times increment in axial force. An increase in bur diameter from 1 to 5.5 mm led to 10.78–14.36% and 23.43–43.90% increase in maximum temperature and axial force, respectively. However, a bur diameter between 2.5 and 4 mm could provide enough grinding force with less thermal damage. Skull base grinding with dry (D) and normal saline (NS) coolants was always accompanied with thermal damage. The results of maximum and duration of temperature, axial force, and surface defect evaluation show CO2 coolants (especially internal CO2 coolant) are the best options to decrease thermal damage. The equations of temperature and axial force were estimated by regression analysis. This may be used as a guideline for neurosurgeons to control damage during skull base grinding and can also be helpful for the programming of robot-assisted skull grinding during surgery.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Abbas GM, Jones RO (2001) Measurements of drill-induced temperature change in the facial nerve during mastoid surgery: a cadaveric model using diamond burs. Annals of Otology, Rhinology & Laryngology 110(9):867–870

Aslan A, Vatansever HS, Aslan GG, Eskiizmir G, Giray G (2005) Effect of thermal energy produced by drilling on the facial nerve: histopathologic evaluation in guinea pigs. J Laryngol Otol 119(8):600–605

Augustin G, Zigman T, Davila S, Udilljak T, Staroveski T, Brezak D, Babic S (2012) Cortical bone drilling and thermal osteonecrosis. Clin Biomech 27(4):313–325

Babbar A, Jain V, Gupta D. Neurosurgical bone grinding. In Biomanufacturing 2019 (137–155). Springer, Cham.

Babbar A, Jain V, Gupta D (2020) Thermo-mechanical aspects and temperature measurement techniques of bone grinding. Materials Today: Proceedings 33:1458–1462

Danda A, Kao YT, Kuttolamadom MA, Tai BL. Characterization of forces in high-speed bone cutting and grinding for haptics rendering. InInternational Manufacturing Science and Engineering Conference 2016 Jun 27 (Vol. 49903, p. V002T03A012). American Society of Mechanical Engineers.

Danda A, Kuttolamadom MA, Tai BL (2017) A mechanistic force model for simulating haptics of hand-held bone burring operations. Med Eng Phys 49:7–13

Enomoto T, Shigeta H, Sugihara T, Satake U (2014) A new surgical grinding wheel for suppressing grinding heat generation in bone resection. CIRP Ann 63(1):305–308

Gholampour S, Deh HH (2019) The effect of spatial distances between holes and time delays between bone drillings based on examination of heat accumulation and risk of bone thermal necrosis. Biomed Eng Online 18(1):1–4

Gholampour S, Hajirayat K (2019) Minimizing thermal damage to vascular nerves while drilling of calcified plaque. BMC Res Notes 12(1):1–7

Gholampour S, Hassanalideh HH, Gholampour M, Frim D (2021) Thermal and physical damage in skull base drilling using gas cooling modes: FEM simulation and experimental evaluation. Comput Methods Programs in Biomed 2021(212):106463

Gholampour S, Shakouri E, Deh HH (2018) Effect of drilling direction and depth on thermal necrosis during tibia drilling: an in vitro study. Technol Health Care 26(4):687–697

Hassanalideh HH, Gholampour S (2020) Finding the optimal drill bit material and proper drilling condition for utilization in the programming of robot-assisted drilling of bone. CIRP J Manuf Sci Technol 31:34–47

Kelley BC, Shaw M, Sokol J, Camarata PJ (2012) A plausible mechanism for optic nerve damage: a comparative study of heat transfer during optic canal decompression. J Neurol Surg B: Skull Base 73(S01):A026

Malkin S, Guo C (2007) Thermal analysis of grinding. CIRP Ann 56(2):760–782

Ren H, Tong Y, Ding XB, Wang X, Jin SQ, Niu XY, Zhao X, Li Q (2014) Abdominal wall-lifting versus CO2 pneumoperitoneum in laparoscopy: a review and meta-analysis. Int J Clin Exp Med 7(6):1558

Shih AJ, Tai BL, Zhang L, Sullivan S, Malkin S (2012) Prediction of bone grinding temperature in skull base neurosurgery. CIRP Ann 61(1):307–310

Shih J, Wang J (2009) Inverse problem of estimating space and time dependent hot surface heat flux in transient transpiration cooling process. Int J Therm Sci 48(7):1398–1404

Tai BL, Zhang L, Wang AC, Sullivan S, Wang G, Shih AJ (2013) Temperature prediction in high speed bone grinding using motor PWM signal. Med Eng Phys 35(10):1545–1549

Tai BL, Zhang L, Wang A, Sullivan S, Shih AJ (2013) Neurosurgical bone grinding temperature monitoring. Procedia Cirp 5:226–230

Wang G, Zhang L, Wang X, Tai BL (2016) An inverse method to reconstruct the heat flux produced by bone grinding tools. Int J Therm Sci 101:85–92

Xiao G, Chen C, Shi B, Cen K, Ni M (2014) Experimental study on heat transfer of oscillating flow of a tubular Stirling engine heater. Int J Heat Mass Transf 71:1–7

Yang M, Li C, Zhang Y, Wang Y, Li B, Jia D, Hou Y, Li R (2017) Research on microscale skull grinding temperature field under different cooling conditions. Appl Therm Eng 126:525–537

Zhang B, Howes TD (1994) Material-removal mechanisms in grinding ceramics. CIRP annals. 43(1):305–8

Zhang B, Peng X (2000) Grinding damage prediction for ceramics via CDM model. J Manuf Sci Eng 122(1):51–58

Zhang L, Tai BL, Wang AC, Shih AJ (2013) Mist cooling in neurosurgical bone grinding. CIRP Ann 62(1):367–370

Zhang L, Tai BL, Wang G, Zhang K, Sullivan S, Shih AJ (2013) Thermal model to investigate the temperature in bone grinding for skull base neurosurgery. J Manuf Sci Eng 35(10):1391–1398

Funding

This study was generously supported by the Margaret Hackett Family Center.

Author information

Authors and Affiliations

Contributions

SG designed the study, collected, analyzed, and interpreted the data, and wrote the manuscript. JD collected and analyzed the data, and wrote the manuscript. DF designed the study, supervised the project, interpreted the data, and completed the final version of the manuscript. All the authors approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

All the procedures and methods performed in research involving the cadaveric studies were conducted in accordance with the Declaration of Helsinki 1964 and its later amendments. The study design and protocol were approved by the Ethics Committee of the Functional Neurosurgery Center at the Shohada Tajrish Hospital with the ethics number 19/87–2/35. It should be noted that written informed consent was obtained from each individual who has generously donated their body for this research.

Consent to participate

Not applicable.

Consent for publication

The authors agree to free publication for all relevant information by the Journal of Neurosurgical Review and its publisher.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gholampour, S., Droessler, J. & Frim, D. The role of operating variables in improving the performance of skull base grinding. Neurosurg Rev 45, 2431–2440 (2022). https://doi.org/10.1007/s10143-022-01736-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10143-022-01736-0