Abstract

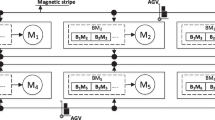

Recently, many production lines that have complicated structures such as parallel, reworks, feed-forward, etc., have become widely used in high-volume industries. Among them, the serial-parallel production line (S-PPL) is one of the more common production styles in many modern industries. One of the methods used for studying the S-PPL design is through a genetic algorithm (GA). One of the important jobs in using a GA is how to express a chromosome. In this study, we attempt to find the nearest optimal design of a S-PPL that will maximize production efficiency by optimizing the following three decision variables: buffer size between each pair of work stations, machine numbers in each of the work stations, and machine types. In order to do this we present a new GA-simulation-based method to find the nearest optimal design for our proposed S-PPL. For efficient use of a GA, our GA methodology is based on a technique that is called the gene family arrangement method (GFAM), which arranges the genes inside individuals. An application example shows that after a number of operations based on the proposed simulator, the nearest optimal design of a S-PPL can be found.

Similar content being viewed by others

References

Dallery Y, Gershwin SB (1992) Manufacturing flow line systems: a review of models and analytical results. Queueing systems 12: 3–94

Gershwin SB (1993) Manufacturing systems engineering. Prentice-Hall, Englewood Cliffs

Burman MH (1995) New results in flow line analysis. PhD Thesis, MIT, Cambridge

Enginarlar E, Li J, Meerkov SM, et al. (2002) Buffer capacity for accommodating machine downtime in serial production lines. Int J Prod Res 40:601–624

Vouros GA, Papadopoulos HT (1998) Buffer allocation in unreliable production lines using a knowledge-based system. Comput Operations Res 25:1055–1067

Spinellis D, Papadopoulos CT, Smith J (2000) Large production line optimization using simulated annealing. Int J Prod Res 38:509–541

Papadopoulos HT, Vidalis MI (2001) A heuristic algorithm for the buffer allocation in unreliable unbalanced production lines. Comput Indust Eng 41:261–277

Jafari MA, Shanthikumar JG (1989) Determination of optimal buffer storage capacities and optimal allocation in multistage automatic transfer lines. IIE Trans 21:130–135

Forrest S (1996) Genetic algorithms. ACM Comput Surveys 28:77–83

Goldberg DE (1989) Genetic algorithms: in search of optimization and machine learning. Addison-Wesley, Reading

Li J (2005) Overlapping decomposition: a system-theoretic method for modeling and analysis of complex production systems. IEEE Trans on Auto Sc and Eng 2:40–54

Chiang SY, Kuo C-T, Meerkov SM (2000) DT-bottlenecks in serial production line: theory and application. IEEE Trans Robotics Autom 16:567–580

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Abu Qudeiri, J., Yamamoto, H., Ramli, R. et al. Genetic algorithm for buffer size and work station capacity in serial-parallel production lines. Artif Life Robotics 12, 102–106 (2008). https://doi.org/10.1007/s10015-007-0449-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10015-007-0449-5