Abstract

Reducing greenhouse gas (GHG) emissions in the transport sector is one of the biggest challenges in the German energy transition. Furthermore, sustainable development does not stop with reducing GHG emissions. Other environmental, social and economic aspects should not be neglected. Thus, here a comprehensive sustainability assessment for passenger vehicles is conducted for 2020 and 2050. The discussed options are an internal combustion engine vehicle (ICEV) fuelled with synthetic biofuel and fossil gasoline, a battery electric vehicle (BEV) with electricity from wind power and electricity mix Germany and a fuel cell electric vehicle (FCEV) with hydrogen from wind power. The life cycle-based assessment entails 13 environmental indicators, one economic and one social indicator. For integrated consideration of the different indicators, the MCDA method Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) is chosen. For the assessment, a consistent assessment framework, i.e. background scenario and system boundaries, and a detailed modelling of vehicle production, fuel supply and vehicle use are the cornerstones. The BEV with wind power is the most sustainable option in 2020 as well as in 2050. While in 2020, the second rank is taken by the ICEV with synthetic biofuel from straw and the last rank by the FCEV, in 2050 the FCEV is the runner-up. With the help of MCDA, transparent and structured guidance for decision makers in terms of sustainability assessment of motorized transport options is provided.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Motivation

The clean energy transition, including all sectors, is an ambitious goal to transform our society from its current state towards one with higher sustainability (EERA 2021). Global energy demand has increased continuously in recent years and is still being dominated by the combustion of fossil hydrocarbons. In 2017, about 80% of primary energy was generated from fossil fuels such as crude oil, natural gas and coal (IEA 2020). More than 35% of the energy is used for mobility applications, i.e. for shipping, aviation and road transport (IEA 2020). The use of fossil raw materials is associated with the emission of large quantities of greenhouse gases (GHG). In particular, carbon dioxide (CO2) accounts for about two-thirds of GHGs in the atmosphere causing global warming (United Nations 2020). In Germany, for example, around 43% of the population uses a car every day (Statista 2021a). At the same time, conventional internal combustion engine vehicles (ICEVs) remain the technology of choice with a share of almost 75% of new registrations (Statista 2021b). These two aspects clearly contradict the German government’s goal of reducing GHG emissions in the transport sector by 40–42% in 2030 compared to 1990 (BMU 2020). In order to achieve the goal of reducing GHG emissions in the transport sector in line with EU Directive 2018/2001 (RED II for short), further development and establishment of alternative drive technologies, e.g. electric motor with fuel cell—FCEV or battery—BEV, and climate-neutral fuels, e.g. synthetic biofuels, are essential (European Parliament 2018). In order to reduce emitted GHGs on a global scale, the scope of consideration needs to include the whole life cycle, i.e. the manufacturing of vehicles and fuels, the operational as well as end-of-life phases of a vehicle. From a sustainability point of view, not only GHG emissions, but also further environmental, economic and social aspects have to be considered (Guinée 2016). This means that transportation technologies must be affordable, socially accepted and environmentally benign. Several challenges can arise from such multifaceted sustainability requirements. In order to be able to make a statement regarding sustainability, first of all, a comprehensive picture of promising alternatives should be provided, i.e. an indicator-based prospective assessment including the whole life cycle needs to be carried out, and secondly, different and possibly conflicting sustainability indicators have to be handled in an integrated manner, i.e. weighed up against each other in order to find the most suitable option(s). Life cycle sustainability assessment (LCSA) using multi-criteria decision analysis (MCDA) is one of the major methods implemented to conduct comprehensive sustainability assessment, not only in the context of energy technologies and systems (Costa et al. 2019; Wulf et al. 2019). MCDA methods allow it to consider different indicators simultaneously and to integrate different preferences related to sustainability assessment (Talukder and Hipel 2021) and are therefore suitable to test our hypothesis that alternative drive technologies and renewable fuels are more sustainable than conventional ones.

Literature review

Within this subsection, we focus on literature dealing with life cycle assessment (LCA), LCSA and MCDA for sustainability assessment of alternative drive technologies, i.e. BEV, FCEV and ICEV fuelled with conventional as well as alternative fuels. Concerning life cycle-based assessments, several recent studies exist discussing different alternative drive technologies and fuels. While, for example, Kawamoto et al. 2019 and Cerdas et al. 2018 focus on CO2 and GHG emissions only, in Lombardi et al. 2017, 18 environmental impacts were assessed. Also, several economic assessments have been recently published, e.g. Morrison et al. 2018, Nassif and Almeida 2020 and Weldon et al. 2018; however, there are few life cycle-based analyses discussing both environmental and economic aspects. An early approach to this topic made by Faria et al. (2012). They performed a well-to-wheel analysis, i.e. an LCA without considering the production of the vehicles, and analysed a BEV in comparison with an ICEV. They concluded that, in the European context, a BEV will have in 2020 comparable costs to an ICEV, but only half the GHG emissions. None of these analyses included any socio-economic evaluations or give special attention to prospective assessment though. Another example is Onat et al. 2019, who used a hybrid multi-regional input–output-based LCSA and fourteen indicators encompassing the three pillars of sustainability (environment, society and economy) to analyse different support utility electric vehicle technologies, i.e. hybrid—HEV, plug-in hybrid—PHEV and full battery—BEV for Qatar. In the same year, Bekel and Pauliuk 2019 performed a prospective comparison of a FCEV and a BEV in Germany with environmental and cost assessments. Their analysis had a focus on several environmental indicators and the comprehensive modelling of the charging infrastructure of BEVs. The focus of Cox et al. 2020 for a prospective comparison of BEVs and FCEV in the European context was the integration of different energy scenarios and its influence on the total cost of ownership and several environmental indicators. More recently, Yan and Sun 2021 have investigated the impact of electric vehicle development on China’s GHG emissions and fossil energy demand from a life cycle perspective. Shinde et al. 2021 assessed the environmental impact of the production and utilization of bio-methane and biogas-based electricity as a vehicle fuel for public transport buses in Sweden, and Rüdisüli et al. (2022) examined GHG mitigation of electricity-based mobility (BEV, FCEV, ICEV fuelled with SNG) from a life cycle point of view in a Swiss scenario setting. All of the above-mentioned studies do not carry out an integrated assessment using, e.g. MCDA, i.e. no final statement on the advantageousness of one of the alternatives including all considered indicators is drawn. In the field of biofuel sustainability assessment, a number of works exist that link the LC(S)A approach with MCDA, e.g. Ren et al. 2015 (bioethanol production pathways in China), Ubando et al. 2016 (algal cultivation systems for sustainable biofuel production), Racz et al. 2018 (biodiesel production alternatives) and Mahbub et al. 2018 (oxymethylene ether as a diesel additive). Kügemann and Polatidis 2020 classify and analyse the literature applying MCDA methods on the evaluation of road transportation fuels and vehicles, pointing out that “some of the authors rely on LCSA for criteria selection as it provides a holistic approach to assess the sustainability of specific products”. For example, Macioł and Rębiasz 2018 examine the influence of different MCDA methods on the assessment results of private passenger vehicles (ICEV, HEV, PHEV and BEV) and Cai et al. 2017 combine multiple MCDA methods and LCA to assess Beijing’s taxi fleet, including BEV, HEV, PHEV and ICEVs based on environmental, economic and on-road policy criteria. Likewise, in Onat et al. (2016a), and Onat et al. (2016b), economic, environmental and social indicators are considered for the assessment of BEV, HEV, PHEV and conventional ICEVs in the USA using MCDA. From this literature review, the need for a comprehensive and prospective sustainability assessment of ICEV (conventional and alternative fuels), BEV and FCEV in order to support decision makers with respect to a sustainable mobility transition in Germany becomes clear.

Scope and structure

In this paper, the question is addressed whether, in addition to the required change in mobility behaviour, alternative drive technologies can contribute to improving not only the climate balance but also overall sustainability of the transport sector in Germany. Therefore, a comprehensive life cycle-based sustainability assessment using MCDA is applied for prospective and comparative sustainability assessment of three different vehicle types, i.e. ICEV, BEV and FCEV. The life cycle-based assessment covers the production of the fuels and the passenger cars (glider, drivetrain, energy storage) and the use of the passenger cars. End-of-life phase is not comprehensively included due to lack of information for certain recycling processes. For sustainability assessment, the indicator set developed within the Helmholtz Initiative Energy System 2050 (Haase et al. 2022) is used together with the MCDA method Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) (Hwang and Yoon 1981). Through sensitivity analysis, the influence of different weightings as well as of uncertain (prospective) input data on the overall results is discussed. Within the section Materials and Methods, the approach for sustainability assessment, related methods and indicators, is presented. Subsequently, considered alternative drive technologies and fuels are technically characterized. Furthermore, system boundaries and modelling details for vehicle production, fuel supply and vehicle use as a basis for prospective economic, environmental and social assessment are given. With the presented approach, individual vehicles are compared to each other for the base year 2020 and for the prospective year 2050. It should be noted that based on these results, no predictions about an optimal individual motorized transport mix in Germany in 2050 are possible as, for example, neither predictions of future availabilities of resources nor of future infrastructures are included in this study. The novelty of our paper arises from the combination of (i) a comprehensive and prospective well-to-wheel analysis of ICEV, BEV and FCEV, (ii) consideration of economic, environmental and social sustainability criteria, and (iii) integrative sustainability assessment using MCDA.

Materials and methods

In this section, the approach for sustainability assessment, technical characteristics and modelling of considered vehicles and fuels as well as input data for the assessment are presented.

Approach for sustainability assessment

In this paper, the approach for sustainability assessment developed within the “Energy System 2050” framework (ES2050) is used (cf. Figure 1) and extended with respect to the application of MCDA for the integrated consideration of sustainability indicators. It consists of the three elements “environmental”, “economic” and “social” assessment in accordance with the triple-bottom line model of sustainability (cf. Haase et al. 2022). Starting point of the assessment is the definition of system boundaries and the characterization of the process chains. Based thereon, the material and energy flows are modelled, and the life cycle inventory (LCI) is created. The prospective environmental and economic assessments, E-LCA—environmental LCA and LCC—life cycle costing, respectively, are based on a detailed modelling of mass and energy flows, and the corresponding LCI, including all relevant upstream as well as downstream process chains. Depending on the respective social indicator, the social assessment is not necessarily related to the LCI. It is based on surveys or interviews, additional databases and statistics as well as models. A full list of the ES2050 indicator set is given in Table 5 in Appendix 1. For the prospective assessment, a consistent assessment framework using harmonized system boundaries as well as assumptions concerning economic, environmental and social input data is applied. Also, a consistent background scenario concerning present and future energy production mix is used. Within the following subsections, methods and indicators for environmental, economic and social assessment are described. Additionally, the MCDA method for the integrative consideration of environmental, economic and social indicators is introduced briefly.

Energy System 2050 (ES2050) approach for sustainability assessment of energy technologies (adapted from Haase et al. 2022)

Environmental assessment

The environmental assessment is conducted following the methodology for LCA according to the international standards ISO 14040 and ISO 14044. For preparing the LCI, the upstream and downstream processes, e.g. raw materials supply, provision of operating materials, and infrastructure, waste and wastewater disposal, and product use are included via the open source software openLCA (GreenDelta 2018) together with datasets from the commercial ecoinvent database v3.3 (cut-off-system model) (Swiss Centre for Live Cycle Inventories 2016). Likewise, the reference processes (production and use of ICEV with fossil gasoline) are modelled using ecoinvent datasets. As far as possible, specific datasets for Germany (DE) are used. If no datasets are available for Germany, datasets for Switzerland (CH), Europe (RER) or worldwide datasets (GLO) are used. For life cycle impact assessment (LCIA), 13 environmental impact categories and corresponding indicators are applied at midpoint as recommended in the ILCD Handbook of the European Commission (EC-JRC 2011). The methods are provided by GreenDelta (LCIA methods v2, ILCD 2011, midpoint).

Economic assessment

For the economic assessment, the method for LCC is chosen. As economic indicator, total costs (TC) are estimated. In our assessment, TC comprise capital expenditures (CAPEX) and operating expenditures (OPEX). End-of-life costs are not included. In this example, capital costs refer to levelized costs of car acquisition without VAT, and operating costs refer to consumables (fuel supply costs) and other operating costs (maintenance and repairs, insurance). Fuel supply costs comprise production costs of fuel as well as costs for transport, storage, service stations and charging stations, respectively. Taxes are excluded from fuel cost calculations.

Social assessment

For prosper and sustainable communities, local investments, employment and economic growth are necessary. From the ES2050 indicator set, domestic value-added is chosen as an indicator for social assessment. The calculation of this indicator is based on methods, data and results from the above introduced economic assessment. If necessary, cost components are further specified. At a sufficient level of detail, cost components are divided by percentages into three categories: domestic value-added, potential domestic value-added and non-domestic value-added. For prospective assessments, estimated prospective costs together with estimated prospective percentages can be used for the estimation of the prospective domestic value-added. For further information regarding this approach, refer to Harzendorf et al. (2021).

Multi-criteria decision analysis

For an integrative assessment of all chosen indicators (see Table 5 in Appendix 1) normalization, aggregation and weighting of indicators is conducted. These calculations are performed in the MS Excel-based tool described in Haase et al. 2020, which is adjusted accordingly. In this paper, the MCDA method TOPSIS (cf. Hwang and Yoon 1981; Lai et al. 1994; García-Cascales and Lamata 2012), belonging to the compensating MCDA methods, is used. TOPSIS is one of the most widely used multi-attribute decision making (MADM) methods for cases when information on attributes is available on a cardinal scale. Its logic is rational and understandable, and the computation processes are straightforward. Also, TOPSIS requires a limited subjective input compared to other approaches. TOPSIS starts with the normalization and weighting of the input data. With the normalized and weighted input data, the different alternatives can be interpreted as points depending on the chosen criteria, i.e. indicators. TOPSIS chooses the best alternative based on the shortest and farthest Euclidean distances from the positive ideal solution and the negative ideal solution, respectively. To determine the so-called performance value of an alternative, the named distances are determined and related to each other (cf. Hwang and Yoon 1981; García-Cascales and Lamata 2012). The higher the performance value is, the more favourable is the discussed option. For aggregation of indicator results, two different procedures are examined and compared (weighting factors for both procedures are given in Table 5 in Appendix 1):

-

“two-step equal weighting”: In a first step (I), 13 environmental indicators are aggregated to one environmental indicator, i.e. the environmental performance value (EPV) is calculated. In a second step (II), three indicators, one for environment, economy and social, respectively, are aggregated and the overall performance value (PV) is calculated. Aggregation for both steps is done using TOPSIS and equal weighting of respective indicators (first step: equal weighting of environmental indicators with 1/13 (7.69%) and second step: equal weighting of sustainability dimensions with 1/3 (33.33%));

-

“hierarchical equal weighting”: All 15 indicators are aggregated in one step using TOPSIS for the calculation of the overall performance value PV with sustainability dimensions being weighted equally (33.33% each) and environmental indicators proportionally with 0.33/13 (2.6%). In this way, the individual environmental indicators are given greater significance for the calculation of PV. Not in terms of weighting, but through the inclusion of the individual results for calculating PVs. As there is a shift of the points of the positive ideal solution and the negative ideal solution, this leads to different distances of the alternatives to these points and consequently might change ranking of alternatives.

Consistent assessment framework

In this section, information on background scenario, system boundaries and technical characteristics are given for the considered alternatives.

Background scenario

For the prospective sustainability assessment, data from the Helmholtz Alliance ENERGY-TRANS, scenario “Target”, are used as a consistent background scenario regarding, for example, future energy production mix (including technology shares) as well as (energy) price projections (Pregger et al. 2020). By using this consistent scenario, we deliberately accept losses in terms of the timeliness of the data. In our case, this is particularly evident in the composition of the electricity mix to charge battery electric vehicles for the year 2050. In order to take this into account, for environmental assessment, modelling of the German electricity mix to charge the BEV in 2050 (foreground system) is additionally based on a more recent study including the in spring 2021 legislated climate-neutral energy supply in Germany by the year 2045 (Stolten et al. 2021) (see Appendix 2). Additionally, estimations of CO2 prices for fossil gasoline are considered for 2050 based on Kemmler et al. (2020) as a consequence of the German Fuel Emissions Trading Act (Brennstoffemissionshandelsgesetz—BEHG) which establishes an Emission Trading System in the sectors heating and transport, starting in 2021 (BMU 2019).

System boundary

For the assessment of different drive technologies and fuels, “vehicle production”, “fuel supply” and “vehicle use” are included (cf. Figure 2). The system boundary includes all related production processes, provision of raw and operating materials, machinery and infrastructure, i.e. all related resource consumptions and emissions along the value chain. For this assessment, “vehicle production” is subdivided into production of vehicle body (glider), drivetrain and energy storage. “Fuel supply” includes fuel production as well as transport of fuels to service stations and service/charging stations, respectively. “Vehicle use” includes consumption of fuels, materials, services and infrastructure. End-of-life phase, in particular recycling potentials, is currently not included as there are only limited data available for the analysed technologies (fuel cells and batteries) and the corresponding indicators. In Fig. 2, the considered vehicle types, drivetrains, corresponding energy storage and fuel types are displayed. In total, five different alternatives are considered: (1) ICEV with low sulphur gasoline (ICEV-fossil), (2) ICEV with synthetic biofuel from straw (ICEV-straw), (3) BEV with electricity from wind power (BEV-wind), (4) BEV with electricity from production mix Germany (BEV-mix_DE) and (5) FCEV with hydrogen from wind power (FCEV-wind). If not stated otherwise, vehicle use as well as fuel supply and vehicle production is assumed to be in Germany. The reference year for prospective assessment is 2050, and base year is 2020. In this study, a total of four renewable and one conventional fuel alternatives are considered. For a better comparability of BEV and FCEV, electricity and H2 from wind power only are assumed. It has to be noted that other renewable fuels, e.g. PV power only to fuel BEVs, will also be relevant in the future though. The same applies to other renewable fuels for ICEV.

Technical characterization

In Table 1, technical characteristics of 100 kW ICEV, BEV and FCEV are given as a basis for modelling. Car weight and fuel consumption of ICEV and BEV are adopted from existing car types (ADAC 2021a, ADAC 2021b). For FCEV, technical details are inspired by ADAC (2021c) and fuel consumption refers to Robinius (2015) and Grube et al. (2021). For all considered cars, a lifetime of 18 years (Statista 2021c) and an annual mileage of 15,000 km (ADAC 2021a) is assumed, resulting in a total lifetime of 270,000 km. To consider uncertainties related to car lifetime, this parameter is varied within sensitivity analyses. Battery capacities are assumed with 35.8 kWh for the BEV (ADAC 2021b) and with 1.4 kWh for the FCEV (Benitez et al. 2021). For battery chemistry, NCM 622 (lithium nickel cobalt manganese oxide) is considered for the BEV in 2020, LFP (lithium iron phosphate) is assumed for BEV in 2050 with energy densities of 150 and 180 Wh/kg, respectively, resulting in battery weights of 239 and 199 kg. For FCEV, LFP battery chemistry is assumed for 2020 and 2050 with energy densities of 52 and 180 Wh/kg resulting in 26 and 8 kg battery weight, respectively, which represents a rather conservative assumption. NCM battery density refers to Ding et al. (2019). LFP battery energy density on pack level for 2020 is derived from Peters and Weil 2018 and for 2050 from theoretical values on cell level reported in Xue et al. (2017) and assumed losses on pack level of 10% (Yang et al. 2021). Nowadays, NCM chemistries are used, wherein the shares of cobalt and manganese are minimized due to criticality, social aspects and cost doubts. LFP, despite its lower energy density, offers significant advantages in these regards.

Modelling of vehicle production, fuel supply and vehicle use

In this section, a brief overview on the modelling of vehicle production, fuel supply and vehicle use from the environmental, economic and domestic value-added perspective is given.

Input data and modelling for environmental assessment

Modelling of vehicle use is based on transport processes from the ecoinvent database. For reasons of comparability and harmonization with technical data of considered vehicles (see Table 1), adjustments of ecoinvent datasets are made regarding, for example, fuel consumption, vehicle weights, tyre wear, road wear emissions and vehicle maintenance (for all vehicles in analogy to the ICEV), provider for roads (Swiss provider only) and vehicle lifetime (270,000 km, explanation see above). For sensitivity analyses, vehicle lifetime is varied (220,000 km and 150,000 km). For all three types of vehicles, adjustments are made regarding the electricity mix for glider production (German electricity production mix). Modelling of the German electricity production mix as part of the background system is based on Pregger et al. (2020) for 2050 and on AGEB (2021) for 2020 (see Table 6 in Appendix). Electricity transmission and voltage transformation are modelled in analogy to the dataset market for electricity, low voltage. Specific aspects of modelling are given for each vehicle type in the following subsections. No modelling of end-of-life phase has been conducted. Processes for recycling and deconstruction are only considered if included in the respective ecoinvent datasets.

Internal combustion engine vehicle (ICEV)

For the ICEV, the dataset transport, passenger car, small size, petrol, EURO 5 is adjusted with respect to car weight, fuel consumption and direct emissions. Fossil gasoline production and supply refers to the dataset market for petrol, low sulphur (97% Europe without Switzerland, 3% Switzerland). Modelling of synthetic biofuel production from straw is based on Haase and Rösch (2019). Transport, storage and infrastructure for regional distribution of synthetic biofuel are modelled in analogy to fossil gasoline.

Battery electric vehicle (BEV)

For the BEV, the dataset transport, passenger car and electric is adjusted with respect to car weight, battery pack (weight and provider) and electricity (consumption and provision). For electricity production from wind power, the dataset electricity production, wind, 1-3 MW turbine, onshore is used. Electricity transmission and voltage transformation are modelled in analogy to the dataset market for electricity, low voltage. The German electricity production mix as part of the foreground system, i.e. to charge battery electric vehicles, is based on Pregger et al. (2020) for 2050 and on AGEB (2021) for 2020. For sensitivity analyses, the future electricity production mix based on Stolten et al. (2021) is used for environmental assessment in 2050 (see Table 6 in Appendix 2). With respect to the battery, battery weight is adjusted according to Table 1 and the provider for battery pack production is adjusted. Datasets for the modelling of the battery packs are based on Mohr et al. (2020) and are adjusted for battery cell production in 2050 with respect to the German electricity production mix 2050 as part of the background scenario (see above) and the German heat production dataset (heat and power co-generation, natural gas, conventional power plant, 100 MW electrical) while for 2020 Korean electricity mix (dataset market for electricity, medium voltage) and heat production dataset (heat and power co-generation, natural gas, conventional power plant, 100 MW electrical) are used. For passenger car production without battery (dataset passenger car production, electric, without battery), the ratio glider/drivetrain is adjusted based on the glider weight and power of the e-Golf (ADAC 2021b). Modelling of public BEV charging stations is based on Kabus et al. (2020). Charging losses are accounted for with 10% in 2020 and with 5% in 2050 for public and private charging, respectively.

Fuel cell electric vehicle (FCEV)

Modelling of the FCEV is based on Benitez et al. (2021) with glider and drivetrain, i.e. electric motor and additional equipment, from ecoinvent and the ratio by weight taken from 2020s Toyota Mirai (ADAC 2021c). The fuel cell is an updated version of the model published by Miotti et al. (2017) (optimistic 2030 scenario) and the tank for hydrogen is made from carbon fibre, which is the cornerstone of the publication from Benitez et al. (2021). The modelling of Li-Ion batteries is based on Mohr et al. (2020) and in analogy to the BEV, adjusted for battery cell production in 2050 with the German electricity production mix 2050 as part of the background scenario (see above) and the German heat production dataset (heat and power co-generation, natural gas, conventional power plant, 100 MW electrical) while for 2020 Korean electricity mix (market for electricity, medium voltage) and heat production dataset (heat and power co-generation, natural gas, conventional power plant, 100 MW electrical) are used. For the supply of hydrogen, hydrogen production from alkaline water electrolysis powered by electricity from onshore wind is chosen to have hydrogen supply with low GHG emissions. Transport and distribution of hydrogen are carried out with high pressure tube trailers (500 bar) as published in Wulf et al. (2018).

Input data and modelling for economic assessment

Car acquisition costs are assumed to be equal for all three vehicle types in 2050 and correspond to acquisition costs of the ICEV in 2020 (ADAC 2021a) excluding VAT and car tax. For the FCEV, this is in line with assumptions in FEV Consulting (2020), where acquisition costs for 2040 are estimated with 22,050 €. For the calculation of levelized costs, a lifetime of 18 years and an interest rate of 2.5% are assumed. Insurance costs for ICEV, BEV and FCEV in 2050 are adopted from insurance costs for ICEV in 2020 (ADAC 2021a). Costs for maintenance and repairs for ICEV are assumed to stay on the level of 2020 (ADAC 2021a). Following Grube et al. (2021), for BEV, costs for maintenance and repairs in 2050 are assumed to decline by 24% and for FCEV by 39% compared to 2020 (ADAC 2021b, ADAC 2021c). Fuel costs are divided into production costs of fuel and costs for transport, storage, service/charging stations, respectively. Starting point for fuel cost estimations for fossil gasoline is the gasoline price and its composition according to MWV (2020). Manufacturing costs of fossil gasoline are calculated as average value of product acquisition costs of the last ten years (46.3 €cent/l). Accordingly, costs for transport, storage and service stations are calculated as average value of contribution margin of the last ten years (14.4 €cent/l). Additionally, costs for fossil CO2 emissions are taken into account with 220 €/t CO2 for 2050 (Kemmler et al. 2020), i.e. 50 €cent/l fossil gasoline for fuel production costs. Manufacturing costs for synthetic gasoline from straw are taken from Haase and Rösch (2019). Costs for transport, storage and service stations for synthetic gasoline from straw are assumed to be equal to fossil gasoline. Costs for 2050 for electricity from wind power and from German electricity production mix are based on Pregger et al. (2020). For the year 2020, electricity production costs are based on BDEW 2021 (Mix DE) and Kost et al. 2018 (wind onshore). Cost estimations for BEV charging stations are based on Kabus et al. (2020) and adjusted concerning electricity costs (electricity from wind power and electricity production mix DE, respectively) for internal consumption. It is assumed that 30% of the charging processes for BEVs take place at public charging stations and that the rest of the charging is conducted at home. Charging losses are accounted for with 10% in 2020 and with 5% in 2050. Manufacturing costs of hydrogen as well as costs for hydrogen transport, storage and service stations are based on Wulf and Zapp (2021). If not stated differently, all costs are given in €2020, and inflation rates are based on Statista (2021d) (Table 2).

Input data and modelling for the estimation of domestic value-added

For the estimation of domestic value-added of the different alternatives, for each cost component the percentage of domestic value-added is estimated. Costs for vehicle use, i.e. costs for maintenance and repairs as well as costs for insurance, are assumed to be fully domestic. Costs for vehicle production, i.e. costs for car acquisition, are subdivided into costs for the glider (around 65% for all vehicle types), and costs for drivetrain and energy storage (BEV and FCEV) based on FEV Consulting (2018), Schmidt et al. (2017), James et al. (2018). For the ICEV, costs for energy storage, i.e. fuel tank, are included in costs for the glider. For the BEV, around 20% of the vehicle costs account for the drivetrain and around 15% for energy storage (Li-Ion battery) in 2050 (FEV Consulting 2018, Schmidt et al. 2017). For the FCEV, around 25% of the costs account for the drivetrain (including battery) and 10% for energy storage (hydrogen tank) in 2050 (James et al. 2018).

As a basis for domestic value-added estimation of vehicle production, a market share of 64% of German manufacturers with respect to the total number of all passenger cars registered in Germany is assumed (cf. Kraftfahrtbundesamt 2021). Additionally, for the production of glider and drivetrain, 58% domestic value-added is assumed for FCEV and ICEV (cf. FEV Consulting 2020) and 53% for BEV (cf. FEV Consulting 2018). For energy storage of the FCEV (hydrogen tank), 57% domestic value-added is assumed for 2050 (cf. FEV Consulting 2020). For energy storage of the BEV (LFP Li-Ion battery), 66% domestic value-added is calculated for 2050 (Ersoy et al. 2021). In Table 3, resulting percentages for domestic value-added for vehicle production as well as percentages for fuel supply and vehicle use are given. For production of fossil gasoline, 13% and for manufacturing of synthetic biofuel from straw 66% domestic value-added are assumed for 2050 based on own calculations. Determining factors for this difference are assumptions on raw materials supply for the respective production processes: crude oil is assumed to be imported (non-domestic value-added) while residual straw for synthetic biofuel production is assumed to be provided domestically (cf. Haase and Rösch 2019). For manufacturing costs of fossil gasoline, all costs other than crude oil are assigned to domestic value-added. Crude oil costs of 40.2 €cent/l are calculated based on Statista (2021e) as average value of the years 2011 to 2020. Further information on underlying cost estimations for domestic value-added estimation of synthetic biofuel production can be found in Haase and Rösch (2019), and shares of domestic value-added of main cost items along the value chain of synthetic biofuel production are given in Table 7 in Appendix 2. For transport, storage and service stations, 100% domestic value-added are assumed for fossil gasoline as well as for synthetic biofuel. For electricity generation, 73% domestic value-added is calculated for electricity from wind power and 33% is assumed for the German electricity production mix. For electricity transmission as well as for BEV charging stations, 100% domestic value-added is assumed. For hydrogen production, 56% domestic value-added, for hydrogen transport, 43% domestic value-added and for hydrogen refuelling stations, 36% domestic value-added are calculated for 2050. Further information on underlying cost estimations as a basis for domestic value-added estimation of hydrogen production and supply can be found in Wulf and Zapp (2021) and shares of domestic value-added of main cost items of hydrogen production are given in Table 7 in Appendix 2. For vehicle maintenance and repairs, 100% domestic value-added is assumed.

Results

In this section, indicator results, i.e. results for 13 environmental indicators according to ILCD (EC-JRC 2011), economic (total costs) and social (domestic value-added) indicators, with respect to 1 km driving distance are given. Based thereon, the so-called performance values for each alternative are calculated using the MCDA method TOPSIS including all chosen indicators. If not stated differently, electricity production mix to fuel BEVs is based on Pregger et al. (2020).

Indicator results

In Table 4, indicator results are summarized for the five different alternatives for the year 2050. Corresponding results for the base year 2020 are given in Table 8 in Appendix 3. For environmental indicators, lower values refer to lower environmental impacts, i.e. better performance from an environmental point of view of the respective alternative. The same applies to total costs per km: lower values are preferable from an economic point of view. For domestic value-added, higher percentages refer to higher domestic value-added, which is preferable from a social point of view. In Table 4, a traffic light-oriented green–yellow–red colour scheme has been used (with dark green indicating best values to dark red indicating worst values) for better readability of the table and to highlight major differences amongst the assessed alternatives.

Indicator names and respective shortcuts for environmental indicators refer to the respective environmental impact categories (cf. Table 5 in Appendix 1 and Table 4). For BEV-mix_DE, results for environmental indicators assuming energy production mix to fuel battery electric vehicles in 2050 based on Stolten et al. (2021) are given in Table 9 in Appendix 3. Also, results for environmental indicators assuming a mileage of 150,000 km instead of 270,000 km are given in Table 9 in Appendix 3 (year 2050). If not stated differently, all results refer to the estimations for the year 2050.

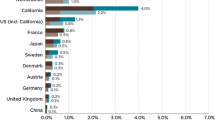

Under given assumptions, in 2050 ICEV-straw and BEV-wind exhibit the highest percentages of domestic value-added. Costs are highest for ICEV-straw and lowest for FCEV-wind compared to the other alternatives. BEV-wind exhibits lowest impacts for the environmental indicator CC—climate change amongst the considered alternatives. For seven out of 13 environmental indicators, BEV-wind exhibits the lowest impacts. For three environmental indicators, ICEV-fossil exhibits the lowest impacts (Eutr-fw—freshwater eutrophication and HT-c/HT-nc—human toxicity carcinogenics/non-carcinogenics). For two environmental indicators FCEV-wind (Ecotox-fw—freshwater ecotoxicity, RD—Resource depletion—mineral, fossils and renewables) and for one environmental indicator ICEV-straw (OD—Ozone Depletion) exhibits the lowest impacts. In Fig. 3, indicator results are displayed as values against reference (ICEV-fossil) for the year 2050. For an overall assessment, MCDA is used and respective results are shown in the following subsection.

When comparing indicator results for FCEV-wind and BEV-wind from this study (year 2050), it can be seen that in 2050 total costs of the FCEV are slightly lower compared to the BEV in 2050. This is the result of assuming vehicle acquisition costs as well as insurance costs for the FCEV being equal to the BEV in 2050 together with lower fuel costs per km in 2050 for the FCEV. In contrary, in Bekel and Pauliuk 2019 total costs of ownership for FCEV are assumed to be almost twice as high than costs for BEV in 2030 which they state to be mainly due to the higher purchasing price and “the consequential higher costs for insurance and tax”. In line with both, Grube et al. 2021 assume further cost degression of FCEVs between 2030 and 2050. Given the high uncertainty of assumptions for the year 2050, sensitivity analysis can help to describe, for example, the impact of higher costs of the FCEV on the overall sustainability performance (see Fig. 7C). Comparing the results for environmental assessment, tendencies of Rüdisüli et al. 2022 (GHG emissions only) and Bekel and Pauliuk 2019 (base case) correspond to the results in this paper, i.e. lower impacts of the BEV-wind compared to the FCEV-wind for the categories Climate Change and Particulate Matter, higher impacts of the BEV-wind compared to the FCEV-wind for the category Human Toxicity—non-cancer. With these results, the findings of Cox et al. 2020 can be further supported that electrification of passenger vehicle powertrains is an effective way of reducing GHG emissions compared to conventional ICEVs, without disadvantages in terms of cost.

Results for multi-criteria decision analysis

In this section, performance values, calculated using the MCDA method TOPSIS, are displayed. If not stated differently, results refer to the year 2050 and “two-step equal weighting” of indicators is applied (see section “Multi-criteria decision analysis”). For the calculated performance values, the higher the value, the better from a sustainability point of view. As a result of the first aggregation step, i.e. aggregation of environmental indicators equally weighted with 1/13, i.e. 7.69% each, BEV-wind performs best from an environmental point of view with an environmental performance value (EPV) of 65%, followed by FCEV-wind (EPV 63%), ICEV-straw (EPV 59%), BEV-mix_DE (EPV 58%) and ICEV-fossil (EPV 28%). As a result of the second aggregation step, i.e. aggregation of results for sustainability dimensions equally weighted with 1/3, i.e. 33.33% each, BEV-wind exhibits the highest performance value (PV 95%), i.e. is the preferable option from a sustainability point of view, followed by the alternative FCEV-wind (PV 87%), and the alternatives BEV-mix_DE (PV 74%) and ICEV-straw (PV 69%) (see Fig. 4A). For the year 2050, overall ranking is not affected when “hierarchical equal weighting” of all indicators is applied instead of “two-step equal weighting” (see Fig. 4C). For 2020, BEV-wind is on rank 1 (86.9%), followed very closely by ICEV-straw on rank 2 (PV 86.8%). FCEV-wind performs on the last rank and represents the negative ideal solution in 2020 (see Fig. 4B). For 2020, ICEV-fossil (rank 2) changes rank with ICEV-straw (rank 3), i.e. overall ranking is affected when “hierarchical equal weighting” of all indicators is applied instead of “two-step equal weighting” (see Fig. 4D). PV results are close though. Rankings of BEV-mix_DE and FCEV-wind remain unchanged. When comparing the results for 2020 and 2050, the biggest difference is for the FCEV-wind (last rank in 2020, second rank in 2050). This reflects the largest changes in the associated input data of the two years, i.e. underlying most positive developments with respect to technical developments, associated costs, environmental impacts and domestic value-added for this technology.

Performance values and resulting rankings are summarized in Table 10 in Appendix 4. To learn more about the influence of input data and weighting of sustainability dimensions (environment, economy, social), sensitivity analyses are carried out.

Sensitivity analysis

In this section, different input data are varied in order to analyse their influence on the overall result. If not stated differently, all sensitivity analyses refer to the year 2050, “two-step equal weighting” of indicators, a vehicle mileage of 270,000 km and the electricity production mix to charge BEVs in 2050 based on Pregger et al. (2020).

Variation of technical input data

Changing the electricity production mix to fuel BEV-mix_DE in 2050 (environmental assessment only) to a more recent German scenario (Stolten et al. 2021) based on the goal to become climate-neutral by 2045 (see Table 6 in Appendix 2) increases the environmental performance of the BEV-mix_DE to an EPV of 61% and the overall performance to PV 80% (“two-step equal weighting”). Overall ranking as well as PVs of the other alternatives are not affected by the variation of the electricity production mix (see Fig. 5A).

If vehicle mileage is decreased to 220,000 km (15 years lifetime), ICEV-straw (rank 4) performs almost equally with BEV-mix_DE (rank 3) with a PV of around 73% for both. A decrease of mileage to 150,000 km (ten years lifetime) results in ICEV-straw performing best from an environmental point of view as well as from a sustainability point of view with an EPV of 67% and a PV of 72%, followed closely by BEV-wind with a PV of 70% (see Fig. 5B). Performance values and resulting rankings are summarized in Table 10 in Appendix 4. BEV-wind ranking first is hardly affected by the variations summarized in Table 10 in Appendix 4. Similarly, Macioł and Rębiasz 2018 found that, regardless of the MCDA method applied (amongst others TOPSIS and AHP), BEVs obtained the highest ranking when comparing them to HEVs, PHEVs and ICEVs with conventional fuel.

Weighting of sustainability dimensions

In this section, weighting of sustainability dimensions environment, economy, social is varied from 0 to 100% each while the ratio of the other two dimensions to each other stays equal (1:1). Figure 6 shows that the alternative BEV-wind performing best is a robust result with respect to the weighting of sustainability dimensions environment and social.

In case that the dimension economy is weighted with more than 60%, FCEV-wind performs better than BEV-wind. Performance values of ICEV-straw are most sensitive with respect to weighting of the dimension environment and economy, while performance values of BEV-wind and FCEV-wind remain rather stable for different weights of environment and economy. The same applies for BEV-wind and different weights of economy. Performance values and resulting ranking of BEV-mix_DE and FCEV-wind are most sensitive to the weighting of the dimension social. Only if the dimension social or the dimension economy is weighted with more than 80%, ICEV-fossil is not in last place.

Variation of economic input data

In this section, total costs per km are varied with ± 100% and resulting performance values are given for selected alternatives (ICEV-straw, FCEV-wind, ICEV-fossil). Additionally, reasonable ranges of respective input values, based on most sensitive and at the same time most uncertain parameters, e.g. vehicle lifetime, synthetic biofuel production costs, hydrogen production costs, acquisition costs of FCEV-wind, are given (see Appendix 5).

In Fig. 7A, sensitivity analysis for total costs of ICEV-straw are displayed. Only if total costs of ICEV-straw decrease by 30%, this alternative becomes the most preferable one from a sustainability point of view. With a decrease of at least 10%, it ranks, however, slightly better than BEV-mix_DE. If synthetic biofuel production costs as one of the most uncertain parameters for prospective cost assessment of this alternative would decrease by 50%, total costs would decrease by 14%. Vice versa, an increase of synthetic biofuel production costs of 50% would lead to 14% increase in total costs. A decrease of 30% of vehicle lifetime leads to an increase in total costs of 11%. Only if total costs of ICEV-straw increase by 60%, this option falls to the last rank and is thus the worst option from a sustainability point of view amongst considered alternatives (see Fig. 7A). From these findings, it can be stated that ICEV-straw can keep up with the other alternatives in 2050, but it is difficult for this alternative to achieve first rank.

Figure 7B shows sensitivity analysis for total costs of FCEV-wind. If total costs of FCEV-wind decrease by at least 10%, this alternative becomes the most preferable one from a sustainability point of view. If hydrogen production costs decrease by 50%, total costs decrease by 8%. However, if car acquisition costs rise by 30%, total costs increase by 12%, if vehicle lifetime decreases by 30%, total costs increase by 14%, and if hydrogen production costs rise by 50%, total costs increase by 8%. As all of the mentioned three parameters haven been chosen in a rather optimistic way, i.e. rather low vehicle acquisition costs, low costs of hydrogen production, long vehicle lifetime, a decrease of total costs of 10% is rather unlikely. If total costs increase by more than 30%, FCEV-wind performs worse than BEV-mix_DE and ICEV-straw. This could for example be the case if vehicle acquisition costs and hydrogen production costs turn out to be higher and vehicle lifetime at the same time shorter than assumed.

Figure 7C shows sensitivity analysis for total costs of ICEV-fossil. Only if total costs decrease by at least 50%, this alternative is no longer in last place. With a CO2 price of 55 €/t (0.8 €cent/km), which is the legal limit for 2026, total costs of ICEV-fossil decrease by around 8%. If crude oil price in 2050 is assumed to be 50% lower (20 €Cent/l), total costs decrease by around 5%. A decrease of total costs of 50% is therefore unlikely. If vehicle lifetime decreases by 30%, total costs increase by 12%. By this, in can be stated that ICEV-fossil ranking last is a robust result.

Variation of input data for domestic value-added

In Fig. 8, sensitivity analysis for overall domestic value-added is displayed for BEV-wind and FCEV-wind. If domestic value-added of BEV-wind decreases by 20%, FCEV-wind performs better than BEV-wind (see Fig. 8A). If battery production would be fully non-domestic, overall domestic value-added of BEV-wind would decrease by around 6%, and if drivetrain of BEV-wind would be fully non-domestic, overall domestic value-added of BEV-wind would decrease by around 4%. A decrease of overall domestic value-added of BEV-wind of 20% is therefore unlikely. If battery production of BEV-wind would be fully domestic, overall domestic value-added would increase by around 3% and if drivetrain of BEV-wind would be fully domestic, overall domestic, value-added would increase by around 9%.

If overall domestic value-added for FCEV-wind increases by at least 20%, FCEV-wind performs better than BEV-wind (see Fig. 8B). If drivetrain of FCEV-wind would be fully domestic, overall domestic, value-added of FCEV-wind would increase by 11%. If energy storage (hydrogen tank) of FCEV-wind would be fully domestic, overall domestic value-added would increase by 5%. From these results it seems possible that the FCEV-wind performs at least equal to BEV-wind. If drivetrain of FCEV-wind would be fully non-domestic, overall domestic value-added of FCEV-wind would decrease by 6%, and if energy storage would be fully non-domestic, overall domestic value-added of FCEV-wind would decrease by 3%.

Conclusions

In this paper, a prospective sustainability assessment of different drive technologies and fuels for individual motorized transport, i.e. BEV, FCEV and ICEV fuelled with conventional fuel and with synthetic biofuel, is carried out in the context of Germany, including economic, environmental and social indicators. With the help of MCDA, an integrated consideration of all indicators and an analysis of the influence of weightings and input data is conducted, thus providing transparent and structured guidance for decision makers. The assessment is based on a detailed modelling of mass and energy flows including the whole life cycle together with consistent assumptions on prospective framework conditions, i.e. future energy production mix (including technology shares) as well as (energy) price projections. The presented approach is suitable for a comparison of single drive technologies and fuels and in particular for demonstrating the use of MCDA for comprehensive sustainability assessment. Robustness and validity ranges of the results are shown, using sensitivity analysis. By this, valuable insights are given to technology developers as well as decision makers as prospective assessment is afflicted with a high degree of uncertainty of underlying assumptions. It must be noted that with the results of this study no predictions about the optimal vehicle fleet for individual motorized transport in 2050 are neither sought nor possible as no assumptions on, for example, availability of resources, infrastructures or usage behaviours in 2050 are included. Also, considerations on the optimal use of primary (e.g. wind energy, lignocellulosic biomass residues) and secondary (electricity, hydrogen, synthetic biofuel) energy carriers are outside the scope of this study and would require a systemic view on the entire (energy) system.

The indicator-based results show different advantages of the different transport alternatives depending on the respective indicators. Via aggregation of indicator results using the MCDA method TOPSIS, chosen alternatives can be compared including all discussed indicators at the same time. The calculated performance values show that alternative technologies and fuels perform better in 2050 compared to ICEV-fossil. Amongst the considered alternatives, BEV-wind performs best under chosen assumptions and is also rather reluctant to give up this first rank. The results show that—under chosen assumptions—FCEV-wind keeps up well with BEV-wind in 2050. However, many parameters of the FCEV need to improve to move from last place in 2020 to a competitive alternative in 2050. This becomes clear if the results for 2050 are contrasted to those calculated for 2020. Moreover, the extent to which a green hydrogen infrastructure and driving with hydrogen in individual motorized transport will play a role in Germany in the future is strongly dependent on whether the corresponding green hydrogen infrastructure and distribution networks will be built.

The modelled alternatives provide a solid database for further analysis concerning, for example, variation of input data for prospective assessment, inclusion of other renewable fuels, such as PV power to fuel BEVs, or assessment of different vehicle user behaviours, such as predominantly inner-city usage vs. long-distance travels.

With respect to MCDA, the development of weighting sets for sustainability criteria involving experts and/or citizens is desirable. With respect to the inclusion of the indicators patent growth and acceptance as additional indicators for sustainability assessment, further research is required in terms of, for example, data gathering for the chosen alternatives as well as calculation routines for MCDA.

In conclusion, it can be said that it is important to remain open to different alternatives to achieve a carbon free energy transition of the transport sector. FCEVs are facing challenges concerning fuel station infrastructure while BEVs, for example, are facing challenges related to charging times, ranges, and recycling of Li-ion batteries. The latter comes also true for FCEV tanks and fuel cells. However, both FCEVs and ICEVs fuelled with synthetic biofuel avoid e.g. problems with charging times. Within further prospective sustainability analysis, it is crucial to have a closer look at underlying assumptions and related uncertainties as well as system boundaries of respective alternatives. In particular, end-of-life aspects should be included comprehensively. Also, the context-specific choice of indicators should undergo a more detailed analysis as this has a major effect on the overall assessment result. The inclusion of stakeholders, not only for the weighting of criteria, but also for the choice of indicators is an important aspect that should be covered in future studies.

Critical reflection and broader context

MCDA offers the possibility to gather a good overview of potential sustainability implications by combining fundamentally different criteria and to incorporate different weights to these. However, any MCDA provides only decision support and does not offer an optimum solution for a problem. The study on hand aims at comparing different alternatives for individual motorized transportation in 2050 from a sustainability perspective and to provide orientation to decision makers. Having this aim in mind, makes it also important to provide a critical reflection to meet the requirements of sustainability related to a path for these technologies until 2050. In the following a critical reflection towards (i) a systemic view on use of energy carriers, (ii) end-of-life considerations and (iii) potential (technology) developments will be provided to set the results into a broader context.

-

(i)

The development of a diversified and complementary portfolio of zero carbon technologies is fundamental to achieve a clean energy transition towards a carbon free energy and transport system. Also, the path towards such a future decarbonized system must be realized in the most efficient way and as fast as possible. To do so, it is crucial to use each energy carrier (e.g. hydrogen, electricity, synthetic biofuel) in a way where it can unfold its biggest potential to reduce global warming out of a systemic view. For green hydrogen this might be its use for ammonia or steel production. Both synthetic biofuels and green hydrogen are also ideally suitable as fuels for ships, planes and long-distance transportation and not necessarily as a solution for mass individual transport. Additionally, limited availabilities of biomass (residues) and green hydrogen need to be considered.

-

(ii)

Market rollout of new technologies as BEVs and FCEVs will impact the mining and metals industry. Primary production and recycling of manufacturing scraps as well as end-of-life products are important sources of material that can have a significant impact in lowering overall environmental impacts (Peters et al. 2021; Meskers et al. 2019). Establishing efficient recycling routes is crucial for both, BEVs and FCEVs, and should be considered adequately in future assessments. For fuel cell and hydrogen technologies, first ideas have been published by Valente et al. (2019) as well as for Li-ion batteries by Costa et al. (2021). However, a consisting modelling of the end-of-life phase of all considered drive technologies is not possible yet.

-

(iii)

Technology development for FCEVs and BEVs is a fast-changing landscape, making it difficult to provide a robust view into future developments. Some developments in the field of batteries are, for example, the use of new Li-based chemistries, solid electrolytes or new anode types that could lead to significant cost and emission reductions (Xu and Reid 2021). In contrast, only limited progress is expected in the field of ICEV-based technologies. With respect to synthetic biofuel production, process enhancements, in particular with respect to carbon efficiencies can be achieved by using hydrogen feed-in (Hennig and Haase 2021). For FCEVs, the energy source for hydrogen production as well as the place of hydrogen production, if necessary hydrogen imports, will have a major influence on the sustainability performance and should be further assessed.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

ADAC (2021a) VW Golf 1.5 TSI OPF ACT IQ.Drive (01/19 - 08/19). ADAC, https://www.adac.de/rund-ums-fahrzeug/autokatalog/marken-modelle/vw/golf/vii-facelift/296758/#technische-daten

ADAC (2021b) VW e-Golf (04/17 - 05/20). ADAC, https://www.adac.de/rund-ums-fahrzeug/autokatalog/marken-modelle/vw/golf/vii-facelift/266575/#technische-daten

ADAC (2021c) Toyota Mirai (12/15 - 12/20). ADAC, https://www.adac.de/rund-ums-fahrzeug/autokatalog/marken-modelle/toyota/mirai/ad1/251604/#technische-daten

AGEB (2021) Stromerzeugung nach Energieträgern 1990 - 2020 (Stand Februar 2021). Arbeitsgemeinschaft Energiebilanzen, https://www.ag-energiebilanzen.de/

BDEW (2021) BDEW-Strompreisanalyse Januar 2021. Bundesverband der Energie- und Wasserwirtschaft, https://www.bdew.de/media/documents/BDEW-Strompreisanalyse_no_halbjaehrlich_Ba_online_28012021.pdf

Bekel K, Pauliuk S (2019) Prospective cost and environmental impact assessment of battery and fuel cell electric vehicles in Germany. Int J Life Cycle Assess 24(12):2220–2237

Benitez A, Wulf C, de Palmenaer A, Lengersdorf M, Röding T, Grube T, Robinius M, Stolten D, Kuckshinrichs W (2021) Ecological assessment of fuel cell electric vehicles with special focus on type IV carbon fiber hydrogen tank. J Cleaner Prod. https://doi.org/10.1016/j.jclepro.2020.123277

BMU (2019) Fuel emissions trading act (Brennstoffemissionshandelsgesetz – BEHG) Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection, Germany

BMU (2020) Klimaschutz in Zahlen. Bundesministerium für Umwelt, Naturschutz und Reaktorsicherheit, Berlin

Cai Y, Applegate S, Yue W, Cai J, Wang X, Liu G, Li C (2017) A hybrid life cycle and multi-criteria decision analysis approach for identifying sustainable development strategies of Beijing’s taxi fleet. Energy Policy. https://doi.org/10.1016/j.enpol.2016.09.047

Cerdas F, Egede P, Herrmann C (2018) LCA of Electromobility. In: Hauschild M, Rosenbaum R, Olsen S (eds) Life Cycle Assessment, Springer, Cham.

FEV Consulting (2018) Implications of powertrain electrification on machinery and component supplier industry. FEV Consulting GmbH, Aachen, Germany

FEV Consulting (2020) Impact of fuel cell technology on the machinery and component supplier industry. FEV Consulting GmBH, Aachen, Germany

Costa D, Quinteiro P, Dias A (2019) A systematic review of life cycle sustainability assessment: current state, methodological challenges, and implementation issues. Sci Total Environ 686:774–787

Costa C, Barbosa J, Gonçalves R, Castro H, Del Campo F, Lanceros-Méndez S (2021) Recycling and environmental issues of lithium-ion batteries: advances, challenges and opportunities. Energy Storage Mater 37:433–465

Cox B, Bauer C, Beltran AM, van Vuuren DP, Mutel CL (2020) Life cycle environmental and cost comparison of current and future passenger cars under different energy scenarios. Appl Energy 269:115021

Ding Y, Cano ZP, Yu A, Lu J, Chen Z (2019) Automotive Li-ion batteries: current status and future perspectives. Electrochem Energy Rev 2(1):1–28

EC-JRC (2011) European Commission-Joint Research Centre-Institute for Environment and Sustainability. International reference life cycle data system (ILCD) handbook - recommendations for Life cycle impact assessment in the European context based on existing environmental impact assessment models and factors. Publications Office of the European Union, Luxemburg

EERA (2021) White paper on the clean energy transition. European Energy Research Alliance, Brussels

Ersoy H, Baumann M, Weil M (2021) Evaluation study of regional added value creation by lithium-ion battery energy storage (BES) towards 2050. In: Energy transition and sustainability conference (APEEN 2021)

European Parliament (2018) Directive (EU) 2018/2001 of the European parliament and of the council of 11 December 2018 on the promotion of the use of energy from renewable sources

Faria R, Moura P, Delgado J, De Almeida AT (2012) A sustainability assessment of electric vehicles as a personal mobility system. Energy Convers Manag 61:19–30

García-Cascales MS, Lamata MT (2012) On rank reversal and TOPSIS method. Math Comput Model 56(5–6):123–132

GreenDelta (2018) openLCA. GreenDelta GmbH, Berlin

Grube T, Kraus S, Reul J, Stolten D (2021) Passenger car cost development through 2050. Transp Res Part D Transp Environ 101:103110

Guinée J (2016) Life cycle sustainability assessment: what is it and what are its challenges? In: Clift R, Druckman A (eds) Taking Stock of Industrial Ecology. Springer International Publishing, Cham

Haase M, Babenhauserheide N, Rösch C (2020) Multi criteria decision analysis for sustainability assessment of 2nd generation biofuels. Procedia CIRP. https://doi.org/10.1016/j.procir.2020.02.124

Haase M, Wulf C, Baumann M, Rösch C, Weil M, Zapp P, Naegler T (2022) Prospective assessment of energy technologies: a comprehensive approach for sustainability assessment. Energy Sustain Soc 12(1):1–41

Haase M, Rösch C (2019) Sustainability assessment of innovative energy technologies - Integrated biomass-based production of fuel, electricity and heat. In: ETA-Florence renewable energies: proceedings of the 27th European biomass conference and exhibition, Lisbon, Portugal, 27.-30.05.2019. ETA-Florence renewable energies 2019, publ. online, pp 1642–1653, Florence, Italy

Harzendorf F, Wulf C, Haase M, Baumann M, Ersoy H, Zapp P (2021) Domestic value added as an indicator for sustainability assessment – a case study on alternative drivetrains in the passenger car sector. Proceedings of the 16th Conference on Sustainable Development of Energy, Water and Environment Sys-tems, Dubrovnik, Kroatien, 10.-15.10.2021. ISSN–1847–7178 (digital proceedings)

Hennig M, Haase M (2021) Techno-economic analysis of hydrogen enhanced methanol to gasoline process from biomass-derived synthesis gas. Fuel Process Technol 216:106776

Hwang C-L, Yoon K (1981) Methods for multiple attribute decision making. In: Multiple attribute decision making. Lecture notes in economics and mathematical systems, Springer, Berlin, Heidelberg

IEA (2020) Data and statistics. International energy agency, https://www.iea.org/data-and-statistics?country=WORLD&fuel=Energy%20supply&indicator=Total%20primary%20energy%20supply%20(TPES)%20by%20source (last accessed July 23, 2020)

James BD, Huya-Kouadio JM, Houchins C, DeSantis DA (2018) Mass production cost estimation of direct H2 PEM fuel cell systems for transportation applications: 2018 update. Strategic Analysis Inc., Arlington

Kabus M, Nolting L, Mortimer BJ, Koj JC, Kuckshinrichs W, De Doncker RW, Praktiknjo A (2020) Environmental impacts of charging concepts for battery electric vehicles: a comparison of on-board and off-board charging systems based on a life cycle assessment. Energies 13(24):6508

Kawamoto R, Mochizuki H, Moriguchi Y, Nakano T, Motohashi M, Sakai Y, Inaba A (2019) Estimation of CO2 Emissions of internal combustion engine vehicle and battery electric vehicle using LCA. Sustainability 11(9):2690

Kemmler A, Kirchner A, der Maur A, Ess F, Kreidelmeyer S, Piégsa A, Spillmann T, Wünsch M, Ziegenhagen I (2020) Energiewirtschaftliche Projektionen und Folgeabschätzungen 2030/2050, Dokumentation von Referenzszenario und Szenario mit Klimaschutzprogramm 2030. PROGNOS AG, FRAUNHOFER ISI, GWS, IINAS, online

Kost C, Shammugam S, Jülch V, Nguyen H-T, Schlegl T (2018) Stromgestehungskosten Erneuerbare Energien. Fraunhofer Institut für solare Energiesysteme (ISE), Freiburg, Germany

Kraftfahrtbundesamt (2021) Personenkraftwagen am 1. Januar 2020 nach ausgewählten Merkmalen. https://www.kba.de/DE/Statistik/Fahrzeuge/Bestand/Jahresbilanz/fz_b_jahresbilanz_archiv/2020/2020_b_barometer.html?nn=2601598

Kügemann M, Polatidis H (2020) Multi-criteria decision analysis of road transportation fuels and vehicles: a systematic review and classification of the literature. Energies 13(1):157

Lai Y-J, Liu T-Y, Hwang C-L (1994) Topsis for MODM. Eur J Oper Res 76(3):486–500

Lombardi L, Tribioli L, Cozzolino R, Bella G (2017) Comparative environmental assessment of conventional, electric, hybrid, and fuel cell powertrains based on LCA. Int J Life Cycle Assess 22(12):1989–2006

Macioł A, Rębiasz B (2018) Multi-criteria decision analysis (MCDA) methods in life-cycle assessment (LCA): a comparison of private passenger vehicles. Operat Res Decis 28(1):5–26

Mahbub N, Oyedun AO, Zhang H, Kumar A, Poganietz W-R (2018) A life cycle sustainability assessment (LCSA) of oxymethylene ether as a diesel additive produced from forest biomass. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-018-1529-6

Meskers C, Caffarey M, Van Camp M (2019) Circular cities, E-mobility and the metals industry—a world in transition. REWAS 2019. The Minerals, Metals & Materials Series, Springer, Cham

Miotti M, Hofer J, Bauer C (2017) Integrated environmental and economic assessment of current and future fuel cell vehicles. Int J Life Cycle Assess 22(1):94–110

Mohr M, Peters JF, Baumann M, Weil M (2020) Toward a cell-chemistry specific life cycle assessment of lithium-ion battery recycling processes. J Ind Ecol 24(6):1310–1322

Morrison G, Stevens J, Joseck F (2018) Relative economic competitiveness of light-duty battery electric and fuel cell electric vehicles. Transp Res Part C Emerg Technol 87:183–196

MWV (2020) Zusammensetzung des Verbraucherpreises für Superbenzin. Mineralöl Wirtschaftsverband e.v., Available from: https://www.mwv.de/statistiken/preiszusammensetzung/ (last accessed February 12, 2020)

Nassif GG, de Almeida SCA (2020) Impact of powertrain hybridization on the performance and costs of a fuel cell electric vehicle. Int J Hydrogen Energy 45(41):21722–21737

Onat NC, Kucukvar M, Tatari O, Zheng QP (2016) Combined application of multi-criteria optimization and life-cycle sustainability assessment for optimal distribution of alternative passenger cars in US. J Cleaner Prod 112:291–307

Onat NC, Gumus S, Kucukvar M, Tatari O (2016) Application of the TOPSIS and intuitionistic fuzzy set approaches for ranking the life cycle sustainability performance of alternative vehicle technologies. Sustain Prod Consumpt 6:12–25

Onat NC, Kucukvar M, Aboushaqrah NN, Jabbar R (2019) How sustainable is electric mobility? A comprehensive sustainability assessment approach for the case of Qatar. Appl Energy 250:461–477

Peters JF, Weil M (2018) Providing a common base for life cycle assessments of Li-Ion batteries. J Cleaner Prod 171:704–713

Peters JF, Baumann M, Binder JR, Weil M (2021) On the environmental competitiveness of sodium-ion batteries under a full life cycle perspective–a cell-chemistry specific modelling approach. Sustain Energy Fuels 5(24):6414–6429

Pregger T, Naegler T, Weimer-Jehle W, Prehofer S, Hauser W (2020) Moving towards socio-technical scenarios of the German energy transition—lessons learned from integrated energy scenario building. Clim Change 162(4):1743–1762

Racz L, Fozer D, Nagy T, Toth AJ, Haaz E, Tarjani JA, Andre A, Selim A, Valentinyi N, Mika LT (2018) Extensive comparison of biodiesel production alternatives with life cycle, PESTLE and multi-criteria decision analyses. Clean Technol Environ Policy 20(9):2013–2024

Ren J, Manzardo A, Mazzi A, Zuliani F, Scipioni A (2015) Prioritization of bioethanol production pathways in China based on life cycle sustainability assessment and multicriteria decision-making. Int J Life Cycle Assess 20(6):842–853

Robinius M (2015) Strom- und Gasmarktdesign zur Versorgung des deutschen Straßenverkehrs mit Wasserstoff. RWTH Aachen, Jülich

Rüdisüli M, Bach C, Bauer C, Beloin-Saint-Pierre D, Elber U, Georges G, Limpach R, Pareschi G, Kannan R, Teske SL (2022) Prospective life-cycle assessment of greenhouse gas emissions of electricity-based mobility options. Appl Energy 306:118065

Schmidt O, Hawkes A, Gambhir A, Staffell I (2017) The future cost of electrical energy storage based on experience rates. Nat Energy 2(8):1–8

Shinde AM, Dikshit AK, Odlare M, Thorin E, Schwede S (2021) Life cycle assessment of bio-methane and biogas-based electricity production from organic waste for utilization as a vehicle fuel. Clean Technol Environ Policy 23(6):1715–1725

Statista (2021a) Bevölkerung in Deutschland nach der Nutzungshäufigkeit eines Autos (auch als Mitfahrer) in den Jahren von 2017 bis 2020. https://de.statista.com/statistik/daten/studie/182654/umfrage/nutzungshaeufigkeit-eines-autos/

Statista (2021b) Anteil ausgewählter Kraftstoffarten an den Neuzulassungen von Personenkraftwagen in Deutschland von 2010 bis 2020. https://de.statista.com/statistik/daten/studie/699301/umfrage/anteil-von-kraftstoffarten-an-neuzulassungen-von-pkw-in-deutschland/

Statista (2021c) Typische Lebensdauer von Autos in Deutschland nach Automarken statista, https://de.statista.com/statistik/daten/studie/316498/umfrage/lebensdauer-von-autos-deutschland/

Statista (2021d) Inflationsrate in Deutschland von 1992 bis 2020 https://de.statista.com/statistik/daten/studie/1046/umfrage/inflationsrate-veraenderung-des-verbraucherpreisindexes-zum-vorjahr/.

Statista (2021e) Preisentwicklung ausgewählter OPEC-Rohöle in den Jahren 1960 bis 2021d. https://de.statista.com/statistik/daten/studie/810/umfrage/rohoelpreisentwicklung-opec-seit-1960/

Stolten D, Markewitz P, Schöb T, Kullmann F, Risch S, Groß T, Hoffmann M, Franzmann D, Triesch T, Kraus S, Maier R, Gillessen B, Heinrichs H, Pflugradt N, Grube T, Linssen J, Kotzur L (2021) Neue Ziele Auf Alten Wegen? Strategien für eine treibhausgasneutrale Energieversorgung bis zum Jahr 2045. Forschungszentrum Jülich, Jülich

Swiss Centre for Live Cycle Inventories (2016) Ecoinvent Database version 3.3. Zurich

Talukder B, Hipel K W (2021) Review and selection of multi-criteria decision analysis (MCDA) technique for sustainability assessment. In: Ren J (ed) Energy systems evaluation (Volume 1). Green Energy and Technology, Springer, Cham

Ubando AT, Cuello JL, El-Halwagi MM, Culaba AB, Promentilla MAB, Tan RR (2016) Application of stochastic analytic hierarchy process for evaluating algal cultivation systems for sustainable biofuel production. Clean Technol Environ Policy 18(5):1281–1294

United Nations (2020) Climate change. https://www.un.org/en/sections/issues-depth/climate-change/ (last accessed December 2020)

Valente A, Iribarren D, Dufour J (2019) End of life of fuel cells and hydrogen products: From technologies to strategies. Int J Hydrogen Energy 44(38):20965–20977

Weldon P, Morrissey P, O’Mahony M (2018) Long-term cost of ownership comparative analysis between electric vehicles and internal combustion engine vehicles. Sustain Cities Soc 39:578–591

Wulf C, Reuß M, Grube T, Zapp P, Robinius M, Hake J-F, Stolten D (2018) Life cycle assessment of hydrogen transport and distribution options. J Cleaner Prod 199:431–443

Wulf C, Werker J, Ball C, Zapp P, Kuckshinrichs W (2019) Review of sustainability assessment approaches based on life cycles. Sustainability 11(20):5717

Wulf C, Zapp P (2021) Sustainability assessment of innovative energy technologies – hydrogen from wind power as a fuel for mobility applications. J Sustain Develop Energy Water Environ Syst. https://doi.org/10.13044/j.sdewes.d8.0371

Xu L, Reid M (2021) Will sodium-ion battery cells be a game-changer for electric vehicle and energy storage markets? Wood Mackenzie, https://www.woodmac.com/news/opinion/will-sodium-ion-battery-cells-be-a-game-changer-for-electric-vehicle-and-energy-storage-markets/

Xue W, Miao L, Qie L, Wang C, Li S, Wang J, Li J (2017) Gravimetric and volumetric energy densities of lithium-sulfur batteries. Curr Opin Electrochem 6(1):92–99

Yan X, Sun S (2021) Impact of electric vehicle development on China’s energy consumption and greenhouse gas emissions. Clean Technol Environ Policy 23(10):2909–2925

Yang X-G, Liu T, Wang C-Y (2021) Thermally modulated lithium iron phosphate batteries for mass-market electric vehicles. Nat Energy 6(2):176–185

Funding

Open Access funding enabled and organized by Projekt DEAL. This work is supported by the Helmholtz Association. This work was partly funded by Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany's Excellence Strategy—EXC 2154—Project number 390874152.

Author information

Authors and Affiliations

Contributions

MH, CW and MB designed the concept, objectives and methods of the study. Material preparation, data collection and analysis were performed by MH, CW, MB, HE, JK and FH. The first draft of the manuscript was written by MH, and all authors commented on previous versions of the manuscript. CW contributed to writing the manuscript, particularly the part Introduction. MB contributed to writing the manuscript, particularly the part Critical reflection and broader concept. LSME contributed to writing the manuscript, particularly the part Introduction. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: indicators for sustainability assessment

See Table

5.

Appendix 2: underlying assumptions for electricity production mix and domestic value-added

See Tables

6 and

7.

Appendix 3: indicator results

See Tables

8 and

9.

Appendix 4: performance values and resulting rankings

See Table

10.

Appendix 5: effect of parameter variations on total costs

See Tables

11,

12 and

13.

Appendix 6: effect of parameter variations on overall domestic value-added

See Tables

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Haase, M., Wulf, C., Baumann, M. et al. Multi-criteria decision analysis for prospective sustainability assessment of alternative technologies and fuels for individual motorized transport. Clean Techn Environ Policy 24, 3171–3197 (2022). https://doi.org/10.1007/s10098-022-02407-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-022-02407-w