Abstract

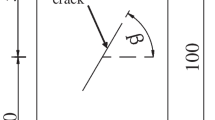

Phyllite, which is a low-grade metamorphic rock with well-developed foliation planes, is encountered frequently during tunnel construction in western China. Its creep behavior is affected significantly by the foliation planes and has a crucial influence on the long-term safety of tunnel structures. Uniaxial compressive creep testing was conducted to analyze the time-dependent features of phyllite obtained from the Zhegu mountain tunnel on the Wenma expressway, China. A new creep model that connects a Maxwell body, a Kelvin body, and a nonlinear visco-plastic body was proposed to describe both the full creep process (including the transient, steady, and accelerated creep stages) and the transversely isotropic characteristics of phyllite. The creep model was also applied to investigate the long-term safety of a cracked tunnel lining in phyllite bedrock. The results showed that the creep strength and corresponding axial strain of phyllite exhibited maximum and minimum values at θ (the angle between the loading direction and the weak planes) = 90° and 30°, respectively. Good agreement was found between the calculated and experimental creep curves, indicating that the creep model replicates the physical creep process of phyllite well. The safety of the cracked lining was affected mainly by the damage degree of cracks and the creep behavior of the surrounding rock. Uncracked sections, because of their greater stiffness, were more sensitive to creep load than cracked ones. The inclination angle of foliation planes influenced the location of unsafe sections (those with a safety factor less than one), and this effect was weakened as the number of pre-existing cracks increased.

Similar content being viewed by others

References

Andargol MBE, Shahriar K, Ramezanzadeh A, Goshtasbi K (2018) The analysis of dates obtained from long-term creep tests to determine creep coefficients of rock salt. Bull Eng Geol Environ 1:1–13

Aydan O, Ito T, Ozbay U et al (2014) ISRM suggested methods for determining the creep characteristics of rock. Rock Mech Rock Eng 47:275–290

Barla G, Debernardi D, Sterpi D (2012) Time-dependent modeling of tunnels in squeezing conditions. Int J Geomec 12:697–710

Brantut N, Heap MJ, Baud P, Meredith PG (2014) Mechanisms of time-dependent deformation in porous limestone. J Geophys Res 119:5444–5463

Chen L, Wang CP, Liu JF, Li Y, Liu J, Wang J (2017) Effects of temperature and stress on the time-dependent behavior of Beishan granite. Int J Rock Mech Min Sci 93:316–323

Chin HP, Rogers JD (1987) Creep parameters of rocks on an engineering scale. Rock Mech Rock Eng 20:137–146

Dubey RK, Gairola VK (2008) Influence of structural anisotropy on creep of rocksalt from Simla Himalaya, India: an experimental approach. J Struct Geol 30:710–718

Fu ZL, Gao YF, Ning W, Xu JP (2007) Creep of anisotropic soil shale. J Min Saf Eng 24:353–356

Guan ZC, Jiang YJ, Tanabashi Y, Huang H (2008) A new rheological model and its application in mountain tunnelling. Tunn Undergr Space Technol 23:292–299

Guan ZC, Jiang YJ, Tanabashi Y (2009) Rheological parameter estimation for the prediction of long-term deformations in conventional tunneling. Tunn Undergr Space Technol 24:250–259

Itasca Consulting Group, Inc. (2009) Fast lagrangian analysis of continua, version 4.0. User’s manual. Consulting Group, Inc.,Minneapolis

Li XC, Yang CL, Ren T, Nie BS, Zhao CH (2017) Creep behaviour and constitutive model of coal filled with gas. Int J Min Sci Technol 27:847–851

Liao MK, Lai YM, Liu EL, Wan XS (2017) A fractional order creep constitutive model of warm frozen silt. Acta Geotech 12:377–389

Lisjak A, Garitte B, Grasselli G, Müller HR, Vietor T (2015) The excavation of a circular tunnel in a bedded argillaceous rock (Opalinus clay): short-term rock mass response and FDEM numerical analysis. Tunn Undergr Space Technol 45:227–248

Liu ZB, Xie SY, Shao JF, Conil N (2015) Effects of deviatoric stress and structural anisotropy on compressive creep behavior of a clayey rock. Appl Clay Sci 114:491–496

Lockner D (1993) Room temperature creep in saturated granite. J Geophys Res 10:475–487

Lu PL, Wu KT, Jiao YB, Li JH, Liu XH (1992) The experimental study of acoustic emission during creep of rocks. Acta Seismol Sin 5:169–176

Manh HT, Sulem J, Subrin D, Billaux D (2015) Anisotropic time-dependent modeling of tunnel excavation in squeezing ground. Rock Mech Rock Eng 48:2301–2317

Meng LB, Li TB, Jiang Y, Wang R, Li YR (2013) Characteristics and mechanisms of large deformation in the Zhegu mountain tunnel on the Sichuan–Tibet highway. Tunn Undergr Space Technol 37:157–164

Ministry of Transport of PRC (2004) Gode for design of road tunnel. China Communication Publisher Ltd., Beijing

Mishra B, Verma P (2015) Uniaxial and triaxial single and multistage creep tests on coal-measure shale rocks. Int J Coal Geol 137:55–65

Paraskevopoulou C, Perras M, Diederichs M, Loew S, Lam T, Jensen M (2018) Time-dependent behaviour of brittle rocks based on static load laboratory testing. Geotech Geol Eng 36:337–376

Sterpi D, Gioda G (2009) Visco-plastic behaviour around advancing tunnels in squeezing rock. Rock Mech Rock Eng 42:319–339

Sun J (1999) Rheological behavior of geomaterials and its engineering applications. China Architecture and Building Press, Beijing

Tang MM, Wang ZY (2008) Experimental study on rheological deformation and stress properties of limestone. J Cent S Univ Technol 15:475–478

Tang H, Wang DP, Huang RQ, Pei XJ, Chen WL (2018) A new rock creep model based on variable-order fractional derivatives and continuum damage mechanics. Bull Eng Geol Environ 77:375–383

Tonon F (2016) Sequential excavation, NATM and ADECO: what they have in common and how they differ. Tunn Undergr Space Technol 25:245–265

Torres CC, Diederichs M (2009) Mechanical analysis of circular liners with particular reference to composite supports. For example, liners consisting of shotcrete and steel sets. Tunn Undergr Space Technol 24:506–532

Wang GJ, Zhang L, Zhang YW, Ding GS (2014) Experimental investigations of the creep–damage–rupture behavior of rock salt. Int J Rock Mech Min Sci 66:181–187

Wang JH, Zhang WJ, Guo X, Koizumi A, Tanaka H (2015) Mechanism for buckling of shield tunnel linings under hydrostatic pressure. Tunn Undergr Space Technol 49:144–155

Wu CZ, Shi ZM, Fu YK, Yang LD, Li QS (2014) Experimental investigations on structural anisotropy on creep of greenschist. Chin J Rock Mech Eng 33:493–499 (in Chinese)

Xu GW, He C, Chen ZQ, Wu D (2018) Effects of the micro-structure and micro-parameters on the mechanical behaviour of transversely isotropic rock in Brazilian tests. Acta Geotech 13:887–910

Yang SQ, Cheng L (2011) Non-stationary and nonlinear visco-elastic shear creep model for shale. Int J Rock Mech Min Sci 48:1011–1020

Yang CH, Daemen JJK, Yin JH (1999) Experimental investigation of creep behavior of salt rock. Int J Rock Mech Min Sci 36:233–242

Yang DS, Chen LF, Yang SQ, Chen WZ, Wu GJ (2014) Experimental investigation of the creep and damage behavior of Linyi red sandstone. Int J Rock Mech Min Sci 72:164–172

Ye GL, Nishimura T, Zhang F (2015) Experimental study on shear and creep behavior of green tuff at high temperature. Int J Rock Mech Min Sci 79:19–28

Zhang SL (2012) Study on health diagnosis and technical condition assessment for tunnel lining structure. Dissertation, Beijing Jiaotong University, China (in Chinese)

Zhao BY, Liu DY, Dong Q (2011) Experimental research on creep behaviors of sandstone under uniaxial compressive and tensile stresses. J Rock Mech Geotech Eng 3:438–444

Zhao XJ, Chen BR, Zhao HB, Jie BH, Ning ZF (2012) Laboratory creep tests for time-dependent properties of a marble in Jinping II hydropower station. J Rock Mech Geotech Eng 4:168–176

Acknowledgements

This research was supported by the National key research and development program of China (Grant No. 2016YFC0802201).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Appendices

Appendix 1: Implementation of ubhm model in FLAC 3D

The three-dimensional finite difference formulas of ubhm is derived as as follows.

-

(1)

Basic formulas

The incremental expression of Eq. 3 has the form:

where

The superscripts N and O denote new and old values during a time step, respectively. \( {\overline{S}}_{ij}^o \) and \( {\overline{S}}_{ij}^N \) are the new and old deviatoric stress tensors, respectively. \( {e}_{ij}^{2,N} \) and \( {e}_{ij}^{2,O} \) are the new and old deviatoric strain tensors, respectively.

Substituting Eqs. (31) and (32) into Eq. (29) yields:

where

Substituting Eqs. (28) and (33) into Eq. (27) yields:

where

\( \varDelta {e}_{ij}^{3\mathrm{J}} \), \( \varDelta {e}_{ij}^{3S} \)are the plastic strain of weak planes and rock matrix, respectively.

The volumetric strain is:

The Mohr-Coulomb criterion of rock matrix are:

where fs is shear yield criterion, ft is tensile yield criterion, Nφ = (1 + sinφ)/(1-sinφ), c, φ, σt are cohesion, friction angle, and tensile strength of rock matrix, respectively.

The corresponding potential functions are:

where gs is shear potential function and gt is tensile potential function, Nψ = (1 + sinψ)/(1-sinψ), ψ is dilation angle.

The function h(σ1, σ3) = 0, which is represented by the diagonal between the strength envelope of fs = 0 and ft = 0 in the principal stress plane (see Fig. 23), is defined to determine the yield type of rock matrix:

where

If the stress falls within domain 1, then shear failure occurs, and the new stress is revised using the flow rule derived from gs. If the stress falls within domain 2, then tensile failure occurs, and the new stress is re-calculated adopting the flow rule derived from gt.

-

(2)

Strain increment of rock matrix

Expressing Eqs. (33) and (39) in principal axes, the definition of trial stresses can be written as follows:

Adding (47) and (48) and expressing the result in principal axes yields:

where

For shear failure, partial differentiation of Eq. (42):

Substituting Eq. (52) into Eq. (49) yields:

where

For tensile failure, partial differentiation of Eq. (43):

Substituting Eq. (55) into Eq. (49) yields:

where

-

(3)

Strain increment of weak planes

The relationship between the global coordinate system and local system is shown in Fig. 24. The stress tensors in the local system are computed adopting Eq. (58):

where C is transformation matrix (Manh et al. 2015).

The Mohr-Coulomb criteria of weak planes are:

where \( {f}_{\mathrm{j}}^{\mathrm{s}} \) is shear yield criterion, \( {f}_{\mathrm{j}}^{\mathrm{t}} \) is tensile yield criterion, cj, φj, and σjt are cohesion, friction angle, and tensile strength of weak planes, respectively; σtjmax is the maximum tensile strength for a weak plane with nonzero friction angle; σn is normal stress.

The corresponding potential functions are:

where gjs is shear potential function, gjt is tensile potential function, and Ψj is dilation angle of weak planes.

The function hj(σ1, σ3) = 0, which is represented by the diagonal between the strength envelope of fjs = 0 and fjt = 0 in the principal stress plane (see Fig. 26), is defined:

where

If the stress falls within domain 1, then shear failure occurs, and the new stress is revised using the flow rule derived from gjs. If the stress falls within domain 2, then tensile failure occurs, and the new stress is re-calculated adopting the flow rule derived from gjt.

For shear failure, partial differentiation of Eq. (61):

Substituting Eq. (66) into Eq. (49) yields:

where

For tensile failure, partial differentiation of Eq. (62):

Substituting Eq. (69) into Eq. (49) yields:

where

Appendix 2: Safety factor of secondary lining

The safety factor is the most intuitive index to evaluate the safety of lining. We adopted the calculation method recommended in the design specification of highway tunnels (Ministry of Transport of PRC 2004):

-

(1)

For e0 ≤ 0.2 h, the bearing capacity of lining is controlled by the compressive strength of concrete. Thus, its safety factor can be calculated using Eq. (72)

where K is the safety factor, Ra is the compressive strength, N is axial force, b is the width of section, h is the height of section, φ is the longitudinal bending coefficient of lining, and α is the influential coefficient of eccentricity:

where

e0 is eccentricity of the axial force, and M is the bending moment.

-

(2)

For e0 > 0.2 h, the bearing capacity of lining is controlled by the tensile strength of concrete. Thus, its safety factor can be calculated using Eq. (75):

where Rl is the tensile strength of concrete.

Rights and permissions

About this article

Cite this article

Xu, G., He, C., Yan, J. et al. A new transversely isotropic nonlinear creep model for layered phyllite and its application. Bull Eng Geol Environ 78, 5387–5408 (2019). https://doi.org/10.1007/s10064-019-01462-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-019-01462-w