Abstract

To evaluate the characteristics of wood ash as fertilizer, composition of inorganic elements and the leaching behavior were studied. The leaching behavior was evaluated by three leaching methods using different solvents (water, hydrochloric acid, and acetic acid: Japanese leaching test Nos. 18 and 19 and modified toxicity characteristic leaching procedure prescribed by the US Environmental Protection Agency). The ash composition varied according to raw materials for fuel and ash collection systems. Concentration of Na, Al, Si, and V became higher in bark ashes while that of K became higher in wood ashes. Pb, Cd, Se, and Zn were more volatile and enriched in fly ashes. Of the nutrient elements, K showed high water solubility and its phytoavailability also appeared high, although the amount of water-soluble K was low in bark ash. Ca and Mg had intermediate solubility while P was less soluble in both water and acetic acid. The amount of hazardous substances having leached was low for most, but not all the ashes, in terms of Pb, Cr and As. Nevertheless, the phytoavailability of these hazardous substances after their application to the forest appeared low, due to their amphoteric leaching behavior and the acidity of Japanese forest soils.

Similar content being viewed by others

Introduction

As a carbon neutral and sustainable energy source, global interest in biomass combustion to generate heat and power is continuously growing. Since its combustion technologies are proven and commercially available compared to other thermal conversion technologies, the consumption of wood as a fossil fuel alternative has steadily increased over the last decade in Japan. For example, the national production of wood pellet fuels increased from 3800 tons in 2003 to 50693 tons in 2009 [1]. Following the Great East Japan Earthquake, which triggered the Fukushima Dai-ichi nuclear power plant accident, this increasing trend toward the use of biomass combustion for heat and energy production is expected to accelerate in Japan. With the adoption of the “Bill on Special Measures Concerning the Procurement of Renewable Energy sourced Electricity by Electric Utilities” in August 2011, which targeted the introduction of a feed-in tariff scheme for renewable energy in Japan, the combustion of biomass fuels for energy will increase.

The increased use of biomass fuels, however, will result in the increased production of ash. Much of the ash is today considered waste and deposited on landfills at considerable cost. Due to the lack of landfill sites and the more stringent regulations designed to protect the environment, ash disposal is becoming costlier. According to a recent evaluation report by the Ministry of Internal Affairs and Communications of Japan, the increasing cost of waste disposal reduces the profitability of municipal biomass projects and hinders their success [2]. With sustainable development in mind, there is a need to reuse and recycle combustion residues into beneficial products.

One such challenge, investigated in many other countries, is to use the combustion residues as fertilizers for agricultural fields and silvicultural sites. Historically, in the USA and Europe, wood has been burned to produce ash derived-potash [3]. Even though wood ashes have increasingly been viewed as waste as other potash production technologies become more economical, they are still continuously applied on areas of forest land for liming, base cation fertilization, and correcting nutrient deficiencies caused by short-rotation wood harvesting [3–7]. In Sweden, in 2006, for example, about 18000 tons of biofuel ash was spread over 6500 ha of forest [4].

These countries have elaborated regulations or recommendations for the recycling of wood ashes [8]. However, there is no clear rule in Japan. To promote the recycling of biomass ash as fertilizer with adopting a philosophy of establishing a strategy for prevention and control in advance, it is necessary to establish clear application rules that maintain the consistency with relevant domestic laws (e.g. Fertilizer Control Act, Waste Management and Public Cleansing Act, and Soil Contamination Countermeasures Act). Since the characteristics of wood ash should much differ reflecting the raw materials for fuel, combustion temperature, and ash collecting systems of combustors, plentiful information on characters of ashes discharged from Japanese combustion equipment is crucial.

For the evaluation of the quality of the ash, two methods have been generally applied. One is quantifying total content of target elements. Japanese Fertilizer Control Act has established official standards on minimum amount of effective components and maximum amount of hazardous components for several types of fertilizer and required the registration to confirm their effectiveness and safety [9, 10], although this act has classified conventionally used plant and wood ashes as “special fertilizers” and required only the amount of effecting components to be specified on the label [10]. In several countries, such as Sweden and Finland, the quality of ash is evaluated by this method before ash application into soil [8].

The other method is quantifying leaching amount of target elements. This method is broadly used to evaluate the potential effects of waste disposal to environment and human health. Each country has developed unique leaching tests differed widely with respect to purpose, L/S (liquid-to-solid) ratio, leaching duration, and solvent pH. In Japan, combustion ash currently landfilled is disposed of via evaluation by a water leaching test (Japanese leaching test No. 13) as prescribed by the Japanese Waste Management and Public Cleansing Act which regulate maximum leaching amount of hazardous components. Accordingly, information on the water leaching characteristics of wood ashes has been accumulated for several types of ashes from muffle furnaces [11, 12], commercial stoves [11, 13], and boilers [13, 14].

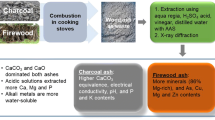

To establish application rules considering the consistency with both domestic regulations on ordinal fertilizer and waste disposal, the characters of each evaluation methods should be known. However, information on the difference between total and leaching amount of composition is scarce on Japanese biomass ashes yet. Then, this study, at first, investigated the total amount of inorganic elements in 19 types of woody ashes discharged from Japanese wood boilers and evaluated the effect of the raw materials for fuel and the ash collecting systems on the ash composition. Next, the total amount of inorganic elements was compared with the extractable amounts with three frequently used leaching methods, differentiated mainly in terms of solvent [water: Japanese leaching test No. 18 (JLT18), acetic acid: modified toxicity characteristic leaching procedure prescribed by the US Environmental Protection Agency (m-TCLP), and hydrochloric acid (HCl): Japanese leaching test No. 19 (JLT19)]. Last, on the basis of the comparison of the solubility to different solvents, phytoavailability of the ash composition was estimated.

Materials and methods

Samples

A total of 19 types of wood pellet combustion ashes were sampled from 13 types of wood boilers (Table 1). From five boilers, both bottom and fly ashes were collected (A, C, D, E, and G). From one boiler (H), two types of ashes originating from the upper and lower parts of the burner were collected. The other seven types of ashes were mixed fly and bottom ashes or ashes with no information on the collected portion. The raw materials for combusted pellet fuels were bark (two boilers: A and B), wood (four boilers: C to F), and bark + wood (7 boilers: G to M). The material tree species were broad-leaved (two boilers: B and M) and coniferous species (remaining 11 boilers). The feedstock of each pellet was from the wood industry, such as molder and planer shavings, diseased trees, thinned trees, trees affected by construction, and forest residue.

Ash digestion

To measure the total amount of inorganic elements, each individual ash of 70–120 mg was digested in Teflon vessel with mixed acids (69 % HNO3 2 ml, 30 % H2O2 2 ml, and 48 % HF 2 ml). The vessel was then heated to 220 °C slowly and the temperature was kept for 2 h. After cooling, HF in the vessel was neutralized by adding 4 % H3BO3 20 ml, and the vessel was re-heated to 180 °C and the temperature was kept about 15 min. After cooling again, the digests were transferred to volumetric flask.

Leaching tests

Three types of leaching test were performed (Table 2): JLT18; JLT19; and m-TCLP. The two Japanese methods are prescribed by the Soil Contamination Countermeasures Act in Japan, [15] while TCLP is prescribed by the US Environmental Protection Agency [16]. While JLT18 has been developed to evaluate the health risk of ingesting ground water having leached from contaminated soil, JLT19 has been developed to evaluate the health risk of directly ingesting contaminated soils and the amount of inorganic elements extractable with 1 M hydrochloric acid, which simulates the digestive fluids in the stomach [15]. TCLP is prescribed by the US Environmental Protection Agency and designed to simulate conditions of a municipal waste landfill with rotting garbage via the use of acetic acid solvent and evaluate the leaching of contaminants from buried solid waste [16]. The JLT18 is similar to the Japanese leaching test No. 13, which is prescribed by the Japanese Waste Management and Public Cleaning Act, but differentiated slightly in terms of sample preparation. In this study, all collected ashes were ground and passed through a 2 mm sieve. The applied leaching methods differed in terms of the solvent types, liquid-to-solid (L/S) ratio, and leaching duration. The JLT18 is performed at L/S = 10/1 (500 ml/50 g), with agitation of 6 h by a horizontal shaker at 200 rpm, and using ultrapure water as a solvent, while the JLT19 is performed at L/S = 100/3 (200 ml/6 g), with agitation of 2 h by a horizontal shaker at 200 rpm, and using 1 M HCl as a solvent. The m-TCLP is performed at L/S = 20/1 (500 ml/25 g), with agitation of 18 h by a horizontal shaker at 90 rpm (correct method of EPA requiring rotary agitation at 30 +2 rpm), using acetic acid as a solvent (fluid type #2, as prescribed by the EPA method, pH 2.88). All reagents and acids were ultrapure or of pro-analytical quality. Prior to the analysis, the obtained leachates were subsequently filtered by membrane filters (Millipore: pore size = 0.45 μm) in JLT Nos. 18 and 19 and by borosilicate grass fiber filters (Whatman: pore size = 0.6–0.8 μm) in the m-TCLP. All leaching tests were carried out in duplicate.

Chemical analysis

The digests and leachates were analyzed according to JIS K0102: for pH (pH meter, TOA Co., HM-30), EC (EC meter, TOA., CM-30R) and the following elements: B, Na, Mg, Al, Si, P, K, Ca, V, Cr, Mn, Fe, Ni, Cu, Zn As, Se, Sr, Cd, Ba, Pb (ICP-MS: Agilent, 7500ce and ICP-AES: Perkin Elmer, Optima 4300 DV).

Statistical analysis

To evaluate the ash composition and its leaching behavior, multivariate statistical methods, including cluster analysis (CA) and principal component analysis (PCA), were used. CA classifies the chemical element species into groups (clusters) based on similarities in solubility to each type of leaching tests. PCA is designed to transform the original variables into new, uncorrelated variables (axes) known as principal components (PCs), which are linear combinations of original variables. By plotting samples in PC ordination diagrams using PC scores, sample relations and grouping would be visualized and provide information on the key variables explaining the differences among groups. Both statistical analyses were performed using PC-ORD ver. 5.30 (MiM software, Oregon, USA), which is used in community ecology.

Results and discussion

Ash composition

Difference of ash composition depending on the raw materials for fuel

The ash composition varied according to the raw materials of fuel. To determine the meaningful element species significantly affected by the raw materials, PCA was performed. As the ash composition, the amount of element dissolved into mixed acids (HNO3, HF, and H2O2) (Table 3) was used. The data matrix used in the analysis consisted of 19 ash samples with 21 elements. Before the analysis, two of the 21 variables (Pb and Zn) with maximum/minimum scores exceeding 100 were log transformed, whereupon all data of each element were relativized by maximum.

The result showed that the first three principal components explained 70.8 % of total variance, where PC1 showed the highest percentage contributions with 35.7 % (Table 4). PC1 positively corresponded to Na, Al, Si, and V and negatively to K (Table 4: in this study, any element variables with R 2 > 0.5 were considered meaningful). As can be seen from the ordination diagrams given in Fig. 1, ash samples originating from the same raw material tended to be scattered closely along the PC1 axes, which suggests that the amount of elements corresponding to PC1 was significantly affected by the raw materials for fuel. Bark ashes were located in the positive part of PC1 (Fig. 1) and tended to contain more Na, Al, Si, and V than the others (Table 3), while the majority of wood ashes were located in the negative part of PC1 (Fig. 1) and tended to contain more K (Table 3). Also ash samples from mixed material (bark + wood) tended to be located in the center of the diagram (Fig. 1) and tended to show medium ash composition (Table 3).

PCA ordination diagrams of 19 ash specimens based on the concentration of 21 inorganic elements (amounts of element dissolved into mixed acids). Filled circle bark pellet ashes, open square wood pellet ashes, times symbol wood + bark (mixed) pellet ashes. Number in figures indicates ash number. Left axis 1 vs. axis 2. Right axis 1 vs. axis 3

Higher concentrations of K in wood ash than bark ash have been reported in many previous studies [5, 6, 12]. For examples, Tsuchiya and Shimogaki [12] reported higher levels of K in wood ashes than bark ashes on Cryptomeria japonica, Pinus densiflora, Larix kaempferi, Quercus serrata, and Betula platyphylla var. japonica. Meanwhile, the higher Si and Al concentrations in bark ashes in this study coincided with the report of Someshwar [5]. However, experimental work of Tsuchiya and Shimogaki [12] reported that conifer species showed higher Al and Si concentrations in bark ashes than wood ashes but that hardwood species showed the opposite tendency. One explanation for this discrepancy may be the contamination of mineral soils [5]. While the bark sample of the experimental work of Tsuchiya and Shimogaki [12] was washed before ash was generated in a muffle furnace, the bark pellet fuel combusted in our studies seemed to contain mineral soils that contaminated during harvesting and processing. Quartz (SiO2) and feldspar [KAl3O8 and (Na, Ca) Al (Si, Al)3O8] originating from soil have been often found in biomass ash [17, 18]. In addition, V is often adsorbed in mineral structures of clay or soil organic matter [19]. Thus, the relatively high concentrations of Na, Si, Al, and V in bark ash may depend on the extent to which mineral soils and organic matter contaminated in combusted fuels.

Meanwhile, PC2 explained 20.0 % of total variance and corresponded to Cr and Ni, while PC3 explained 15.2 % of total variance and corresponded to Pb (Table 4). However, the concentration of these elements in ashes was considered unrelated to the raw materials for wood fuel. Since Cr and Ni are frequently used metals for coating of stainless steel, then the simultaneous occurrence of both metals in ashes suggests the contamination from furnaces. Moreover, as will be discussed below, the Pb concentration differed significantly in different ash collection systems, even though the same fuel was combusted, e.g. Ash Nos. 11 and 12 (fly and bottom ashes from boiler G).

Difference of ash composition depending on boiler ash collecting systems

As well as the raw materials for fuel, the ash collecting systems of the boilers affected the ash composition. To estimate the effect of ash collection systems on the ash composition, the amounts of element dissolved into mixed acids (HNO3, HF, and H2O2) (Table 3) were compared between fly and bottom ashes for five boilers: A, C, D, E and G. To classify the element species on the basis of the element accumulation pattern of fly and bottom ashes, CA was performed based on five valuables: (1) average; (2) median; (3) maximum; and (4) minimum score of the element concentration ratio in fly ash to bottom ash (fly/bottom); and (5) the boiler number for which the fly ash showed a higher element concentration than the bottom ash. Log transformation of data was performed for the first four variables to ensure normal distribution, and all variables were then standardized to a mean of zero and a standard deviation of one. Square Euclidian was applied as a similarity measurement and Ward’s methods as a linkage method, respectively.

A dendrogram of CA (Fig. 2) provided three groups of element species, based on similarity in terms of the accumulated differences between fly and bottom ashes. Group I consists of Pb, Cd, Se, and Zn; all of which were highly concentrated in fly ash compared to bottom ashes, which suggests their higher volatility in the combustion process. An experimental study of Sano et al. [20], in which the element concentrations of wood pellet ashes formed at 815 and 550 °C in a muffle furnace was compared, estimated that ~95 % of Pb and Cd, and ~65 % of Zn were volatized in combustion at 815 °C. This high volatility was also observed by Misra et al. [21]. A study on coal combustion by Huang et al. [22] revealed that the volatility of Se was equivalent or higher than that of Pb, Zn, and Cd. Group II consists of As, B, P, Cu, Mn, Fe, Ba, Mg, Ca, Na, Sr, and K. Since these elements showed relatively low fly/bottom values compared to Group I (Fig. 2), it is thought that they could be partly volatized but their volatility was lower than Group I. Among this group, the behavior of As in the combustion process, which has been effectively studied due to its toxicity and its relatively high volatility at lower temperature, has also been confirmed [23]. Previous studies also showed that K could volatize at high temperatures [20, 21]. Group III consists of V, Si, Ni, Cr, and Al and was separated from group II by the lower minimum fly/bottom value and the lower frequency of cases where the element concentration of fly ash exceeded that of bottom ash (Fig. 2). However, the difference in volatility between the groups was unclear because the maximum scores on the element concentration ratio of fly ash to the bottom ash elements of Group III were equivalent or higher than those of Group II. Previous studies showed that Cr could volatize at high temperatures [20, 21]. Group III is characterized by including representative elements originated from non-wood materials, such as soil materials(V, Si, and Al) and metal plating of furnace (Cr and Ni).

Evaluation of leaching behavior of ash composition by three standardized leaching methods

Comparison of pH and electrical conductivity on three leaching solutions

Table 5 shows the pH value and electrical conductivity (EC) of ash solutions based on three types of leaching test. All solutions of the JLT18 were highly alkaline, with pH values ranging from 11.9 to 13.3, while all solutions of the JLT19 were highly acidic, ranging from 0.06 to 0.44. Most of the solutions of m-TCLP were highly alkaline, but some of the ashes originating from the wood (ash Nos. 6, 16, and 18) showed relatively weak alkalinity and hence relatively wide-ranging pH values, from 7.7 to 12.5. EC became lowest in the solutions of JLT18 and peaked in JLT19, which means that considerable electrolyte was dissolved in the acid solvent. The highest EC values in the JLT19 solution suggested that the amount of inorganic elements extractable with 1 M hydrochloric acid was more reflective of the ash composition.

Comparison of leaching amounts of inorganic elements

Tables 6, 7, and 8 show the leaching amounts of inorganic elements for JLT18, m-TCLP, and JLT19, respectively. The leaching amounts of inorganic elements varied according to the leaching methods used. To facilitate interpretation of the leaching behavior of each element species, the analyzed 21 elements were grouped using CA with 6 variables: (1) mean and (2) median values of the ratio of the amount extracted with the JLT19 solution to that dissolved into the mixed acids (JLT19/Total); (3) mean and (4) median values of the ratio of the amount extracted with the JLT18 solution to that dissolved into the mixed acids (JLT18/Total); (5) the number of ash samples for which JLT19/Total exceeded 0.8; and (6) the number of ash samples for which the ratio of the amount extracted with the m-TCLP solution to that with the JLT18 solution (m-TCLP/JLT18) exceeded one. Variables (1)–(4) were log transformed to ensure normal distribution, and all variables including (5) and (6) were then standardized to a mean of zero and a standard deviation of one. Square Euclidian was applied as a similarity measurement and Ward’s methods as a linkage method. In this study, we regarded as the dissolved amounts into mixed acids as “total amount” of the element in the ashes. However, there were several samples for which (JLT18, JLT19, or m-TCLP)/Total exceeded one. The supposed reason for this is the difference of amount of ashes offered for the digestion and three leaching tests. The amount of digestible ashes was very small (70–120 mg) compared to the amount of ashes offered for leaching tests. The effect of sample smallness assumed to become large if the target element distributed unevenly or if insoluble charcoal particle were included much. In spite of this limitation of ash digestion, we adopted the results because small (JLT18, JLT19, or m-TCLP)/Total values appeared to indicate the insolubility of ashes composition to each solution.

The result of CA (Fig. 3) classified the 21 elements into 7 groups. The first four groups (1, 2, 3 and 4) were characterized as more frequent cases in which JLT19/Total value was exceeded 0.8 (Fig. 3). Group 1 consists of K, Na, and B. These elements showed relatively higher JLT18/Total value compared to other elements, which suggests their high concentrations in ash, presented in water-soluble form. Group 2 consists of Mg, which did not dissolve in the JLT18 solutions at all, but dissolved in the m-TCLP solutions to some extent. Group 3 consists of Ca and Sr and Group 4 consists of As and Cd. Although these elements showed lower water solubility than Group 1, trace amounts were dissolved in both JLT18 and m-TCLP solutions. Group 4 is separated from Group 3 by the relatively higher frequency of cases where the m-TCLP/JLT18 values were lower than one.

Classification of 21 inorganic elements in wood ash based on the comparison of the total amount of inorganic elements with the amount extracted with water (the JLT18 solution), acetic acid (the m-TCLP solution), and 1 M HCl (the JLT19 solution). Filled triangle bark pellet ashes, open circle wood pellet ashes, straight line wood + bark (mixed) pellet ashes. Asterisk the values of ratio for several specimens were calculated using the value of detection limit

Although biomass ashes have been traditionally used as potash fertilizer because of the high water solubility of K, this was not always the case. The JLT18/Total value for K declined in bark ashes (10.6–20 %) compared to wood ashes (78.5–103.8 %) (Fig. 3), which suggests that a large portion of K in bark ash presented in water-insoluble form. This analytical result may be due to the contamination of primary minerals, such as feldspar, in bark ash as mentioned above. In general, external inorganic materials, which have been added to during harvesting and logistics, are considered much less reactive than inherent inorganic materials, which exist as part of the organic structure of materials [17, 24, 25]. Most of the K in bark ash was thought to originate from external material, and the leaching behavior of other elements having exhibited similar leaching patterns to K (Na, B, Al, and Si, etc.) seems attributable to the contamination of external material to some extent.

Conversely, alkaline earth metals in Group 3 (Ca and Sr) showed opposite behavior to K, i.e. the JLT18/Total value rose in bark ash (Fig. 3). For instance, the JLT18/Total values for Ca were higher in bark ashes (2.4–3.8 %) than in wood ashes (0.01–0.76 %). The higher leaching amount for bark ash was probably due to chemical speciation, although no evidence could be obtained from our result. For instance, Ca of ash occurs in a variety of chemical speciation. Although all soluble forms, such as CaO and Ca (OH)2, dominate, CaCO3, despite its low solubility, is also present in abundance [17, 24, 25]. A significant fraction of Ca in studied bark ash is likely to be present in the form of CaO at the start of the leaching. In general, CaO is formed by combustion at a relatively high temperature [12, 21], and transformed into Ca(OH)2 and CaCO3 by exposure to air during storage and leaching [25]. Another factor, besides the chemical speciation of the alkali earth metal, is precipitation with other element species, such as phosphate. It has been suggested that large amounts of dissolved P species at ash particle surfaces with high pH and many Ca2+ ions may form solid calcium phosphate [Ca5OH(PO4)3] [25].

As and Cd in Group 4 have been known for their amphoteric leaching behavior, i.e. they were extractable under both acidic (low pH) and alkaline (high pH) conditions, but relatively insoluble at medium pH values. Wang et al. [26] reported on coal fly ash that less As was in the dissolved phase between pH 3 and 8, but soluble As concentration was increased when pH was less than 3 or greater than 7. According to a review by the Environment Agency of the UK [27], the theoretical solubility of Cd is minimum between pH 10 and 11, and increased less than pH 10 or greater than pH 11.

The latter three element groups (5, 6, and 7) were characterized by the relatively higher frequency of cases where the JLT19/Total values were lower than 0.8 (Fig. 3), which suggests that a large portion of these elements in ash presented as in 1 N HCl insoluble form. Group 5 consists of Ni and Ba and is separated from the other groups by the higher frequency of cases where the m-TCLP/JLT18 values were higher than one. Group 6 (P, Mn, Fe, Cu, Zn, and Pb) was separated from Group 7 (Al, Cr, Se, Si, and V) by the relatively lower mean and average value of JLT18/Total.

Some of the element species included in Groups 6 and 7 have been known for their amphoteric leaching behavior as well as Group 4. According to a review by the Environment Agency of the UK [27], the theoretical solubility of Zn, Cu and Pb hydroxides is minimum between 8.5 and 9.5, and increases less than pH 8.5 or greater than pH 9.5. That of Cr is minimum between pH 7 and 8. For Fe, the solubility is minimum between pH 10 and 11. Gupta et al. [28] also reported the amphoteric leaching behavior of Al as well as Cr, Pb, Zn on the fly ash of municipal solid waste. An additional explanation for the leaching behavior of Groups 4, 6, and 7 may be precipitation with other elements at a higher pH. As mentioned above, the lower solubility of P at a higher pH may depend on the formation of insoluble calcium phosphate. Inoba and Shimogaki [29] suggested that the solubility of Se and As at high pH decreased when the concentration of Ca was high. As well as the solution pH, the L/S ratio, leaching duration, and temperature would also affect the precipitation.

The evaluation on the phytoavailability of wood ash composition

Our results verified that wood combustion residues contain nutrients such as K, Ca, Mg, and P (Table 3). However, their phytoavailability after soil application can be varied by element species. Based on a comparison of extractability among the three leaching methods, their phytoavailability immediately after soil application will be K > Ca > Mg > P. Because of the high water solubility (Fig. 3), the availability of K will increase immediately after the application of the ash. However, no long-term effects can be expected. Conversely, the application of ash will not result in an immediate increase in P availability. Because of the low water solubility (Fig. 3), P in the ash will become available to plants over a longer period, due to the effects of weathering and organic acid.

Most of the studied ashes showed low leaching amounts of hazardous substances, but four specimens showed relatively high values: ash Nos. 6 and 8 for Pb; Nos. 8, 9 and 15 for Cr; and No. 15 for As (Tables 6, 7, 8). This means that an analytical check is necessary before recycling wood ash originating from a boiler. The presence of highly soluble Pb in Nos. 6 and 8 (the fly ashes of boilers D and E) seems to be the result of combustion at high temperature and the effective ash gathering ability of the cyclone. Because fly ash is liable to contain easily volatile hazardous substances as shown above (Fig. 2), many might become unsuitable for land application depending on the combustion circumstances. In addition, the presence of highly soluble Cr in ashes is a frequent concern in biomass combustion industries [11, 13, 30–32]. In general, chromium compounds exist in oxidized states between 0 and +VI, the most stable being +III and +VI, but Cr(III) are easily converted into Cr(VI) during combustion, with the oxidizing condition prevailing [30]. In general, Cr(VI) shows higher toxicity than Cr(III). Because the oxidation state +VI is more stable than +III at higher pH values in an aqueous solution [33], ash leachate often exceeds the limit value for Cr(VI) [30]. Moreover, the contamination of Cr from furnace walls has also been suspected [11, 14, 32]. Simultaneous occurrence of Cr and Ni in studied ashes (Table 4) supports the suspicion of contamination. However, such contamination can be reduced by lining the walls of the furnace with ceramics [14, 32]. Finally, the reason for the presence of highly soluble As in the ash No. 15 was unknown. One explanation may be the co-combustion of wood from demolition or chromated copper arsenate (CCA) preserved wood because ash No. 15 also contains relatively higher amounts of Cr and Cu, as well as As, compared to the others (Table 3). To prevent the contamination of hazardous substances, checks on safety of the feedstock of fuel should be necessary.

Nevertheless, the phytoavailability of Pb, Cr, and As in ashes appeared low compared to that predicted by the leaching amounts in water (the JLT18 solution) because of the amphoteric leaching behavior. When the ash dissolves in an acid environment like a forest soil, the alkalinity of the ash is consumed and the hazardous elements are exposed to a pH far lower than in ash, reducing their solubility. Moreover, under the soil environment, Cr(VI) will react with humic acid and revert to an oxidation state +III [34]. Therefore, to control the leaching amount of these hazardous substances, setting an adequate application dose considering the soil-dependent solubility of ash is crucial.

Our results also suggest that the methods compared in this study have its merit and demerits for evaluating the property of wood combustion residues as fertilizer. For most of chemically synthesized fertilizers of Japan, their performance and risk have been evaluated by the total amount of nutrients and hazardous substances under the Japanese Fertilizer Control Act [9]. However, the comprehensive characteristics of wood ashes will not be evaluated solely by information on the total amount, because of their complex chemical mixture. For instance, as discussed above, the total amount of K in the ash cannot always become plant available immediately after application, particularly bark ashes with low water-soluble K: effective K concentration in ash would be overestimated by the test of total amount. In addition, the phytoavailability of hazardous substances with amphoteric behavior might be overestimated by the leaching test using water. To evaluate the performance and risk of wood combustion residues as fertilizer, more studies including the leaching tests of ash-applied soils and plant growth tests will be needed.

Conclusions

To evaluate the characteristics of wood ash as fertilizer, composition of inorganic element and the leaching behavior was investigated for biomass combustion ashes from wood pellet boilers in Japan. The main results are listed below.

-

1.

Ash composition varied according to raw materials for fuel and ash collecting systems.

-

2.

Bark ashes tended to show high Na, Al, Si, and V concentration while wood ashes tended to show high K concentration.

-

3.

Pb, Cd, Se, and Zn were more volatile and enriched in fly ashes.

-

4.

Of the major nutrient elements, K showed high water solubility and its phytoavailability also appeared high, although the amount of water-soluble K was low in bark ash. Ca and Mg had intermediate solubility while P was less soluble in both water and acetic acid.

-

5.

The amount of hazardous substances was low for most, but not all the ashes, suggesting the need for analytical checks before applying the ash to land.

-

6.

Of the studied ashes, simultaneous concentration of Cr and Ni was observed. Since these metals were frequently used for coating of stainless steel, the contamination from furnace was suspected.

-

7.

The phytoavailability of hazardous substances such as Pb, Cd, Se, Cr, and As in ashes after their application to the forest appeared low, due to their amphoteric leaching behavior and the acidity of Japanese forest soils.

References

The Ministry of Agriculture, Forestry and Fisheries of Japan (2011) Annual report on trends in forests and forestry, fiscal year 2010 (in Japanese), p 30

The Ministry of Internal Affairs and Communications of Japan (2011) Evaluation report on Japanese policy to biomass utilization (in Japanese), p 38

Campbell AG (1990) Recycling and disposing of wood ash. Tappi J 73:141–146

Karltum E, Saarsalmi A, Ingerslev M, Mandre M, Andersson S, Gaitnieks T, Ozolinčius R, Varnagiryte-Kabasinskiene I (2008) Wood ash recycling-possibility and risks. In: Röser D, Asikainen A, Raulund-Rasmussen K, Stupak I (eds) Sustainable use of forest biomass for energy: a synthesis with focus on the Baltic and Nordic Region. Springer, The Netherlands, pp 79–108

Someshwar AV (1996) Wood and combination wood-fired boiler ash characterization. J Environ Qual 25:962–972

Pitman RM (2006) Wood ash use in forestry—a review of the environmental impacts. Forestry 79:563–588

Agusto MR, Bakker C, Meredieu C (2008) Wood ash application to temperate forest ecosystems—potential benefit and drawbacks. Plant Soil 306:181–198

Stupak I, Asikainen A, Röser D, Pasanen K (2008) Review of recommendations for forest energy harvesting and wood ash recycling. In: Röser D, Asikainen A, Raulund-Rasmussen K, Stupak I (eds) Sustainable use of forest biomass for energy: a synthesis with focus on the Baltic and Nordic Region. Springer, The Netherlands, pp 155–196

Sugiura K, Yamamoto A, Kawamura K, Asaki H (2007) Creation of the food and agricultural material inspection center in Japan. Vet Ital 43(4):799–806

JETRO (2010) Handbook for industrial products import regulations 2009, http://www.jetro.go.jp/en/reports/regulations/pdf/industrial2009e_1007p.pdf. Accessed 15 May 2012

Sano T, Miura S, Furusawa H, Kaneko S, Yoshida T, Nomura T, Ohara S (2011) Leaching characteristic of wood pellet combustion residues from different combustion equipments. In: Proceedings of the European biomass conference and exhibition, vol 19, pp 1836–1840

Tsuchiya Y, Shimogaki H (2010) Evaluation of environmental safety for woody biomass ash-Leaching characteristics of woody biomass ash after low temperature combustion (in Japanese). Environmental Science Research Laboratory Rep. No. V08016

Takahashi T, Tomiyama K, Wakasugi, M (2008) Effective utilization and evaluation of toxic substance for woody biomass combustion ash (in Japanese). In: Annual report of Hokkaido Industrial Research Institute, vol 307, pp 59–67

Sogawa K, Sadao Y (2009) Surveillance study to recycle wood pellet combustion ash properly and safely (in Japanese). In: Annual report of Kochi Prefectural Environmental Research Center, vol 26, pp 17–23

Ministry of the Environment Government of Japan (2007) Soil contamination countermeasures. http://www.env.go.jp/en/water/soil/contami_cm.pdf. Accessed 15 May 2012

United States Environmental Protection Agency (1992) Method 1311 Toxicity characteristic leaching procedure, http://www.epa.gov/wastes/hazard/testmethods/sw846/pdfs/1311.pdf. Accessed 15 May 2012

Bostrom D, Skoglund N, Grimm A, Boman C, Ohman M, Brostrom M, Backman R (2012) Ash transformation chemistry during combustion of biomass. Energy Fuels 26:85–93

Steenari BM, Lindqvist O (1997) Stabilisation of biofuel ashes for recycling to forest soil. Biomass Bioenergy 13:39–50

Kabata-Pendias A, Pendias H (2001) Trace elements in soils and plants, 3rd edition. CRC Press, Boca Raton, pp 234–238

Sano T, Miura S, Furusawa H, Kaneko S, Yoshida T, Ohara S (2012) Effect of ashing temperature on the ash content and its composition upon the combustion woody biomass (in Japanese with English summary). Wood Ind 67(6):252–257

Misra MK, Ragland KW, Baker AJ (1993) Wood ash composition as a function of furnace temperature. Biomass Bioenergy 4:103–116

Huang YJ, Jin BS, Zhong ZP, Xiao R, Tang ZY, Ren HF (2004) Trace elements (Mn, Cr, Pb, Se, Zn, Cd and Hg) in emissions from a pulverized coal boiler. Fuel Process Technol 86:23–32

Pedersen AJ, van Lith SC, Frandsen SD, Holgersen LB (2006) Release to the gas phase of metals, S and Cl during combustion of dedicated water fractions. Fuel Process Technol 91:1062–1072

Steenari BM, Marsic N, Karlsson LG, Tomsic A, Lindqvist O (1998) Long-term leaching of stabilized wood ash. Scand J For Res Suppl 2:3–16

Steenari BM, Karlsson LG, Lindqvist O (1999) Evaluation of the characteristics of wood ash and the influence of ash agglomeration. Biomass Bioenergy 16:119–136

Wang J, Wang T, Burken JG, Chusuei CC, Ban H, Ladwig K, Huang CP (2008) Adsorption of arsenic (V) onto fly ash: a speciation-based approach. Chemosphere 72:381–388

Bone BD, Barnard LH, Boardman DI, Carey PJ, Hills CD, Jones HM, MacLeod CL, Tyrer M (2004) Review of scientific literature on the use of stabilization/solidification for the treatment of contaminated soil, solid waste and sludges. Science Report, Environment Agency, Gov. UK. http://publications.environment-agency.gov.uk/PDF/SCHO0904BIFP-E-E.pdf. Accessed 15 May 2012

Gupta LP, Kawahata H, Takeuchi M, Ohta H (2005) Temperature and pH dependence of some metals leaching from fly ash of municipal solid waste. Resour Geol 55:357–372

Inoba S, Shimogaki H (2004) A laboratory study on leaching characteristics of As and Se from fly ash (in Japanese with English summary). Abiko Research Laboratory Report No. U03064

Pohlandt-Schwandt K (1999) Treatment of wood ash containing soluble chromate. Biomass Bioenergy 16:447–462

Pohlandt-Schwandt K, Salthammer T, Marutzky R (2002) Reduction of soluble chromate in wood ash by formaldehyde. Biomass Bioenergy 22:139–143

Sonoda T, Hotta M, Yonekura I, Miura M, Saito H (2006) Control technology of metal corrosion caused by wood pellet ash (in Japanese). J Local Indep Adm Agency Iwate Ind Res Inst 13:112–115

Kabata-pendias A, Mukherjee AB (2007) Trace elements from soil to humans. Springer, Berlin, pp 173–197

Nakayasu K, Fukushima M, Tanaka S, Sasaki K, Nakamura H (1999) Comparative studies of the reduction behavior of chromium (VI) by humic substances and their precursors. Environ Toxicol Chem 18:1085–1090

Acknowledgments

This study was supported by the Ministry of Agriculture, Forestry and Fisheries of Japan under the “Research and development projects for application in promoting new policy of Agriculture, Forestry and Fisheries (No. 21056)”. We also thank anonymous wood pellet production companies and the Japan Wood Pellet Association for ash samplings.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Sano, T., Miura, S., Furusawa, H. et al. Composition of inorganic elements and the leaching behavior of biomass combustion ashes discharged from wood pellet boilers in Japan. J Wood Sci 59, 307–320 (2013). https://doi.org/10.1007/s10086-013-1337-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-013-1337-3