Abstract

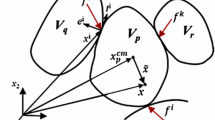

Over the past 30 years, the Discrete Element Method (DEM) has rapidly gained popularity as a tool for modelling the behaviour of granular assemblies and is being used extensively in both scientific and industrial applications. However, it is far from clear from reviewing the literature whether the large number of DEM codes have been verified and checked against fundamental benchmark problems. DEM simulates the dynamics of each particle in an assembly by calculating the acceleration resulting from all the contact forces and body forces. It is clearly necessary that such a model be validated or verified by comparing with experimental results, analytical solutions or other numerical results (e.g. Finite Element Analysis (FEA) results) at particle impact level. There appears to be no standard benchmark tests against which DEM codes can be verified. It is thus essential and useful to establish a set of standard benchmark tests to confirm that these DEM codes are modelling the particle dynamics as intended. This paper proposes a set of benchmark tests to verify DEM codes at particle impact level for spherical particles. The analytical solutions derived from elasticity theory for elastic normal collision of two spheres or a sphere with a rigid plane are first reviewed. These analytical solutions apply only to the elastic regime for normal impact. Secondly, the analytical solutions of frictional oblique impact between two spheres or a sphere with a rigid plane are scrutinized and derived. These analytical solutions originate from the dynamics principles and should be satisfied for any DEM contact force model with prescribed friction and restitution coefficients. A set of eight benchmark tests are designed and performed using commercial DEM codes. Test 1 and Test 2 consider the elastic normal impact of two spheres or a sphere with a rigid plane, whereas the other tests (Test 3–Test 8) investigate the energy dissipation due to the collision. These benchmark tests also involve different types of material. The DEM results were compared with the analytical solutions, experimental or FEA results found in the literature. All benchmark tests showed good to excellent match, providing a quantitative verification for the codes used in this study. These benchmark tests not only verify DEM codes but also enhance the understanding of fundamental impact phenomena for modelling a large number of particles.

Similar content being viewed by others

References

Cundall P.A., Strack O.D.L.: Discrete numerical-model for granular assemblies. Geotechnique 29, 47–65 (1979)

Zhu H.P., Yu A.B., Wu Y.H.: Numerical investigation of steady and unsteady state hopper flows. Powder Technol. 170, 125–134 (2006)

Ketterhagen W.R., Curtis J.S., Wassgren C.R., Hancock B.C.: Predicting the flow mode from hoppers using the discrete element method. Powder Technol. 195, 1–10 (2009)

Tao H., Baosheng J., Zhong W.Q, Wang X.F., Ren B., Zhang Y., Xiao R.: Discrete element method modeling of non-spherical granular flow in rectangular hopper. Chem. Eng. Process. 49, 151–158 (2010)

Kwan C.C., Mio H., Chen Y.Q., Ding Y.L., Saito F., Papadopoulos D.G., Bentham A.C., Ghadiri M.: Analysis of the milling rate of pharmaceutical powders using the Distinct Element Method (DEM). Chem. Eng. Sci. 60, 1441–1448 (2005)

Yang R.Y., Jayasundara C.T., Yu A.B., Curry D.: DEM simulation of the flow of grinding media in IsaMill. Miner. Eng. 19, 984–994 (2006)

Cleary P.W., Sinnott M.D., Morrison R.D.: DEM prediction of particle flows in grinding processes. Int. J. Numer. Methods Fluids 58, 319–353 (2008)

Müller C.R., Holland D.J., Sederman A.J., Scott S.A., Dennis J.S., Gladden L.F.: Granular temperature: comparison of magnetic resonance measurements with discrete element model simulations. Powder Technol. 184, 241–253 (2008)

Chu K.W., Wang B., Yu A.B., Vince A.: CFD-DEM modelling of multiphase flow in dense medium cyclones. Powder Technol. 193, 235–247 (2009)

Maio F.P.D., Renzo A.D., Trevisan D.: Comparison of heat transfer models in DEM-CFD simulations of fluidized beds with an immersed probe. Powder Technol. 193, 257–265 (2009)

Lu L.S., Hsiau S.S.: Mixing in a vibrated granular bed: diffusive and convective effects. Powder Technol. 184, 31–43 (2008)

Majid M., Walzel P.: Convection and segregation in vertically vibrated granular beds. Powder Technol. 192, 311–317 (2009)

Naeini S.E., Spelt J.K.: Two-dimensional discrete element modeling of a spherical steel media in a vibrating bed. Powder Technol. 195, 83–90 (2009)

Luding S.: Cohesive, frictional powders: contact models for tension. Granul. Matter 10, 235–246 (2008)

Härtl J., Ooi J.Y.: Experiments and simulations of direct shear tests: porosity, contact friction and bulk friction. Granul. Matter 10, 263–271 (2008)

Chung Y.C., Ooi J.Y.: A study of influence of gravity on bulk behaviour of particulate solid. Particuology 6, 467–474 (2008)

Holst J.M.F.G., Ooi J.Y., Rotter J.M., Rong G.H.: Numerical modeling of silo filling. I: continuum analyses. J. Eng. Mech. 125, 94–103 (1999)

Holst J.M.F.G., Rotter J.M., Ooi J.Y., Rong G.H.: Numerical modeling of silo filling. II: discrete element analyses. J. Eng. Mech. 125, 104–110 (1999)

Timoshenko S.P., Goodier J.N.: Theory of Elasticity. 3rd edn. McGraw-Hill, New York (1970)

Hertz H.: Miscellaneous Papers. McMillan, New York (1896)

Maw N., Barber J.R., Fawcett J.N.: The oblique impact of elastic spheres. Wear 38, 101–114 (1976)

Mindlin R.D., Deresiewicz H.: Elastic spheres in contact under varying oblique forces. J. Appl. Mech. (Trans. ASME) 20, 327–344 (1953)

Vu-Quoc L., Zhang X., Lesburg L.: Normal and tangential force-displacement relations for frictional elasto-plastic contact of spheres. Int. J. Solids Struct. 38, 6455–6489 (2001)

Zhang X., Vu-Quoc L.: Modeling the dependence of the coefficient of restitution on the impact velocity in elasto-plastic collisions. Int. J. Impact Eng. 27, 317–341 (2002)

Wu C.Y., Thornton C., Li L.Y.: Coefficients of restitution for elastoplastic oblique impacts. Adv. Powder Technol. 14, 435–448 (2003)

Vu-Quoc L., Zhang X.: An elastoplastic contact force-displacement model in the normal direction: displacement-driven version. Proc. R. Soc. Lond. Ser. A 455, 4013–4044 (1999)

Vu-Quoc L., Lesburg L., Zhang X.: An accurate tangential force-displacement model for granular-flow simulations: contacting spheres with plastic deformation, force-driven formulation. J. Comput. Phys. 196, 298–326 (2004)

Zhang X., Vu-Quoc L.: An accurate elasto-plastic frictional tangential force-displacement model for granular flow simulations: displacement-driven formulation. J. Comput. Phys. 225, 730–752 (2007)

Foerster S.F., Louge M.Y., Chang H., Allia K.: Measurements of the collision properties of small spheres. Phys. Fluids 6, 1108–1115 (1994)

Kharaz A.H., Gorham D.A., Salman A.D.: An experimental study of the elastic rebound of spheres. Powder Technol. 120, 281–291 (2001)

Plantard G., Papini M.: Mechanical and electrical behaviors of polymer particles: Experimental study of the contact area between two particles.Experimental validation of a numerical model. Granul. Matter 7, 1–12 (2005)

Tsuji Y., Tanaka T., Ishida T.: Lagrangian numerical-simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71, 239–250 (1992)

Itasca Consulting Group Inc. PFC3D–Particle Flow Code in Three Dimensions, Version 3.0. Minneapolis, USA (2003)

DEM Solutions Ltd. EDEM Discrete Element Code, Beta Version. Edinburgh, UK (2005). (http://www.dem-solutions.com/)

Chung,Y.C.: Discrete element modelling and experimental validation of a granular solid subject to different loading conditions. PhD Thesis, University of Edinburgh, Edinburgh, UK (2006)

Walton O.R.: Numerical simulation of inelastic, frictional particle–particle interactions. In: Roco, M.C. (eds) Particulate Two-Phase Flow, pp. 884–911. Butterworth-Heinemann, Boston (1993)

Vu-Quoc L., Zhang X.: An accurate and efficient tangential force-displacement model for elastic frictional contact in particle-flow simulations. Mech. Mater. 31, 235–269 (1999)

Meriam J.L., Kraige L.G.: Engineering Mechanics-Dynamics. Wiley, New York (2003)

Ning, Z., Ghadiri, M.: Incorporation of Rayleigh damping into TRUBAL and determination of the critical time step. (1996)

Renzo A.D., Maio F.P.D.: Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem. Eng. Sci. 59, 525–541 (2004)

Johnson K.L.: Contact Mechanics. Cambridge University Press, Cambridge (1985)

Thornton C., Randall C.W.: Applications of theoretical contact mechanics to solid particle system simulation. In: Satake, M., Jenkins, J.T. (eds) Micromechanics of Granular Materials, pp. 133–142. Elsevier, Amsterdam (1988)

Thornton C., Ning Z., Wu C.Y., Nasrullah M., Li L.Y.: Contact mechanics and coefficients of restitution. In: Poschel, T., Luding, S. (eds) Granular Gases, pp. 55–66. Springer, Berlin (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, Y.C., Ooi, J.Y. Benchmark tests for verifying discrete element modelling codes at particle impact level. Granular Matter 13, 643–656 (2011). https://doi.org/10.1007/s10035-011-0277-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-011-0277-0