Abstract

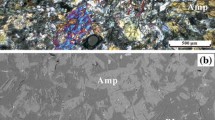

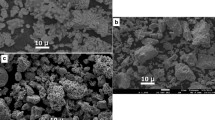

The synthesis of titanium pyrophosphate is carried out, and the material is sintered at different temperatures between 370 and 970 °C. Yttrium is added during the synthesis to act as acceptor dopant, but it is mainly present in the material in secondary phases. The conductivity is studied systematically as a function of sintering temperature, pH2O, pO2, and temperature (100–400 °C). Loss of phosphorus upon sintering above 580–600 °C is confirmed by energy dispersive spectroscopy and combined thermogravimetry and mass spectrometry. The conductivity decreases with increasing sintering temperature and decreasing phosphorus content. The highest conductivity is 5.3 × 10−4 S cm−1 at 140 °C in wet air (pH2O = 0.22 atm) after sintering at 370 °C. The conductivity is higher in wet atmospheres than in dry atmospheres. The proton conduction mechanism is discussed, and the conductivity is attributed to an amorphous secondary phase at the grain boundaries, associated with the presence of excess phosphorus in the samples. A contribution to the conductivity by point defects in the bulk may explain the conductivity trend in dry air and the difference in conductivity between oxidizing and reducing atmospheres at 300–390 °C. Slow loss of phosphorus by evaporation over time and changes in the distribution of the amorphous phase during testing are suggested as causes of conductivity degradation above 220 °C.

Similar content being viewed by others

References

Yang C, Costamagna P, Srinivasan S, Benziger J, Bocarsly AB (2001) Approaches and technical challenges to high temperature operation of proton exchange membrane fuel cells. J Power Sources 103:1–9

Hsiao CY, Selman R (1997) The degradation of SOFC electrodes. Solid State Ionics 98:33–38

Tanasini P, Cannarozzo M, Costamagna P, Faes A, Van Herle J, Hessler-Wyser A, Comninellis (2009) Experimental and theoretical investigation of degradation mechanisms by particle coarsening in SOFC electrodes. Fuel Cells 9:740–752

Norby T (1999) Solid-state protonic conductors: principles, properties, progress and prospects. Solid State Ionics 125:1–11

Nagao M, Kamiya T, Heo P, Tomita A, Hibino T, Sano M (2006) Proton conduction in In3+ doped SnP2O7 at intermediate temperatures. J Electrochem Soc 153:A1604–A1609

Jin Y, Shen Y, Hibino T (2010) Proton conduction in metal pyrophosphates (MP2O7) at intermediate temperatures. J Mater Chem 20:6214–6217

Phadke SR, Bowers CR, Wachsman ED, Nino JC (2011) Proton conduction in acceptor doped SnP2O7. Solid State Ionics 183:26–31

Tomita A, Kajiyama N, Kamiya T, Nagao M, Hibino T (2007) Intermediate-temperature proton conduction in Al3 + −doped SnP2O7. J Electrochem Soc 154:B1265–B1269

Tanimoto S, Hirukawa S, Shirai T, Sato S, Kusano T, Saito M, Kuwano J, Shiroishi H (2009) Shell-core type proton conducting TiP2O7-based solid electrolytes. Key Eng Mat 388:57–60

Jin Y, Lee B, Hibino T (2010) Development and application of SnP2O7-based proton conductors to intermediate-temperature fuel cells. J Jpn Petrol Inst 53:12–23

Nalini V, Haugsrud R, Norby T (2010) High-temperature proton conductivity and defect structure of TiP2O7. Solid State Ionics 181:510–516

Nalini V, Sørby MH, Amezawa K, Haugsrud R, Fjellvåg H, Norby T (2011) Structure, water uptake, and electrical conductivity of TiP2O7. J Am Ceram Soc 94:1514–1522

Miyazaki K, Kato Y, Matsui T, Hayashi S, Iriyama Y, Fukutsuka T, Abe T, Ogumi Z (2012) Formation of “fuzzy” phases with high proton conductivities in the composites of polyphosphoric acid and metal oxide nanoparticles. Phys Chem Chem Phys 14:11135–8

Shirai T, Satou S, Saito M, Kuwano J, Shiroishi H (2009) Proton conductivity and microstructures of the core-shell type solid electrolytes in the MO2-In2O3-P2O5 (MTi, Sn, Zr) systems. Solid State Ionics 180:569–574

Tran ATT, Duke M, Gray PG, Diniz da Costa JC (2006) Proton conductivities of titanium phosphate at high temperature for PEMFC. Dev Chem Eng Miner Process 14:101–118

Norberg ST, Svensson G, Albertsson J (2001) A TiP2O7 superstructure. Acta Crystallogr C 57:225–227

Ohtsuka H, Aomura K (1962) Activation of solid phosphoric acid by heat treatment. Bulletin of The Japan Petroleum Institute 4:3–14

Hwang MJ, Lee SY, Han CS (2006) A study on electric conductivity of phosphoric acid supported on nano-pore rice husk silica in H2|Pt|H3PO4/RHS|Pt|O2 fuel cells. J Nanosci Nanotechno 6:3491–3493

Huang Y, Li Q, Jensen AH, Yin M, Jensen JO, Christensen E, Pan C, Bjerrum NJ, Xing W (2012) Niobium phosphates as an intermediate temperature proton conducting electrolyte for fuel cells. J Mater Chem 22:22452–22458

Harrison DE, Hummel FA (1959) Reactions in the system TiO2-P2O5. J Am Ceram Soc 42:487–490

Bamberger CE, Begun GM (1987) Synthesis and characterization of titanium phosphates, TiP2O7 and (TiO)2P2O7. J Less-Common Met 134:201–206

Nogami M, Matsushita H, Goto Y, Kasuga T (2000) A sol–gel-derived glass as a fuel cell. Adv Mater 12:1370–1372

Harley G, Yu R, Dejonghe L (2007) Proton transport paths in lanthanum phosphate electrolytes. Solid State Ionics 178:769–773

Harley G, De Jonghe LC (2010) Proton transport in doped La-metaphosphate glasses. Solid State Ionics 181:424–429

Chatzichristodoulou C, Hallinder J, Lapina A, Holtappels P, Mogensen M (2013) Phase composition and long-term conductivity of acceptor doped Ce(PO3)4 and CeP2O7 with variable P/metal ratio and of CeP2O7-KH2PO4 composite. J Electrochem Soc 160:F798–F805

Schmidt TJ (2006) Durability and degradation in high-temperature polymer electrolyte fuel cells. ECS Transactions. ECS, pp 19–31

Brown EH, Whitt CD (1952) Vapor pressure of phosphoric acids. Ind Eng Chem 44:615–618

Kreller CR, Wilson MS, Mukundan R, Brosha EL (2012) Garzon FH (2012) Proton conductivity and stability of In3+ doped SnP2O7 with varying P:M. ECS PRIME 178:1–2

Acknowledgments

This work was financially supported by The Catalysis for Sustainable Energy (CASE) initiative funded by the Danish Ministry of Science, Technology, and Innovation. Special thanks to Laila Grahl-Madsen at IRD A/S for the generous supply of PEM CCB electrodes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lapina, A., Chatzichristodoulou, C., Hallinder, J. et al. Electrical conductivity of titanium pyrophosphate between 100 and 400 °C: effect of sintering temperature and phosphorus content. J Solid State Electrochem 18, 39–47 (2014). https://doi.org/10.1007/s10008-013-2225-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-013-2225-x