Abstract

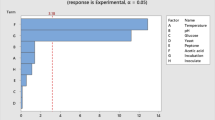

Central composite rotatable design of RSM was used for the optimization of medium composition for pullulan production from de-oiled rice bran by Aureobasidium pullulans in shake-flask fermentations. The sugars from de-oiled rice bran were extracted in distilled water under moist steam pressure and the obtained de-oiled rice bran extract (DRBE) was used for the optimization of medium composition. RSM optimized medium components (DRBE sugars, 3.88%; yeast extract, 0.24%; (NH4)2SO4, 0.06%; K2HPO4, 0.57% (w/v), and pH, 5.22) supported 5.48% (w/v) pullulan production and 0.88 (A600/100) biomass yield. Coefficient of determination for pullulan production (0.99) and biomass yield (0.99) was close to 1.0 which justifies significance of model. Lack of fit for both responses was non-significant, which shows fitness of quadratic model. FTIR and NMR spectral attributes confirmed the structure of pullulan. XRD patterns verified the amorphous nature of pullulan. De-oiled rice bran was found as a potential substrate for pullulan production.

Similar content being viewed by others

References

Cheng KC, Demirci A, Catchmark MJ. Effects of plastic composite support and pH profiles on pullulan production in a biofilm reactor. Appl. Microbiol. Biotechnol. 86: 853–861 (2009).

Einhorn-Stoll U, Kunzek H. Thermoanalytical characterisation of processing dependent structural changes and state transitions of citrus pectin. Food Hydrocoll. 23: 40–52 (2009).

Gao W, Kim YJ, Chung CH, Li J, Lee JW. Optimization of mineral salts in medium for enhanced production of pullulan by Aureobasidium pullulans HP-2001 using an orthogonal array method. Biotechnol. Bioprocess Eng. 15: 837–845 (2010).

Goksungur Y, Ucan A, Guvenc U. Production of pullulan from beet molasses and synthetic medium by Aureobasidium pullulans. Turk. J. Biol. 28: 23–30 (2004).

Goksungur Y, Uzunogullari P, Dagbagli S. Optimization of pullulan production from hydrolysed potato starch waste by response surface methodology. Carbohydr. Polym. 83: 1330–1337 (2011).

Harvey LM. Production of microbial polysaccharides by continuous culture of fungi. Ph.D. Thesis, University of Strathclyde, Glasgow (1984).

Hilares RT, Resende J, Orsi AC, Ahmed MA, Lacerda MT, da Silva S.S, Santos JC. Exopolysaccharide (pullulan) production from sugarcane bagasse hydrolysate aiming to favor the development of biorefineries. Int. J. Biol. Macromol. 127: 169–177 (2019).

Hiorth M, Kjøniksen A-L, Knudsen KD, Sande SA, Nyström B. Structural and dynamical properties of aqueous mixtures of pectin and chitosan. Eur. Polym. J. 41: 1718–1728 (2005).

Kacuráková M, Capek P, Sasinkova V, Wellner N, Ebringerova A. FT-IR study of plant cell wall model compounds: pectic polysaccharides and hemicellulose. Carbohydr. Polym. 43: 195–203 (2000).

Lazaridou A, Biliaderis CG, Roukas T, Izydorczyk M. Production and characterization of pullulan from beet molasses using a nonpigmented strain of Aureobasidium pullulans in batch culture. Appl. Biochem. Biotechnol. 97: 1–22 (2002).

Li BX, Zhang N, Peng Q, Yin T, Guan FF, Wang GL, Li Y. Production of pigment-free pullulan by swollen cell in Aureobasidium pullulans NG which cell differentiation was affected by pH and nutrition. Appl. Microbiol. Biotechnol. 84: 293–300 (2009).

Mehta A, Prasad GS, Choudhury AR. Cost effective production of pullulan from agri-industrial residues using response surface methodology. Int. J. Biol. Macromol. 64: 252–256 (2014).

Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31: 426–428 (1959).

Ono K, Yasuda N, Ueda S. Effect of pH on pullulan elaboration by Aureobasidium pullulans S-1. Agric. Biol. Chem. 41: 2113–2118 (1977).

Reed-Hamer B, West TP. Effect of complex nitrogen-sources on pullulan production relative to carbon source. Microbios 80: 83–90 (1994).

Scott TA, Melvin EH. The determination of hexoses with anthrone. Anal. Biochem. 25: 1656–1658 (1953).

Sharmila G, Muthukumaran C, Nayan G, Nidhi B. Extracellular biopolymer production by Aureobasidium pullulans MTCC 2195 using jack fruit seed powder. J. Polym. Environ. 21: 487–494 (2013).

Shin CY, Kim YH, Lee HS, Kim YN, Byun SM. Production of pullulan by fed-batch fermentation. Biotechnol. Lett. 9: 621–624 (1987).

Singh RS, Saini GK. Pullulan-hyperproducing color variant strain of Aureobasidium pullulans FB-1 newly isolated from phylloplane of Ficus sp. Bioresour. Technol. 99: 3896–3899 (2008a).

Singh RS, Saini GK. Production, purification and characterization of pullulan from a novel strain of Aureobasidium pullulans FB-1. J. Biotechnol. 136: S506–S507 (2008b).

Singh RS, Saini GK. Biosynthesis of pullulan and its applications in food and pharmaceutical industry. Part 2, pp. 509–553. In: Microorganisms in Sustainable Agriculture and Biotechnology. Satyanarayana T, Johri BN, Prakash A (eds). Springer Science + Business Media B.V. (2012).

Singh RS, Saini GK. Pullulan as therapeutic tool in biomedical applications. pp. 263–291. In: Advances in Industrial Biotechnology. Singh RS, Pandey A, Larroche C (eds). IK International Publishing House Pvt. Ltd., India (2014).

Singh RS, Kaur N. Microbial biopolymers for edible film and coating applications. pp. 187–216. In: Advances in Biotechnology. Nawani NN, Khetmalas M, Razdan PN, Pandey A (eds). IK International Publishing House Pvt. Ltd., India (2015).

Singh RS, Kaur N. Biochemical and molecular characterization of a new pullulan producer Rhodosporidium paludigenum PUPY-06. J. Appl. Biol. Biotechnol. 6: 28–37 (2018).

Singh RS, Saini GK, Kennedy JF. Pullulan: microbial sources, production and applications. Carbohydr. Polym. 73: 515–531 (2008).

Singh RS, Saini GK, Kennedy JF. Downstream processing and characterization of pullulan from a novel colour variant strain of Aureobasidium pullulans FB-1. Carbohydr. Polym. 78: 89–94 (2009a).

Singh RS, Singh H, Saini GK. Response surface optimization of the critical medium components for pullulan production by Aureobasidium pullulans FB-1. Appl. Biochem. Biotechnol. 152: 42–53 (2009b).

Singh RS, Kaur N, Kennedy JF. Pullulan and pullulan derivatives as promising biomolecules for drug and gene targeting. Carbohydr. Polym. 123: 190–207 (2015).

Singh RS, Kaur N, Rana V, Kennedy JF. Recent insights on applications of pullulan in tissue engineering. Carbohydr. Polym. 153: 455–462 (2016).

Singh RS, Kaur N, Rana V, Kennedy JF. Pullulan: a novel molecule for biomedical applications. Carbohydr. Polym. 171: 102–121 (2017).

Singh RS, Kaur N, Sharma R, Rana V. Carbamoylethyl pullulan: QbD based synthesis, characterization and corneal wound healing potential. Int. J. Biol. Macromol. 118: 2245–2255 (2018).

Soppirnath KS, Aminabhavi TM. Water transport and drug release study from cross-linked polyacrylamide grafted guar gum hydrogel microspheres for the controlled release application. Eur. J. Pharm. Biopharm. 53: 87–98 (2002).

Srikanth S, Swathi M, Tejaswini M, Sharmila G, Muthukumarana C, Jaganathan MK, Tamilarasan K. Statistical optimization of molasses based exopolysaccharide and biomass production by Aureobasidium pullulans MTCC 2195. Biocatal. Agric. Biotechnol. 3: 7–12 (2014).

Sunphorka S, Chavasiri W, Oshima Y, Ngamprasertsith S. Protein and sugar extraction from rice bran and de-oiled rice bran using subcritical water in a semi-continuous reactor: optimization by response surface methodology. Int. J. Food Eng. 8: https://doi.org/10.1515/1556-3758.2262 (2012).

Thirumavalavan K, Manikkadan TR, Dhanasekar R. Pullulan production from coconut by-products by Aureobasidium pullulans. Afr. J. Biotechnol. 8: 254–258 (2009).

Trovatti E, Fernandes SCM, Rubatat L, Perez DDS, Freire CSR, Silvestre AJD, Neto CP. Pullulan-nanofibrillated cellulose composite films with improved thermal and mechanical properties. Compos. Sci. Technol. 72: 1556–1561 (2012).

Yoon S, Hong E, Kim S, Lee P, Kim M, Yang H, Ryu Y. Optimization of culture medium for enhanced production of exopolysaccharide from Aureobasidium pullulans. Bioprocess Biosyst. Eng. 35: 167–172 (2012).

Zhang C, Gao D, Ma Y, Zhao X. Effect of gelatin addition on properties of pullulan films. J. Food Sci. 78: C805-C810 (2013).

Acknowledgement

Authors acknowledge Head, Department of Biotechnology, Punjabi University, Patiala, for providing essential laboratory facilities to execute the present work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, R.S., Kaur, N. Understanding response surface optimization of medium composition for pullulan production from de-oiled rice bran by Aureobasidium pullulans. Food Sci Biotechnol 28, 1507–1520 (2019). https://doi.org/10.1007/s10068-019-00585-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-019-00585-w