Abstract

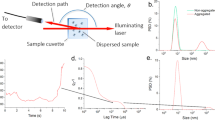

Traditional aggregate size measuring methods are time-consuming, taxing, and do not deliver online measurements. A new online detection system for determining aggregate size and shape based on a digital camera with a charge-coupled device, and subsequent digital image processing, have been developed to overcome these problems. The system captures images of aggregates while falling and flat lying. Using these data, the particle size and shape distribution can be obtained in real time. Here, we calibrate this method using standard globules. Our experiments show that the maximum particle size distribution error was only 3 wt%, while the maximum particle shape distribution error was only 2 wt% for data derived from falling aggregates, having good dispersion. In contrast, the data for flat-lying aggregates had a maximum particle size distribution error of 12 wt%, and a maximum particle shape distribution error of 10 wt%; their accuracy was clearly lower than for falling aggregates. However, they performed well for single-graded aggregates, and did not require a dispersion device. Our system is low-cost and easy to install. It can successfully achieve online detection of aggregate size and shape with good reliability, and it has great potential for aggregate quality assurance.

Similar content being viewed by others

Abbreviations

- K :

-

Scaling factor

- a :

-

Particle perimeter

- b :

-

Minor equivalent axis of particle

- l c :

-

Particle perimeter

- s :

-

Particle area

- d :

-

Diameter of aggregate

- V :

-

Particle volume

- S :

-

Sphericity

- P equal :

-

Perimeter of a circle of equal projection area

- P real :

-

Particle projection real perimeter

- A:

-

Projected area

References

Al-Rousan T, Masad E, Tutumluer E, Pan T (2007) Evaluation of image analysis techniques for quantifying aggregate shape characteristics. Constr Build Mater 21:978–990

Cai X, Su M, Shen J (2010) Particle size measurement techniques and applications. Chemical Industry Press, Beijing

Chen L, Chen Z, Feng A (2014) Image analysis algorithm and verification for on-line molecular sieve size and shape inspection. Adv Powder Technol 25:508–513

Fernlund JMR (2005a) Image analysis method for determining 3-D size distribution of coarse aggregates. Bull Eng Geol Environ 64:159–166

Fernlund JMR (2005b) Image analysis method for determining 3-D shape of coarse aggregate. Cem Concr Res 35:1629–1637

Hardy AJ, Ryan TM, Kemeny JM (1997) Block size distribution of in situ rock masses using digital image processing of drill core. Int J Rock Mech Min 34:303–307

Horiba (2014) Particle analyzer CAMSIZER® P4. Horiba Scientific. http://www.horiba.com/fileadmin/uploads/Scientific/Documents/PSA/Brochures/CAMSIZER_P4_Brochure.pdf. Accessed October 2014

Kim H, Haas C, Rauch A, Browne C (2002) Dimensional ratios for stone aggregates from three-dimensional laser scans. J Comput Civ Eng 16(3):175–183

Kim W, Moon S, Kim H, Yoo J, Kim H (2009) Optical design and manufacturing technology for high resolution laser scanning unit. Int J Precis Eng Manuf 10:141–146

Kwan AKH, Mora CF, Chan HC (1999) Particle shape analysis of coarse aggregate using digital image processing. Cem Concr Res 29:1403–1410

Liao CW, Tarng YS (2009) On-line automatic optical inspection system for coarse particle size distribution. Powder Technol 189:508–513

Masad E, Al RT, Button J, Little D, Tutumluer E (2007) Test methods for characterizing aggregate shape, texture, and angularity. National Cooperative Highway Research Program NCHRP Report 555, Washington D.C

Mayer F, Beucher S (1990) Morphology segmentation. J Vis Commun Image R 1(1):21–46

Niblack W (1986) An introduction to image processing. Lect Notes Comput Sc 15(4):219–229

Nikjah R, Beaulieu NC (2006) Anti-jamming capacity and performance analysis of multiple access spread spectrum systems in AWGN and fading environments. IEEE Icc 11:5153–5159

Otsu (1979) A threshold selection method from gray-level histograms. Ieee T Syst Man Cyb Smc- 9(1):62–66

Pal NR, Pal SK (1993) A review on image segmentation techniques. Pattern Recogn 26(9):1277–1294

Pieri L, Bittelli M (2006) Laser diffraction transmission electron microscopy and image analysis to evaluate a bimodal Gaussian model for particle size distribution in soils. Geoderma 135:118–132

Pine Instrument, Texas A & M, Texas DOT (2011) Aggregate imaging measurement system (AIMS). FHWA Home. http://www.fhwa.dot.gov/hfl/partnerships/aims2/ppt.cfm. Accessed January 2011

Steger C, Ulrich M, Wiedemann C (2008) Machine vision algorithms and applications. Weinheim, WILEY-VCH

Sympatec GmbH System-Partikel-Technik (2010) QICPIC particle size of grain shape analyzer manual. Yellow River Conservancy Press, Zhengzhou

Syvitski J (1991) Principles, methods and application of particle size analysis. Cambridge University Press, London

Tafesse SZ (2012) Physical characterization of coarse clasts with 3D image-analysis method: development, evaluation and application. PhD thesis, Royal Institute of Technology. https://www.diva-portal.org/smash/get/diva2:547294/FULLTEXT01.pdf

Wu Y, Li D, Li Z, Yang W (2014) Fast processing of foreign fiber images by image blocking. Inf Process Agric 1:2–13

Zhang Y, Qiao X, Zhang Y, Wang C (2006) Development of area measurement instrument for plant leaf applying CCD and image analysis technology. Chin J Sci Instrum 27:345–347

Zhang D, Du A, Lin G, Jing W (2007) Method of camera calibration based on image processing. Infrared Laser Eng 36:293–297

Acknowledgments

We are indebted to four anonymous reviewers and Chief Editor L. Nasdala for their constructive comments on this paper. This work was financially supported by a special project of the National and International Scientific and Technological Cooperation (2015DFA710402), a major project of the Foundation of Science and Technology in Fujian Province (2016H6013, 2014H6017), a Joint innovation project for Industrial technology in Fujian Province, and a Subsidized Project for Cultivating Postgraduates’ Innovative Ability in Scientific Research at Huaqiao University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial handling: L. Nasdala

Rights and permissions

About this article

Cite this article

Yang, J., Chen, S. An online detection system for aggregate sizes and shapes based on digital image processing. Miner Petrol 111, 135–144 (2017). https://doi.org/10.1007/s00710-016-0458-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00710-016-0458-y