Abstract

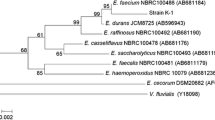

Amylolytic lactic acid bacterium (ALAB) strain S21 was isolated from Thai indigenous fermented rice noodles and identified as Lactobacillus plantarum, based on 16S rDNA sequence and recA gene analysis. L. plantarum S21 exhibited a specific growth rate (μ) of 0.24 1/h in modified MRS broth containing 10 g/L of starch as the sole carbon source, and a high efficacy in producing lactic acid (9.41, 24.48, 41.84, 74.33, and 94.04 g/L from 10, 25, 50, 75, and 100 g/L of cassava starch, respectively), which are higher values than previously reported for ALAB. Crude amylase from L. plantarum S21 had broad pH stability (3.5–8.0), and hydrolyzed starch to maltose and glucose as the major and minor products. L. plantarum S21 should be considered useful for industrial bioconversion of starch to lactic acid.

Similar content being viewed by others

References

Miller C, Fosmer A, Rush B, McMullin T, Beacom D, Suomimen P. Industrial production of lactic acid. pp. 179–188. In: Comprehensive Biotechnology. Moo-Yong M (ed). Elsevier, Amsterdam, The Netherlands (2011)

John RP, Anisha GS, Nampoothiri KM, Pandey A. Direct lactic acid fermentation: Focus on simultaneous saccharification and lactic acid production. Biotechnol. Adv. 27: 145–152 (2009)

Wee YJ, Kim JN, Ryu HW. Biotechnological production of lactic acid and its recent applications. Food Technol. Biotechnol. 44: 163–172 (2006)

Abdel-Rahman MA, Tashiro Y, Sonomoto, K. Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: Overview and limits. J. Biotechnol. 156: 286–301 (2011)

Reddy G, Altaf Md, Naveena BJ, Venkateshwar M, Vijay Kumar E. Amylolytic bacterial lactic acid fermentation-A review. Biotechnol. Adv. 26: 22–34 (2008)

Ohkouchi Y, Inoue Y. Direct production of l(+)-lactic acid from starch and food wastes using Lactobacillus manihotivorans LMG18011. Bioresource Technol. 97: 1554–1562 (2006)

Shibata K, Flores DM, Kobayashi G, Sonomoto K. Direct lactic acid fermentation with sago starch by a novel amylolytic lactic acid bacterium, Enterococcus faecium. Enzyme Microb. Technol. 41: 149–155 (2007)

Xiaodong W, Xuan G, Rakshit SK. Direct fermentation of lactic acid from cassava or other starch substrates. Biotechnol. Lett. 9: 841–843 (1997)

Holt JG. Bergey’s Manual of Determinative Bacteriology. 9th ed. Williams and Wilkins, Baltimore, MD, USA. pp. 559–567 (1994)

Nishiguchi MK, Doukakis P, Egan M, Kizirian D, Phillips A, Prendini L, Rosenbaum HC, Torres E, Wyner Y, DeSalle R, Giribet G. DNA isolation procedures. pp. 249–287. In: Techniques in Molecular Systematics and Evolution. Desalle GR, Garibet G, Wheeler W (eds). Birkhäuser Verlag Basel, Switzerland (2002)

Thompson JD, Gibson TJ, Plewniak, Jeanmougin F, Higgins DG. The CLUSTAL_X windows interface: Flexible strategies for multiple sequence alignment aided by quality analysis tools. Nucleic Acids Res. 25: 4876–4882 (1997)

Page RDM. TreeView: An application to display phylogenetic trees on personal computers. Comput. Appl. Biosci. 12: 357–358 (1996)

Torriani S, Felis G, Dellaglio F. Differentiation of Lactobacillus plantarum, L. pentosus, and L. paraplantarum by recA gene-derived primers. Appl. Environ. Microbiol. 67: 3450–3454 (2001)

Miller GL. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31: 426–428 (1959)

Dobois M, Gilles KA, Hamilton JK, Rebers PA, Rebers PA. Colorimetric method for determination of sugar and related substances. Anal. Chem. 28: 350–356 (1956)

Litchfield JH. Lactic acid microbially produced. pp. 362–372. In: Encyclopedia of Microbiology. Schaechter M (ed). Elsevier, Oxford, UK (2009)

Fu W, Mathews AP. Lactic acid production from lactose by Lactobacillus plantarum: Kinetic model and effects of pH, substrate and oxygen. Biochem. Eng. J. 3: 163–170 (1999)

Giraud E, Lelong B, Raimbault M. Influence of pH and initial lactate concentration on the growth of Lactobacillus plantarum. Appl. Microbiol. Biotechnol. 36: 96–99 (1991)

Keatkrai J, Jirapakkul W. Volatile profile of Khanom-Jeen, Thai fermented rice noodles and the changes during the fermentation process. J. Soc. Sci. Thailand 36: 46–51 (2010)

Leroy F, Vuyst LD. Growth of the bacteriocin-producing Lactobacillus sakei strain CTC 494 in MRS broth is strongly reduced due to nutrient exhaustion: A nutrient depletion model for the growth of lactic acid bacteria. Appl. Environ. Microbiol. 67: 4407–4413 (2001)

Kwon S, Lee PC, Lee EG, Chang YK, Chang N. Production of lactic acid by Lactobacillus rhamnosus with vitamin-supplemented soybean hydrolysate. Enzyme Microb. Technol. 26: 209–215 (2000)

Castillo Martinez FA, Balciunas EM, Salgado JM, Dominguez-Gonzalez JM, Converti A, de Souza Oliveira RP. Lactic acid properties, applications and production: A review. Trends Food Sci. Technol. 30: 70–83 (2013)

Giraud E, Champailler A, Raimbault M. Degradation of raw starch by a wild amylolytic strain of Lactobacillus plantarum. Appl. Environ. Microbiol. 60: 4319–4323 (1994)

Panda SH, Ray RC. Direct conversion of raw starch to lactic acid by Lactobacillus plantarum MTCC 1407 in semi-solid fermentation using sweet potato (Ipomoea batatas L.) flour. J. Sci. Ind. Res. 67: 531–537 (2008)

Vishnu C, Seenayya G, Reddy G. Direct fermentation of various pure and crude starch substrates to L(+) lactic acid using Lactobacillus amylophilus GV6. World J. Microbiol. Biotechnol. 18: 429–433 (2002)

Vishnu C, Seenaya G, Reddy G. Direct conversion of starch to L(+) lactic acid by amylase producing Lactobacillus amylophilus GV6. Bioprocess Eng. 23: 155–158 (2000)

Petrova P, Petrov K. Direct starch conversion into L-(+)-lactic acid by a novel amylolytic strain of Lactobaicllus paracasei B41. Starch 64: 10–17 (2012)

Petrov K, Urshev Z, Petrova P. L(+)-lactic acid production from starchy a novel amylolytic Lactobacoccus lactis subsp. lactis B84. Food Microbiol. 25: 550–557 (2008)

Narita J, Nakahara S, Fukuda H, Kondo A. Efficient production of L(+)-lactic acid from raw starch by Streptococcus bovis 148. J. Biosci. Bioeng. 97: 423–425 (2004)

Chaplin MF, Bucke C. Enzyme Technology. Press Syndicate of the University of Cambridge, New York, NY, USA. pp. 2–39 (1990)

Enache M, Popescu G, Dumitru L, Kamekura M. The effect of Na+/Mg2+ ratio on the amylase activity of haloarchaea isolated from Techirghiol Lake, Romania, a low salt environment. Proc. Rom. Acad. Series B Chem. Life. Sci. Geosci. 1: 3–7 (2009)

Santoyo MC, Loiseau G, Sanoja RR, Guyot JP. Study of starch fermentation at low pH by Lactobacillus fermentum Ogi E1 reveals uncoupling between growth and α-amylase production at pH 4.0. Int. J. Food Microbiol. 80: 77–87 (2003)

Aguilar G, Morlon-Guyot J, Trejo-Aguilar B, Guyot JP. Purification and characterization of an extracellular α-amylase produced by Lactobacillus manihotivorans LMB 18010T, an amylolytic lactic acid bacterium. Enzyme Microb. Technol. 27: 406–413 (2000)

Burgess-Cassler A, Imam S. Partial purification and comparative characterization of α-amylase secreted by Lactobacillus amylovorus. Curr. Microbiol. 23: 207–213 (1991)

Sajedi RH, Naderi-Manesh H, Khajeh K, Ahmadvand R, Ranjbar B, Asoodeh A, Moradian F. A Ca-independent α-amylase that is active and stable at low pH from Bacillus sp. KR-8104. Enzyme Microb. Technol. 36: 666–671 (2005)

Sharma A, Satyanarayana T. Microbial acid-stable α-amylases: Characteristics, genetic engineering and applications. Process Biochem. 48: 201–211 (2013)

Andersson U, Radstrom P. β-Glucose 1-phosphate-interconverting enzymes in maltose- and trehalose-fermenting lactic acid bacteria. Environ. Microbiol. 4: 81–88 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kanpiengjai, A., Rieantrakoonchai, W., Pratanaphon, R. et al. High efficacy bioconversion of starch to lactic acid using an amylolytic lactic acid bacterium isolated from Thai indigenous fermented rice noodles. Food Sci Biotechnol 23, 1541–1550 (2014). https://doi.org/10.1007/s10068-014-0210-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-014-0210-5