Abstract

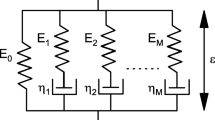

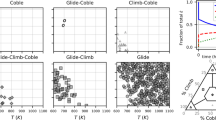

A new visco-hyperelastic constitutive model is developed to describe the dynamic compressive behavior of polymer-bonded explosive (60 wt% RDX, 16 wt% aluminum, and 24 wt% HTPB) and its polymer binder. The constitutive relationship comprises two parts: a component with a strain-energy function to characterize large deformation and a viscoelastic model to describe dynamic viscoelastic behavior. The hyperelastic model parameters are curve-fitted using quasi-static compressive test data under a strain rate of \(0.0001\,\hbox {s}^{-1}\). The time–temperature superposition principle master modulus curves are studied using relaxation tests at different temperatures, and their compressive relaxation time and modules are obtained by fitting the master modulus curves. To obtain the rational dynamic compressive results, a modified split-Hopkinson compressive bar setup is designed such that the specimens are in dynamic stress equilibrium and deformed homogeneously at nearly constant strain rates. A comparison of the constitutive relationship with the experimental results revealed a good agreement and demonstrates its potential to describe the dynamic mechanical behavior of the PBX and its polymer binder.

Similar content being viewed by others

Abbreviations

- \(\varepsilon \) :

-

Strain (–)

- \(\dot{\varepsilon }\) :

-

Strain rate (1/s)

- \(\sigma \) :

-

Stress (MPa)

- \(\beta \) :

-

Ratio of the wave impedances of the specimen and bar (–)

- \(\alpha _{k} \) :

-

Degree of stress uniformity in a specimen (–)

- \(\tau _{i} \) :

-

Relaxation time (s)

- \(\lambda =l/{l_{0}}\) :

-

Stretch, where \(l_0\) and l the original and current thickness, respectively, of the specimen during deformation (–)

- \(\dot{\lambda }\) :

-

Stretch rate (1/s)

- \({\varvec{\upsigma }}\) :

-

Cauchy stress tensor (MPa)

- \(\sigma _{ij} \) :

-

Components of \({\varvec{\upsigma }}\) (MPa)

- \(\varOmega \) :

-

Constitutive functional (–)

- A :

-

Cross-sectional area (\({\text {mm}}^{{2}}\))

- \(a_{T} \) :

-

Shift factor (–)

- \({\mathbf{B}}\) :

-

Left Cauchy–Green deformation tensor (–)

- \(B_{ij} \) :

-

Components of \({\mathbf{B}}\) (–)

- \({\mathbf{C}}\) :

-

Right Cauchy–Green deformation tensor (–)

- \(C_{{1}}\) :

-

Constant value (–)

- \(C_{{2}}\) :

-

Constant value (–)

- c :

-

Elastic wave velocity (m/s)

- \({\mathbf{E}}\) :

-

Green–Lagrange strain tensor (–)

- \({\dot{\mathbf{E}}}\) :

-

Strain rate tensor (–)

- \(E_{ij} \) :

-

Components of \({\mathbf{E}}\) (–)

- E :

-

Young’s modulus (GPa)

- \({\mathbf{F}}\) :

-

Deformation gradient tensor (–)

- \(F_{ij} \) :

-

Components of \({\mathbf{F}}\) (–)

- \({\mathbf{I}}\) :

-

Unit tensor (–)

- \(I_{1} \) :

-

First strain invariant (–)

- \(I_{2} \) :

-

Second strain invariant (–)

- l :

-

Length (mm)

- k :

-

Incident wave travel times (–)

- \(M_{i}\) :

-

Compressive relaxation modulus (MPa)

- n :

-

Number of wave transit from one end of specimen to the other (–)

- p :

-

Pressure (MPa)

- t :

-

Time (s)

- T :

-

Temperature (\({^\circ }\hbox {C}\))

- \({T}_0\) :

-

Reference temperature (\({^\circ }\hbox {C}\))

- \(\Delta t\) :

-

Time for elastic wave to transit between ends of a specimen (s)

- U :

-

Stress-energy function (–)

- b:

-

The incident/transmitted bar

- s:

-

Specimen

- i:

-

Incident

- r:

-

Reflected

- t:

-

Transmitted

- e:

-

Elastic

- v:

-

Viscoelastic

References

Xiao, Y., Sun, Y., Zhen, Y., et al.: Characterization, modeling and simulation of the impact damage for polymer bonded explosives. Int. J. Impact Eng 103, 149–158 (2017)

Barua, A., Zhou, M.: A Lagrangian framework for analyzing microstructural level response of polymer-bonded explosives. Model. Simul. Mater. Sci. Eng. 19(5), 55001–55024 (2011)

Clements, B.E., Mas, E.M.: A theory for plastic-bonded materials with a bimodal size distribution of filler particles. Model. Simul. Mater. Sci. Eng. 12(3), 407–421 (2004)

Asay, B.W.: Shock Wave Science and Technology Reference Library, vol. 5. Non-Shock Initiation of Explosives. Springer, Berlin (2010)

Colak, O.U.: Mechanical behavior of PBXW-128 and PBXN-110 under uniaxial and multiaxial compression at different strain rates and temperatures. Turk. J. Eng. Environ. Sci. 28(2004), 55–65 (2004)

Cady, C., Blumenthal, W., Gray, G., et al.: Mechanical properties of plastic-bonded explosive binder materials as a function of strain-rate and temperature. Polym. Eng. Sci. 46(6), 812–819 (2006)

Thompson, D.G., Deluca, R., Brown, G.W.: Time-temperature analysis, tension and compression in PBXs. J. Energ. Mater. 30(4), 299–323 (2012)

Swanson, S., Christensen, L.: A constitutive formulation for high-elongation propellants. J. Spacecr. Rockets 20(6), 559–566 (1983)

Park, S., Schapery, R.: A viscoelastic constitutive model for particulate composites with growing damage. Int. J. Solids Struct. 34(8), 931–947 (1997)

Mas, E.M., Clements, B.E., Blumenthal, W.R., et al.: A viscoelastic model for PBX binders. Furnish, M.D., Thadhani, N.N., Horie, Y. Shock Compression of Condensed Matter—2001, Pts 1 and 2, Proceedings, pp. 661–664 (2002)

Xiao, Y., Sun, Y., Yang, Z., et al.: Dynamic compressive properties of polymer bonded explosives under confining pressure. Propellants Explos. Pyrotech. 42, 1–11 (2017)

Burke, M., Woytowitz, P., Reggi, G.: Nonlinear viscoelastic constitutive model for solid propellant. J. Propul. Power 8(3), 586–591 (1992)

Jung, G.-D., Youn, S.-K.: A nonlinear viscoelastic constitutive model of solid propellant. Int. J. Solids Struct. 36(15), 3755–3777 (1999)

Tarver, C.M., Chidester, S.K., Nichols, A.L.I.: Critical conditions for impact- and shock-induced hot spots in solid explosives. J. Phys. Chem. 100(100), 5794–5799 (1996)

Rai, N.K., Schmidt, M.J., Udaykumar, H.S.: Collapse of elongated voids in porous energetic materials: effects of void orientation and aspect ratio on initiation. Phys. Rev. Fluids 2(4), 043201 (2017)

Chen, W., Song, B.: One-dimensional dynamic compressive behavior of EPDM rubber. J. Eng. Mater. Technol. 125(3), 294–301 (2003)

Wang, L.L., Huang, D., Gan, S.: Nonlinear viscoelastic constitutive relations and nonlinear viscoelastic wave propagation for polymers at high strain rates. IUTAM Symposia (International Union of Theoretical and Applied Mechanics), pp 137–146 (1996)

Osher, S.: Convergence of generalized MUSCL schemes. SIAM J. Numer. Anal. 22(5), 947–961 (1985)

Wang, Y., Chen, Y.: Application of piezoelectric PVDF film to the measurement of impulsive forces generated by cavitation bubble collapse near a solid boundary. Exp. Therm Fluid Sci. 32(2), 403–414 (2007)

Zeng, F., Sun, Y., Zhou, Y., et al.: A molecular dynamics simulation study to investigate the elastic properties of PVDF and POSS nanocomposites. Modell. Simul. Mater. Sci. Eng. 19(2), 025005–25016 (2011)

Frew, D., Forrestal, M.J., Chen, W.: Pulse shaping techniques for testing brittle materials with a split Hopkinson pressure bar. Exp. Mech. 42(1), 93–106 (2002)

Yang, L., Shim, V.: An analysis of stress uniformity in split Hopkinson bar test specimens. Int. J. Impact Eng. 31(2), 129–150 (2005)

Frew, D., Forrestal, M.J., Chen, W.: A split Hopkinson pressure bar technique to determine compressive stress–strain data for rock materials. Exp. Mech. 41(1), 40–46 (2001)

Ravichandran, G., Subhash, G.: Critical appraisal of limiting strain rates for compression testing of ceramics in a split Hopkinson pressure bar. J. Am. Ceram. Soc. 77(1), 263–267 (1994)

Chen, W., Lu, F., Frew, D., et al.: Dynamic compression testing of soft materials. J. Appl. Mech. 69(3), 214–223 (2002)

Parab, N.D., Roberts, Z.A., Harr, M.H., et al.: High speed X-ray phase contrast imaging of energetic composites under dynamic compression. Appl. Phys. Lett. 109(13), 3725–3744 (2016)

Williams, M.L., Landel, R.F., Ferry, J.D.: The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 77(14), 3701–3707 (1955)

Rivlin, R.S.: Proceedings of the first symposium on naval structural mechanics (1960)

Han, C.D.: Mechanical properties of solid polymers. J. Polym. Sci. Polym. Lett. Ed. 23(2), 119–119 (1985)

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 41(2), 389–412 (1993)

Mooney, M.: A theory of large elastic deformation. J. Appl. Phys. 11(9), 582–592 (1940)

Treloar, L.R.G.: Stresses and birefringence in rubber subjected to general homogeneous strain. Proc. Phys. Soc. 60(2), 135 (1949)

Ogden, R.W.: Large deformation isotropic elasticity—on the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. London 326(1567), 565–584 (1972)

Brown, R.: Physical Testing of Rubber. Springer, Boston, MA (2006)

Li, C., Lua, J.: A hyper-viscoelastic constitutive model for polyurea. Mater. Lett. 63(7), 877–880 (2009)

Pouriayevali, H., Guo, Y., Shim, V.: A visco-hyperelastic constitutive description of elastomer behaviour at high strain rates. Procedia Eng. 10, 2274–2279 (2011)

Blumenthal, W., Thompson, D., Cady, C., et al.: Compressive properties of PBXN-110 and its HTPB-based binder as a function of temperature and strain rate. In: Proceedings of the 12th International Detonation Symposium, F. (2002)

Clements, B.E., Mas, E.M.: Dynamic mechanical behavior of filled polymers. I. Theoretical developments. J. Appl. Phys. 90(7), 5522–5534 (2001)

Acknowledgements

The present work is supported by the National Natural Science Foundation of China (NSFC 11802273), the opening project of Science and Technology on Electromechanical Dynamic Control Laboratory (6142601180404), Shanxi Province Science Foundation for Youths (201901D211279) and Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (2019L0586).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao, Y., Fan, C., Wang, Z. et al. Visco-hyperelastic constitutive modeling of the dynamic mechanical behavior of HTPB casting explosive and its polymer binder. Acta Mech 231, 2257–2272 (2020). https://doi.org/10.1007/s00707-020-02655-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-020-02655-1