Abstract

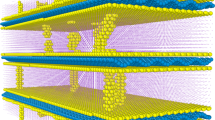

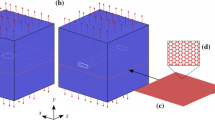

To clarify the strengthening mechanism of coated/embedded graphene in metal matrix nanocomposites, nanoindentation responses of graphene-coated/embedded copper nanocomposites are investigated using molecular dynamics simulations, with the consideration of indentation force–displacement relation, stress distribution, evolution of microstructure and dislocation, and elastic recovery. Results show that two mechanisms, graphene layer bearing surface tensile stress disperses the contact stress and blocks the propagation of dislocations, contribute to the enhanced hardness and improved load bearing capacity, but one is often dominant for different nanocomposites. The former dominates in graphene-coated structure while the latter dominates in graphene-embedded structure, and the reinforcement is more obvious in the coated structure. The graphene delays the plastic deformation of matrix, and its elastic recovery is boosted due to the stress homogenization effect. The embedded graphene promotes the stress concentration and accelerates the plastic deformation of up Cu film, weakening its width elastic recovery. The observations will provide a practical guide for the mechanical optimization and design of metal–graphene nanocomposites.

Similar content being viewed by others

References

Gao X, Shen Y, Ma Y, Wu S, Zhou Z (2019) Graphene/GeTe van der Waals heterostructure: functional Schottky device with modulated Schottky barriers via external strain and electric field. Comput Mater Sci 170:109200

Zhang HF, Wu DP, Ning XJ (2019) Atomistic mechanism for graphene based gaseous sensor working. Appl Surf Sci 470:448–453

Lan ZQ, Zeng L, Jiong G, Huang XT, Liu HZ, Hua N, Guo J (2019) Synthetical catalysis of nickel and graphene on enhanced hydrogen storage properties of magnesium. Int J Hydrogen Energ 44(45):24849–24855

Gao X, Yue HY, Guo EJ, Zhang H, Lin XY, Yao LH, Wang B (2016) Preparation and tensile properties of homogeneously dispersed graphene reinforced aluminum matrix composites. Mater Design 94:54–60

Balandin AA, Ghosh S, Bao WZ, Calizo I, Teweldebrhan D, Miao F, Lau CN (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8(3):902–907

Schriver M, Regan W, Gannett WJ, Zaniewski AM, Crommie MF, Zettl A (2013) Graphene as a long-term metal oxidation barrier: worse than nothing. ACS Nano 7(7):5763–5768

Lee C, Wei XD, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321(5887):385–388

Haghighi S, Ansari R, Ajori S (2020) A molecular dynamics study on the interfacial properties of carbene-functionalized graphene/polymer nanocomposites. Int J Mech Mater Des 16(2):387–400

Ansari R, Ajori S, Motevalli B (2012) Mechanical properties of defective single-layered graphene sheets via molecular dynamics simulation. Superlattice Microst 51(2):274–289

Ansari R, Ajori S, Malakpour S (2016) Prediction of structural and mechanical properties of atom-decorated porous graphene via density functional calculations. Eur Phys J Appl Phys 74(1):10401

Mokhalingam A, Kumar D, Srivastava A (2017) Mechanical behaviour of graphene reinforced aluminum nano composites. Mater Today 4(2, Part A):3952–3958

Rezaei R, Deng C, Tavakoli-Anbaran H, Shariati M (2016) Deformation twinning-mediated pseudoelasticity in metal-graphene nanolayered membrane. Philos Mag Lett 96(8):322–329

Alian AR, Dewapriya MAN, Meguid SA (2017) Molecular dynamics study of the reinforcement effect of graphene in multilayered polymer nanocomposites. Mater Design 124:47–57

Vardanyan VH, Urbassek HM (2019) Dislocation interactions during nanoindentation of nickel-graphene nanocomposites. Comput Mater Sci 170:109158

Liu XY, Wang FC, Wang WQ, Wu HA (2016) Interfacial strengthening and self-healing effect in graphene-copper nanolayered composites under shear deformation. Carbon 107:680–688

Zhang C, Lu C, Pei LQ, Li JQ, Wang R, Tieu K (2019) The negative Poisson’s ratio and strengthening mechanism of nanolayered graphene/Cu composites. Carbon 143:125–137

Chang SW, Nair AK, Buehler MJ (2013) Nanoindentation study of size effects in nickel-graphene nanocomposites. Philos Mag Lett 93(4):196–203

Kim Y, Lee J, Yeom MS, Shin JW, Kim H, Cui Y, Kysar JW, Hone J, Jung Y, Jeon S, Han SM (2013) Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites. Nat Commun 4:2114

Duan K, Zhu FL, Tang K, He LP, Chen YM, Liu S (2016) Effects of chirality and number of graphene layers on the mechanical properties of graphene-embedded copper nanocomposites. Comput Mater Sci 117:294–299

Weng S, Ning H, Fu T, Hu N, Zhao Y, Huang C, Peng X (2018) Molecular dynamics study of strengthening mechanism of nanolaminated graphene/Cu composites under compression. Sci Rep 8(1):3089

Yue HY, Yao LH, Gao X, Zhang SL, Guo E, Zhang H, Lin XY, Wang B (2017) Effect of ball-milling and graphene contents on the mechanical properties and fracture mechanisms of graphene nanosheets reinforced copper matrix composites. J Alloys Compd 691:755–762

Yan YP, Zhou SR, Liu S (2017) Atomistic simulation on nanomechanical response of indented graphene/nickel system. Comput Mater Sci 130:16–20

Rong Y, He HP, Zhang L, Li N, Zhu YC (2018) Molecular dynamics studies on the strengthening mechanism of Al matrix composites reinforced by grapnene nanoplatelets. Comput Mater Sci 153:48–56

Klemenz A, Pastewka L, Balakrishna SG, Caron A, Bennewitz R, Moseler M (2014) Atomic scale mechanisms of friction reduction and wear protection by graphene. Nano Lett 14(12):7145–7152

Wang WH, Peng Q, Dai YQ, Qian ZF, Liu S (2016) Distinctive nanofriction of graphene coated copper foil. Comput Mater Sci 117:406–411

Zhu XF, Zhao YB, Ma LP, Zhang GP, Ren WC, Peng XH, Hu N, Rintoul L, Bell JM, Yan C (2019) Graphene coating makes copper more resistant to plastic deformation. Compos Commun 12:106–111

Zhao YB, Peng XH, Fu T, Zhu XF, Hu N, Yan C (2018) Strengthening mechanisms of graphene coated copper under nanoindentation. Comput Mater Sci 144:42–49

Peng WX, Sun K, Abdullah R, Zhang M, Chen J, Shi JQ (2019) Strengthening mechanisms of graphene coatings on Cu film under nanoindentation: a molecular dynamics simulation. Appl Surf Sci 487:22–31

Koltsova T, Nasibulina L, Anoshkin I, Mishin V, Kauppinen E, Tolochko O, Nasibulin A (2012) New hybrid copper composite materials based on carbon nanostructures. J Mater Sci Eng B 2:240–246

Yan Y, Lv J, Liu S (2018) Chirality and grain boundary effects on indentation mechanical properties of graphene coated on nickel foil. Nanotechnology 29(16):165703

He X, Bai QS, Shen RQ (2018) Atomistic perspective of how graphene protects metal substrate from surface damage in rough contacts. Carbon 130:672–679

Peng WX, Sun K, Zhang M, Shi JQ, Chen J (2019) Effects of graphene coating on the plastic deformation of single crystal copper nano-cuboid under different nanoindentation modes. Mater Chem Phys 225:1–7

Verlet L (1967) Computer “experiments” on classical fluids. I. Thermodynamical properties of Lennard-Jones molecules. Phys Rev 159(1):98–103

Plimpton S (1995) Fast parallel algorithms for short-range molecular-dynamics. J Comput Phys 117(1):1–19

Zhang Z, Yang S, Guo D, Yuan B, Guo X, Zhang B, Huo Y (2015) Deformation twinning evolution from a single crystal in a face-centered-cubic ternary alloy. Sci Rep 5:11290

Zhang JJ, Begau C, Geng L, Hartmaier A (2015) Atomistic investigation of wear mechanisms of a copper bi-crystal. Wear 332:941–948

Johnson RA (1988) Analytic nearest-neighbor model for fcc metals. Phys Rev B Condens Matter 37(8):3924–3931

Vodenitcharova T, Zhang LC (2004) Mechanism of bending with kinking of a single-walled carbon nanotube. Phys Rev B 69(11):115410

Neek-Amal M, Peeters FM (2010) Nanoindentation of a circular sheet of bilayer graphene. Phys Rev B 81(23):235421

Bashirvand S, Montazeri A (2016) New aspects on the metal reinforcement by carbon nanofillers: a molecular dynamics study. Mater Design 91:306–313

Huang SP, Mainardi DS, Balbuena PB (2003) Structure and dynamics of graphite-supported bimetallic nanoclusters. Surf Sci 545(3):163–179

Stuart SJ, Tutein AB, Harrison JA (2000) A reactive potential for hydrocarbons with intermolecular interactions. J Chem Phys 112(14):6472–6486

Wang P, Cao Q, Yan Y, Nie Y, Liu S, Peng Q (2019) Graphene surface reinforcement of iron. Nanomaterials (Basel):9(1)

Pastewka L, Pou P, Perez R, Gumbsch P, Moseler M (2008) Describing bond-breaking processes by reactive potentials: importance of an environment-dependent interaction range. Phys Rev B:78(16)

Fu T, Peng XH, Zhao YB, Li TF, Li QB, Wang ZC (2016) Molecular dynamics simulation of deformation twin in rocksalt vanadium nitride. J Alloys Compd 675:128–133

Fu T, Peng XH, Weng SY, Zhao YB, Gao FS, Deng LJ, Wang ZC (2016) Molecular dynamics simulation of effects of twin interfaces on Cu/Ni multilayers. Mat Sci Eng A-Struct 658:1–7

Fu T, Peng X, Chen X, Weng S, Hu N, Li Q, Wang Z (2016) Molecular dynamics simulation of nanoindentation on Cu/Ni nanotwinned multilayer films using a spherical indenter. Sci Rep 6:35665

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model Simul Mater Sci 18(1):015012

Tsuzuki H, Branicio PS, Rino JP (2007) Structural characterization of deformed crystals by analysis of common atomic neighborhood. Comput Phys Commun 177(6):518–523

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Model Simul Mater Sci 20(8):085007

Montazeri A, Mobarghei A (2018) Nanotribological behavior analysis of graphene/metal nanocomposites via MD simulations: new concepts and underlying mechanisms. J Phys Chem Solids 115:49–58

Koinkar VN, Bhushan B (1997) Scanning and transmission electron microcopies of single-crystal silicon microworn/machined using atomic force microscopy. J Mater Res 12(12):3219–3224

Michel KH, Verberck B (2008) Theory of the evolution of phonon spectra and elastic constants from graphene to graphite. Phys Rev B 78(8):085424

Liu CL, Fang TH, Lin JF (2007) Atomistic simulations of hard and soft films under nanoindentation. Mat Sci Eng A-Struct 452:135–141

Gao Y, Ruestes CJ, Tramontina DR, Urbassek HM (2015) Comparative simulation study of the structure of the plastic zone produced by nanoindentation. J Mech Phys Solids 75:58–75

Ziegenhain G, Urbassek HM, Hartmaier A (2010) Influence of crystal anisotropy on elastic deformation and onset of plasticity in nanoindentation: a simulational study. J Appl Phys 107(6):061807

Goel S, Beake B, Chan CW, Faisal NH, Dunne N (2015) Twinning anisotropy of tantalum during nanoindentation. Mat Sci Eng A-Struct 627:249–261

Zhang L, Huang H, Zhao H, Ma Z, Yang Y, Hu X (2013) The evolution of machining-induced surface of single-crystal FCC copper via nanoindentation. Nanoscale Res Lett 8(1):211

Wang CH, Fang TH, Cheng PC, Chiang CC, Chao KC (2015) Simulation and experimental analysis of nanoindentation and mechanical properties of amorphous NiAl alloys. J Mol Model 21(6):161

Li J, Lu B, Zhang Y, Zhou H, Hu G, Xia R (2020) Nanoindentation response of nanocrystalline copper via molecular dynamics: grain-size effect. Mater Chem Phys 241:122391

Acknowledgments

The work is financially supported by the National Natural Science Foundation of China (Grant Nos. 12072241, 11102140, and 51575404).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors have declared that they have no competing financial interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., An, Q., Li, J. et al. Strengthening mechanisms of graphene in copper matrix nanocomposites: A molecular dynamics study. J Mol Model 26, 335 (2020). https://doi.org/10.1007/s00894-020-04595-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-020-04595-y