Abstract

Aggregates are necessary materials for the construction industry. Owing to their favourable properties, andesites are frequently used rock materials; hence, the investigation of their mechanical and aggregate properties has great significance. This paper introduces the analyses of 13 Hungarian andesite lithotypes. The samples were collected from six andesite quarries in Hungary. Cylindrical specimens and aggregate samples with 10.0/14.0-mm-sized grains were made from rock blocks. The specimens were tested in dry, water-saturated and freeze–thaw subjected conditions. Bulk density, uniaxial compressive strength, modulus of elasticity, indirect tensile strength and water absorption were measured. The abrasion resistance was tested by micro-Deval tests. The flakiness indexes of the samples were also measured. The data set of the laboratory test results provided input for further, one- and two-variable statistical analyses. According to the test results, there is no significant difference between the strength parameters measured in water-saturated and in freeze–thaw subjected conditions. The correlation and regression analyses revealed relationships between some rock mechanical parameters, as well as between micro-Deval coefficient and uniaxial compressive strength.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural stones are essential building materials, as they are used as dimension stones and aggregates (Přikryl 2017). Their applicability is controlled by their mechanical properties. Andesite, which is one of the most common igneous rock types in Hungary, has favourable properties. It is often used as aggregate, in concrete (Zhang et al. 2013; Beushausen and Dittmer 2015), road (Xu et al. 2015; Kong et al. 2017) and railway constructions (Gálos and Kárpáti 2007; Ferestade et al. 2017), or as armour stone in hydraulic engineering (Ertas and Topal 2008; Ozden and Topal 2009).

Numerous test methods have been introduced to evaluate the aggregate properties: the polished stone value (PSV) test (Szatkowski and Hoskings 1972; Descantes and Hamard 2015), the aggregate impact (AIV) test (Afolagboye et al. 2017), the aggregate crushing value (ACV) test (Shipway 1964; Palassi and Danesh 2016), the Nordic test (Eerola et al. 1982; Erichsen et al. 2011), the Hummel test (Hummel 1954; Reznák et al. 1982), the Stübel test (Reznák and Ács 1965), the slake durability test (Hudec 1978; Ghobadi and Babazadeh 2015; Miščević and Vlastelica 2011) and many more. Nowadays, the Los Angeles (Woolf and Runner 1935; Räisänen and Torppa 2005; Ajalloeian and Kamani 2017) and the micro-Deval tests (L’Haridon 1965; Tourenq 1971; Czinder and Török 2017; Liu et al. 2017) are the most common aggregate tests in Europe. Both of them apply rotating drums, and the test results are the ratio of the fragmented/abraded and the original mass of the sample. The micro-Deval test, which is also the focus of the present paper, was developed in the 1960s in France (Tourenq 1971; Hanna et al. 2003), and a multitude of test results have been gained to date. New test methods are also developed to investigate specific properties of the aggregates, for example, Fischer (2017) introduced a new laboratory test method, namely, the laboratory pulsating test, to evaluate the railway ballast breakage more realistically than Los Angeles and micro-Deval tests do.

The correlations between the different rock mechanical parameters have been studied thoroughly. Correlation between the uniaxial compressive strength (UCS) and modulus of elasticity (Marek and Szabó-Balog 1987; Dinçer et al. 2004; Görög 2007; Engidasew and Barbieri 2014; Török and Czinder 2017), between bulk density and UCS (Marek and Szabó-Balog 1987; Siratovich et al. 2012; Török and Czinder 2017) and between the point load index and UCS (Rigopoulos et al. 2013; Kahraman 2014; Karaman et al. 2015) has been found. The relations among aggregate properties can be also investigated by correlation analyses. Links were suggested between the LA test results and the micro-Deval coefficients (MDE) (Xirouchakis 2013; Tabatai et al. 2013; Török 2015); between the PSV, MDE and LA values (Đokić et al. 2015); between the LA, AIV and ACV values (Al-Harthi 2001; Fowler et al. 2006; Palassi and Danesh 2016); and between the MDE and Deval values (Emszt 2005). Applying different standards to the same aggregate test leads to test results that are difficult to compare. Gökalp et al. (2016) made MDE tests according to the EN and ASTM standards and compared the abrasion losses.

The rock mechanical and aggregate properties also showed dependence. Interrelation was found between LA and bulk density (Ugur et al. 2010). According to numerous studies, UCS correlates with LA (Al-Harthi 2001; Kahraman and Fener 2007; Ugur et al. 2010; Rigopoulos et al. 2013) and MDE (Capik and Yilmaz 2017).

The shape properties of the grains, namely the flakiness and the shape indexes, also affect the aggregate properties. The effects were analysed by Los Angeles (Kausay 1971a; Kausay 1971b) and micro-Deval tests as well (Rigopoulos et al. 2013; Bobály and Gálos 2016). According to the results, the flaky grains reduce the resistance to abrasion or fragmentation. Guo et al. (2018) studied the effect of grain size and shape on resistance to fragmentation with image analysis. Imaging techniques were also used to measure and describe the aggregate shape properties (Profitis et al. 2012, 2013) or the grain size (Profitis et al. 2013). According to Wang et al. (2015), correlation was found between gradient angularity and MDE values.

Mineralogical properties affect rock mechanical and aggregate properties. The micro-fabric (Přikryl 2001, 2013), micro-cracks (Freire-Lista et al. 2015; Freire-Lista and Fort 2017), pore size and the interconnections of pores (Benavente et al. 2004; Germinario and Török 2019) significantly affect rock durability and weathering. In the case of andesitic rocks, the relative abundance of phenocrysts affects UCS (Ündül 2016). The inverse proportional effect was found between the mean grain size (crystal size) of the rock material and UCS, and the connection was described by linear (Yılmaz et al. 2011; Khanlari et al. 2015) and logarithmic (Přikryl 2001) functions. The size of quartz and plagioclase grains has significant positive effect, and the grain size of the biotite has negative effect on indirect tensile strength (Yılmaz et al. 2015). The mineralogical composition (Pang et al. 2010) and wearing of the rocks (Erichsen et al. 2011) as well as weathering (Miščević and Vlastelica 2019) also affect aggregate properties. The increasing amount and decreasing average grain size of hornblendes reduce the resistance to fragmentation (Räisänen 2004). Relationships were also found between the amount of the aluminium, sodium and iron oxides and LA coefficient in the case of sandstones (Tugrul and Yılmaz 2012). Textural properties can affect the physical and mechanical properties as well (Afolagboye et al. 2016), as Wang et al. (2015) obtained a relationship between the change of the texture index and the micro-Deval coefficient. The porosity or water absorption may also affect the MDE values (Rogers et al. 1991; Capik and Yilmaz 2017; Holleran et al. 2017).

Recent paper introduces the results of a research what is dealing with strength and aggregate properties of andesites. The statistical investigation uses previous (Török and Czinder 2017) and new laboratory test results.

Materials

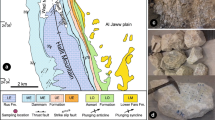

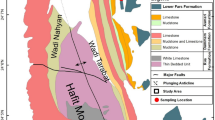

In this study, 13 andesite lithotypes from different parts of Hungary were analysed. The andesite samples were mainly obtained from operating quarries of Hungary (Fig. 1). Seven lithotypes were from the Mátra Mountains (three from Gyöngyössolymos, two from Gyöngyöstarján and one from Recsk), two lithotypes were from the Mecsek Mountains (Komló) and four lithotypes were from the Zemplén Mountains (Sárospatak). The andesites of the most important quarries of Hungary were involved in the research.

The tested andesite shows a wide range of lithological characteristics (Table 1). Their micro-fabric ranges from porphyric hyalopilitic, porphyric slightly pilotaxitic to porphyric holocrystalline (Fig. 2).

Microscopic images of selected andesite types. a Andesite 1—Gyöngyössolymos. b Andesite 4—Gyöngyöstarján. c Andesite 7—Komló. d Andesite 8—Nógrádkövesd. e Andesite 9—Recsk. f Andesite 13—Sárospatak. All images were taken with single polar, except image e where crossed polars were used (scale bar 0.5 mm) (compare the textural descriptions given in Table 1)

Methods

Laboratory tests

The laboratory tests involved both strength tests (carried out on regularly shaped specimens) and the analyses of aggregate properties. The cylindrical specimens were drilled from rock blocks and cut with cutting disc. The cut surface of the specimens was polished. The aggregate test samples were prepared by crushing the rock blocks and sieving. The samples were grouped by block. The cylindrical specimens were tested in dry (D), water-saturated (W) and freeze–thaw (F–T) subjected conditions.

The cylindrical specimens were grouped according to the bulk density and the propagation speed of the ultrasonic wave. The measured strength parameters included the uniaxial compressive strength (UCS), indirect tensile strength (σt) and modulus of elasticity (E). The UCS values were calculated with the following equation:

where UCS is the modified compressive strength value recalculated from specimens with a diameter of 50 mm and a height of 100 mm, UCSm is the measured compressive strength value, d is the diameter and h is the height of the specimen (Hoek and Brown 1980; Gálos and Vásárhelyi 2006). The freeze–thaw subjected specimens were analysed after 50 F–T cycles. The water absorption and weight loss caused by the F–T cycles were also measured. The tests were carried out according to the relevant European and American standards (Table 2).

The abrasive properties were analysed by the micro-Deval abrasion test. Five hundred grams of 10.0/14.0-mm-sized samples (10.0/11.2 mm, 150 g; 11.2/14.0 mm, 350 g) were used. The samples are loaded in steel drums (height, 154 mm; diameter, 200 mm) and rotated by 12,000 times with a 100 rot/min rate. The abrasive impact is provided by 1500 ml water and 5000-g steel balls (diameter, 10 mm). The abraded samples should be washed and sieved on a 1.6-mm sieve. The result of the test is the micro-Deval coefficient (MDE), which is the ratio of the abraded mass and the original mass of the test sample in percentage by mass. The micro-Deval tests were carried out according to the EN 1097-1:2012 standard (Tests for mechanical and physical properties of aggregates. Part 1: Determination of the resistance to wear—micro-Deval).

The flakiness index (FI) of the samples was also measured. The relevant European standard (EN 933-3:2012—Tests for geometrical properties of aggregates. Part 3: Determination of particle shape. Flakiness index) prescribes the investigation of particle size fractions of 10.0/12.5 mm or 12.5/16.0 mm with bar sieves at a slot width of 6.3 mm or 8.0 mm. Since there is no suggestion in the standard to the investigation of the particle size fraction of 10.0/14.0 mm, the flakiness of some samples was determined with grid sieve at a 6.3-mm slot width and others with sieves at a 8.0-mm slot width. Flakiness index is the proportion of the mass that passed the bar sieve and the total mass of the sample denoted in percentage by mass. Both FI and MDE tests were made in pairs. Their average value was used in further analyses.

The laboratory tests, the number of test results and the relevant standards are shown in Table 2. The D, W and F–T subjected conditions are not divided here. Altogether, 777 cylindrical specimens were created and measured.

Statistical analyses

The laboratory test results provided the database for further statistical analyses, for which Microsoft Excel as well as IBM SPSS Statistics 22 were used. The one-variable analyses included the determination of the statistical indices: minimum, average, maximum and median values, standard deviation, coefficient of variation (which is the ratio of the standard deviation and the average value, a coefficient without dimension) and number of the results.

Outliers were excluded from the data set in two steps. First, the UCS values were analysed based on their stress–strain curves. In some cases, micro-cracks reduced the UCS of the specimens, which had a visible effect on the irregular shape of the stress–strain curve (Fig. 3). In those cases, the measured UCS values were not representative and, therefore, the values were excluded from the data set. The second step was the selection of the outlier elements by analyses of the outliers according to the dispersion (described by the interquartile range) of the studied parameter. Boxplot diagrams (Fig. 4) were used. The grey box represents the interquartile range, the line across that is the median. Outliers are signed with circles, the difference between them and the edge of the interquartile box is less than the treble of the interquartile range, but more than 1.5 times of it. The outliers, which do not satisfy this criterion, are the extreme outliers and are marked by stars (Sajtos and Mitev 2007). The extreme outliers were excluded from further statistical analyses in all cases.

The significance of the difference between the strength parameters in D, W and F–T conditions was analysed by Welch’s t test. Welch’s test is a two-sample statistical test, which is suitable to investigate the equality of the mean values of two independent variables at a certain significance level. The test does not require the equality of the standard deviations of the studied random variables (Bolla and Krámli 2006). The Welch’s t test was applied if the number of elements reached 3. In other cases, the investigation of the equality of two groups of results was controlled by the average values and the distributions of them.

The interrelations of the different variables were analysed by correlation and regression analyses. The average values of the results determined for each rock blocks and each rock type were managed separately. The strength of a relationship was described by the R2 value.

Results and discussion

According to the evaluation of the stress–strain curves of the compressive tests, 19 UCS and E values were excluded from the database. Test results were also excluded from further research based on the analyses of the outliers (Table 3).

Previous studies have shown that strength reduction can be observed after water saturation (limestones: Ertas and Topal 2008; Török and Vásárhelyi 2010) and freeze–thaw testing (andesites: Fener and İnce 2015; Yavuz 2011). According to the current results of the Welch’s t tests, there is no significant difference between the strength parameters (UCS, E, σt) measured in W and F–T conditions on the significance level of 0.05, with the exception of E of andesite-8, as well as UCS, E and σt of andesite-9. On the 0.01 significance level, there are no significant differences between these parameters in W and F–T conditions. In consequence, the strength parameters of the W and F–T conditions were managed collectively in a united group (signed with U). The strength reduction (caused by the water saturation) changed in a wider range (andesite-9, 6%; andesite-4, 45%) (Fig. 5) according to the level of weathering. Similar results were measured on other andesite lithotypes (Zalooli et al. 2018); Fener and İnce (2015) detected 24% strength reduction after 30 F–T cycles, and Yavuz (2011) detected 8% after 30 and 13% after 50 cycles.

The highest uniaxial compressive strength and modulus of elasticity values were measured in the case of andesite-9 (Figs. 6 and 7). Contrary to what was suspected, andesite-9 provided lower indirect tensile strength than other lithotypes, and andesite-1, andesite-2, andesite-3 and andesite-6 produced higher values in dry conditions. The high uniaxial compressive strength and modulus of elasticity of andesite-9 can be attributed to the alteration, i.e. silicification, that modified the micro-fabric of the andesite.

The test results of the studied andesites are shown in Table 4. The test results were compared with previously published data sets of other lithotypes (Table 5). The highest UCS were measured on andesite-9 (271 MPa; detailed in this study), on basalt from Ethiopia (256 MPa; sample ID, 21; Engidasew and Barbieri 2014) and on a Turkish andesite (175 MPa; sample ID, 16; Engin 2013) (Fig. 8) in dry condition.

The uniaxial compressive strength of the different lithotypes (red columns: results of andesites; blue columns: results of other lithotypes; sample ID: according to Table 5)

Two-variable analyses

Two data sets were analysed in the course of the two-variable tests. Both included every test result; the difference is the groupage of them:

-

DS-1: The properties of the different rock blocks were managed separately. The mean values of the laboratory test results of 61 rock blocks were included in the investigation.

-

DS-2: The different lithotypes were managed separately. The mean values of the laboratory test results of 13 lithotypes were included in the investigation.

The evaluation of both data sets was necessary. On the one hand, the results of the investigations DS-2 are more general. On the other hand, the higher level of reliability was found at lithotypes where higher number of rock blocks were tested (DS-1).

In Figs. 10, 11, 12, 13, 14, 15, 16 and 17, the different colours mean the different origins of the studied andesites:

-

G—andesites from Gyöngyössolymos—andesite-1, andesite-2, andesite-3

-

GT—andesites from Gyöngyöstarján—andesite-4, andesite-5

-

K—andesites from Komló—andesite-6, andesite-7

-

N—andesite from Nógrádkövesd—andesite-8

-

R—andesite from Recsk—andesite-9

-

S—andesites from Sárospatak—andesite-10, andesite-11, andesite-12, andesite-13

In the case of the investigation of DS-1, the regression curves and the Pearson coefficients associated with the different origins are also presented. There is one exception, namely, the andesites from Gyöngyöstarján (andesite-4 and andesite-5) where only two data points were obtained from that group.

From the results of the correlation analyses, the R values are summarized in correlation matrices (Tables 6 and 7).

The correlation coefficient matrix of the strength parameters available in the literature (collected in Table 5) is represented in Table 8. The number of the related parameters (except the relationship between the bulk density and the uniaxial compressive strength) is not sufficient to perform the correlation analyses appropriately.

Similarly to previous studies, a strong linear correlation was found between bulk density measured in D and W conditions (Figs. 9 and 10), and the R2 value reached 0.98 (Török and Vásárhelyi 2010, R2 = 0.97; Török and Czinder 2017, R2 = 0.95–0.98). A relationship between the water absorption (wa) and the bulk density measured in dry condition (ρd) was found. It has been also proved for other lithotypes (Marek and Szabó-Balog 1987; Engidasew and Abay 2016; Török and Vásárhelyi 2010). The Pearson coefficients of the relationships between water absorption and the bulk densities are 0.831 (DS-1) and 0.879 (DS-2) (Fig. 11). The correlation between the wa and ρd values was found for the andesites of Komló (K), Recsk (R) and Sárospatak (S).

Multiple researchers have found relationships between UCS and E in the case of andesites (Dinçer et al. 2004; Török and Czinder 2017) and other lithotypes (Dinçer et al. 2004; Engidasew and Barbieri 2014). The currently studied andesites showed similar trends in dry condition (DS-1: R2 = 0.799; DS-2: R2 = 0.877) and in the case of the united group of W and F–T conditions (DS-1: R2 = 0.698; DS-2: R2 = 0.763). Lower R2 values can be observed if the Origin is considered as the initial point of the curve (Fig. 12). (D condition: DS-1: R2 = 0.699; DS-2: R2 = 0.745. U condition: DS-1: R2 = 0.401; DS-2: R2 = 0.540)

A positive linear relationship was found between the UCS values under the D and U conditions, which are in accordance with the results reported by Török and Vásárhelyi (2010). The Pearson coefficients are 0.868 (DS-1, Fig. 13) and 0.906 (DS-2, Fig. 14). While strong correlation was found by the investigation of every test result, the separate analyses of the andesites with different origins caused Pearson coefficients lower than 0.5 in every case and lower than 0.01 in the cases of andesite-8 (N—Nógrádkövesd) and andesite-9 (R—Recsk).

Indirect tensile strength did not show correlation with any other rock mechanical parameter. The highest value of Pearson coefficient (R) was 0.42 in the case of the investigation of the relationship between water absorption and indirect tensile strength, according to the data of DS-1.

According to previous studies, a correlation could be found between the rock mechanical parameters and the aggregate properties. In most cases, these correlations were described by logarithmic functions in both cases of UCS vs. LA links (Al-Harthi 2001, R2 = 0.78; Kahraman and Fener 2007, R2 = 0.50–0.96; Ugur et al. 2010, R2 = 0.80; Rigopoulos et al. 2013, R2 = 0.86) and UCS vs. MDE (Capik and Yilmaz 2017, R2 = 0.66). Previous studies (Al-Harthi 2001, R2 = 0.76; Török and Czinder 2017, R2 = 0.84) suggested that the interrelation between the UCS and MDE could be described by exponential forms too. In the frame of this study, the link between these parameters was sought in linear, logarithmic and exponential forms too (Table 9). The highest correlation was determined for the exponential equations. The values of the different lithotypes are summarized in Table 6 and are also plotted in Fig. 15.

Relationship between the uniaxial compressive strength values measured in dry (D) condition and the micro-Deval coefficient according to DS-1. Circles: andesites studied in this paper; crosses: test results of other lithotypes (the meaning of the sample IDs are available in Table 5)

The flakiness of the samples from Gyöngyössolymos (G) and Nógrádkövesd (N) was measured with a bar sieve with the slot of 6.3 mm and others with the 8-mm slotted bar sieve. The effect of the flakiness on the abrasion properties was investigated through the introduction of two variables. These variables were calculated according to the flakiness and micro-Deval test results (the latter ones were made in pairs):

where ΔFI and ΔMDE are the ratios of the flakiness indexes and micro-Deval test results which were made in pair, FI1 and MDE,1 are the test results of the sample with the smaller FI value in the pair and FI2 and MDE,2 are the test results of the sample with the higher FI value in the pair.

Previous studies (Rigopoulos et al. 2013; Bobály and Gálos 2016; Guo et al. 2018) suggested that the shape of the particles affect aggregate properties. Bobály and Gálos (2016) investigated railway ballast of andesite from Komló (Hungary). They found linear correlation between aggregate properties (Los Angeles and micro-Deval values) and shape indicators (flakiness and shape indexes), with R2 values within 0.526 and 0.800. They also revealed that the sum of FI and SI also correlates with the LA and MDE values. It suggests that flaky or elongated particles are more prone to cracking (Guo et al. 2018). For the ultramafic rocks a linear (R2 = 0.456), for trachyte and mafic rocks, a power function (R2 = 0.730) was used for the description of the interrelation between FI and MDE (Rigopoulos et al. 2013). The FI and SI values are not independent; a strong positive linear correlation was revealed between them (Xirouchakis 2013).

The minor lithological differences of the studied andesites are also reflected in the results. The porphyric holocrystalline andesites, andesite-6 and andesite-7 (Komló) and andesite-9 (Recsk) (Table 1), have the highest dry uniaxial strength (Fig. 5). However, these high strength values are not prerequisites of high MDE values, since it seems that later diagenetic processes such as silification can have a more substantial influence on aggregate quality (low MDE) than the primary micro-fabric which is the holocrystalline matrix. It is evidenced by comparing the results of Recsk andesite (andesite-9), which has the highest strength and best aggregate properties vs. the results of andesite-8 which also has holocrystalline micro-fabric, but low strength values and aggregate properties (Table 4). The basalt-like micro-fabric such as pilotaxitic texture can also increase the strength and durability of andesite. A good example of this is the andesite-3 which has slightly pilotaxitic micro-fabric, but only this fine crystalline variety of Gyöngyössolymos site has high quality, while the other two lithotypes of the same site (andesite-1 and andesite-2) have lower strength and aggregate quality due to the larger crystal size (Table 4).

The test results of the studied aggregates suggest that there is no link between abrasion properties and flakiness in the case of andesites with 10.0/14.0-mm-sized grains. The results of the sieve tests with neither 6.3 mm (Fig. 16) nor 8.0 mm sieves (Fig. 17) suggest any existing connection between these parameters. Negative ΔMDE values are attributed to those specimens, when higher MDE values were measured on the samples with lower FI. Negative values were observed in a relatively high amount, namely 44% of the measurements. These perceptions do not contradict the results of previous studies since Bobály and Gálos (2016) and Guo et al. (2018) dealt with aggregates with ballast-sized grains, while in this paper, aggregates with smaller particles were studied.

Conclusions

-

According to the test results, there is no significant difference between strength parameters (uniaxial compressive strength, modulus of elasticity, indirect tensile strength) measured in water-saturated and freeze–thaw subjected samples. These results were confirmed by Welch’s t tests.

-

Significant differences were observed between the different andesite lithotypes. The highest strength and the most favourable aggregate properties were measured at the andesite from Recsk: UCS = 271 MPa; MDE = 4 m%. This is closely linked to the micro-fabric, later post-volcanic processes, namely to the calcite cementation and silicification.

-

From the studied thirteen lithological varieties, andesite-3 from Gyöngyössolymos and andesite-9 from Recsk have the highest quality in terms of micro-Deval abrasion, due to their micro-fabric and/or diagenetic alteration.

-

Relationships were found between the rock mechanical parameters of the studied andesite. Linear correlations were obtained between:

-

1

Bulk densities measured in dry and water-saturated conditions

-

2

Water absorption and bulk density measured in dry condition

-

3

Uniaxial compressive strengths measured in dry and in the united conditions

-

4

Uniaxial compressive strength and modulus of elasticity both in dry condition and in the case of the united group of the water-saturated and freeze–thaw subjected conditions

The interrelations were detected if the whole data set of the test results was taken into account. In some cases, when the andesites of different micro-fabrics were analysed, no such connections were found.

-

1

-

The relationship between uniaxial compressive strength and micro-Deval coefficients was analysed using linear, logarithmic and exponential forms. In contrast to the results of the previous studies, where linear functions were found, the best Pearson coefficients were provided by exponential functions to describe the connection between rock mechanical and aggregate properties.

-

The flakiness and micro-Deval test results did not seem to have a link for the studied aggregates of 10.0/14.0 mm in size, although the relationship between them in the case of larger particle sizes was proved by previous studies.

-

Most of the studied andesites (except andesite-13 from Sárospatak) have favourable strength and abrasion properties. According to these tests, the Hungarian andesites are suitable materials of railway ballast, gabions, retaining walls, armour stone structures and aggregates in concrete or asphalt.

References

Afolagboye LO, Talabi AO, Akinola OO (2016) Evaluation of selected basement complex rocks from Ado-Ekiti, SW Nigeria, as source of road construction aggregates. Bull Eng Geol Environ 75:853–865. https://doi.org/10.1007/s10064-015-0766-1

Afolagboye LO, Talabi AO, Oyelami CA (2017) The use of index tests to determine the mechanical properties of crushed aggregates from Precambrian basement complex rocks, Ado-Ekiti, SW Nigeria. J Afr Earth Sci 129:659–667. https://doi.org/10.1016/j.jafrearsci.2017.02.013

Ajalloeian R, Kamani M (2017) An investigation of the relationship between Los Angeles abrasion loss and rock texture for carbonate aggregates. Bull Eng Geol Environ 9 p. https://doi.org/10.1007/s10064-017-1209-y

Al-Harthi AA (2001) A field index to determine the strength characteristics of crushed aggregate. Bull Eng Geol Environ 60:193–200. https://doi.org/10.1007/s100640100107

Benavente D, Garcia del Cura MA, Fort R, Ordónez S (2004) Durability estimation of porous building stones from pore structure and strength. Eng Geol 74:113–127

Beushausen H, Dittmer T (2015) The influence of aggregate type on the strength and elastic modulus of high strength concrete. Constr Build Mater 74:132–139. https://doi.org/10.1016/j.conbuildmat.2014.08.055

Bobály J, Gálos M (2016) Szemalak hatása a vasúti Los Angeles- és a vasúti mikro-Deval vizsgálatok eredményeire. (The effect of the grain shape on the results of the railway Los Angeles and micro-Deval test results – in Hungarian.). Sínek Világa 58(5):8–14

Bolla M, Krámli A (2006) Statisztikai következtetések elmélete. (Conception of the statistical conclusions – in Hungarian) Typotex Kiadó, Budapest. 406 p

Capik M, Yilmaz AO (2017) Modeling of micro Deval abrasion loss based on some rock properties. J Afr Earth Sci 134:549–556. https://doi.org/10.1016/j.jafrearsci.2017.04.006

Caricato A, Woods L, Mohan C (2010) Weathering of rock as armourstone: a case study on Bahrain limestone. In: In Proceedings of 32nd Conference on Coastal Engineering, 11 p. https://doi.org/10.9753/icce.v32.structures.32

Çelik MY, Aygün A (2019) The effect of salt crystallization on degradation of volcanic building stones by sodium sulfates and sodium chlorides. Bull Eng Geol Environ, 21 p. https://doi.org/10.1007/s10064-018-1354-y

Czinder B, Török Á (2017) Long-term durability tests of andesite aggregates from Hungary. Cent Eur Geol 60(3):333–343. https://doi.org/10.1556/24.60.2017.010

Deliormanlı AH (2012) Cerchar abrasivity index (CAI) and its relation to strength and abrasion test methods for marble stones. Constr Build Mater 30:16–21. https://doi.org/10.1016/j.conbuildmat.2011.11.023

Demirdag S (2013) Effects of freezing-thawing and thermal shock cycles on physical and mechanical properties of filled and unfilled travertines. Constr Build Mater 47:1395–1401. https://doi.org/10.1016/j.conbuildmat.2013.06.045

Descantes Y, Hamard E (2015) Parameters influencing the polished stone value (PSV) of road surface aggregates. Constr Build Mater 100:246–254. https://doi.org/10.1016/j.conbuildmat.2015.10.002

Dinçer I, Acar A, Çobanoğlu I, Uras Y (2004) Correlation between Schmidt hardness, uniaxial compressive strength and Young’s modulus for andesites, basalts and tuffs. Bull Eng Geol Environ 63:141–148. https://doi.org/10.1007/s10064-004-0230-0

Đokić O, Motavić V, Erić S, Šarić K (2015) Influence of engineering properties on Polished Stone Value (PSV): a case study on basic igneous rocks from Serbia. Constr Build Mater 101:1088–1096. https://doi.org/10.1016/j.conbuildmat.2015.10.033

Eerola M, Alkio R, Hobeda P (1982) Stenmaterial för vägbeläggningar : bestämning av slitstyrka. (Abrasion resistance to road paving aggregate – in Sweedish.) technical research Centre of Finland Tutkimuksia 55. 45 p

Emszt Gy (2005) Hazai ágyazati kőanyagok kőzetfizikai vizsgálata és minősítése. (Investigation and classification of Hungarian railway ballasts – in Hungarian.) Thesis work, Budapest University of Technology and Economics, Faculty of Civil Engineering, Specialization of Stone Structural Engineering

Engidasew TA, Abay A (2016) Assessment and evaluation of volcanic rocks used as construction materials in the City of Addis Ababa. Momona Ethiopian J Sci 8(2):193–212. https://doi.org/10.4314/mejs.v8i2.7

Engidasew TA, Barbieri G (2014) Geo-engineering evaluation of Termaber basalt rock mass for crushed stone aggregate and building stone from Central Ethiopia. J Afr Earth Sci 99:581–594. https://doi.org/10.1016/j.jafrearsci.2013.11.020

Engin IC (2013) Investigation on the usage of different rock aggregates as abrasive materials in natural stone aging process. Arab J Geosci 6:5043–5054. https://doi.org/10.1007/s12517-012-0714-3

Erichsen E, Ulvik A, Sævik K (2011) Mechanical degradation of aggregate by the Los Angeles-, the micro-Deval- and the Nordic test methods. Tock Mech Rock Eng 44:333–337. https://doi.org/10.1007/s00603-011-0140-y

Ertas B, Topal T (2008) Quality and durability assessments of the armourstones for two rubble mound breakwaters (Mersin, Turkey). Environ Geol 53:1235–1247. https://doi.org/10.1007/s00254-007-0712-z

Fener M, İnce İ (2015) Effects of the freeze–thaw (F–T) cycle on the andesitic rocks (Sille-Konya/Turkey) used in construction building. J Afr Earth Sci 109:96–106. https://doi.org/10.1016/j.jafrearsci.2015.05.006

Ferestade I, Hosseini Tehrani P, Heirady R (2017) Fracture toughness estimation of ballast stone used in Iranian railway. J Rock Mech Geotech Eng 9(5):892–899. https://doi.org/10.1016/j.jrmge.2017.03.017

Fischer S (2017) Breakage test of railway ballast materials with new laboratory method. Per Pol Civil Eng 61(4):794–802. https://doi.org/10.3311/PPci.8549

Fowler DW, Allen JJ, Lange A, Range P (2006) The prediction of coarse aggregate performance by micro-Deval and other aggregate tests. Research Report ICAR 507-1F. 616 p

Freire-Lista DM, Fort R (2017) Exfoliation microcracks in building granite. Implications for anisotropy. Eng Geol 220:85–93. https://doi.org/10.1016/j.enggeo.2017.01.027

Freire-Lista DM, Fort R, Varas-Muriel MJ (2015) Freeze–thaw fracturing in building granites. Cold Reg Sci Technol 113:40–51. https://doi.org/10.1016/j.coldregions.2015.01.008

Gálos M, Kárpáti L (2007) Testing of Hungarian aggregates for railway ballast according to MSZ EN 13450: 2003. Cent Eur Geol 50(4):353–361. https://doi.org/10.1556/CEuGeol.50.2007.4.5

Gálos M, Vásárhelyi B (2006) Kőzettestek osztályozása az építőmérnöki gyakorlatban. (Rock mass classification in the engineering geology practice – in Hungarian.) Műegyetem Kiadó, Budapest. 144 p

Germinario L, Török Á (2019) Variability of technical properties and durability in volcanic tuffs from the same quarry region – examples from Northern Hungary. Eng Geol 262. https://doi.org/10.1016/j.enggeo.2019.105319

Ghobadi MH, Babazadeh R (2015) An investigation on the effect of accelerated weathering on strength and durability of Tertiary sandstones (Qazvin province, Iran). Environ Earth Sci 73:4237–4250. https://doi.org/10.1007/s12665-014-3708-5

Gökalp İ, Uz VE, Saltan M (2016) Testing the abrasion resistance of aggregates including by-products by using micro-Deval apparatus with different standard test methods. Constr Build Mater 123:1–7. https://doi.org/10.1016/j.conbuildmat.2016.06.141

Görög P (2007) Characterization and mechanical properties of the Eocene Buda Marl. Cent Eur Geol 50(3):241–258. https://doi.org/10.1556/CEuGeol.50.2007.3.4

Guo Y, Markine V, Song J, Jing G (2018) Ballast degradation: effect of particle size and shape using Los Angeles Abrasion test and image analysis. Constr Build Mater 169:414–424. https://doi.org/10.1016/j.conbuildmat.2018.02.170

Hanna AN, Folliard K, Smith K (2003) Aggregate tests for Portland cement concrete pavements: review and recommendations. Research results digest, no. 281, NCHRP. 28 p

Hoek E, Brown ET (1980) Underground excavations in rock. The Institution of Mining and Metallurgy, London 532 p

Holleran I, Wilson DJ, Black P, Holleran G, Walubita LF (2017) Optimizing the durability of the coarse fraction of porous asphalt RAP for effective recycling. IOP Conf Ser Mat Sci Eng 236:012010. https://doi.org/10.1088/1757-899X/236/1/012010

Hudec PP (1978) Development of durability tests for shales in embankment and swamp backfills. Ontario Ministry of Transportation and Communications, Report. 51 p

Hummel A (1954) Die Ermittlung der Kornfestigkeit von Ziegelsplitt und anderen Leichtbeton-Zuschlagstoffen. (The determination of the particle strength of crushed brick and other lightweight concrete aggregates – in German). Deutscher-Ausschuss für Stahlbeton 114. 21 p

Jamshidi A, Nikudel MR, Khamehchiyan M (2016) Evaluation of the durability of Gerdoee travertine after freeze–thaw cycles in fresh water and sodium sulfate solution by decay function models. Eng Geol 202:36–43. https://doi.org/10.1016/j.enggeo.2016.01.004

Johansson E, Miskowsky K, Loorents KJ (2009) Estimation of rock aggregates quality using analyses of drill cuttings. J Mater Eng Perform 18(3):299–304. https://doi.org/10.1007/s11665-008-9284-7

Kahraman S (2014) The determination of uniaxial compressive strength from point load strength for pyroclastic rocks. Eng Geol 170:33–42. https://doi.org/10.1016/j.enggeo.2013.12.009

Kahraman S, Fener M (2007) Predicting the Los Angeles abrasion loss of rock aggregates from the uniaxial compressive strength. Mater Lett 61:4861–4865. https://doi.org/10.1016/j.matlet.2007.06.003

Karaman K, Kaya A, Kesimal A (2015) Use of the point load index in estimation of the strength rating for the RMR system. J Afr Earth Sci 106:40–49. https://doi.org/10.1016/j.jafrearsci.2015.03.006

Kausay T (1971a) Összefüggés a zúzottkő- és kavicstermékek szemalakja és Los Angeles vizsgálat szerinti aprózódási vesztesége között I. (Relationship between the shape of the grains and the fragmented loss of Los Angeles tests for aggregates I. – in Hungarian) Építőanyag. 23(7):248–254

Kausay T (1971b) Összefüggés a zúzottkő- és kavicstermékek szemalakja és Los Angeles vizsgálat szerinti aprózódási vesztesége között II. (Relationship between the shape of the grains and the fragmented loss of Los Angeles tests for aggregates II. – in Hungarian) Építőanyag. 23(8):288–297

Khanlari GR, Naseri F (2018) Prediction of aggregate modified index (AMI) using geomechanical properties of limestones. Bull Eng Geol Environ 77:803–814. https://doi.org/10.1007/s10064-016-0984-1

Khanlari G, Sahamieh RZ, Abdilor Y (2015) The effect of freeze–thaw cycles on physical and mechanical properties of Upper Red Formation sandstones, central part of Iran. Arab J Geosci 8:5991–6001. https://doi.org/10.1007/s12517-014-1653-y

Kong D, Xiao Y, Wu S, Tang N, Ling J, Wang F (2017) Comparative evaluation of designing asphalt treated base mixture with composite aggregate types. Constr Build Mater 156:819–827. https://doi.org/10.1016/j.conbuildmat.2017.09.020

L’Haridon R (1965) Essai Micro-Deval destiné a prévior à partir de petits échantillons, les qualitiés routières des roches carottées. Bull Liaison Lab Routières Ponts Chausées 14:1–21

Liu J, Zhao S, Mullin A (2017) Laboratory assessment of Alaska aggregates using micro-Deval test. Front Struct Civ Eng 11(1):27–34. https://doi.org/10.1007/s11709-016-0359-5

Marek I, Szabó-Balog A (1987) Qualification of mass composition characteristics of rocks. Per Pol Civil Eng 32(3–4):227–246

Miščević P, Vlastelica G (2011) Durability characterization of marls from the region of Dalmatia, Croatia. Geotech Geol Eng 29:771–781. https://doi.org/10.1007/s10706-011-9416-y

Miščević P, Vlastelica G (2019) Estimation of embankment settlement caused by deterioration of soft rock grains. Bull Eng Geol Environ 78:1843–1853. https://doi.org/10.1007/s10064-017-1203-4

Ozden UA, Topal T (2009) Evaluation of andesite source as armourstone for a rubble mound breakwater (Hisarönü, Turkey). Environ Earth Sci 59:39–49. https://doi.org/10.1007/s12665-009-0002-z

Palassi M, Danesh A (2016) Relationships between abrasion/degradation of aggregate evaluated from various tests and the effect of saturation. Rock Mech Rock Eng 49:2937–2943. https://doi.org/10.1007/s00603-015-0869-9

Pang L, Wu S, Zhu J, Wan L (2010) Relationship between petrographical and physical properties of aggregates. J Wuhan Uni Technol Mater Sci Ed 25(4):678–681. https://doi.org/10.1007/s11595-010-0069-0

Přikryl R (2001) Some microstructural aspects of strength variation in rocks. Int J Rock Mech Min Sci 38(5):671–682. https://doi.org/10.1016/S1365-1609(01)00031-4

Přikryl R (2013) Durability assessment of natural stone. Q J Eng Geol Hydrogeol 46:377–390. https://doi.org/10.1144/qjegh2012-052

Přikryl R (2017) Constructional geomaterials: versatile earth resources in the service of humankind—introduction to the thematic set of papers on: challenges to supply and quality of geomaterials used in construction. Bull Eng Geol Environ 76:1–9. https://doi.org/10.1007/s10064-016-0985-0

Profitis E, Chatzitheodoridis E, Xirouchakis D (2012) Digital methods for flakiness and shape definition. In: Paipetis AS, Matikas TE, Aggelis DG, Van Hemelriijck D (eds) Emerging technologies in non-destructive testing V. CRC Press, London, pp 437–440. https://doi.org/10.13140/2.1.2433.6324

Profitis E, Kapatos D, Chatzitheodoridis E, Xirouchakis D, Loupasakis C (2013) Digital methods for measuring grain size parameters of aggregate–binder mixtures. Bull Geol Soc Greece 47(3):1834–1843. https://doi.org/10.12681/bgsg.11062

Räisänen M (2004) Relationships between texture and mechanical properties of hybrid rocks from the Jaala–Iitti complex, southeastern Finland. Eng Geol 74:197–211. https://doi.org/10.1016/j.enggeo.2004.03.009

Räisänen M, Torppa A (2005) Quality assessment of a geologically heterogeneous rock quarry in Pirkanmaa county, southern Finland. Bull Eng Geol Environ 64:409–418. https://doi.org/10.1007/s10064-005-0006-1

Reznák L, Ács P (1965) Útlaboratóriumi Kézikönyvek: Kő és kohósalakkő. (Handbook for laboratories of road constructions: stone and slag stone. – in Hungarian.) Útügyi Kutató Intézet, Budapest. 164 p

Reznák L, Kovács J, Badinszky P (1982) Hazai útépítési kőanyagok. (Hungarian rock materials for road constructions – In Hungarian.) Közlekedéstudományi Intézet, Budapest. 304 p

Rigopoulos I, Tsikoruas B, Pomonis P, Hatzipanagiotou K (2013) Determination of the interrelations between the engineering parameters of construction aggregates from ophiolite complexes of Greece using factor analyses. Constr Build Mater 49:747–757. https://doi.org/10.1016/j.conbuildmat.2013.08.065

Rogers CA, Bailey ML, Price B (1991) Micro-Deval test for evaluating the quality of fine aggregate for concrete or asphalt. Transp Res Rec 1301:68–76

Sajtos L, Mitev A (2007) SPSS kutatási és adatelemzési kézikönyv. (SPSS manual for research and induction – in Hungarian.) Alinea Kiadó, Budapest. 404 p

Shipway CH (1964) A study of the aggregate crushing test. Proc 2nd Australian Road Research Board (ARRB) Conference 2(2):981–96

Siratovich PA, Davidson J, Villeneuve M, Gravley D, Kennedy B, Cole J, Wyering L, Price L (2012) Physical and mechanical properties of the Rotokawa Andesite from production wells RK 27_L2, RK 28 and RK 30. In: New Zealand Geothermal Workshop 2012 Proceedings. 7 p

Sonmez H, Tuncay E, Gokceoglu C (2004) Models to predict the uniaxial compressive strength and the modulus of elasticity for Ankara agglomerate. Int J Rock Mech Min Sci 41:717–729. https://doi.org/10.1016/j.ijrmms.2004.01.011

Szatkowski WS, Hoskings JR (1972) The effect of traffic and aggregate on the skidding resistance of bituminous surfacing. Laboratory report LR 504. Transport and Road Research Laboratory, Crowthorne. 24 p

Tabatai H, Titi H, Lee CW, Qamhia I, Fella GP (2013) Investigation of testing methods to determine long-term durability of Wisconsin aggregates. Final report, Wisconsin Highway Research Program #0092-10-08, 103 p

Topal T, Doyuran V (1997) Engineering geological properties and durability assessment of the Cappadocian tuff. Eng Geol 47:175–187

Tourenq C (1971) L’essai micro-Deval. Bull Liaison Lab Cent Ponts Chaussees 54:69–76

Török Á (2015) Los Angeles and micro-Deval values of volcanic rocks and their use as aggregates, examples from Hungary. In: Lollino G, Manconi A, Guzzetti AF, Culshaw M, Bobrowsky P, Luino F (eds) Engineering geology for society and territory (vol. 5, urban geology, sustainable planning and landscape exploitation). Springer International Publishing, Basel, pp 115–118. https://doi.org/10.1007/978-3-319-09048-1_23

Török Á, Czinder B (2017) Relationship between density, compressive strength, tensile strength and aggregate properties of andesites from Hungary. Environ Earth Sci 76:639. https://doi.org/10.1007/s12665-017-6977-y

Török Á, Vásárhelyi B (2010) The influence of fabric and water content on selected rock mechanical parameters of travertine, examples from Hungary. Eng Geol 115:237–245. https://doi.org/10.1016/j.enggeo.2010.01.005

Tugrul A, Yılmaz M (2012) Assessing the quality of sandstones for use as aggregate in concrete. Mag Concr Res 64(12):1067–1078. https://doi.org/10.1680/macr.11.00179

Tuncay EB, Kılınçarslan Ş, Yağmurlu F (2016) Investigation of usability as aggregate of different originated rocks. Earth Environ Sci:44, 7 p. https://doi.org/10.1088/1755-1315/44/2/022002

Ugur I, Demirdag S, Yavuz H (2010) Effect of rock properties on the Los Angeles abrasion and impact test characteristics of the aggregates. Mater Charact 61:90–96. https://doi.org/10.1016/j.matchar.2009.10.014

Ündül Ö (2016) Assessment of mineralogical and petrographic factors affecting petro-physical properties, strength and cracking processes of volcanic rocks. Eng Geol 210:10–22. https://doi.org/10.1016/j.enggeo.2016.06.001

Wang D, Wang H, Bu Y, Schulze C, Oeser M (2015) Evaluation of aggregate resistance to wear with micro-Deval test in combination with aggregate imaging techniques. Wear 338-339:288–296. https://doi.org/10.1016/j.wear.2015.07.002

Woolf DO, Runner D (1935) The Los Angeles abrasion machine for determining the quality of coarse aggregate. Am Soc Test Mater Proc 35(2):511–532

Xirouchakis D (2013) Correlations between mechanical and geometrical parameters in aggregates: a tool for quality assessment and control. Bull Geol Soc Greece 47(3):2069–2080. https://doi.org/10.12681/bgsg.11091

Xu O, Han S, Zhang C, Liu Y, Xiao F, Xu J (2015) Laboratory investigation of andesite and limestone asphalt mixtures containing sodium chloride-based anti-icing filler. Constr Build Mater 98:671–677. https://doi.org/10.1016/j.conbuildmat.2015.08.126

Yavuz H (2011) Effect of freeze–thaw and thermal shock weathering on the physical and mechanical properties of an andesite stone. Bull Eng Geol Environ 70:187–192. https://doi.org/10.1007/s10064-010-0302-2

Yılmaz NG, Goktan RM, Kibici Y (2011) Relations between some quantitative petrographic characteristics and mechanical strength properties of granitic building stones. Int J Rock Mech Min Sci 48:506–513. https://doi.org/10.1016/j.ijrmms.2010.09.003

Yılmaz M, Tugrul A, Karasahin M, Boz I (2015) Assessing the stripping properties of granite aggregates in bituminous mixtures. Bull Eng Geol Environ 74:673–682. https://doi.org/10.1007/s10064-014-0631-7

Zalooli A, Freire-Lista DM, Khamehchiyan M, Nikudel MR, Fort R, Ghasemi S (2018) Ghaleh-khargushi rhyodacite and Gorid andesite from Iran: characterization, uses, and durability. Environ Earth Sci 77:315. https://doi.org/10.1007/s12665-018-7485-4

Zhang W, Zakaria M, Hama Y (2013) Influence of aggregate materials characteristics on the drying shrinkage properties of mortar and concrete. Constr Build Mater 49:500–510. https://doi.org/10.1016/j.conbuildmat.2013.08.069

Acknowledgements

Open access funding provided by Budapest University of Technology and Economics. The authors are thankful to Bobály János from KŐKA Kő- és Kavicsbányászati Ltd. and to László Ézsiás from COLAS Északkő Ltd. for providing rock blocks for the laboratory tests. The authors are also indebted to the co-workers of the Laboratory of Engineering Geology and Material Testing Laboratory (Budapest University of Technology and Economics), especially to Gyula Emszt, Bálint Pálinkás, Krisztián Takács and Anna Szijártó for their participation and help in carrying out the laboratory tests.

Funding

The financial support was provided by the National Research, Development and Innovation (NKFI) Fund (ref. no. K 116532). The research reported in this paper was also supported by the BME-Water Sciences and Disaster Prevention FIKP grant of EMMI (BME FIKP-VÍZ).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Czinder, B., Török, Á. Strength and abrasive properties of andesite: relationships between strength parameters measured on cylindrical test specimens and micro-Deval values—a tool for durability assessment. Bull Eng Geol Environ 80, 8871–8889 (2021). https://doi.org/10.1007/s10064-020-01983-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-020-01983-9