Abstract

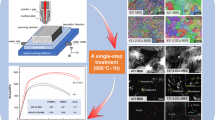

The microstructure and corrosion behavior in 3.5% NaCl solution of type 204 metastable austenitic stainless steels with 15% cold-rolling reduction and different Cu contents (i.e., 0, 0.87, and 1.46%) were investigated by X-ray (XRD), electron beam backscatter diffraction (EBSD), X-ray photoelectron spectroscopy (XPS), and electrochemical measurement techniques. Due to the suppressive effect of alloying Cu on the martensite transformation, both α′- and ε-martensite phases show lower volume fractions in the specimens with higher Cu contents. The Cu addition results in forming the passive films with higher Cr/Fe ratio and small amount of copper oxides. The alloying Cu enhances the passivation ability and pitting corrosion resistance of the cold-rolled stainless steels.

Similar content being viewed by others

References

Kim YH, Kim KY, Lee YD (2004) Nitrogen-alloyed, metastable austenitic stainless steel for automotive structural applications. Mater Manuf Process 19(1):51–59

Jacques P, Furnémont Q, Mertens A, Delannay F (2001) On the sources of work hardening in multiphase steels assisted by transformation-induced plasticity. Philos Mag A 81(7):1789–1812

Joseph MJ, Jabbar MA (2019) Effect of aging process on the microstructure, corrosion resistance and mechanical properties of stainless steel AISI 204. Case Stud Constr Mater 11:e00253

Grässel O, Frommeyer G (1998) Effect of martensitic phase transformation and deformation twinning on mechanical properties of Fe–Mn–Si–AI steels. Mater Sci Technol 14(12):1213–1217

Wu CC, Wang SH, Chen CY, Yang JR, Chiu PK, Fang J (2007) Inverse effect of strain rate on mechanical behavior and phase transformation of superaustenitic stainless steel. Scripta Mater 56(8):717–720

Zhang YC, Li MC, Bi HY, Gu JQ, Chen DX, Chang E, Zhang W (2018) Martensite transformation behavior and mechanical properties of cold rolled metastable Cr-Mn-Ni-N austenitic stainless steels. Mater Sci Eng A 724:411–420

Charles J (2007) The new 200-series: an alternative answer to Ni surcharge? Risks or opportunities? Rev Met Paris 104(6):308–317

Tavares SM, Pardal JM, Silva MJGD, Abreu HFG, Silva MRD (2009) Deformation induced martensitic transformation in a 201 modified austenitic stainless steel. Mater Charact 60(8):907–911

Xi T, Shahzad M, Xu D, Zhao JL, Yang CG, Qi M, Yang K (2016) Copper precipitation behavior and mechanical properties of Cu-bearing 316L austenitic stainless steel: a comprehensive cross-correlation study. Mater Sci Eng A 675:243–252

Phaniraj MP, Shin YM, Lee J, Goo NH, Kim DL, Suh JY, Jung WS, Shim JH, Choi IS (2015) Development of high strength hot rolled low carbon copper-bearing steel containing nanometer sized carbides. Mater Sci Eng A 633:1–8

Gonzalez BM, Castro CSB, Buono VTL, Vilela JMC, Andrade MS, Moraes JMD, Mantel MJ (2003) The influence of copper addition on the formability of AISI 304 stainless steel. Mater Sci Eng A 343(1–2):51–56

Pardo A, Merino MC, Carboneras M, Coy AE, Arrabal R (2007) Pitting corrosion behaviour of austenitic stainless steels with Cu and Sn additions. Corros Sci 49(2):510–525

Sourisseau T, Chauveau E, Baroux B (2005) Mechanism of copper action on pitting phenomena observed on stainless steels in chloride media. Corros Sci 47(5):1097–1117

Hong IT, Koo CH (2005) Antibacterial properties, corrosion resistance and mechanical properties of Cu-modified SUS 304 stainless steel. Mater Sci Eng A 393(1–2):213–222

Ujiro T, Satoh S, Staehle RW, Smyrl WH (2001) Effect of alloying Cu on the corrosion resistance of stainless steels in chloride media. Corros Sci 43(11):2185–2200

De AK, Murdock DC, Mataya MC, Speer JG, Matlock DK (2004) Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scripta Mater 50(12):1445–1449

Zhang YC, Li MC, Bi HY, Chen DX, Gu JQ, Chang E (2019) Mechanical properties of cold-rolled metastable Cr-Mn-Ni-N austenitic stainless steel at low ambient temperature. Mater Sci Eng A 759:224–233

Elsener B, Addari D, Coray S, Rossi A (2011) Nickel-free manganese bearing stainless steel in alkaline media-electrochemistry and surface chemistry. Electrochim Acta 56(12):4489–4497

Luo H, Dong CF, Xiao K, Li XG (2011) Characterization of passive film on 2205 duplex stainless steel in sodium thiosulphate solution. Appl Surf Sci 258(1):631–639

Wagner CD, Riggs WN, Davies LE, Moulder JF, Muilenberg GE (1978) Handbook of X-ray photoelectron spectroscopy. Perkin Elmer Co., Eden Prairie

Liu JB, Chen CC, Feng Q, Fang XY, Wang HT, Liu F, Lu J (2017) Dislocation activities at the martensite phase transformation interface in metastable austenitic stainless steel: an in-situ TEM study. Mater Sci Eng A 703:236–243

Das A, Sivaprasad S, Ghosh M, Chakraborti PC, Tarafder S (2008) Morphologies and characteristics of deformation induced martensite during tensile deformation of 304LN stainless steel. Mater Sci Eng A 486(1–2):283–286

Lee H, Jo MC, Sohn SS, Zargaran A, Ryu JH, Kim NJ, Lee S (2018) Novel medium-Mn (austenite + martensite) duplex hot-rolled steel achieving 1.6 GPa strength with 20% ductility by Mn-segregation-induced TRIP mechanism. Acta Mater 147:247–260

Luo H, Li XG, Dong CF, Xiao K (2013) The influence of Cu on the electrochemical behaviour of 304 stainless steel in 0.1M H3PO4 solution. Surf Interface Anal 45(4):793–799

Geng HM, Wu XC, Wang HB, Min YA (2008) Effects of copper content on the machinability and corrosion resistance of martensitic stainless steel. J Mater Sci 43(1):83–87

Pardo A, Merino MC, Coy AE, Viejo F, Arrabal R, Matykina E (2008) Pitting corrosion behaviour of austenitic stainless steels-combining effects of Mn and Mo additions. Corros Sci 50(6):1796–1806

Yang Y, Zeng HT, Xin SS, Hou XL, Li MC (2020) Electrochemical corrosion behavior of 2205 duplex stainless steel in hot concentrated seawater under vacuum conditions. Corros Sci 165:108383

Olsson COA (1995) The influence of nitrogen and molybdenum on passive films formed on the austenoferritic stainless steel 2205 studied by AES and XPS. Corros Sci 37(3):467–479

Raov VS, Singhal LK (2009) Electrochemical and surface analytical approach to passive film on 200 series stainless steels formed in sulfuric acid. ISIJ Int 49:1902–1906

Kocijan A, Donik C, Jenko M (2007) Electrochemical and XPS studies of the passive film formed on stainless steels in borate buffer and chloride solutions. Corros Sci 49(5):2083–2098

Wang C, Jiang F, Wang FH (2004) The characterization and corrosion resistance of cerium chemical conversion coatings for 304 stainless steel. Corros Sci 46(1):75–89

Olson GB, Cohen M (1972) A mechanism for the strain-induced nucleation of martensitic transformations. J Less-Common Met 28(1):107–118

Murr LE, Staudhammer KP, Hecker SS (1982) Effects of strain state and strain rate on deformation-induced transformation in 304 stainless steel: part II. Microstructural study. Metall Mater Trans A 13(4):627–635

Dumay A, Chateau JP, Allain S, Migot S, Bouaziz O (2008) Influence of addition elements on the stacking-fault energy and mechanical properties of an austenitic Fe–Mn–C steel. Mater Sci Eng A 483-484:184–187

Frommeyer G, Brüx U (2006) Microstructures and mechanical properties of high-strength Fe-Mn-Al-C light-weight TRIPLEX steels. Steel Res Int 77(9–10):627–633

Natutani T (1989) Effect of deformation-induced martensitic transformation on the plastic behavior of metastable austenitic stainless steel. Mater Trans 30(1):33–45

Li MC, Wang SD, Ma RY, Han PH, Bi HY (2012) Effect of cyclic oxidation on electrochemical corrosion of type 409 stainless steel in simulated muffler condensates. J Solid State Electrochem 16(9):3059–3067

Xin SS, Li MC (2014) Electrochemical corrosion characteristics of type 316L stainless steel in hot concentrated seawater. Corros Sci 81:96–101

Freire L, Carmezim MJ, Ferreira MGS, Montemor MF (2010) The passive behaviour of AISI 316 in alkaline media and the effect of pH: a combined electrochemical and analytical study. Electrochim Acta 55(21):6174–6181

Kocijan A, Merl DK, Jenko M (2011) The corrosion behaviour of austenitic and duplex stainless steels in artificial saliva with the addition of fluoride. Corros Sci 53(2):776–783

Mandel M, Böhme F, Hauser M, Wendler M, Tuchscheerer F, Krüger L (2016) The influence of plastic deformation on the corrosion behavior of a cast high-alloy CrMnNi TRIP steel. Steel Res Int 87(8):1105–1110

Mudali UK, Shankar P, Ningshen S, Dayal RK, Khatak HS, Raj B (2002) On the pitting corrosion resistance of nitrogen alloyed cold worked austenitic stainless steels. Corros Sci 44(10):2183–2198

Zhang YC, Li MC, Bi HY (2019) The mechanism of pitting initiation and propagation at deformation bands intersection of cold-rolled metastable stainless steel in acidic ferric chloride solution. J Mater Sci 54(24):14914–14925

Lv JL, Guo WL, Liang TX (2016) The effect of pre-deformation on corrosion resistance of the passive film formed on 2205 duplex stainless steel. J Alloys Compd 686(25):176–183

Hermas AA, Ogura K, Adachi T (1995) Accumulation of copper layer on a surface in the anodic polarization of stainless steel containing Cu at different temperatures. Electrochim Acta 40(7):837–844

Oh KN, Toor IH, Ahn SH, Kwon HS (2013) Effects of Cu on the passive film stability of Fe-20Cr-xCu (x = 0, 2, 4 wt.%) alloys in H2SO4 solution. Electrochim Acta 88:170–176

Asami K, Hashimoto K, Shimodaira S (1977) XPS determination of compositions of alloy surfaces and surface oxides on mechanically polished iron-chromium alloys. Corros Sci 17(9):713–723

Babic R, Metikos-Hukovic M, Jukic A (2001) A study of copper passivity by electrochemical impedance spectroscopy. J Electrochem Soc 148(4):B146–B151

Adeloju SB, Duan YY (1994) Corrosion resistance of Cu2O and CuO on copper surfaces in aqueous media. Br Corros J 29(4):309–314

Pardo A, Merino MC, Carboneras M, Viejo F, Arrabal R, Muñoz J (2006) Influence of Cu and Sn content in the corrosion of AISI 304 and 316 stainless steels in H2SO4. Corros Sci 48(5):1075–1092

Kim ST, Park YS (2007) Effect of copper addition on corrosion behavior of high-performance austenitic stainless steel in highly concentrated sulfuric acid solution-part 1. Corrosion 63(2):114–126

Funding

Financial support was provided by National Natural Science Foundation of China (Grant Nos. U1960103 and U1660205).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, X., Liu, L., Sui, F. et al. Influence of Cu on the microstructure and corrosion resistance of cold-rolled type 204 stainless steels. J Solid State Electrochem 24, 1197–1206 (2020). https://doi.org/10.1007/s10008-020-04614-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-020-04614-1