Abstract

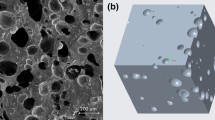

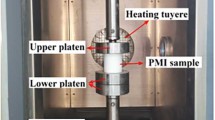

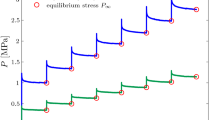

In this study, a constitutive model based on microscopic physical mechanism of silicone rubber foams was established. A theoretical statistical model of rubber elasticity considering the effect of dangling chains was modified to build this model. When a strain amplification factor (X) was introduced, the theoretical model could fit the tensile stress-strain data of mono- and bi-modal foam matrix well (Adj. R-Square = 0.9989, 0.9983). Parameters related to the polymer network, namely, average molecular weight (Mc) and volume fraction (ϕ) of chain segments between adjacent cross-linking points (network strands), were calculated by probabilistic method from the number-average molecular weight (Mn), vinyl content (wVi) of the primary polysiloxanes and percent conversion (q) of vinyl groups. The primary and infinite strain amplification factors (X0, X∞) and decay exponent (z), introduced by X and related to the nanoparticles, were obtained by fitting. Inspired by the fact that the actual strain of matrix was lower than that of the foams’, we introduced another item, strain hysteresis item (H, related with the foam porosity and cell structure), into the statistical model as well. With the same above values of Mc, ϕ, X0 and X∞, the model could also fit the compressive stress-strain data of mono- and bi-modal foams well (Adj. R-Square = 0.9948, 0.9985). Interestingly, the strain hysteresis items of the mono- and bi-modal foams almost completely coincided under all experimental strains, which may be attributed to the almost equal porosity and similar cell structure of the two foams. This constitutive model may connect the macroscopic stress-strain behaviour to the parameters of microscopic molecular structures, promisingly providing a basis for the performance improvement and optimization of silicone rubber foams.

Similar content being viewed by others

References

Song, L.; Lu, A.; Feng, P.; Lu, Z. Preparation of silicone rubber foam using supercritical carbon dioxide. Mater. Lett. 2014, 121, 126–128

Chen, H. B.; Liu, B.; Huang, W.; Wu, W. H. Gamma radiation induced effects of compressed silicone foam. Polym. Degrad. Stab. 2015, 114, 89–93

Kumar, A.; Mollah, A. A.; Keshri, A. K.; Kumar, M.; Singh, K.; Rallabhandi, K. D. V. S.; Seelaboyina, R. Development of macroporous silicone rubber for acoustic applications. Ind. Eng. Chem. Res. 2016, 55(32), 8751–8760

Liao, X.; Xu, H.; Li, S.; Zhou, C.; Li, G.; Park, C. B. The effects of viscoelastic properties on the cellular morphology of silicone rubber foams generated by supercritical carbon dioxide. RSC Adv. 2015, 5(129), 106981–106988

Liu, P.; Liu, D.; Zou, H.; Fan, P.; Xu, W. Structure and properties of closed-cell foam prepared from irradiation crosslinked silicone rubber. J. Appl. Polym. Sci. 2009, 113(6), 3590–3595

Yang, Q.; Yu, H.; Song, L.; Lei, Y.; Zhang, F.; Lu, A.; Liu, T.; Luo, S. Solid-state microcellular high temperature vulcanized (HTV) silicone rubber foam with carbon dioxide. J. Appl. Polym. Sci. 2017, 134(20), 44807

Labouriau, A.; Robison, T.; Meincke, L.; Wrobleski, D.; Taylor, D.; Gill, J. Aging mechanisms in RTV polysiloxane foams. Polym. Degrad. Stabil. 2015, 121, 60–68

Rusch, K. C. Energy-absorbing characteristics of foamed polymers. J. Appl. Polym. Sci. 1970, 14(6), 1433–1447

Avalle, M.; Belingardi, G.; Ibba, A. Mechanical models of cellular solids: Parameters identification from experimental tests. Int. J. Impact. Eng. 2007, 34(1), 3–27

Gibson, L. J. Modelling the mechanical behavior of cellular materials. Mat. Sci. Eng A-Struct. 1989, 110, 1–36

Itskov, M.; Knyazeva, A. A rubber elasticity and softening model based on chain length statistics. Int. J. Solids. Struct. 2016, 80, 512–519

Schlögl, S.; Trutschel, M. L.; Chassé, W.; Riess, G.; Saalwächter, K. Correction to entanglement effects in elastomers: macroscopic vs microscopic properties. Macromolecules 2015, 48(8), 2855–2855

Guth, E.; James, H. M. Elastic and thermoelastic properties of rubber like materials. Ind. Eng. Chem. Res. 1941, 33(5), 624–629

Rubinstein, M.; Panyukov, S. Elasticity of polymer networks. Macromolecules 2002, 35(17), 6670–6686

Vega, D. A.; Villar, M. A.; Alessandrini, J. L.; Vallés, E. M. Terminal relaxation of model poly(dimethylsiloxane) networks with pendant chains. Macromolecules 2001, 34(13), 4591–4596

Tsenoglou, C. Rubber elasticity of cross-linked networks with trapped entanglements and dangling chains. Macromolecules 1989, 22(1), 284–289

Lorenz, H.; Klüppel, M.; Heinrich, G. Microstructure-based modelling and FE implementation of filler-induced stress softening and hysteresis of reinforced rubbers. ZAMM-Z. Angew. Math. Me. 2012, 92(8), 608–631

Klüppel, M.; Schramm, J. A generalized tube model of rubber elasticity and stress softening of filler reinforced elastomer systems. Macromol. Theor. Simul. 2000, 9(9), 742–754

Marrucci, G. A mechanical model for rubbers containing entanglements. Rheo. Acta 1979, 18(2), 193–198

Curro, J. G.; Pincus, P. A theoretical basis for viscoelastic relaxation of elastomers in the long-time limit. Macromolecules 1983, 16(4), 559–562

Xu, Q.; Pang, M.; Zhu, L.; Zhang, Y.; Feng, S. Mechanical properties of silicone rubber composed of diverse vinyl content silicone gums blending. Mater. Design 2010, 31(9), 4083–4087

Urayama, K. Network topology-mechanical properties relationships of model elastomers. Polym. J. 2008, 40(8), 669–678

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51473151 and 51703210).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, CS., Lu, A., Sun, SM. et al. Establishment of Constitutive Model of Silicone Rubber Foams Based on Statistical Theory of Rubber Elasticity. Chin J Polym Sci 36, 1077–1083 (2018). https://doi.org/10.1007/s10118-018-2125-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-018-2125-8