Abstract

There is a growing consensus that the increase in greenhouse gases results in unfavorable changes to the Earth’s climate and is responsible for global warming. Due to this ecological imbalance, governments are under growing pressure to enact strict legislation to control these emissions in their respective countries. Consumers also demand eco-friendly products and are moving toward firms that are socially and environmentally responsible. Therefore, industries are facing increased pressure to adopt sustainable production approaches. This paper demonstrates how a mixed integer linear program can be used to optimize the balance of overall cost and carbon emissions in the production, storage, and distribution of products in a regulatory environment that includes a cap and trade policy. The model is computationally tested for fifteen case instances of different sizes. The main contributions of the proposed model are (a) to link the emission parameters to various decision variables to support the decision making related to carbon costs and carbon emissions, (b) to address international trade issues by considering international parameters such as imports, exports, and government subsidies and perform a country-specific analysis for carbon emissions, and (c) to identify the extent to which the operational adjustment can be used as an alternative to the costly investment in carbon reduction technologies to reduce emissions.

Graphical abstract

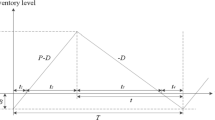

Proposed MILP model framework

Similar content being viewed by others

References

Amin SH, Baki F (2017) A facility location model for global closed-loop supply chain network design. Appl Math Model 41:316–330

Arampantzi C, Minis I (2017) A new model for designing sustainable supply chain networks and its application to a global manufacturer. J Clean Prod 156:276–292

Avagyan AB (2017) Environmental building policy by the use of microalgae and decreasing of risks for Canadian oil sand sector development. Environ Sci Pollut Res 24(25):20241–20253

Avagyan AB (2018) Algae to energy and sustainable development. Technologies, resources, economics and system analyses. New design of global environmental policy and live conserve industry. Amazon, ISBN-13: 978-1718722552, ISBN-10: 1718722559, ASIN: B07DFQBFFD

Bag S, Anand N, Pandey KK (2017) Green supply chain management model for sustainable manufacturing practices. In: Green supply chain management for sustainable business practice. IGI Global, pp 153–189

Benjaafar S, Li Y, Daskin M (2013) Carbon footprint and the management of supply chains: insights from simple models. IEEE Trans Autom Sci Eng 10(1):99–116

Bhatnagar R, Viswanathan S (2000) Re-engineering global supply chains: alliances between manufacturing firms and global logistics services providers. Int J Phys Distrib Logist Manag 30(1):13–34

Carvalho H, Govindan K, Azevedo SG, Cruz-Machado V (2017) Modelling green and lean supply chains: an eco-efficiency perspective. Resour Conserv Recycl 120:75–87

Cholette S, Venkat K (2009) The energy and carbon intensity of wine distribution: a study of logistical options for delivering wine to consumers. J Clean Prod 17(16):1401–1413

Cohen MA, Lee HL (1988) Strategic analysis of integrated production-distribution systems: models and methods. Oper Res 36(2):216–228

Creazza A, Dallari F, Melacini M (2010) Evaluating logistics network configurations for a global supply chain. Supply Chain Manag Int J 15(2):154–164

Das R, Shaw K (2017) Uncertain supply chain network design considering carbon footprint and social factors using two-stage approach. Clean Technol Environ Policy 19(10):2491–2519

Dekker R, Bloemhof J, Mallidis I (2012) Operations research for green logistics–an overview of aspects, issues, contributions and challenges. Eur J Oper Res 219(3):671–679

Dong L, Kouvelis P, Su P (2013) Global facility network design in the presence of competition. Eur J Oper Res 228(2):437–446

Ferdows K (1989) Mapping international factory networks. Managing international manufacturing, 3, p 21

Ganji EN, Shah S, Coutroubis A (2017) December. Sustainable supply and demand chain integration within global manufacturing industries. In: 2017 IEEE international conference on Industrial Engineering and Engineering Management (IEEM). IEEE, pp 1807–1811

Jiang Y, Li B, Qu X, Cheng Y (2016) A green vendor-managed inventory analysis in supply chains under carbon emissions trading mechanism. Clean Technol Environ Policy 18(5):1369–1380

Kaur H, Singh SP (2018) Heuristic modeling for sustainable procurement and logistics in a supply chain using big data. Comput Oper Res 98:301–321

Kouvelis P, Rosenblatt MJ, Munson CL (2004) A mathematical programming model for global plant location problems: analysis and insights. IIE Trans 36(2):127–144

Lamba K, Singh SP (2018) Dynamic supplier selection and lot-sizing problem considering carbon emissions in a big data environment. Technol Forecast Soc Change. https://doi.org/10.1016/j.techfore.2018.03.020

MacCarthy BL, Atthirawong W (2003) Factors affecting location decisions in international operations a Delphi study. Int J Oper Product Manag 23(7/8):794–819

Meijboom B, Voordijk H (2003) International operations and location decisions: a firm level approach. Tijdschrift voor economische en sociale geografie 94(4):463–476

Melo MT, Nickel S, Da Gama FS (2006) Dynamic multi-commodity capacitated facility location: a mathematical modeling framework for strategic supply chain planning. Comput Oper Res 33(1):181–208

Mishra S, Singh SP, Johansen J, Cheng Y, Farooq S (2018) Evaluating indicators for international manufacturing network under circular economy. Manag Decis. https://doi.org/10.1108/MD-05-2018-0565

Nagurney A, Liu Z, Woolley T (2006) Optimal endogenous carbon taxes for electric power supply chains with power plants. Math Comput Model 44(9–10):899–916

Nielsen (2011) The green gap between environmental concerns and the cash register. http://www.nielsen.com/us/en/insights/news/2011/the-green-gap-between-environmental-concerns-and-the-cash-register.html. Accessed on 6 June 2018

Rusinko C (2007) Green manufacturing: an evaluation of environmentally sustainable manufacturing practices and their impact on competitive outcomes. IEEE Trans Eng Manage 54(3):445–454

Schwanberg VD (2018) Can the Paris agreement save us from a climate catastrophe? LANCET Planet Health 2(4):PE 140. https://doi.org/10.1016/S2542-5196(18)30056-1

Srinivasan S, Khan SH (2018) Multi-stage manufacturing/re-manufacturing facility location and allocation model under uncertain demand and return. Int J Adv Manuf Technol 94(5–8):2847–2860

Sundarakani B, De Souza R, Goh M, Shun C (2008) Measuring carbon footprints across the supply chain. In: Proceedings of the 13th international symposium on logistics, July 2008, Bangkok, Thailand, pp 555–562

Sundarakani B, De Souza R, Goh M, Wagner SM, Manikandan S (2010) Modeling carbon footprints across the supply chain. Int J Prod Econ 128(1):43–50

The Emission Gap Report (2017) A UN environment synthesis report. https://wedocs.unep.org/bitstream/handle/20.500.11822/22070/EGR_2017.pdf. Accessed on 6 June 2018

The Paris Agreement (2015) https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement. Accessed on 10 June 2018

Turken N, Carrillo J, Verter V (2017) Facility location and capacity acquisition under carbon tax and emissions limits: to centralize or to decentralize? Int J Prod Econ 187:126–141

Wang G, Gunasekaran A (2017) Modeling and analysis of sustainable supply chain dynamics. Ann Oper Res 250(2):521–536

Xu L, Wang C (2017) Sustainable manufacturing in a closed-loop supply chain considering emission reduction and remanufacturing. Resour Conserv Recycl 131:297–304

Xu L, Mathiyazhagan K, Govindan K, Haq AN, Ramachandran NV, Ashokkumar A (2013) Multiple comparative studies of green supply chain management: pressures analysis. Resour Conserv Recycl 78:26–35

Yang J, Guo J, Ma S (2016) Low-carbon city logistics distribution network design with resource deployment. J Clean Prod 119:223–228

Funding

Funding was provided by Department of Science and Technology, Ministry of Science and Technology and UK-India Education and Research Initiative.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Mishra, S., Singh, S.P. An environmentally sustainable manufacturing network model under an international ecosystem. Clean Techn Environ Policy 21, 1237–1257 (2019). https://doi.org/10.1007/s10098-019-01704-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-019-01704-1