Abstract

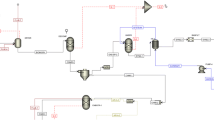

Ethanol produced from renewable resources is widely regarded as an option to substitute traditional fossil fuels. By coupling the ethanol production to biogas production, an energy autarkic process with minimum ecological footprint can be created. Capable engineering tools are needed to design such processes due to their complexity and the integration necessary. Here, we present a modeling strategy that can serve this task as it allows the steady-state flowsheet simulation of biotechnological production of alternative fuels from renewable resources. The modeling concept is explained and applied to a small-scale self-sustaining ethanol production (1,000 t/a fuel-grade ethanol). An adjunct pinch-analysis for heat integration further demonstrates the potential of the tool developed for the investigation and design of future production of fuel and chemical raw materials.

Similar content being viewed by others

References

Batstone DJ (2002) Anaerobic digestion model No.1 (ADM1). Water Sci Technol 45:65–73

Bösch P, Schausberger P, Beckmann G et al (2008) Example of optimisation and heat integration on a basis of ethanol plants. J Mech Eng 59:205–216

Cardona CA, Sanchez OJ (2007) Fuel ethanol production: process design trends and integration opportunities. Bioresour Technol 98:2415–2457

Dipama J, Teyssedou A, Sorin M (2008) Synthesis of heat exchanger networks using genetic algorithms. Appl Therm Eng 28:1763–1773

Gmehling J, Onken U, Kreysa G (2003) Dechema data series, DECHEMA, Frankfurt/Main

Institut für Energetik und Umwelt GmbH (Leipzig), Bundesforschungsanstalt für Landwirtschaft (Braunschweig), and Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. (Darmstadt) (2006) Handreichung Biogasgewinnung und -nutzung. Fachagentur Nachwachsende Rohstoffe, Gülzow, ISBN 3-00-014333-5 (in German)

Jacques KA, Lyons TP, Kelsall DR (2003) The alcohol textbook, 4th edn. Bath Press, Bath, ISBN 1897676131

Kawazuishi K, Prausnitz JM (1987) Correlation of vapor–liquid equilibria for the system ammonia–carbon dioxide–water. Ind Eng Chem Res 26:1482–1485

Kemp IC (2007) Pinch analysis and process integration, 2nd edn: a user guide on process integration for the efficient use of energy. Butterworth-Heinemann, Oxford, ISBN 0750682604

Kwiatkowski JR, McAloon AJ, Taylor F et al (2006) Modeling the process and costs of fuel ethanol production by the corn dry-grind process. Ind Crops Prod 23:288–296

Liebmann B, Pfeffer M, Wukovits W et al (2007) Modeling of small-scale bioethanol plants with renewable energy supply. In: 10th conference on process integration modeling and optimisation for energy saving and pollution reduction, PRES’07, Chemical Engineering Transactions 12:309–314

NASA Thermodynamic Database (2008) http://www.galcit.caltech.edu/EDL/public/thermo.html. Accessed 10 April 2008

Perz EW (1991) A computer method for thermal power cycle calculation. J Eng Gas Turbines Power 113:184–189

Perz EW, Bergmann S (2003) IPSEpro V4.0 user documentation. Graz

Pfeffer M (2006) Modelle für die Prozessanalyse von Bioethanolproduktionsanlagen mittels Simulation, PhD Thesis, Vienna University of Technology, Vienna (in German)

Smith R (2005) Chemical process design and integration. Wiley and Sons, Chichester, ISBN 0471486817

Sobacan G, Glavic P (2000) Optimization of ethanol fermentation process design. Appl Therm Eng 20:529–543

Acknowledgments

The authors gratefully acknowledge the support by “Energy Systems of Tomorrow”, a subprogram of the Federal Ministry of Transport, Innovation and Technology (BMVIT) in cooperation with the Austrian Industrial Research Promotion Fund (FFG). The partners within this project shall be acknowledged for contributing their process know-how.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schausberger, P., Bösch, P. & Friedl, A. Modeling and simulation of coupled ethanol and biogas production. Clean Techn Environ Policy 12, 163–170 (2010). https://doi.org/10.1007/s10098-009-0242-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-009-0242-3