Abstract

Aluminium was anodised in H2SO4 solutions 0.25–1.53 M, temperatures 0–35 °C, times up to 90 min and voltage 25 V. Anodising was followed chronoamperometrically. The passing charge, consumed Al, formed oxide, transport numbers of oxygen anions in barrier layer and film thicknesses were determined. Films were examined to detect abnormal film growth, called burning. It was found that the current in Al anode is closely solely ionic, and the only processes occurring are those related with ionic charge transport and heat release and its abduction for which suitable equations were formulated relating many parameters. At each concentration, the temperatures, current densities and times up to which normal film growth occurs and above which stain-like mild, island-like intermediate, strong, strong-destructive and mixed burning appears were found. Burning emerges at lower concentrations, temperatures and times for thinner Al. Low concentrations and temperatures among thresholds where mild and next-kind burning first appear define windows of conditions where thick enough dark or black films grow. Peculiar chronoamperometric plot characterises each film growth type. Though other burning kinds can appear at each surface region or in the whole surface, strong and strong-destructive emerge only at the lower Al side around which the efficiency of solution stirring is highest. The mechanisms of normal and abnormal film growth were formulated showing that different processes and interacting variable parameters, some of which are noted for first time, regulate each film growth type. These can predict methods to avoid abnormal film growth.

Similar content being viewed by others

Abbreviations

- a 2 and a 3 :

-

Activation (half jump) distances of O2−and Al3+ transport inside the barrier layer (nanometres)

- Al3+ aq,hydr :

-

Hydrated Al3+ in aqueous solution

- AM Al :

-

Atomic mass of Al

- A 2 and A 3 :

-

N 2,m v 2 n 2 FN A −1 and N 3,m v 3 n 3 FN A −1 (milliamperes per square centimetre)

- A 2,a and A 3,a :

-

Average A 2 and A 3 across the barrier layer (milliamperes per square centimetre)

- B 2 :

-

n 2 a 2 and B 3 = n 3 a 3 (manometres)

- c a :

-

Concentration of H2SO4 anodising electrolyte (Molar)

- C p,Al :

-

Molar heat capacity of Al (joules per mole per Kelvin)

- d Al :

-

Density of Al (2.7 g cm−3)

- D, D b and D c :

-

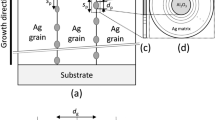

Diameter of the hemispherical section surface across the barrier layer, pore base diameter and cell width in steady state (nanometres)

- 2−1(D c–D b):

-

Barrier layer thickness (nanometres)

- ΔH :

-

Enthalpy change between ordinary and transient oxide lattice structures (joules per mole)

- ΔH a :

-

Average ΔH across the barrier layer (joules per mole)

- ΔH o 298 K(Al):

-

Standard formation enthalpy of Al (kilojoules per mole)

- ΔH o 298 K(Al2O3):

-

Standard formation enthalpy of Al2O3 (kilojoules per mole)

- ΔH o 298 K(Al3+):

-

Standard formation enthalpy of Al3+ (kilojoules per mole)

- ΔH o 298 K,hydr(Al3+):

-

Standard hydration enthalpy of Al3+ (kilojoules per mole)

- ΔH o 298 K(H+):

-

Standard formation enthalpy of H+ (kilojoules per mole)

- ΔH o 298 K,hydr(H+):

-

Standard hydration enthalpy of H+ (kilojoules per mole)

- ΔH o 298 K(H2Ol):

-

Standard formation enthalpy of liquid H2O (kilojoules per mole)

- ΔH r o 298 K and ΔH r o T :

-

Standard enthalpy (per mol of Al2O3) of reaction 2Al + tn an3H2O = tn anAl2O3 + tn an6H+ aq,hydr + tn ca2Al3+ aq,hydr + 6e−(kilojoules per mole) and this enthalpy at T ≠ 298 K

- Δm :

-

Difference of Al anode mass after and before anodising (grams)

- ΔP bl, ΔP pfs, ΔP attl and ΔP bs :

-

Potential drops across the barrier layer, in pore-filling solution, in attached layer and in adjacent bath solution layer up to reference electrode (volts)

- E :

-

local field strength in each equipotential surface across the barrier layer (volts per nanometre)

- E a = 2ΔP bl(D c–D b)−1 :

-

Average field strength across the barrier layer (volts per nanometre)

- E pfs, E attl and E bs :

-

Field strength in pore-filling solution, attached layer and adjacent bath solution layer up to reference electrode across each plane parallel to film surface (volts per micrometre)

- F :

-

Faraday’s constant (96,487 C mol−1)

- h f, h, h attl and h bs :

-

Film thickness, length of pores (≈ h f) and thicknesses of attached layer and adjacent layer up to reference electrode (micrometres)

- H+ aq,hydr :

-

Hydrated H+ in aqueous solution

- j and j a :

-

Current density and average current density during potentiostatic anodising (milliamperes per square centimetre)

- j pfs, j attl and j bs :

-

Ionic current density in pore-filling solution, attached layer and adjacent bath solution layer up to reference electrode across each plane parallel to film surface (milliamperes per square centimetre)

- k :

-

Rate constant of film thickness increase 6.9833 × 10−5 cm3 C−1

- k ht,ox, k ht,pfs and k ht,attl :

-

Thermal conductivity of oxide, pore-filling solution and attached layer (watt per centimetre per Kelvin)

- k ht,f :

-

Combined thermal conductivity of oxide and pore-filling solution (watt per centimetre per Kelvin)

- k ht,t :

-

Total coefficient of heat transport from Al anode to bath solution (watt per square centimetre per Kelvin)

- l Al,0 :

-

Initial Al metal thickness (millimetres)

- l Al = l Al,0–S Al −1 d Al −1 AM Al Q(3 F)−1 :

-

Mean thickness of Al metal remaining unconsumed during anodising (millimetres)

- me:

-

Metal

- m|o:

-

Metal|oxide interface

- m Al :

-

Mass of Al remaining unconsumed during anodising (grams)

- m Al,sod :

-

Consumed Al mass found by selective oxide dissolution (grams or milligrams)

- m ox,mb :

-

Mass of oxide found by the mass balance method (grams or milligrams)

- m ox,sod :

-

Mass of oxide found by its selective dissolution (grams or milligrams)

- n :

-

Surface density of oxide cells/pores near Al substrate surface in steady state (per square centimetre)

- n 2 and n 3 :

-

Valences of O2−and Al3+ ions

- N A :

-

Avogadro constant (6.022 × 1023 mol−1)

- N 2,m and N 3,m :

-

Surface concentrations of mobile O2−and Al3+ in each equipotential surface across the barrier layer (per square centimetre)

- v 2 and v 3 :

-

Vibration frequencies of O2−and Al3+ ions or the number of chances per s the ions may jump the energy barrier (activation energy) if they have sufficient energy (per second)

- o|e:

-

Oxide|electrolyte interface

- ox:

-

Oxide

- p and p a :

-

Local porosity at each position across the film and average porosity of the entire film (dimensionless)

- P an :

-

Anodic potential versus SHE (volts)

- P an–P cath :

-

Potential difference between anode and cathode or anodising voltage (volts)

- P an–P ref :

-

Potential difference between anode and reference electrode (volts)

- Q :

-

Passing electric charge (coulomb)

- Q ac,Al, Q ac,ox, Q ac,pfs and Q ac,attl :

-

Heat accumulated in Al metal substrate, oxide, pore-filling solution and attached layer (joules)

- R :

-

Universal gas constant (8.314 J K−1 mol−1)

- R pfs, R attl and R bs :

-

Ohmic resistances in pore-filling solution, attached layer and adjacent bath solution layer up to reference electrode (ohm)

- S:

-

Equipotential hemispherical surface across the barrier layer

- SS:

-

Plane across the film parallel to film and Al substrate surfaces

- S’S’:

-

Outer boundary plane of attached layer on Al anode

- S Al :

-

One face entire geometric surface area of Al specimen (square centimetres)

- S g :

-

Geometric surface area of Al specimens that is oxidised during anodising (square centimetre)

- S = 2−1 S g πnD 2 :

-

Area of hemispherical surface with diameter D across the barrier layer per unit of S g (square centimetres)

- S a :

-

Average S across the barrier layer ≈ 2−1 S g(2.093 + 2−1 πnD b 2) (square centimetres)

- t :

-

Anodising time (minutes or seconds)

- tn an and tn ca :

-

Transport numbers of O2−and Al3+ across the barrier layer (dimensionless)

- tn an,a :

-

Average tn an when j and/or T an vary during anodising (dimensionless)

- T :

-

Temperature of bath bulk solution (degrees Centigrade or Kelvin)

- T an :

-

Real anodising temperature in the barrier layer region (degrees Centigrade or Kelvin)

- T fs :

-

Temperature at film surface during anodising (degrees Centigrade or Kelvin)

- u i,pfs, u i,attl and u i,bs,:

-

Specific ionic conductance (conductivity) of i species in pore-filling solution, attached layer and adjacent bath solution layer up to reference electrode at each plane parallel to film surface (per ohm per micrometre)

- û i,pfs, û i,attl and û i,bs :

-

Average u i,pfs, u i,attl and u i,bs along pores and in attached and adjacent layer (per ohm per micrometre)

- W 2 and W 3 :

-

Real activation energies of O2−and Al3+ transport across the barrier layer (joules per mole)

- W 2,a and W 3,a :

-

Average W 2 and W 3 across the barrier layer (joules per mole)

References

Sheasby PG, Pinner R (2001) The surface treatment and finishing of aluminium and its alloys, 6th edn. ASM International & Finishing Publications Ltd, USA-UK

Martin CR (1996) Chem Mater 8:1739–1746

Kovtyukhova N, Mallouk TE (2005) Adv Mater 17:187–192

Sulka GD (2008) Highly ordered anodic porous alumina formation by self-organized anodizing. In: Eftekhari A (ed) Nanostructured materials in electrochemistry. Wiley-VGH, Wienheim

Ganley JC, Riechmann KL, Seebauer EG, Masel RI (2004) J Catal 227(1):26–32

Pellin MJ, Stair PC, Xiong G, Elam JW, Birrell J, Curtiss L, George SM, Han CY, Iton L, Kung H, Kung M, Wang HH (2005) Catal Lett 102(3–4):127–130

Surganov VF, Gorokh GG (1993) Mater Lett 17:121–124

Surganov V, Janson C, Nielsen JCG, Morgen P, Gorokh G, Larsen AN (1988) Electrochim Acta 33:517–519

Dell’Oca CJ, Fleming PJ (1976) J Electrochem Soc 123:1487–1493

Parkhutik VP (1986) Corros Sci 26:295–310

Parkhutik VP, Shershulsky VI (1992) J Phys D Appl 25:1258–1263

Patermarakis G, Chandrinos J, Masavetas K (2007) J Solid State Electrochem 11:1191–1204

Jessensky O, Müller F, Gösele U (1998) Appl Phys Lett 72(10):1173–1175

Zhang L, Cho HS, Li F, Metzger RM, Doyle WD (1998) J Mater Sci Lett 17:291–294

Jessensky O, Müller F, Gösele U (1998) J Electrochem Soc 145:3735–3740

Nielsch K, Choi J, Schwirn K, Wehrspoh RB, Gösele U (2002) Nano Lett 2(7):677–680

Li AP, Müller F, Birner A, Nielsch K, Gösele U (1997) J Appl Phys 84(11):6023–6026

Li AP, Müller F, Gösele U (2000) Electrochem Solid State Lett 3(3):131–134

Masuda H, Yotsuy M, Asano M, Nishio K, Nakao M, Yokoo A, Tamamura T (2001) Appl Phys Lett 78(6):826–828

Pan H, Lin J, Feng Y, Gao H (2005) IEEE Transac Nanotechnol 3:462–467

Keller F, Hunter MS, Robinson DL (1953) J Electrochem Soc 100:411–419

Diggle JW, Downie TC, Goulding CW (1969) Chem Rev 69:365–405

Young L (1961) Anodic Oxide Films. Academic Press, London

Thompson GE, Furneaux RC, Wood GC (1978) Corros Sci 18:481–498

Patermarakis G, Lenas P, Karavassilis C, Papayiannis G (1991) Electrochim Acta 36:709–725

Patermarakis G, Kerassovitou P (1992) Electrochim Acta 37:125–137

Napolskii KS, Roslyakov IV, Eliseev AA, Petukhov AV, Byelov DV, Grigiryeva NA, Bouwman WG, Lukashin AV, Kvashnina KO, Chumacov AP, Grigoryev SV (2010) Appl Crystallogr 43:531–538

Masuda H, Asoh H, Wanatab M, Nishio M, Nakao M, Tamamura T (2001) Adv Mater 13:189–192

Kustandi TS, Loh WW, Gao H, Low HY (2010) ACS Nano 4(5):2561–2568

Masuda H, Fukuda K (1995) Science 268:1466–1468

Sulka GD, Stroobants S, Moshehalkov V, Borghs G, Celis JP (2002) J Electrochem Soc 149(7):D97–D103

Masuda H, Hasegwa F, Ono S (1997) J Electrochem Soc 144:L127–L130

Li F, Zhang L, Metzger RM (1998) Chem Mater 10:2470–2480

Patermarakis G (2009) J Electroanal Chem 635:39–50

Montero-Moreno JM, Sarret M, Müller C (2010) Micropor Mesopor Mat 136:68–74

Brace AW (1992) Anodic Coating Defects. Technicopy Books, Stonehouse, Glos, England

Brace AW (2000) The technology of anodizing aluminium. Interall S.r.l, Modelna

Patermarakis G, Tzouvelekis D (1994) Electrochim Acta 39:2419–2429

Patermarakis G, Moussoutzanis K (2001) Corros Sci 43:1433–1464

Tu GC, Chen IT, Shimizu K (1990) J Japan Inst Light Metals 40(5):382–389

Thompson DA (1961) Trans Inst Metal Fin 12(7):148–150

Thompson DA (1976) Trans Inst Metal Fin 54:97–103

Scott BA (1965) Trans Inst Metal Fin 43:1–8

Pernick J (1988) Plating and Surf Fin 75(6):32–34

Hoshin OS, Matsumoto S (1986) Metal Fin 84(7):31–35

Hoshino S, Imamura T, Matsumoto M, Kojima K (1977) J Metal Fin Soc Japan 28(3):167–171

Chu SZ, Wada K, Inoue S, Isogai M, Yasumori A (2005) Adv Mater 17:2115–2119

Lee W, Kim JC, Gösele U (2010) Adv Funct Mater 20:21–27

Moradi M, Noormohammadi M, Behzadi F (2011) J Phys D: Appl Phys 44:045301, 7 pp

Li Y, Zheng M, Ma L, Shen W (2006) Nanotechnology 17:5101–5105

Patermarakis G, Moussoutzanis K (2009) Electrochim Acta 54:2434–2443

Patermarakis G, Moussoutzanis K (2011) J Electroanal Chem 659:176–190

Davies CW (1967) Electrochemistry. Newness, London

Patermarakis G, Diakonikolaou J (2012) J Solid State Electrochem 16:2921–2939

Patermarakis G, Karayianni H, Masavetas K, Chandrinos J (2009) J Solid State Electrochem 13:1831–1847

Patermarakis G, Moussoutzanis K (1995) Electrochim Acta 40:699–708

Vogel AI (1976) Macro and semimicro quantitative analysis. Longman, London

Alexeyev VN (1980) Qualitative chemical analysis. Mir Publishers, Moscow

Dodos D (1975) Electrochemical data. Elsevier, Budapest

Koryta J, Dvořak J, Bocháčková V (1970) Electrochemistry. Methuen, London

Samsonov GV (1973) The oxide handbook. IFI/Plenum, New York

Karapetyants MK (1978) Chemical thermodynamics. Mir, Moscow

Weast RC (ed) (1980) Handbook of chemistry and physics, 60th edn. Boca Raton, CRC

Perry RH, Green DW (1999) Perry’s chemical engineers’ handbook, 7th ed. New York, NY, McGraw–Hill

Patermarakis G, Moussoutzanis K (2005) J Solid State Electrochem 9:205–233

Patermarakis G (2006) J Solid State Electrochem 10:211–222

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patermarakis, G., Kapiris, G. Processes, parameters and mechanisms controlling the normal and abnormal growth of porous anodic alumina films. J Solid State Electrochem 17, 1133–1158 (2013). https://doi.org/10.1007/s10008-012-1976-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-012-1976-0