Abstract

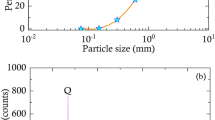

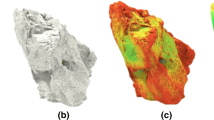

Morphology is an important grain scale property that substantially influences the macroscopic behavior of granular materials. Particle-based methods such as discrete element method are suitable to study the morphology effect because the particle geometry can be systematically controlled. However, coupling realistic particle morphology with simulation involves significant computational costs. Therefore, considerably simplified particle morphology has been typically adopted in the particle-based simulations to keep the computational costs manageable. This paper aims to systematically address how modeling error results from the morphology simplification and investigates how the modeled fidelity of particle morphology influences the simulated granular material behavior. To this end, a spectrum of particle morphology is developed by gradually simplifying a polyhedral particle model that represents a realistic particle morphology. The modeled fidelity is then quantified in term of Shape Factor and Angularity Factor to characterize the global form and the local angularity of the particle morphology. A set of 3D printed particles is developed from the numerical particle models and used in laboratory testing for systematic parametric study. A series of triaxial compression tests is performed on the synthetic specimens with the 3D printed particles. The result indicates the relative importance of high-fidelity modeling of (1) local angularity under low-confining pressure and (2) global form under high-confining pressure. This study also demonstrates the potential of leveraging 3D printed synthetic particles to study the morphology-dependent mechanical behavior of granular materials.

Graphic abstract

Similar content being viewed by others

References

Cho, G.-C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 132, 591–602 (2006). https://doi.org/10.1061/(ASCE)1090-0241(2006)132:5(591)

Payan, M., Senetakis, K., Khoshghalb, A., Khalili, N.: Effect of gradation and particle shape on small-strain Young’s modulus and Poisson’s ratio of sands. Int. J. Geomech. (2016). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000811

Lee, C., Suh, H.S., Yoon, B., Yun, T.S.: Particle shape effect on thermal conductivity and shear wave velocity in sands. Acta Geotech. (2017). https://doi.org/10.1007/s11440-017-0524-6

Cook, C.S., Tanyu, B.F., Yavuz, A.B.: Effect of particle shape on durability and performance of unbound aggregate base. J. Mater. Civ. Eng. 29, 04016221 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001752

Shin, H., Santamarina, J.C.: Role of particle angularity on the mechanical behavior of granular mixtures. J. Geotech. Geoenviron. Eng. 139, 353–355 (2013). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000768

Stark, N., Hay, A.E., Cheel, R., Lake, C.B.: The impact of particle shape on the angle of internal friction and the implications for sediment dynamics at a steep, mixed sand–gravel beach. Earth Surf. Dyn. 2, 469–480 (2014). https://doi.org/10.5194/esurf-2-469-2014

Ericson, C.: Real-Time Collision Detection. CRC Press (2005). ISBN: 9781558607323. Available at: https://www.sciencedirect.com/book/9781558607323/real-timecollision-detection

Nezami, E.G., Hashash Y, M.A., Zhao, D., Ghaboussi, J.: Shortest link method for contact detection in discrete element method. Int. J. Numer. Anal. Methods Geomech. 30, 783–801 (2006). https://doi.org/10.1002/nag.500

Lee, S.J., Hashash, Y.M.A., Nezami, E.G.: Simulation of triaxial compression tests with polyhedral discrete elements. Comput. Geotech. 43, 92–100 (2012). https://doi.org/10.1016/j.compgeo.2012.02.011

Smeets, B., Odenthal, T., Vanmaercke, S., Ramon, H.: Polygon-based contact description for modeling arbitrary polyhedra in the Discrete Element Method. Comput. Methods Appl. Mech. Eng. 290, 277–289 (2015). https://doi.org/10.1016/j.cma.2015.03.004

Gilbert, E.G., Johnson, D.W., Keerthi, S.S.: Fast procedure for computing the distance between complex objects in three-dimensional space. IEEE J. Robot. Autom. 4, 193–203 (1988). https://doi.org/10.1109/56.2083

Ferellec, J.-F., McDowell, G.R.: A simple method to create complex particle shapes for DEM. Geomech. Geoengin. 3, 211–216 (2008). https://doi.org/10.1080/17486020802253992

O’Sullivan, C.: Particle-based discrete element modeling: geomechanics perspective. Int. J. Geomech. 11, 449–464 (2011). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000024

Mollon, G., Zhao, J.: 3D generation of realistic granular samples based on random fields theory and Fourier shape descriptors. Comput. Methods Appl. Mech. Eng. 279, 46–65 (2014). https://doi.org/10.1016/j.cma.2014.06.022

Ng, T.: Discrete element method simulations of the critical state of a granular material. Int. J. Geomech. 9, 209–216 (2009). https://doi.org/10.1061/(ASCE)1532-3641(2009)9:5(209)

Zhao, S., Zhou, X., Liu, W.: Discrete element simulations of direct shear tests with particle angularity effect. Granul. Matter 17, 793–806 (2015). https://doi.org/10.1007/s10035-015-0593-x

Azéma, E., Estrada, N., Radjaï, F.: Nonlinear effects of particle shape angularity in sheared granular media. Phys. Rev. E 86, 1–15 (2012). https://doi.org/10.1103/PhysRevE.86.041301

Azema, E., Preechawuttipong, I., Radjai, F.: Binary mixtures of disks and elongated particles: texture and mechanical properties. Phys. Rev. E 94, 042901 (2016). https://doi.org/10.1103/PhysRevE.94.042901

Höhner, D., Wirtz, S., Scherer, V.: A study on the influence of particle shape on the mechanical interactions of granular media in a hopper using the Discrete Element Method. Powder Technol. 278, 286–305 (2015). https://doi.org/10.1016/j.powtec.2015.02.046

Latham, J.-P., Munjiza, A., Garcia, X., Xiang, J., Guises, R.: Three-dimensional particle shape acquisition and use of shape library for DEM and FEM/DEM simulation. Miner. Eng. 21, 797–805 (2008). https://doi.org/10.1016/j.mineng.2008.05.015

Zhang, B., Regueiro, R., Druckrey, A., Alshibli, K.: Construction of poly-ellipsoidal grain shapes from SMT imaging on sand, and the development of a new DEM contact detection algorithm. Eng. Comput. (2018). https://doi.org/10.1108/ec-01-2017-0026

Lim, K.: Discrete modeling of granular media: a NURBS-based approach (2015). https://thesis.library.caltech.edu/8734/. Accessed 2 Dec 2019

Jerves, A.X., Kawamoto, R.Y., Andrade, J.E.: Effects of grain morphology on critical state: a computational analysis. Acta Geotech. 11, 493–503 (2016). https://doi.org/10.1007/s11440-015-0422-8

Zheng, J., Hryciw, R.D.: Traditional soil particle sphericity, roundness and surface roughness by computational geometry. Géotechnique 65, 494–506 (2015). https://doi.org/10.1680/geot.14.P.192

Alshibli, K.A., Druckrey, A.M., Al-Raoush, R.I., Weiskittel, T., Lavrik, N.V.: Quantifying morphology of sands using 3D imaging. J. Mater. Civ. Eng. 27, 04014275 (2015). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001246

Terzaghi, K., Peck, R.B., Mesri, G.: Soil Mechanics in Engineering Practice. Wiley, Hoboken (1996)

Sukumaran, B., Ashmawy, A.K.: Quantitative characterisation of the geometry of discrete particles. Géotechnique 51, 619–627 (2001). https://doi.org/10.1680/geot.2001.51.7.619

Wadell, H.: Sphericity and roundness of rock particles. J. Geol. 41, 310–331 (1933)

Tutumluer, E., Rao, C., Stefanski, J.A.: Video Image Analysis of Aggregates. Urbana, Illinois (2000)

Al-Rousan, T., Masad, E., Myers, L., Speigelman, C.: New methodology for shape classification of aggregates. Transp. Res. Rec. J. Transp. Res. Board 1913, 11–23 (2005). https://doi.org/10.3141/1913-02

Hryciw, R.D., Zheng, J., Ohm, H.-S., Li, J.: Innovations in optical geocharacterization. In: Geo-congress 2014 Keynote Lectures: Geo-characterization and Modeling for Sustainability, pp. 97–116 (2014)

Wang, L., Sun, W., Tutumluer, E., Druta, C.: Evaluation of aggregate imaging techniques for quantification of morphological characteristics. Transp. Res. Rec. J. Transp. Res. Board 2335, 39–49 (2013). https://doi.org/10.3141/2335-05

Lu, S., Landis, E.N., Keane, D.T.: X-ray microtomographic studies of pore structure and permeability in Portland cement concrete. Mater. Struct. 39, 611–620 (2007). https://doi.org/10.1617/s11527-006-9099-7

3D Hubs: Additive manufacturing technologies infographic. https://www.3dhubs.com/what-is-3dprinting#technologies/sites/all/themes/hubs3d/images/landingpage/3d-101/technologies/additive-manufacturing-infographic. Accessed 2 Dec 2019

Hull, C.W.: US4575330 A: apparatus for production of three-dimensional objects by stereolithography (1984). https://www.google.com/patents/US4575330. Accessed 2 Dec 2019

Redwood, B., Schöffer, F., Garret, B.: The 3D Printing Handbook: Technologies, Design and Applications (2017). ISBN: 9789082748505. Available at: https://www.3dhubs.com/3d-printing-handbook/

Formlabs: Formlabs Design Guide (2016) Available at: https://archive-media.formlabs.com/upload/formlabs-design-guide.pdf. Accessed 16 Feb 2017

Formlabs: Clear—photopolymer resin for form 1+ (2014). http://formlabs.com/media/upload/Clear-DataSheet.pdf. Accessed 2 Dec 2019

Zguris, Z.: How Mechanical Properties of Stereolithography 3D Prints are Affected by UV Curing. Formlabs White Paper (2016). Available at: https://formlabs.com/media/upload/How-Mechanical-Properties-of-SLA-3D-Prints-Are-Affected-by-UV-Curing.pdf

ASTM: ASTM D638—standard test method for tensile properties of plastics. ASTM International 08.01 (2014). https://doi.org/10.1520/d0638-14

Watters, M.P., Bernhardt, M.L.: Curing parameters to improve the mechanical properties of stereolithographic printed specimens. Rapid Prototyp. J. 24, 46–51 (2018). https://doi.org/10.1108/RPJ-11-2016-0180

ASTM: ASTM D695—standard test method for compressive properties of rigid plastics. ASTM International 08.01 (2015). https://doi.org/10.1520/d0695-15

Jacobs, S.A.: Insitu measurement of Florida limestone modulus and strength properties. Department of Civil and Coastal Engineering, University of Florida, Gainesville. Thesis (2003)

Zhang, B., Lee, S.J., Qian, Y., Tutumluer, E., Bhattacharya, S.: A smartphone-based image analysis technique for ballast aggregates. In: International Conference on Transportation and Development 2016, pp. 623–630. American Society of Civil Engineers (2016)

The Blender Foundation: Blender (2019). Available at: www.blender.org. Accessed 2 Dec 2019

Bian, X., Li, W., Qian, Y., Tutumluer, E.: Micromechanical particle interactions in railway ballast through DEM simulations of direct shear tests. Int. J. Geomech. 19, 04019031 (2019). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001403

Alshibli, K.A., Jarrar, M.F., Druckrey, A.M., Al-Raoush, R.I.: Influence of particle morphology on 3D kinematic behavior and strain localization of sheared sand. J. Geotech. Geoenviron. Eng. (2016). https://doi.org/10.1061/(asce)gt.1943-5606.0001601

Alshibli, K.A., Cil, M.B.: Influence of particle morphology on the friction and dilatancy of sand. J. Geotech. Geoenviron. Eng. 144, 04017118 (2018). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001841

Zhao, S., Zhou, X., Liu, W.: Discrete element simulations of direct shear tests with particle angularity effect. Granul. Matter 17, 793–806 (2015). https://doi.org/10.1007/s10035-015-0593-x

ASTM: ASTM D2850-15 standard test method for unconsolidated-undrained triaxial compression test on cohesive soils. ASTM International (2015)

ASTM: ASTM D7181-11 standard test method for consolidated drained triaxial compression test for soils. ASTM International (2011). https://doi.org/10.1520/d7181-11

Thornton, C.: Numerical simulations of deviatoric shear deformation of granular media. Géotechnique 50, 43–53 (2000). https://doi.org/10.1680/geot.2000.50.1.43

Matsumura, S., Kobayashi, T., Mizutani, T.: Manufacture of bonded granular soil using X-ray CT scanning and 3D printing. Geotech. Test. J. 40, 20160237 (2017). https://doi.org/10.1520/GTJ20160273

Gupta, R., Salager, S., Wang, K., Sun, W.: Open-source support toward validating and falsifying discrete mechanics models using synthetic granular materials—part I: experimental tests with particles manufactured by a 3D printer. Acta Geotech. (2018). https://doi.org/10.1007/s11440-018-0703-0

Hanaor, D.A.H., Gan, Y., Revay, M., Airey, D.W., Einav, I.: 3D printable geomaterials. Géotechnique 66, 323–332 (2016). https://doi.org/10.1680/jgeot.15.P.034

Mitchell, J.K., Soga, K.: Fundamentals of Soil Behavior. Wiley, Hoboken (2005)

Formlabs: Form 1+ (2014). Available at: http://formlabs.com/. Accessed 29 Aug 2017

Acknowledgements

This work is sponsored in part by Florida International University (FIU) with the new faculty start-up fund provided to the corresponding author. The opinions, findings, conclusions, or recommendations expressed in this article are solely those of the authors and do not represent the opinions of FIU. The authors would like to thank Mr. Edgar Polo for his help with the laboratory triaxial compression tests and Dr. Benjamin Boesl for his help on the tensile test on the 3D printed specimen. The authors would like to extend the appreciation to the editor and the anonymous reviewers for the valuable comments that helped enhance the final quality of this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, Y., Lee, S. & Sukumaran, B. Influence of particle morphology simplification on the simulation of granular material behavior. Granular Matter 22, 19 (2020). https://doi.org/10.1007/s10035-019-0987-2

Received:

Published:

DOI: https://doi.org/10.1007/s10035-019-0987-2