Abstract

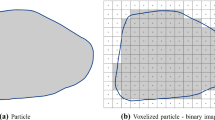

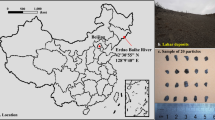

Using a cluster of pebbles to generate clumps is a common procedure to explore granular particles' micro- or macro-scale mechanical responses in DEM simulations. The struggle is to balance the number of pebbles and the shape accuracy of generated clumps compared to the original particles. A low-cost multi-image-based method is adopted in this paper to extract 3D triangular networks of original particles. A voxel-based clump generation method, namely V-CLUMP, is developed to generate clumps based on triangular networks. The operations, such as gradual discretization, surface cell optimization, and candidate pebble hollowing out, are proposed to improve the accuracy and efficiency of clump generation. The ideal of corner preserving is also adopted, and a novel image-based method to detect corners and ridges of particles or clumps is proposed in this paper. Clumps for four idealized geometrical shapes and five quintessential particles are generated using the V-CLUMP. The parameters, including the number of pebbles, volume, projection area, sphericity, roundness, and roughness, are used to evaluate the performance of the clump generation method proposed in this study. The result shows that the absolute value of the errors for most generated clumps with 30 to 120 pebbles in macro-scale descriptors, i.e., volume, projection area, and sphericity, are less than 6%. A better result of meso- and micro- descriptors, i.e., roundness and roughness, can be obtained by selecting optimum clump generation parameters. The code takes less than one second to a few minutes, within the acceptable limits. However, pebble hollowing out and corner detecting are still time-consuming, and more efficient algorithms are needed to improve the performance of the operations.

Similar content being viewed by others

References

Liu, G.Y., Xu, W.J., Govender, N., Wilke, D.N.: Simulation of rock fracture process based on GPU-accelerated discrete element method. Powder Technol. 377, 640–656 (2021). https://doi.org/10.1016/j.powtec.2020.09.009

Fang, C.F., Gong, J., Jia, M.T., Nie, Z.H., Li, B., Mohammed, A., Zhao, L.H.: DEM simulation of the shear behaviour of breakable granular materials with various angularities. Adv. Powder Technol. 32(11), 4058–4069 (2021). https://doi.org/10.1016/j.apt.2021.09.009

Nagata, Y., Tsunazawa, Y., Tsukada, K., Yaguchi, Y., Ebisu, Y., Mitsuhashi, K., Tokoro, C.: Effect of the roll stud diameter on the capacity of a high-pressure grinding roll using the discrete element method. Miner. Eng. (2020). https://doi.org/10.1016/j.mineng.2020.106412

Song, Z.Y., Konietzky, H., Herbst, M.: Drawing mechanism of fractured top coal in longwall top coal caving. Int. J. Rock Mech. Min. Sci. (2020). https://doi.org/10.1016/j.ijrmms.2020.104329

Gan, J., Yu, A.: DEM study on the packing density and randomness for packing of ellipsoids. Powder Technol. 361, 424–434 (2020). https://doi.org/10.1016/j.powtec.2019.07.012

Wouterse, A., Luding, S., Philipse, A.P.: On contact numbers in random rod packings. Granul. Matter 11(3), 169–177 (2009). https://doi.org/10.1007/s10035-009-0126-6

Kou, M., Zhou, H., Wu, S., Shen, Y.: DEM simulation of cubical particle percolation in a packed bed. Powder Technol. 361, 306–314 (2020). https://doi.org/10.1016/j.powtec.2019.08.012

Xu, Z., Yang, J., Ding, Y., Zhao, Y., Li, J., Hu, B., Xia, C.: Packing and void structures of octahedral, dodecahedral and icosahedral granular particles. Granul. Matter 23(4), 88 (2021). https://doi.org/10.1007/s10035-021-01156-9

Yuan, Y., Liu, L.F., Deng, W., Li, S.X.: Random-packing properties of spheropolyhedra. Powder Technol. 351, 186–194 (2019). https://doi.org/10.1016/j.powtec.2019.04.018

Zhao, S.W., Zhang, N., Zhou, X.W., Zhang, L.: Particle shape effects on fabric of granular random packing. Powder Technol. 310, 175–186 (2017). https://doi.org/10.1016/j.powtec.2016.12.094

Zhao, S.W., Zhou, X.W.: Effects of particle asphericity on the macro- and micro-mechanical behaviors of granular assemblies. Granul. Matter (2017). https://doi.org/10.1007/s10035-017-0725-6

Favier, J.F., Abbaspour-Fard, M.H., Kremmer, M., Raji, A.O.: Shape representation of axi-symmetrical, non-spherical particles in discrete element simulation using multi-element model particles. Eng. Comput. 16(4), 467–480 (1999). https://doi.org/10.1108/02644409910271894

Das, N.: Modeling three-dimensional shape of sand grains using discrete element method, University of South Florida, (2007)

Ferellec, J.F., McDowell, G.R.: A method to model realistic particle shape and inertia in DEM. Granul. Matter 12(5), 459–467 (2010). https://doi.org/10.1007/s10035-010-0205-8

R. Taghavi: Automatic clump generation based on mid-surface. In: Proceedings, 2nd international FLAC/DEM symposium, Melbourne, (2011)

Haeri, S.: Optimisation of blade type spreaders for powder bed preparation in additive manufacturing using DEM simulations. Powder Technol. 321, 94–104 (2017). https://doi.org/10.1016/j.powtec.2017.08.011

Angelidakis, V., Nadimi, S., Otsubo, M., Utili, S.: CLUMP: A code library to generate universal multi-sphere particles. SoftwareX 15, 100735 (2021). https://doi.org/10.1016/j.softx.2021.100735

Zheng, J., Hryciw, R.D.: An image based clump library for DEM simulations. Granul. Matter (2017). https://doi.org/10.1007/s10035-017-0713-x

Zheng, J., Hryciw, R.D.: A corner preserving algorithm for realistic DEM soil particle generation. Granular Matter 18(4), 84 (2016). https://doi.org/10.1007/s10035-016-0679-0

Zheng, J., He, H., Alimohammadi, H.: Three-dimensional Wadell roundness for particle angularity characterization of granular soils. Acta Geotech. 16(1), 133–149 (2021). https://doi.org/10.1007/s11440-020-01004-9

Laurentini, A.: The visual hull concept for silhouette-based image understanding. IEEE Trans. Pattern Anal. Mach. Intell. 16(2), 150–162 (1994). https://doi.org/10.1109/34.273735

Cheung, K.M., Baker, S., Kanade, T.: Shape-from-silhouette across time part I: theory and algorithms. Int. J. Comput. Vision 62(3), 221–247 (2005). https://doi.org/10.1007/s11263-005-4881-5

Ferellec, J.F., McDowell, G.R.: A simple method to create complex particle shapes for DEM. Geomech. Geoeng. 3(3), 211–216 (2008). https://doi.org/10.1080/17486020802253992

Li, C., Xu, W., Meng, Q.: Multi-sphere approximation of real particles for DEM simulation based on a modified greedy heuristic algorithm. Powder Technol. 286, 478–487 (2015). https://doi.org/10.1016/j.powtec.2015.08.026

Zheng, J., Hryciw, R.D.: Traditional soil particle sphericity, roundness and surface roughness by computational geometry. Geotechnique 65(6), 494–506 (2015). https://doi.org/10.1680/geot.14.P.192

J. Sorokin, ridgefilt(img,L,sigma,alpha), MATLAB Central File Exchange, https://www.mathworks.com/matlabcentral/fileexchange/67019-ridgefilt-img-l-sigma-alpha,Accessed March, 1, 2022

A. K. Ashmawy, V. V. Hoang and B. Sukumaran: Evaluating the influence of particle shape on liquefaction behavior using discrete element modeling. In: The Thirteenth International Offshore and Polar Engineering Conference, May 2003, Honolulu, Hawaii, USA, (2003)

Wadell, H.: Volume, shape, and roundness of rock particles. J. Geol. 40(5), 443–451 (1932). https://doi.org/10.1086/623964

Wadell, H.: Sphericity and roundness of rock particles. J. Geol. 41(3), 310–331 (1933). https://doi.org/10.1086/624040

Wadell, H.: Volume, shape, and roundness of quartz particles. J. Geol. 43(3), 250–280 (1935). https://doi.org/10.1086/624298

Acknowledgements

This paper is supported by the National Natural Science Foundation of China (Grant No: 51934008, 51674264, 51904305) and the China Scholarship Council (Grant No: 202006430019). The first authors also thank Dr. Vasileios Angelidakis for providing code help.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, L., Wang, J., Yang, S. et al. A voxel-based clump generation method used for DEM simulations. Granular Matter 24, 89 (2022). https://doi.org/10.1007/s10035-022-01251-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-022-01251-5