Abstract

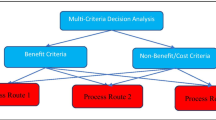

A stable and secure source of raw materials is the key to any successful industrial activity. Resource criticality is often discussed in the context of the impact on the economies of certain geographic regions. However, the availability of required resources first of all concerns the competitiveness of industrial companies, especially in those countries which do not possess abundant natural resources. The Lithuanian economy relies heavily on imports since the country does not have abundant natural resources. The paper introduces resource criticality as an additional dimension for evaluating and prioritizing resource efficiency improvement options. Evaluation of resource criticality was integrated into the methodology for evaluation of Cleaner Production. Simple additive weighting (SAW) was used to solve the multi-criteria decision-making problem. The previous study on the natural resources that are imported to Lithuania revealed that metals are among the most important raw materials in terms of economic importance, supply, and environmental risks. Therefore, a typical metal processing company in Lithuania was selected for the detailed investigation of technological processes and Cleaner Production possibilities. The selected company processes about 3000 tons of various metals per year. The results of Process Material Flow Analysis show that most of the metal waste is generated during the metal plate cutting process (about 30.3 % of total metal consumption). Three resource efficiency improvement alternatives were evaluated and compared. The suggested decision support system was tested in order to decide on a definitive solution. The results reveal that evaluation of resource criticality in terms of geostrategic supply risk and economic importance can be used as an advantageous criterion to support the prioritization of Cleaner Production alternatives.

Similar content being viewed by others

Abbreviations

- EI i :

-

Relative environmental indicator for input or output flow i

- X i (t):

-

Amount of input or output flow i per year

- P(t):

-

Production volume

- IM i :

-

Economic importance of resource i

- p i :

-

Annual expenses for resource i

- TC:

-

Total annual costs of production for the company

- SR i :

-

Geostrategic supply risk of resource i

- WGI c :

-

Rescaled score of the World Governance Indicator of country c

- a i,c :

-

Share % of the supply of resource i from origin country c

- ρi,1 :

-

Share of pre-consumer recycled material (new scrap)

- W plan :

-

Environmental effect

- P :

-

Payback period

- I :

-

Total project investments

- S :

-

Savings

- v(a n ):

-

Value function of simple additive weighting

- w k :

-

Weight assigned to criterion k

- v k (f(a n )):

-

One-dimensional value function

References

Achzet B, Helbig C (2013) How to evaluate raw material supply risks- an overview. Res Pol 38:435–447

Alkaya E, Demirer GN (2014) Improving resource efficiency in surface coating/painting industry: practical experiences from a small-sized enterprise. Clean Technol Environ Policy 16:1565–1575

Almeida CMVB, Bonilla SH, Giannetti BF, Huisingh D (2013) Cleaner Production initiatives and challenges for a sustainable world: an introduction to this special volume. J Clean Prod 47:1–10

Alonso E, Gregory J, Field F (2007) Policy analysis material availability and the supply chain: risks, effects, and responses. Environ Sci Technol 41:6649–6656

Antonopoulos I-S, Perkoulidis G, Logothetis D, Karkanias C (2014) Ranking municipal solid waste treatment alternatives considering sustainability criteria using the analytical hierarchical process tool. Resour Conserv Recycl 86:149–159

Bai S, Zhang J, Wang Z (2015) A methodology for evaluating cleaner production in the stone processing industry: case study of a Shandong stone processing firm. J Clean Prod 102:461–476

Benito JM, Cambiella A, Lobo A et al (2010) Formulation, characterization and treatment of metalworking oil-in-water emulsions. Clean Technol Environ Policy 12:31–41

Benjamin MFD, Tan RR, Razon LF (2015) Probabilistic multi-disruption risk analysis in bioenergy parks via physical input–output modeling and analytic hierarchy process. Sustain Prod Consum 1:22–33

Chakhmouradian AR, Smith MP, Kynicky J (2015) From “strategic” tungsten to “green” neodymium : a century of critical metals at a glance. Ore Geol Rev 64:455–458

Clarens AF, Zimmerman JB, Koeolein GA et al (2008) Comparison of life cycle emissions and energy consumption for environmentally adapted metalworking fluid systems. Environ Sci Technol 42:8534–8540

de Carvalho Pinto PC, de Oliveira Carvalho MM, Linhares FM et al (2015) A cleaner production of sodium hydrogen carbonate: partial replacement of lime by steel slag milk in the ammonia recovery step of the Solvay process. Clean Technol Environ Policy. doi:10.1007/s10098-015-0973-2

Emrah A, Göksel ND (2013) Greening of production in metal processing industry through process modifications and improved management practices. Resour Conserv Recycl 77:89–96

European Commission (2001) Reference document on best available techniques in the ferrous metals processing industry

European Commission (2010) Critical Raw Materials for the EU. Brussels

European Commission (2013) Market Access Database. http://madb.europa.eu/madb/indexPubli.htm. Accessed 27 Oct 2014

Gečys V, Čapas V (2012) Investigation of the quality of the lase-cut parts. Eng Educ Technol 18–25

Gupta S, Dangayach GS, Singh AK, Rao PN (2015) Analytic hierarchy process (AHP) model for evaluating sustainable manufacturing practices in indian electrical panel industries. Proc Soc Behav Sci 189:208–216

Kliopova I (2002) Cleaner production through process control: analysis, methodical and implementation

Kliopova I, Bagdonas A (2003) Optimization of electroplating processes in Lithuanian machine and instrument industry. Environ Res Eng Manag 3:29–37

Kliopova I, Staniskis JK (2006) The evaluation of Cleaner Production performance in Lithuanian industries. J Clean Prod 14:1561–1575

Knašyte M, Kliopova I, Staniškis JK (2012) Economic importance, supply and environmental risks of imported resources in Lithuanian industry. Environ Res Eng Manag 2:40–47

Kong G, White R (2010) Toward cleaner production of hot dip galvanizing industry in China. J Clean Prod 18:1092–1099

Laforest V, Raymond G, Piatyszek É (2013) Choosing cleaner and safer production practices through a multi-criteria approach. J Clean Prod 47:490–503

Laurinkevičiūtė A, Stasiškienė Ž (2011) SMS for decision making of SMEs. Clean Technol Environ Policy 13:797–807

Madanhire I, Mugwindiri K, Mbohwa C (2014) Enhancing cleaner production application in fertilizer manufacturing: case study. Clean Technol Environ Policy. doi:10.1007/s10098-014-0823-7

Magalhães JM, Silva JE, Castro FP, Labrincha JA (2005) Physical and chemical characterisation of metal finishing industrial wastes. J Environ Manag 75:157–166

Malinauskienė M, Kliopova I, Hugi C, Staniškis JK (2015) Geostrategic supply risk and economic importance as drivers for implementation of cleaner production and industrial symbiosis measures in a nitrogen fertilizer production company. (Submitted to Journal of Industrial Ecology 2015-11-09)

Mancini L, Sala S, Recchioni M et al (2015) Potential of life cycle assessment for supporting the management of critical raw materials. Int J Life Cycle Assess 20:100–116

Paraskevas D, Kellens K, Dewulf W, Duflou JR (2014) Environmental modelling of aluminium recycling: a life cycle assessment tool for sustainable metal management. J Clean Prod 105:357–370

Peck D, Kandachar P, Tempelman E (2015) Critical materials from a product design perspective. Mater Des 65:147–159

Qin XS, Huang GH, Chakma A et al (2008) A MCDM-based expert system for climate-change impact assessment and adaptation planning—a case study for the Georgia Basin, Canada. Expert Syst Appl 34:2164–2179

Roelich K, Dawson DA, Purnell P et al (2014) Assessing the dynamic material criticality of infrastructure transitions: a case of low carbon electricity. Appl Energy 123:378–386

Serpantinas (2007) Žurnalas apie pjovimo technologijas ir medžiagas. 1(7)

Statistics Lithuania. http://www.stat.gov.lt/en/home. Accessed 27 Jan 2014

Tan RR, Promentilla MAB (2013) A methodology for augmenting sparse pairwise comparison matrices in AHP: applications to energy systems. Clean Technol Environ Policy 15:713–719

Tan RR, Aviso KB, Huelgas AP, Promentilla MAB (2014) Fuzzy AHP approach to selection problems in process engineering involving quantitative and qualitative aspects. Process Saf Environ Prot 92:467–475

Tseng ML, Lin YH, Chiu ASF, Liao JCH (2008) Using FANP approach on selection of competitive priorities based on cleaner production implementation: a case study in PCB manufacturer, Taiwan. Clean Technol Environ Policy 10:17–29

UNEP: United Nations Environment Programme (2002) Changing production patterns: learning from the experience of national cleaner production centers

UNIDO (1991) Cleaner Production (CP). http://www.unido.org/en/what-we-do/environment/resource-efficient-and-low-carbon-industrial-production/cp/cleaner-production.html#pp1[g1]/0/. Accessed 13 Oct 2015

Velasquez M, Hester PT (2013) An analysis of multi-criteria decision making methods. Int J Oper Res 10:56–66

Villar A, Parrondo J, Arribas JJ (2014) Waste heat recovery technology in continuous casting process. Clean Technol Environ Policy 17:555–562

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Malinauskienė, M., Kliopova, I., Slavickaitė, M. et al. Integrating resource criticality assessment into evaluation of cleaner production possibilities for increasing resource efficiency. Clean Techn Environ Policy 18, 1333–1344 (2016). https://doi.org/10.1007/s10098-016-1091-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1091-5