Abstract

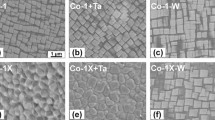

The degradation of materials involving corrosion in handling nitric acid in the spent fuel nuclear reprocessing plant is a serious issue. In the present work, the corrosion resistance of American Iron and Steel Institute (AISI) type 304L stainless steel (SS) and nitric acid grade (NAG) type 310L SS in 1 to 11.5 M HNO3 and boiling 15.65 M HNO3 was evaluated. In both the alloy steels, the open circuit potential and corrosion potential are shifted to more noble potential with increasing concentrations. However, the passive current density was not affected, and the transpassive potential was shifted to higher potential with increasing concentrations. The corrosion rate measured in boiling 15.65 M HNO3 after 240 h shows a much lower corrosion rate in type 310L SS (∼0.06 ± 0.012 mm/y) then type 304L SS (∼0.18 ± 0.02–0.2 ± 0.001 mm/y). These observations are corroborated with the scanning electron microscope (SEM) morphologies that show severe intergranular corrosion (IGC) attack in type 304L SS then in type 310L SS. The X-ray photoelectron spectroscopy (XPS) study of the passive oxide films of both alloy steels shows the presence of Cr2O3 and SiO2, and the depth profile indicated predominant Si enrichment.

Similar content being viewed by others

References

Raj B, Kamachi Mudali U (2006) Materials development and corrosion problems in nuclear fuel reprocessing plants. Prog Nucl Energy 48:283–313

Fauvet P, Balbaud F, Robin R, Tran QT, Mugnier A, Espinoux D (2008) Corrosion mechanisms of austenitic stainless steels in nitric media used in reprocessing plants. J Nucl Mater 375:52–64

Whillock GOH, Worthington SE (2010) Corrosion in nitric acid. In: Richardson TJA, Cottis BRA, Lindsay R, Lyon S, Scantlebury DJD, Stott H, Graham M (eds) Shreir’s corrosion, vol 2. Elsevier, Amsterdam, pp. 1250–1269

Schillmoller CM (1999) Select the best alloys to resist nitric acid. Chem Eng Prog 95:65–69

Ningshen S, Kamachi Mudali U, Ramya S, Raj B (2011) Corrosion behaviour of AISI type 304L stainless steel in nitric acid media containing oxidizing species. Corros Sci 53:64–70

Kain V, De PK (2005) Controlling corrosion in the back end of fuel cycle using nitric acid grade stainless steels. Int J Nucl Energy Sci Technol 1:220–231

Ningshen S, Kamachi Mudali U, Amarendra G, Raj B (2009) Corrosion assessment of nitric acid grade austenitic stainless steels. Corros Sci 51:322–329

Whillock GOH, Dunnett BF, Takeuchi M (2005) Techniques for measuring the end-grain corrosion resistance of austenitic stainless steels. Corrosion 61:58–67

Dillon CP (1992) Corrosion of stainless steels by nitric acid. Mater Perform 31:51–53

Kapoor K, Kain V, Gopalkrishna T, Sanyal T, De PK (2003) High corrosion resistant Ti–5%Ta–1.8%Nb alloy for fuel reprocessing application. J Nucl Mater 322:36–44

Robin R, Miserque F, Spagnol V (2008) Correlation between composition of passive layer and corrosion behavior of high Si-containing austenitic stainless steels in nitric acid. J Nucl Mater 375:65–71

Armijo JS, Wilde BE (1968) Influence of Si content on the corrosion resistance of austenitic Fe-Cr-Ni alloys in oxidizing acids. Corros Sci 8:649–664

Ningshen S, Sakairi M, Suzuki K, Ukai S (2014) The surface characterization and corrosion resistance of 11 % Cr ferritic/martensitic and 9–15 % Cr ODS steels for nuclear fuel reprocessing application. J Solid State Electrochem 18:411–425

Ningshen S, Sakairi M, Suzuki K, Ukai S (2013) The passive film characterization and anodic polarization behavior of 11 % Cr ferritic/martensitic and 15 % Cr oxide dispersion strengthened steels in different electrolytic solutions. Appl Surf Sci 248:345–355

Ningshen S, Sakairi M, Suzuki K, Ukai S (2014) The corrosion resistance and passive film compositions of 12 % Cr and 15 % Cr oxide dispersion strengthened steels in nitric acid media. Corros Sci 78:322–334

Armstrong RD, Cleland GE, Whillock GOH (1998) Effect of dissolved chromium species on the corrosion of stainless steel in nitric acid. J Appl Electrochem 28:1205–1211

Otero E, Pardo A, Saenz E, Utrilla M, Hierro P (1996) A study of the influence of nitric acid concentration on the corrosion resistance of sintered austenitic stainless steel. Corros Sci 38:1485–1493

Evans UR (1960) The corrosion and oxidation of metals. Edward Arnold, London

Hamada E, Yamada K, Nagoshi M, Makiishi N, Sato K, Ishii T, Fukuda K, Ishikawa S, Ujiro T (2010) Direct imaging of native passive film on stainless steel by aberration corrected STEM. Corros Sci 52:3851–3854

Ningshen S, Sakairi M, Suzuki K, Okuno T (2015) Corrosion performance and surface analysis of Ti-Ni-Pd-Ru-Cr alloy in nitric acid solution. Corros Sci 91:120–128

Rutten OWJS, Sandwijk AV, Weert GV (1999) The electrochemical reduction of nitrate in acidic nitrate solutions. J Appl Electrochem 29:87–92

Kajimura H, Nagano H (1992) Effects of Cr and P on the corrosion resistance behavior of stainless steels in nitric acid containing oxidizing ions. Kairyo Kankyo 41:10–18

Olsson C-OA, Landolt D (2003) Passive films on stainless steels/chemistry, structure and growth. Electrochim Acta 48:1093–1104

Castle JE, Clayton CR (1977) The use of in the x-ray photo-electron spectroscopy analyses of passive layers on stainless steel. Corros Sci 17:7–26

Betova I, Bojinov M, Laitinen T, Mäkelä K, Pohjanne P, Saario T (2002) The transpassive dissolution mechanism of highly alloyed stainless steels—I. Experimental results and modelling procedure. Corros Sci 44:2675–2697

Sato N (1982) Anodic breakdown of passive films on metals. J Electrochem Soc 129:255–260

Macdonald DD (1992) The point defect model for the passive state. J Electrochem Soc 139:3434–3449

Betova I, Bojinov M, Kinnunen P, Laitinen T, Pohjanne P, Saario T (2002) Mechanism of transpassive dissolution of nickel-based alloys studied by impedance spectroscopy and rotating ring-disc voltammetry. Electrochim Acta 47:2093–2107

Song GL (2005) Transpassivation of Fe-Cr-Ni stainless steels. Corros Sci 47:1953–1987

Vignal V, Delrue O, Heintz O, Peultier J (2010) Influence of the passive film properties and residual stresses on the micro-electrochemical behavior of duplex stainless steels. Electrochim Acta 55:7118–7125

Abreu CM, Cristóbal MJ, Losada R, Nóvoa XR, Pena G, Pérez MC (2006) The effect of Ni in the electrochemical properties of oxide layers grown on stainless steels. Electrochim Acta 51:2991–3000

Massoud T, Maurice V, Klein LH, Wiame F, Marcus P (2013) Intergranular effects on the local electronic properties of the passive film on nickel. Corros Sci 69:245–251

Mayuzumi M, Ohta J, Kako K, Kawakami E (2000) Effect of silicon and manganese additions on the transpassive corrosion of high-purity Fe-18 % Cr-14 % Ni alloys. Corrosion 56:910–920

Streicher MA (1959) General and intergranular corrosion of austenitic stainless steels in acids. J Electrochem Soc 106:161–180

Randle V, Owen G (2006) Mechanisms of grain boundary engineering. Acta Mater 54:1777–1783

Jin WZ, Kokawa H, Wang ZJ, Yutaka S, Sato YS, Hara N (2010) Improvement of transpassive intergranular corrosion resistance of 304 austenitic stainless steel by thermomechanical processing for twin-induced grain boundary engineering. ISIJ Int 50:476–481

Kajimura H, Usuki N, Nagano H (1998) Dual layer corrosion protective film formed on Si bearing austenitic stainless steel in highly oxidizing nitric acid. Electrochem Soc Proc 97:332–334

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ningshen, S., Sakairi, M. Corrosion degradation of AISI type 304L stainless steel for application in nuclear reprocessing plant. J Solid State Electrochem 19, 3533–3542 (2015). https://doi.org/10.1007/s10008-015-2891-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-015-2891-y