Abstract

Poly(ether)s represent an important class of polymers and are typically formed by ring-opening polymerization, Williamson ether synthesis, or self-condensation of alcohols. The oxa-Michael reaction presents another method to form poly(ether)s with additional functional groups in the polymer backbone starting from di- or triols and electron deficient olefins such as acrylates, sulfones, or acrylamides. However, research on oxa-Michael polymerization is still limited. Herein, we outline the principles of the oxa-Michael polymerization and focus on the synthesis and preparation of poly(ether-sulfone)s, poly(ether-ester)s, poly(ether)s, and poly(ether-amide)s. Further, challenges as well as future perspectives of the oxa-Michael polymerization are discussed.

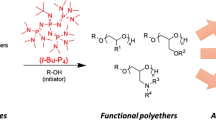

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Motivation

Poly(ether)s are a widespread polymer class and have received increasing interest because of their versatility regarding structural modifications and their excellent properties in terms of chemical and thermal stability. Depending on the monomers employed, the materials’ properties range from liquid to highly crystalline allowing for their use in a variety of applications [1]. Aliphatic poly(ether)s are typically formed by ring-opening polymerization (ROP) of the corresponding cyclic ether [2]. The worldwide production of poly(ether)s derived from epoxides amounts to several million tons per year [3]. However, ROP fails in the synthesis of poly(ether)s containing six or more methylene units, as cyclic ethers show enormous stability. In this case, poly(ether) synthesis is performed by Williamson ether synthesis in which the ether bond is formed by the nucleophilic substitution of an alkoxide on an organohalide. This method is highly efficient but the use of alkyl halides limits its industrial applicability [4]. Alternatively, poly(ether)s can be produced by self-condensation of alcohols either at high temperatures (> 200 °C) using acidic catalysts or at lower temperatures (65–130 °C) using bifunctional acid–base activation [5].

Another method that allows the preparation of poly(ether)s is the oxa-Michael polymerization which evolved as hetero-variant of the Michael reaction, one of the most important carbon–carbon bond formation reactions in organic chemistry [6, 7]. In the oxa-Michael reaction, oxygen-based nucleophiles such as alcohols (donors) react with electron-deficient α,β-unsaturated compounds (acceptors) whereupon an ether bond is formed. Thus, additional functional groups can easily be included in the polymer backbone by selecting donors and acceptors with, e.g. multiple bonds or other functionalities.

In general, the oxa-Michael reaction satisfies “click” criteria as it can be performed in high efficiency under mild reaction conditions. Additionally, a wide substrate scope is accessible, and many functional groups are tolerated. Therefore, it is widely used in small molecule synthesis, especially in natural product synthesis [8,9,10]. However, in polymer chemistry the oxa-Michael reaction has received less attention so far. Instead, academic as well as industrial researchers have focused on other Michael variants, namely aza-Michael [11,12,13,14], carba-Michael [14,15,16], and thia-Michael [14, 17,18,19,20] polymerization in which amines, CH-acidic compounds, and thiols are used as donors, respectively. The dominance of these Michael variants can be explained by the higher reactivity of the donors allowing for a relatively easy preparation of a large variety of polymers. However, the oxa-Michael addition comprises several advantages over the well-established aza- and thia-Michael reaction. Contrary to amines and thiols which often suffer from high toxicity and bad odor, alcohols are potentially less toxic and of low-odor. Moreover, alcohols show better storage stability than thiols which are prone to oxidative disulfide bond formation [21]. Further, ethers are stable compounds in contrast to thioethers which tend to oxidize [22]. Thus, alcohols are a promising Michael donor alternative which potentially might also be derived from renewable feedstocks [23, 24].

Nonetheless, the oxa-Michael polymerization proves to be significantly more challenging than other Michael variants because of the lower reactivity of alcohols compared to amines or thiols. On the one hand, alcohols are less acidic than thiols and on the other hand, alkoxides have a relatively poor nucleophilicity. Moreover, in the past the reversibility of the alcohol addition step was noted as challenging [9].

First oxa-Michael polymerizations, also termed as hydrogen transfer polymerizations, date as far back as the seventies. However, especially in the past decades many advances were made. We, therefore, herein present a comprehensive overview of the literature reporting the preparation of poly(ether)s by oxa-Michael polymerization. In the following, we term the reaction as “oxa-Michael polymerization” and not as “hydrogen (or proton) transfer polymerization” which also frequently appears in literature. We feel that the latter does not differentiate between the Michael variants as protons are essentially transferred in any Michael addition reaction. Moreover, hydroxyl-yne polyaddition reactions [25,26,27,28], which one might also consider as oxa-Michael polymerization are not within the scope of this review. However, a detailed review on hydroxyl-yne reactions and the applications thereof in polymer chemistry was recently disclosed by Worch and Dove et al. [29].

Introduction to the oxa-Michael addition

In principle, the oxa-Michael reaction involves the addition of an alcohol (Michael donor) to an electron-deficient olefin (Michael acceptor) (Scheme 1). However, as the nucleophilicity of the alcohol itself is too low for a direct conjugate addition, a catalyst is required to generate the corresponding alkoxide [8]. The first oxa-Michael reaction dates back to 1878 when Loydl reported the synthesis of malic acid from fumaric acid, which results from the reaction of an alkoxide with the α,β-unsaturated carbonyl compound [6]. When multifunctional acceptors and donors are employed, polymers can be formed.

Mechanism of the oxa-Michael reaction

As aforementioned, in the oxa-Michael reaction a catalyst is required to ensure the formation of an alkoxide which can then undergo conjugate addition. Both Brønsted and Lewis bases have been reported to efficiently catalyze oxa-Michael reactions. Thus, mechanistically, two reaction pathways have been proposed (Scheme 2).

In the Brønsted base catalyzed reaction, a base (B) deprotonates the alcohol generating an alkoxide which attacks the electron deficient Michael acceptor in β-position to the electron withdrawing group (EWG) [30]. Thereby, a carbanion in α-position to the EWG is formed, which is further protonated by another alcohol closing the cycle. The conjugated acid of the strong base (HB+) is acting as the counter ion.

The Lewis base (LB) initiated pathway has first been reported by Toste and co-workers [31] and differs mainly in the initiation step as neutral Lewis bases with low Brønsted basicity are used as catalysts. Accordingly, the Lewis base does not deprotonate the alcohol but attacks the Michael acceptor and forms a strongly basic zwitterion. The zwitterion subsequently subtracts a proton from the alcohol, generating the alkoxide. This alkoxide then attacks another Michael acceptor leading to an ion pair which upon proton transfer from an alcohol releases the oxa-Michael product. A trimethylphosphine-catalyzed pathway of the reaction of methyl vinyl ketone and methanol has been calculated by Jiang and co-workers [32]. They found out that the transition states of the addition of the phosphine to the Michael acceptor and the subsequent deprotonation of methanol have similar free energy barriers in the range of 84 kJ mol−1. The addition of the alkoxide to the Michael acceptor and protonation accounts to slightly lower barriers of 67 kJ mol−1. Thus, the formation of the zwitterion and the deprotonation of the alcohol can be considered as rate-determining steps. The oxa-Michael product could theoretically also be obtained via a SN2 reaction. However, this pathway was ruled out as it has a three times higher energy barrier [32].

The Brønsted and Lewis base catalyzed mechanisms differ in two aspects. While deprotonation of the alcohol in the Brønsted base catalyzed mechanism is fast, the formation the alkoxide via the Lewis base initiation is much slower [33]. The important difference of the two variants during propagation lies in the reactivity of the formed alkoxide species. The sterically demanding cations in the Lewis base initiated pathway lead to much higher energy alkoxide species and a higher energy carbanion when compared to those stabilized by smaller cations as in case of the Brønsted base catalyzed variants [34]. The higher energies translate to higher reactivities and can be explained by the greater separation between the anion and the cation stabilized by the larger Lewis base [35]. Moreover, for the thiol-Michael reaction the protonated base from the Brønsted base catalyzed pathway is suspected to be negatively impacting the reaction kinetics as an additional proton source, while the alcohol enacts as the sole proton source in the Lewis base initiated pathway [36]. Therefore, the Lewis base initiated reaction has the potential to proceed at higher reaction rates with lower catalytic loading relative to the Brønsted base catalyzed pathway.

Catalysts in oxa-Michael polymerizations

Only few reports on Brønsted or Lewis acid catalyzed oxa-Michael reactions are available [37,38,39], as in general deprotonation of the alcohol is crucial and activation of the Michael acceptor by Lewis acids is not sufficient. Instead, Brønsted or Lewis bases are as aforementioned commonly used as catalysts. In oxa-Michael polymerizations inorganic bases qualifying as Brønsted bases, e.g. alkali hydrides or hydroxides, have long been implemented as catalysts [40,41,42]. Recently, a variety of organocatalysts became more important in Michael polymerizations [43, 44].

Multiple organocatalysts ranging from nitrogen- and phosphorous-based species to N-heterocyclic carbenes [44, 45] have been used in oxa-Michael reactions (Fig. 1). Regarding phosphines, alkyl phosphines [31, 46] are highly reactive catalysts but suffer from poor oxidation stability and require exclusion of oxygen. However, also triphenyl phosphine (PPh3) has commonly been used as catalyst [31, 47, 48]. Recently, it could be shown that electron donating substituents such as methoxy groups on the phenyl rings enhance the reactivity of the phosphine catalyst. Tris(4-methoxyphenyl)phosphine (TMPP) and tris(2,4,6-trimethoxyphenyl)phosphine (TTMPP) are stronger Lewis bases and outperform the commonly used PPh3 [33, 49]. Moreover, the strong Lewis base TTMPP has been reported to compete with phosphazene bases in oxa-Michael polymerizations [33].

Phosphazene bases are extremely strong, organic Brønsted bases with low nucleophilicity [50]. Among the commercially available ones, P2-tBu is highly interesting as it allows reactions at ambient atmosphere due to good oxygen, hydrolysis, and thermal stability [51]. Contrarily, P4-tBu is extremely hygroscopic and requires rigorous exclusion of moisture [52]. In general, phosphazene bases are among the most efficient catalysts for oxa-Michael reactions and polymerizations [53].

Further, organocatalysts including amidines and guanidines have been tested in oxa-Michael reactions. Whereas 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) frequently has been used [41, 43, 54], reactions with 1,1,3,3-tetramethylguanidine (TMG) are rather scarce, although its results are promising [33]. Both bases have been reported to also undergo nucleophilic attack with Michael acceptors [13, 55].

Amines are another class of organocatalysts which were studied in oxa-Michael reactions. However, triethylamine (TEA), N,N-diisopropyethylamine (DIPEA), 1,4-diazabi-cyclo[2.2.2]octane (DABCO), and quinuclidine (ABCO) show hardly any conversion in oxa-Michael reactions [33, 43, 47, 56, 57]. Contrarily, 4-dimethylaminopyridine (DMAP) performed well in specific oxa-Michael polymerizations [57, 58].

Last but not least, N-heterocyclic carbenes (NHC), which find numerous applications as catalysts in polymerization reactions [59], also proved to be efficient in oxa-Michael reactions [44, 60, 61]. NHCs show exceptionally high Lewis basicity as indicated by their methyl cation affinities, which are more than 100 kJ mol−1 higher compared to those of PPh3, DMAP, or DABCO [62]. The group of Matsuoka successfully investigated a variety of NHC catalysts such as TPT and IDipp in oxa-Michael polymerizations [44, 60].

Reactivity of Michael donor and Michael acceptor

Further influencing factors of oxa-Michael additions are the nature of the Michael acceptor and donor.

Michael acceptor

Concerning the Michael acceptor, the nature of the electron withdrawing group as well as the substitution of the double bond governs its reactivity. According to theoretical calculations of the electrophilicities of Michael acceptors [63] and kinetic studies of the alcohol addition to an activated vinyl group [64], the reactivity of Michael acceptors decreases from maleimides towards acrylamides as depicted in Fig. 2.

Additionally, it was found that the reactivities of Michael acceptors correlate with the energy of the lowest unoccupied molecular orbital (LUMO) of the Michael acceptor if small subsets of acceptors (e.g. substituted acrylates) are regarded. Another possibility to determine the reactivity of a Michael acceptor is by calculating its methyl anion affinity, i.e. the negative of the Gibbs’ free energy of the addition of a methyl anion to a Michael acceptor [65].

Methacrylates, crotonates, and methacrylamides are widely used in industrial applications as they have a lower toxicity compared to their unsubstituted analogues [66]. However, the reactivity of substituted acrylates is significantly lower due to the inductive effect of the alkyl group and increased steric congestion [63]. Thus, with these acceptors no oxa-Michael polymerizations have been reported yet. So far, only oxa-Michael polymerizations based on vinyl sulfones, acrylates and acrylamides are known (vide infra).

Michael donor

The reactivity of an alcohol in the oxa-Michael reaction depends on both its acidity and the nucleophilicity of its corresponding alkoxide. The former parameter depends on the molecule’s capability of delocalizing negative charge and is highest when the OH group is adjacent to an aromatic ring (pKA phenol: 10.2) or in propargylic position to a sp-hybridized carbon (pKA prop-2-yn-1-ol: 12.4) [67]. As well-stabilized anions are not prone to undergo a nucleophilic attack and thus, delocalize their charge, the acidity of an alcohol is inversely related to the nucleophilicity of the corresponding alkoxide.

In case of Lewis base catalysis, the efficiency of the proton transfer from the alcohol to the zwitterionic species depends on the alcohol’s acidity. It has been reported that more acidic alcohols enhance this reaction step especially in case of strong Michael acceptors. In the oxa-Michael reaction of acrylonitrile, for instance, increasing acidity of the tested alcohols (propan-1-ol, prop-2-en-1-ol, and prop-2-yn-1-ol), respectively, resulted in higher product conversions [33].

Further, a higher nucleophilicity of the alkoxides increases the reaction rate. For simple alkoxides a moderate increase in nucleophilicity in the order MeO– < EtO– < n-PrO– < i-PrO– has been reported [68]. Recently, we showed that in case of weak Michael acceptors, the nucleophilicity of the alkoxide is the crucial parameter. For example, n-propanol was much more efficient than propargyl alcohol in the oxa-Michael reaction with tert-butyl acrylate or acrylamide [33].

Thus, a balance of both acidity and nucleophilicity of the Michael donor is desired. Especially for weak Michael acceptors sufficient nucleophilicity of the alkoxide is crucial, whereas with strong Michael acceptors alkoxides are in general nucleophilic enough to react. In these cases, the acidity of the alcohol is more important and governs the speed of the reaction.

Effects of solvent and temperature

In general, oxa-Michael polymerizations can be performed under mild conditions with catalytic loadings ranging between 5 and 20 mol%. Polymerization under solvent-free conditions have been reported both for Brønsted [40, 53] and Lewis-base [49, 58, 60, 69] catalyzed variants. Especially, Lewis base catalyzed reactions benefit from solvent-free conditions as several examples in literature show worse performance in terms of yield and molar masses in presence of solvent (e.g. THF, CDCl3 or benzene-d6) [33, 44, 47]. Our group recently studied the influence of solvents and the concentration dependence of the oxa-Michael reactions in detail. Whereas, for instance, under bulk conditions full conversion of acrylonitrile and n-propanol was achieved with TTMPP (a Lewis base) within minutes, diluted mixtures showed hardly any conversion. Contrary, reactions catalyzed by P2-tBu (a Brønsted base) were hardly affected by dilution [33]. The preparation of hyperbranched oxa-Michael polymers catalyzed by phosphazene bases was, for example, even performed in N,N-dimethylformamide (DMF) [21]. Thus, phosphazene bases enable oxa-Michael reactions in solution. Moreover, if solvents are used, polar protic solvents such as tert-butanol are advantageous as they might stabilize anionic intermediates, promote proton transfer and activate the Michael acceptor by hydrogen bond donation [33, 70].

The effect of the reaction temperature has also been studied numerous times [44, 53, 57, 71]. Oxa-Michael polymerizations proceed nicely at room temperature and higher molar mass can be obtained compared to polymerizations at elevated temperatures. The worse performance at high temperatures results from side reactions. In specific concurring vinyl addition reactions such as Rauhut-Currier reaction or anionic polymerization cause lower molar masses [71, 72].

Oxa-Michael polymerization

In principle a wide variety of poly(ether)s could be synthesized by oxa-Michael polymerizations. Depending on the acceptor and donor, valuable functional groups can be introduced into the polymer backbone. In fact, however, researchers have mainly employed highly reactive Michael acceptors since these are most likely to react with the low-reactive alcohols. The use of divinyl sulfone allows the formation of poly(ether-sulfone)s. Aliphatic polymers with polar sulfone groups might, e.g. be interesting in flame-retardant materials due to good chemical and heat resistance [73], in optical elements because of high refractive indices [74, 75] or in electrochemistry due to a wide electrochemical window [76]. By using diacrylates and dialcohols poly(ether-ester)s can be obtained [33, 53]. However, the oxa-Michael homopolymerization of hydroxy functionalized acrylates such as 2-hydroxyethyl acrylate (HEA) creates such poly(ether-ester)s as well [40]. Based on the ester functionalities these polymers are degradable and might allow depolymerization via transesterification [77, 78]. In case of acrylamides, poly(ether-amide)s can be synthesized which are, e.g. interesting as thermoresponsive fluorescent polymers in biological applications [79]. Such poly(ether-amide)s also have been reported to show good biocompatibility [71]. Moreover, the formation of simple poly(ether)s with ketone or ester functionalities in the side chain is possible [80]. Further functionalities can also be included in the polymer backbone by selecting various alcohols. For example, Z-butenediol or butynediol introduces double or triple bonds and thus, allows post-modification or crosslinking of the polymer [44].

In the following, oxa-Michael polymerizations reported in literature are summarized and structured based on the functionalities in the polymer backbone introduced by the Michael acceptor.

Poly(ether-sulfone)s

Oxa-Michael additions using highly reactive and commercially available divinyl sulfone as acceptor have frequently been reported during the last century. Especially in the textile industry, vinyl sulfones were applied in the modification of cellulose. Polymeric adducts of divinyl sulfone and water were disclosed as crosslinking agents for cellulose [81]. Alternatively, masked vinyl sulfone adducts, such as bis(hydroxyethyl)sulfone—the adduct of divinyl sulfone and water—or other adducts of vinyl sulfone and alcohols, were used as crosslinkers [82]. Crosslinking thereof with cellulose proceeded under alkaline conditions at elevated temperatures (Scheme 3) [83,84,85].

Moreover, vinyl sulfone moieties were used as crosslinkers in resins [86] and in waterborne coatings [87]. In the latter, under basic conditions and upon drying, water is released. The thereby formed vinyl sulfone is then susceptible to crosslinking with alcohols.

Yu et al. disclosed the oxa-Michael reaction of divinyl sulfone and hydroxyl-based water-soluble polymers such as hyaluronic acid, polyethylene glycol, dextran, alginate and polyvinyl alcohol in alkaline aqueous media. Such polymers might find an application as hydrogels in biomedicine [88].

Besides utilizing divinyl sulfone as crosslinking agent in polymerizations via oxa-Michael addition, the synthesis of various poly(ether-sulfone)s has been reported. In those reactions divinyl sulfone polymerizes with alcohols via a step-growth mechanism. In the 1960s, the oxa-Michael polymerization of divinyl sulfone and 1,4-butanediol has been reported at 120 °C in the presence of sodium hydride. Free vinyl groups of the obtained prepolymer (molar mass about 700 g mol−1) were further crosslinked with methyl methacrylate via radical polymerization [89]. Later, Strasser et al. showed the polyaddition of divinyl sulfone and various diols including ethylene glycol, Z-butene-1,4-diol, but-2-yne-1,4-diol, etc. [47, 58]. Polymerization initiated by Lewis bases (DMAP or PPh3) proceeded at room temperature and the obtained polymers were further cured at 80 °C overnight (Scheme 4). Polymers with number average molar masses (Mn) around 1000 g mol−1 were obtained [58].

Another example including a vinyl sulfone monomer is the polymerization of 2-hydroxyethyl vinyl sulfone reported by Brendel and co-workers. 2-Hydroxyethyl vinyl sulfone functions as AB-type monomer comprising acceptor and donor in one molecule. Both Brønsted and Lewis bases caused homopolymerization at 40 °C within 24 h yielding polymers with molar masses between 2000 and 3600 g mol−1 [90].

Inspired by the work of Brendel, our group recently disclosed the formation of the identical poly(ether-sulfone) by the polymerization of divinyl sulfone and water. To the best of our knowledge, water was used for the first time as a monomer in a copolymerization reaction with two components. Aliphatic poly(ether-sulfone)s with relatively high molar mass (Mn = 5300 g mol−1, Đ = 2.5) were obtained in an interfacial polymerization reaction that proceeded at room temperature and without additional solvent (Scheme 5). Further, the potential use of the derived poly(ether-sulfone)s in electrochemistry was demonstrated. The material was characterized as solid polymer electrolyte based on its high electrochemical stability, appealing conductivity and solvent-free membrane preparation [57].

Crosslinked poly(ether-sulfone)s

To obtain crosslinked poly(ether-sulfone)s, triols or higher functional alcohols need to be employed in the oxa-Michael polymerization of divinyl sulfone. Reports on trifunctional alcohols, namely glycerol, 2-ethyl-2-(hydroxymethyl)-propane-1,3-diol and triethanolamine, in the reaction with divinyl sulfone are available. Solid, insoluble crosslinked materials with a glass transition temperature (Tg) in the range of 0–30 °C were obtained and solubility tests in dichloromethane revealed a soluble fraction between 3 and 10 wt% [58, 91]. Moreover, the synthesis of poly(ethylene) glycol hydrogels prepared by the oxa-Michael reaction of ethylene glycol, divinyl sulfone and glycerol has been reported [92].

Another strategy towards crosslinked materials combines oxa-Michael polymerization and Lewis base initiated anionic polymerization (Scheme 6). Diols were employed in a substoichiometric ratio with divinyl sulfone to obtain vinyl-terminated oligomers. Subsequently, the oligomers were crosslinked via anionic polymerization. This dual-curing process led to significantly improved mechanical and thermal properties of the obtained polymers. Insoluble materials with high Tg were obtained [72].

Poly(ether-ester)s

For the synthesis of poly(ether-ester)s via oxa-Michael polymerization, mainly AB-type monomers are used. The homopolymerization of hydroxy functionalized acrylates such as 2-hydroxyethyl acrylate (HEA) is among the most well studied oxa-Michael polymerizations.

In the 1970s the oxa-Michael polymerization of HEA—back then referred to as hydrogen transfer polymerization—was reported for the first time with alkali hydrides or alkoxides as catalysts (Scheme 7a). Molar masses between 1000 and 2000 g mol−1 were obtained at elevated temperatures (50–80 °C) under solvent-free conditions (Table 1). Besides Brønsted base catalysts, Lewis base initiation of the homopolymerization of HEA was demonstrated with triphenyl phosphine (PPh3). However, with 1100 g mol−1 the molar mass of the obtained polymer was lower compared to polymers catalyzed by alkali metal hydrides and alkoxides. Moreover, acrylic acid, 3-hydroxypropyl acrylate and 2-hydroxypropyl acrylate were polymerized in a similar manner [40].

Further on, other groups studied the polymerization of HEA with similar catalysts. Rozenberg, for example, obtained polymers with a Mn of 1100 g mol−1 with lithium tert-butoxide at room temperature (Table 1) [93]. During the reaction, transesterification was noted as inevitable side reaction (Scheme 7b). However, identification of the polymer’s structure turned out to be challenging as main characteristics of the polymer such as molar mass or the nature of the end groups do not change thereby. End group distribution of the polymers showed the formation of polyesterdiacrylates, macrocycles and polyesterdiols [42, 93].

At the same time, Gibas et al. reported HEA based polymers with a Mn of up to 9000 g mol−1 with alkoxides and alkali hydrides at room temperature after 2 h (Table 1) [94]. No other group reported such high molar masses of poly(HEA) with the same catalysts thereafter. As the molar masses of the polymer samples were only determined after purification by Gibas et al., shorter polymer strands might have been removed unintentionally.

In the past 10 years, the polymerization of HEA was again studied more extensively. To enable polymerization at ambient reaction temperature N-heterocyclic carbenes were employed in the polymerization of hydroxy functionalized acrylates. With 10 mol% TPT (a triazol-5-ylidene based NHC catalyst (Fig. 1)) a polymer of HEA was synthesized at room temperature with a Mn of 1500 g mol−1 in 56% yield [44]. Also with an imidazol-2-ylidene based NHC catalyst (IDipp) similar results were obtained (Table 1). Moreover, the use of THF as solvent reduced the molar mass and yield. Additionally, the possibility of post-modification of oxa-Michael polymers with double bonds in the backbone by, e.g. thiol-ene click reaction was demonstrated [44].

As an alternative to hydroxy functionalized acrylates, the oxa-Michael polymerization of diacrylates and diols renders poly(ether-ester)s as well (Scheme 8).

In 2018, Jiang and co-workers were the first to employ phosphazene bases in the oxa-Michael polymerization [53]. Rapid polymerization of ethylene glycol and neopentyl glycol diacrylate could be observed with 5 mol% P2-tBu at room temperature or 50 °C under solvent-free conditions yielding polymers with a molar mass in the range of 3300 and 3600 g mol−1. The polymerization of diacrylates was feasible with primary and secondary alcohols. However, the phosphazene base was not effective in catalyzing the reaction of tertiary alcohols with acrylates. Transesterification occurred as side reaction and was facilitated by elevated temperatures (50 or 100 °C) or increasing catalyst loading [53].

The phosphazene base P2-tBu was further used to catalyze the homopolymerization of HEA at room temperature, yielding macromolecules with a Mn of 2300 g mol−1 (Table 1) [95]. Moreover, ring opening polymerization of ε-caprolactone combined with an oxa-Michael polymerization of HEA or neopentyl glycol diacrylate was disclosed with the aforementioned P2-tBu [95, 96]. The copolymerization of HEA and acrylamides via oxa- and aza-Michael reaction with P4-tBu was studied as well [97].

Recently, it could be shown that besides phosphazene bases, also a strong Lewis base, namely tris(2,4,6-trimethoxyphenyl)phosphine (TTMPP), can efficiently catalyze the oxa-Michael polymerization of acrylates. In general, electron-rich phosphine catalysts such as PPh3, TMPP, or TTMPP initiate the polymerization of HEA [49]. However, TTMPP clearly outperformed other Lewis base catalysts in terms of double bond conversion and molar mass of the formed polymer (Mn about 1280 g mol−1) after 24 h at room temperature [33]. In case of TMPP, elevated temperatures (80 °C) were needed to achieve similar double bond conversions as with TTMPP. However, it was noted that at the same time higher temperatures yielded lower molar masses compared to room temperature experiments. This is the result of another double bond consuming reaction, namely the Rauhut–Currier reaction (depicted as side reaction in Scheme 7c), which is facilitated at high temperatures. Consumption of the acrylate by Rauhut–Currier reaction resulted in a higher double-bond conversion but caused a deviation in stoichiometry deteriorating oxa-Michael polymerization. Thus, polymers with a lower molar mass were obtained at elevated temperatures [49].

Besides, the polymerization of 1,4-butanediol diacrylate with 1,4-butanediol was studied with TTMPP within our group [33]. Moreover, the performance of TTMPP and P2-tBu was compared in this reaction. Both catalysts show similar good conversion of the acrylate (> 85% after 1 h) and exceed common organocatalysts (PPh3, DMAP, DBU, TMG) by far. However, the macromolecules obtained with P2-tBu show a higher molar mass (Mn = 2500 g mol−1) compared to TTMPP initiated polymers (Mn = 1400 g mol−1) [33]. Nonetheless, so far AA-BB type oxa-Michael polymerizations of acrylates and diols have not been reported with any other catalysts than phosphazene base or TTMPP.

Another approach towards poly(ether-ester)s was demonstrated by concomitant oxa-Michael and transesterification reaction (Scheme 9). Transesterification, an omnipresent side reaction in oxa-Michael chemistry of acrylates, was utilized in the polymerization of commercially available monoacrylates and diols. By this approach the pre-synthesis of AB type monomers such as hydroxy functionalized acrylates could be avoided. Various oligomers with molecular mass between 700 and 1000 g mol−1 were obtained from ethyl acrylate and diols such as (Z)-2-butene-1,4-diol, 2-butyne-1,4-diol, or 1,2-propanediol with 5 mol% DBU as catalyst within 24 h [69].

Besides, copolymerization of acrylic acid and diols has been reported via combined oxa-Michael addition and condensation reaction. The polymerization of acrylic acid and ethylene glycol yielded polymers of a molar mass up to 1300 g mol−1 at 80 °C with Brønsted acids. Moreover, solely acrylic acid could be oligomerized with Brønsted bases or acids (Mn about 400 g mol−1). The obtained polyester was further either depolymerized or used in radical copolymerization with additional vinyl monomers [60]. In addition, reports on oligomerization of 2-trifluoromethacrylic acid by oxa-Michael addition are available [39].

Coupled or hyperbranched poly(ether-ester)s

In general, the reaction of diacrylates and diols or hydroxy-functionalized AB type acrylates only renders soluble, linear polymers which suffer from low molar masses (< 10.000 g mol−1). Although known for aza- [98,99,100], carba- [101, 102] and thia- [103,104,105] Michael reaction, the formation of crosslinked materials starting from triacrylates and alcohols has not been reported so far. Neither Brønsted nor Lewis bases allow the polymerization of triacrylates with polyols. However, another approach towards high molar mass materials includes the combination of the oxa-Michael reaction with other coupling reactions similar as shown for crosslinked poly(ether-sulfone)s. Alternatively, hyperbranched polymers can be formed from ABx type monomers.

Coupled poly(ether-ester)s

Lately, the group of Jiang disclosed the preparation of high molar mass polymers by combining the oxa-Michael polymerization with the Rauhut–Currier reaction, a coupling reaction of two acrylates (Scheme 10) [71]. Before, Rauhut–Currier units were usually regarded as hindering because they cause a disadvantageous shift in stoichiometry. However, in a new context the reaction was utilized to link oxa-Michael polymer strands at a later stage in the polymerization.

In detail, they found that higher molar masses can be obtained in the polymerization of HEA when the temperature is kept at − 5 °C for 12 h and increased to 80 °C for another 6 h with 1 mol% P2-tBu as catalyst. By using low temperatures in the early polymerization stage, the Rauhut–Currier side reaction could be suppressed. Later, elevated temperatures were beneficial as they lower the viscosity in the system and thus, promote end group mobility leading to higher molar masses. With this approach, the weight average molar mass (Mw) of poly(HEA) could be more than doubled (15.3 kg mol−1 vs. 6.9 kg mol−1). The reaction was further exploited by introducing a small amount of diacrylate (2 mol%) and P4-tBu, showing a stronger basicity than P2-tBu, at the last polymerization stage at elevated temperature (80 °C). Again, high temperatures promoted both the mobility of the end groups and the Rauhut–Currier reaction. The diacrylate, namely 1,4-butanediol diacrylate, then reacted either with an acrylate end group in a Rauhut–Currier fashion or with a hydroxy end group via oxa-Michael addition. Thus, due to the additional coupling the molar mass could be increased to 355.8 kg mol−1 (Đ = 9.8) over 24 h at 80 °C which is the highest that has ever been reported for polymers derived from oxa-Michael reactions. The obtained polymer was further used to prepare biodegradable materials by UV-curing with microfluidic spinning [71].

Hyperbranched poly(ether-ester)s

The excess of a reactive group as, e.g. in case of ABx type monomers enables the formation of hyperbranched polymers [106]. Few examples of hyperbranched oxa-Michael polymers have been reported. The synthesis of hyperbranched polymers starting from acrylates functionalized with two hydroxy groups, in specific from 2,2-bis(hydroxymethyl)-propyl acrylate, was attempted by Kadokawa et al. [48, 107]. In the reaction, PPh3 (5 mol%) was used as catalyst at temperatures above 80 °C. Reaction times of up to 48 h resulted in polymers with molar masses around 1200 to 2700 g mol−1 in 22% yield at most [48].

Furthermore, phosphazene bases were used for the formation of hyperbranched polymers with high molar masses (Mw > 40 kg mol−1). Polymers were synthesized starting from trifunctional hydroxyl monomers and diacrylates in DMF (Scheme 11) [21]. Besides hyperbranched poly(ether-ester)s, poly(amino-ether-ester)s were synthesized from triethanolamine and diacrylate via oxa-Michael polymerization catalyzed by P2-tBu at room temperature in solution [108].

Methacrylates in poly(ether-ester)s

Even though methacrylates are interesting monomers due to their higher stability and lower toxicity compared to acrylates, the use thereof in oxa-Michael polymerization is scarce. The low reactivity of methacrylates allows only slow oligomerization [54]. Gibas et al. showed the synthesis of oligo(ether–ester)s based on 2-hydroxyethyl methacrylate (HEMA) or monomethacrylates of di-, tri- and tetraethylene glycols with NaH or KOtBu. Thermal treatment (80 to 100 °C) of the monomers for 2 h, followed by a reaction at room temperature over several days was required to obtain oligomers (with a Mn of about 700 g mol−1). As transesterification occurred as side reaction, irregular structures formed. Without elevated temperatures, no oligomerization was observed. However, longer thermal treatment resulted in gelation which is most likely a result of free radical or anionic polymerization of the double bond at high temperatures [54]. Alternatively, HEMA was oligomerized at 80 °C initiated by potassium [92].

Poly(ether)

Linear poly(ether)s with ketone or ester functionalities in the side chain of the polymer were synthesized by oxa-Michael polymerization starting from AB type monomers with β-substituted vinyl groups (Scheme 12). Poly(ether)s with molar masses of up to 1400 g mol−1 were obtained by a procedure at low temperatures (-40 °C) in THF with a Brønsted base catalyst [80].

Subclass poly(ether-lactone)s

Moreover, Eugene Chen introduced naturally occurring Tulipalin B, a hydroxyl-functionalized methylene butyrolactone, in Michael chemistry [109]. Polymerization thereof could be initiated by NHC catalysts or phosphazene bases. In any case, polymers with a molar mass up to 13.2 kg mol−1 were obtained. Although the mechanism is yet not fully resolved, results indicated the formation of a branched copolymer of poly(vinyl-ether-lactone)s. Carba-Michael reactions causes poly(vinyl-lactone)s units, whereas oxa-Michael polymerization gives poly(ether-lactone) repeat units (Scheme 13). Additionally, olefinic moieties, most likely derived from dehydration and branching were observed in the polymer. Branching probably resulted from the interaction of unreacted OH groups with vinyl units in the polymer in an oxa-Michael fashion [109, 110].

Poly(ether-amide)s

Poly(ether-amide)s synthesized from acrylamides and alcohols are a rare class of oxa-Michael polymers. Li et al., for instance, reported the synthesis of hyperbranched poly(ether-amide)s [111, 112]. AB2 or AB3 type amide monomers were synthesized starting from (meth)acryloyl chloride and multihydroxyl primary amines. In the following, the Michael addition was initiated by either KOtBu or PPh3 and the homopolymerization was performed at 60 °C over 2 days in solution (Scheme 14). Thereafter, the surface was modified by another Michael addition of N-isopropylacrylamide with the hydroxyl end groups to introduce a temperature sensitive functionality [112].

Another approach towards oxa-Michael based hyperbranched poly(ether-amide)s was reported by Jiang’s group. N,N′-methylenebis(acrylamide) was reacted with triols at room temperature in DMF using P2-tBu as catalyst for 36 h. Thereby, thermoresponsive nonconjugated fluorescent poly(ether-amide)s with potential application in cell imaging or drug delivery were synthesized [79].

Degradability and reprocessability

As recyclability of polymers is more important than ever, herein, also the degradability and reprocessability of polymers synthesized by oxa-Michael addition is addressed. In general, efficient methods for the depolymerization and degradation of poly(ester)s or poly(amide)s have been reported [78, 113, 114]. Jiang and coworkers disclosed enzymatic degradation of poly(ether-ester)s and poly(ether-ester-amide)s prepared by oxa-Michael polymerization [71, 95]. Full degradation of a copolymer derived from HEA and acrylamide, for example, was observed in lipase B phosphate buffer solution within 18 days [71].

Within our group, we selected a different approach and studied the potential of the reverse oxa-Michael reaction in polymerization. Recently, we showed that the oxa-Michael reaction is highly reversible in both small molecules and polymers. Oxa-Michael polymers were degraded at elevated temperature (140 °C) in the presence of a Brønsted base catalyst or were depolymerized in additional presence of alcohols. Further, an exemplary oxa-Michael poly(ether-sulfone) network could be reprocessed at elevated temperatures under basic conditions (Fig. 3) and showed dynamic properties in rheology studies [91]. Thus, this example can be regarded as the first oxa-Michael based covalent adaptable network (CAN). Santos et al. recently demonstrated the dynamic exchange of phenols in vinyl ethers derived from hydroxyl-yne reactions [115]. CANs based on aza- and thiol-Michael reaction and the reprocessability thereof have already received increasing attention over the past years [98, 116, 117].

Reproduced from Ref. [91]

a Poly(ether-sulfone) network incl. DBU as catalyst; b photo of cut material (presented in a) in an aluminium mold; c photo of uniform membrane obtained after hot press treatment (140 °C, 1 h, 50 bar) of the cut pieces depicted in b.

Moreover, also poly(ether-sulfone) networks prepared by dual-curing based on oxa-Michael reaction and anionic polymerization (see 'Crosslinked poly(ether-sulfone)s') show a similar reprocessing behavior. Thus, even if lower amounts of oxa-Michael repeat units are present in the polymer, the self-healing characteristics of the network are retained [72].

Challenges and perspectives

One of the main challenges of the oxa-Michael polymerization is the difficulty to form high molar mass poly(ether)s and cross-linked polymers, which are essential to achieve material properties required for high-performance applications. Complications do not only arise from the low acidity of the alcohols and the poor nucleophilicity of the corresponding alkoxides, but also from the lack of non-toxic, highly reactive Michael acceptors. Additionally, stoichiometric imbalance, caused for example by Rauhut-Currier reactions in case of acrylates, is detrimental for the step-growth mechanism of the oxa-Michael polymerization. Moreover, the obtained products are thermodynamically only slightly favored over their educts impeding the formation of polymers with high molar masses. Instead, equilibrium mixtures of monomers and polymers are obtained. Thus, only poly(ether)s with low molar mass (< 10.000 g mol−1) are accessible and hardly any networks based on oxa-Michael chemistry have been reported.

Moreover, the number of catalysts active in oxa-Michael polymerization is limited. While this issue does not present a problem for highly reactive divinyl sulfone, diacrylates and acrylamide can only be converted by phosphazene bases, especially P2-tBu and the strong Lewis base TTMPP. Another challenge stems from the solubility of the Michael donor and acceptor in each other under solvent-free conditions which are necessary to increase reactivity. Further, only few liquid or soluble polyols are available.

However, the oxa-Michael polymerization comprises several green aspects as it is an atom efficient reaction which can be carried out under mild, solvent-free conditions at ambient atmosphere. Moreover, potentially less toxic and cheap alcohols derived from renewable feedstocks might be utilized in the future [23, 24]. Thus, to take advantage of the benefits, oxa-Michael oligomers or polymers with low molar mass might be used as prepolymers in the future. Vinyl termination of poly(ether)s allows further crosslinking of the polymers by e.g. radical or anionic polymerization [60, 72]. Additionally, the choice of functionalized alcohols might allow subsequent reactions, e.g. if double or triple bonds are included in the polymer backbone. Thus, these options present a work-around to obtain polymer networks and allow a variety of applications.

Moreover, the reversibility of the oxa-Michael reaction opens new perspectives for future applications as depolymerization and reprocessability become increasingly important in industry. In this respect, including oxa-Michael units in a network might allow depolymerization or reprocessability of the material, while retaining the material’s properties. Therefore, the combination of different polymerization reactions enables the preparation of polymers with overall improved properties.

Conclusion

The oxa-Michael reaction represents a facile method to form poly(ether)s with versatile properties as various functional groups for further modification can easily be included in the polymer backbone. In this review several fundamental aspects within oxa-Michael reactions have been addressed. Further, various classes of poly(ether)s, accessible by oxa-Michael polymerization, were presented according to functionalities introduced by the Michael acceptor. Recent work on the degradability and reprocessability of poly(ether) based polymers and networks was outlined. Finally, challenges and the potential of the oxa-Michael polymerization in terms of possible synthetic routes to obtain better material properties and the recyclability of poly(ether)s derived from oxa-Michael polymerization were discussed.

Data availability

As no original research is presented in this review article, no previously undisclosed data were used.

References

Bossion A, Heifferon KV, Meabe L, Zivic N, Taton D, Hedrick JL, Long TE, Sardon H (2019) Prog Polym Sci 90:164

Herzberger J, Niederer K, Pohlit H, Seiwert J, Worm M, Wurm FR, Frey H (2016) Chem Rev 116:2170

Brocas A-L, Mantzaridis C, Tunc D, Carlotti S (2013) Prog Polym Sci 38:845

Klein R, Wurm FR (2015) Macromol Rapid Commun 36:1147

Basterretxea A, Gabirondo E, Jehanno C, Zhu H, Flores I, Müller AJ, Etxeberria A, Mecerreyes D, Coulembier O, Sardon H (2019) ACS Sustainable Chem Eng 7:4103

Loydl F (1878) Justus Liebigs Ann Chem 192:80

Tokoroyama T (2010) Eur J Org Chem 2010:2009

Nising CF, Bräse S (2008) Chem Soc Rev 37:1218

Nising CF, Bräse S (2012) Chem Soc Rev 41:988

Hu J, Bian M, Ding H (2016) Tetrahedron Lett 57:5519

Love D, Kim K, Domaille DW, Williams O, Stansbury J, Musgrave C, Bowman C (2019) Polym Chem 10:5790

Kodolitsch K, Gobec F, Slugovc C (2020) Eur J Org Chem 19:2973

Edinger D, Weber H, Žagar E, Pahovnik D, Slugovc C (2021) ACS Appl Polym Mater 3:2018

Mather BD, Viswanathan K, Miller KM, Long TE (2006) Prog Polym Sci 31:487

Noordover B, Liu W, McCracken E, DeGooyer B, Brinkhuis R, Lunzer F (2020) J Coat Technol Res 17:1123

Konuray O, Fernández-Francos X, Ramis X, Serra À (2018) Polymers 10:1

Nair DP, Podgórski M, Chatani S, Gong T, Xi W, Fenoli CR, Bowman CN (2014) Chem Mater 26:724

Podgórski M, Chatani S, Bowman CN (2014) Macromol Rapid Commun 35:1497

Lowe AB (2010) Polym Chem 1:17

Hoyle CE, Bowman CN (2010) Angew Chem Int Ed 49:1540

Jiang Q, Zhang Y, Du Y, Tang M, Jiang L, Huang W, Yang H, Xue X, Jiang B (2020) Polym Chem 11:1298

Geven M, d’Arcy R, Turhan ZY, El-Mohtadi F, Alshamsan A, Tirelli N (2021) Eur Polym J 149:110387

Behr A, Eilting J, Irawadi K, Leschinski J, Lindner F (2008) Green Chem 10:13

Zakzeski J, Bruijnincx PCA, Jongerius AL, Weckhuysen BM (2010) Chem Rev 110:3552

Shi Y, Bai T, Bai W, Wang Z, Chen M, Yao B, Sun JZ, Qin A, Ling J, Tang BZ (2017) Chem Eur J 23:10725

Si H, Wang K, Song B, Qin A, Tang BZ (2020) Polym Chem 11:2568

Wang J, Li B, Xin D, Hu R, Zhao Z, Qin A, Tang BZ (2017) Polym Chem 8:2713

Wang K, Si H, Wan Q, Wang Z, Qin A, Tang BZ (2020) J Mater Chem C 8:16121

Worch JC, Stubbs CJ, Price MJ, Dove AP (2021) Chem Rev 121:6744

Thiyagarajan S, Krishnakumar V, Gunanathan C (2020) Chem Asian J 15:518

Stewart IC, Bergman RG, Toste FD (2003) J Am Chem Soc 125:8696

Wang X, Li S, Jiang Y (2005) J Phys Chem A 109:10770

Fischer SM, Kaschnitz P, Slugovc C (2022) Catal Sci Technol 12:6204

Wang C, Qi C (2013) Tetrahedron 69:5348

Dempsey SH, Kass SR (2022) J Org Chem 87:15466

Huang S, Kim K, Musgrave GM, Sharp M, Sinha J, Stansbury JW, Musgrave CB, Bowman CN (2021) Polym Chem 12:3619

Wabnitz TC, Spencer JB (2003) Org Lett 5:2141

Bernal P, Tamariz J (2006) Tetrahedron Lett 47:2905

Tran-Do M-L, Eid N, Totée C, Gimello O, Améduri B (2021) Polym Chem 12:4508

Saegusa T, Kobayashi S, Kimura Y (1975) Macromolecules 8:950

Nadeau F, Sindt M, Oget N (2015) New J Chem 39:9155

Rozenberg BA (2007) Polym Sci Ser C 49:355

Murtagh JE, McCooey SH, Connon SJ (2005) Chem Commun 227

Matsuoka S, Namera S, Suzuki M (2015) Polym Chem 6:294

Flanigan DM, Romanov-Michailidis F, White NA, Rovis T (2015) Chem Rev 115:9307

Inanaga J, Baba Y, Hanamoto T (1993) Chem Lett 22:241

Strasser S, Slugovc C (2015) Catal Sci Technol 5:5091

Kadokawa J, Kaneko Y, Yamada S, Ikuma K, Tagaya H, Chiba K (2000) Macromol Rapid Commun 21:362

Fischer SM, Renner S, Boese AD, Slugovc C (2021) Beilstein J Org Chem 17:1689

Boileau S, Illy N (2011) Prog Polym Sci 36:1132

Schwesinger R, Schlemper H., Hasenfratz C, Willaredt J, Dambacher T, Breuer T, Ottaway C, Fletschinger M, Boele J, Fritz H, Putzas D, Rotter HW, Bordwell FG, Satish AV, Ji G, Peters E, Peters K, Schnering HG, Walz L (1996) Liebigs Ann 1055

Schwesinger R (2010) Encyclopedia of Reagents for Organic Synthesis. Wiley

Yang H, Zuo Y, Zhang J, Song Y, Huang W, Xue X, Jiang Q, Sun A, Jiang B (2018) Polym Chem 9:4716

Gibas M, Korytkowska-Wałach A (2003) Polymer 44:3811

Maji B, Stephenson DS, Mayr H (2012) ChemCatChem 4:993

Huang R, Li Z, Yu J, Chen H, Jiang B (2019) Org Lett 21:4159

Ratzenböck K, Ud Din MM, Fischer SM, Žagar E, Pahovnik D, Boese AD, Rettenwander D, Slugovc C (2022) Chem Sci 13:6920

Strasser S, Wappl C, Slugovc C (2017) Polym Chem 8:1797

Naumann S, Dove AP (2015) Polym Chem 6:3185

Murase T, Matsuoka S, Suzuki M (2018) Polym Chem 9:2984

Phillips EM, Riedrich M, Scheidt KA (2010) J Am Chem Soc 132:13179

Maji B, Breugst M, Mayr H (2011) Angew Chem Int Ed 50:6915

Allgäuer DS, Jangra H, Asahara H, Li Z, Chen Q, Zipse H, Ofial AR, Mayr H (2017) J Am Chem Soc 139:13318

Ring RN, Tesoro GC, Moore DR (1967) J Org Chem 32:1091

Zhuo L-G, Liao W, Yu Z-X (2012) Asian J Org Chem 1:336

Yoshii E (1997) J Biomed Mater Res 37:517

Krüger JM, Choi C-Y, Lossada F, Wang P, Löschke O, Auhl D, Börner HG (2022) Macromolecules 55:989

Phan TB, Mayr H (2005) Can J Chem 83:1554

Ratzenböck K, Pahovnik D, Slugovc C (2020) Polym Chem 11:7476

Fedotova A, Kondrashov E, Legros J, Maddaluno J, Rulev AY (2018) C R Chim 21:639

Yao H, Song Y, Huang W, Jiang L, Jiang Q, Xue X, Jiang B, Yang H (2022) Macromolecules 55:8283

Fischer SM, Schallert V, Uher JM, Slugovc C (2023) Polym Chem. https://doi.org/10.1039/D3PY00035D

Schmidt-Winkel P, Wudl F (1998) Macromolecules 31:2911

Okutsu R, Suzuki Y, Ando S, Ueda M (2008) Macromolecules 41:6165

Ziegenbalg N, Elbinger L, Schubert US, Brendel JC (2022) Polym Chem 13:5019

Wu W, Bai Y, Wang X, Wu C (2021) Chin Chem Lett 32:1309

Horn HW, Jones GO, Wei DS, Fukushima K, Lecuyer JM, Coady DJ, Hedrick JL, Rice JE (2012) J Phys Chem A 116:12389

Jehanno C, Pérez-Madrigal MM, Demarteau J, Sardon H, Dove AP (2019) Polym Chem 10:172

Jiang Q, Zhao L, Du Y, Huang W, Xue X, Yang H, Jiang L, Jiang Q, Jiang B (2022) Polym Chem 13:631

Matsuoka S, Hoshiyama Y, Tsuchimoto K, Suzuki M (2017) Chem Lett 46:1718

Welch CM (1966) Polymeric adducts of divinyl sulfone with water. US Patent 3281204A, Oct 25, 1966; (1966) Chem Abstr 66:19770

Kumeta K, Nagashima I, Matsui S, Mizoguchi K (2004) Polym J 36:472

Tesoro GC (1962) Text Res J 32:189

Welch CM (1963) Text Res J 33:165

Rowland SP (1969) Text Res J 39:173

Berrisford DJ, Lovell PA, Whiting A (2006) Method for crosslinking of resin and crosslinkable resin compositions with improved storage stability. US Patent 2006009572A1, Jan 12, 2006; (2004) Chem Abstr 141:24550

Kaur J, Krishnan R, Ramalingam B, Jana S (2020) RSC Adv 10:17171

Yu Y, Chau Y (2012) Biomacromol 13:937

Tashlick I, Culbertson HM (1964) Cross-linked sulfone polymers. US Patent 3153021, Oct 13, 1964; (1965) Chem Abstr 62:9670

Ziegenbalg N, Lohwasser R, D’Andola G, Adermann T, Brendel JC (2021) Polym Chem 12:4337

Ratzenböck K, Uher JM, Fischer SM, Edinger D, Schallert V, Zagar E, Pahovnik D, Slugovc C (2023) Polym Chem 14:651

Wang H, Cheng F, He W, Zhu J, Cheng G, Qu J (2017) Biointerphases 12:02C414

Rozenberg BA (2004) Des Monomers Polym 7:135

Gibas M, Korytkowska-Walach A (2003) Polym Bull 51:17

Yang H-J, Chai C-Q, Zuo Y-K, Huang J-F, Song Y-Y, Jiang L, Huang W-Y, Jiang Q-M, Xue X-Q, Jiang B-B (2020) Chin J Polym Sci 38:231

Yang H, Zhang J, Zuo Y, Song Y, Huang W, Jiang L, Jiang Q, Xue X, Jiang B (2019) Macromol Chem Phys 220:1900147

Yang H, Zhang J, Song Y, Jiang L, Jiang Q, Xue X, Huang W, Jiang B (2021) Macromol Chem Phys 222:231

Taplan C, Guerre M, Du Prez FE (2021) J Am Chem Soc 143:9140

Naga N, Fujioka S, Inose D, Ahmed K, Nageh H, Nakano T (2019) RSC Adv 10:60

González G, Fernández-Francos X, Serra À, Sangermano M, Ramis X (2015) Polym Chem 6:6987

Moszner N, Rheinberger V (1995) Macromol Rapid Commun 16:135

Wang T, Wang J, He X, Cao Z, Xu D, Gao F, Zhong J, Shen L (2019) Coatings 9:37

Ma X, Sun Q, Zhou Z, Jin E, Tang J, van Kirk E, Murdoch WJ, Shen Y (2013) Polym Chem 4:812

Zhang Y, Miao H, Shi W (2011) Prog Org Coat 71:48

Chatani S, Wang C, Podgórski M, Bowman CN (2014) Macromolecules 47:4949

Gao C, Yan D (2004) Prog Polym Sci 29:183

Kadokawa J, Ikuma K, Tagaya H (2002) J Macromol Sci Part A 39:879

Jiang Q, Du Y, Zhang Y, Zhao L, Jiang L, Huang W, Yang H, Xue X, Jiang B (2020) J Polym Sci 58:2718

Tang J, Chen EY-X (2015) Org Chem Front 2:1625

Tang J, Chen EY-X (2017) Eur Polym J 95:678

Lin Y, Dong Z-M, Liu X-H, Li Y-S (2007) J Polym Sci A Polym Chem 45:4309

Lin Y, Gao J-W, Liu H-W, Li Y-S (2009) Macromolecules 42:3237

Payne J, Jones MD (2021) Chemsuschem 14:4041

Thiyagarajan S, Maaskant-Reilink E, Ewing TA, Julsing MK, van Haveren J (2021) RSC Adv 12:947

Santos T, Pérez-Pérez Y, Rivero DS, Diana-Rivero R, García-Tellado F, Tejedor D, Carrillo R (2022) Org Lett 24:8401

Zhang B, Digby ZA, Flum JA, Chakma P, Saul JM, Sparks JL, Konkolewicz D (2016) Macromolecules 49:6871

Daymon SP, Miller KM (2018) Polymer 145:286

Acknowledgements

Financial support by the Austrian Federal Ministry for Digital and Economic Affairs, the National Foundation for Research, Technology and Development, and the Christian Doppler Research Association (Christian Doppler Laboratory for Organocatalysis in Polymerization) is gratefully acknowledged. Note Parts of this review are based on the PhD thesis “Oxa-Michael Chemistry: Synthesis, Use and Reprocessability of Polyethers” of Karin Ratzenböck published in October 2022 at the Graz University of Technology and on the PhD thesis “Lewis Base Catalyzed Oxa-Michael Polymerization: From Fundamentals to Applications” of Susanne M. Fischer published in December 2022 at the Graz University of Technology.

Funding

Open access funding provided by Graz University of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ratzenböck, K., Fischer, S.M. & Slugovc, C. Poly(ether)s derived from oxa-Michael polymerization: a comprehensive review. Monatsh Chem 154, 443–458 (2023). https://doi.org/10.1007/s00706-023-03049-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-023-03049-4