Abstract

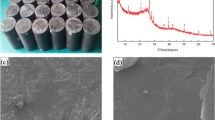

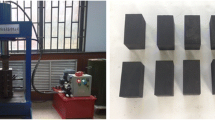

Effective methane extraction in underground coal seams can improve the efficient utilization of fossil energy and reduce the risk of safety accidents in coal mines. Pulsating nitrogen fatigue fracturing technology is proposed as a novel and effective method to enhance gas production in low-permeability coal seams and improve gas extraction efficiency. In this study, a pulsating gas test system was established to apply fatigue fracturing of pulsating nitrogen to low-permeability coal. Mercury intrusion tests, wave velocity tests, and triaxial compression tests were used to reveal the changes in microstructure and mechanical properties of low-permeability coal under fatigue fracturing tests. Results show that the residual deformation of the coal changes considerably under fatigue fracturing. The strain of the coal is characterized by a periodic “expansion–contraction” variation with the intrusion and discharge of the pulsating nitrogen, and the residual strain increases gradually in this process. After fatigue fracturing, facilitates the seepage of gas and the development of micropores and transition pores toward mesopores and macropores enhances the permeability of the coal. The specific surface area of the pores is considerably improved in the transition pores and mesopores. The pore fractal dimension of the coal tends to decrease under fatigue fracturing, resulting in a more uniform distribution of pores and enhanced interpore connectivity within the coal. The fatigue period is negatively correlated with the strength and wave velocity evolution of the coal, and the peak intensity first decreases rapidly and then gradually stabilizes. The fatigue fracturing results in a substantial increase in the spatial complexity and connectivity of the fracture distribution throughout the specimen. On the basis of the evolution characteristics of residual volumetric strain, a fatigue damage model was constructed to analyze the characteristics of fatigue deformation and failure of coal.

Highlights

-

The pulsating nitrogen fatigue test of low-permeability coal was carried out.

-

The change of residual deformation of coal under pulsating nitrogen fatigue is obtained.

-

The influence mechanism of pulsating nitrogen fatigue on pore structure is analyzed.

-

The macromechanical parameters and damage evolution characteristics under pulsating nitrogen fatigue are evaluated.

Similar content being viewed by others

Abbreviations

- \(M_{ad}\) :

-

Moisture

- \(A_{ad}\) :

-

Ash

- \(V_{ad}\) :

-

Volatile matter

- \(V_{daf}\) :

-

Dry ash free volatile matter

- \(\overline{V}\) :

-

Average value of incremental pores

- \(S\) :

-

Variance of incremental pores

- \(\Delta V_{i}\) :

-

Incremental volume of different pore diameters

- \(n\) :

-

Number of measuring points

- \(r_{{{\text{max}}}}\) :

-

Largest pore size

- \(P\left( r \right)\) :

-

Density function of the pore size distribution

- \(D\) :

-

Fractal dimension of the pores

- \(a\) :

-

Proportional constant determined by the pore geometry

- \(V_{s}\) :

-

Total pore volume

- \(S_{v}\) :

-

Cumulative volume fraction of pores

- \(P_{C}\) :

-

Capillary pressure

- \(\sigma\) :

-

Surface tension of the liquid

- \(\vartheta\) :

-

Wetting contact angle

- \(r_{{{\text{max}}}}\) :

-

Maximum pore size

- \(S_{v}\) :

-

Volume fraction of the intruded liquid phase

- \(\sigma\) :

-

Peak strength

- \(E\) :

-

Elastic modulus

- \(\mu\) :

-

Poisson’s ratio

- \(V_{p}\) :

-

Wave velocity

- \(\phi_{0}\) :

-

Initial porosity

- \(V_{p0}\) :

-

Initial pore volume

- \(V_{0}\) :

-

Initial appearance total volume

- \(\varepsilon_{v}\) :

-

Volumetric strain

- \(\phi_{d}\) :

-

Critical porosity of microdamage

- \(\varepsilon_{vd}\) :

-

Critical volumetric strain of microdamage

- \(N_{d}\) :

-

Ultimate number of fatigue cycles

- \(\varepsilon_{v}^{e}\) :

-

Elastic volumetric strain

- \(\varepsilon_{v}^{p}\) :

-

Residual plastic volumetric strain

References

Abel JC (1981) Application of nitrogen fracturing in the Ohio Shale. In SPE Eastern Regional Meeting, Columbus, Ohio, November 4–6

Aminzadeh F (2018) Hydraulic fracturing, an overview. J Sustain Energy Eng 6(3):204–228

Chen J, Li X, Cao H, Zhu Q (2022) Experimental study on the mechanism of coupled dynamic–static fracturing on damage evolution and crack propagation in tight shale. Energy Rep 8:7037–7062

Dodge J, Metze T (2017) Hydraulic fracturing as an interpretive policy problem: lessons on energy controversies in Europe and the USA. J Environ Policy Planning 19(1):1–13

Figueiredo B, Tsang CF, Rutqvist J, Niemi A (2017) The effects of nearby fractures on hydraulically induced fracture propagation and permeability changes. Eng Geol 228:197–213

Gottschling JC, Royce TN (1985) Nitrogen gas and sand: a new technique for stimulation of Devonian shale. J Pet Technol 37(05):901–907

Grundmann SR, Rodvelt GD, Dials GA, Allen RE (1998) Cryogenic nitrogen as a hydraulic fracturing fluid in the devonian shale. In SPE Eastern Regional Meeting. OnePetro.

Hall M, Kilpatrick JE (2010) Surface Microseismic Monitoring of Slick Water and Nitrogen Fracture Stimulations, Arkoma Basin, Oklahoma. Society of Petroleum Engineers Unconventional Gas Conference, Pittsburgh, PA (23–25 February 2010).

Hou P, Gao F, Ju Y, Liang X, Zhang Z, Cheng H, Gao Y (2016) Experimental investigation on the failure and acoustic emission characteristics of shale, sandstone and coal under gas fracturing. J Nat Gas Sci Eng 35:211–223

Hou P, Xue Y, Gao F, Dou F, Su S, Cai C, Zhu C (2022) Effect of liquid nitrogen cooling on mechanical characteristics and fracture morphology of layer coal under Brazilian splitting test. Int J Rock Mech Mining Sci 151:105026

Jiráková H, Frydrych V, Vintera J, Krasny O, Vanecek M (2015) Results of the rock hydraulic fracturing research project. Tunel Undergr Constr Mag Czech Tunn Assoc Slovak Tunn Assoc 24(4):57–64

Lau HC, Li H, Huang S (2017) Challenges and opportunities of coalbed methane development in China. Energy Fuels 31(5):4588–4602

Liu J, Xue Y, Zhang Q, Wang H, Wang S (2022) Coupled thermo-hydro-mechanical modelling for geothermal doublet system with 3D fractal fracture. Appl Therm Eng 200:117716

Liu Q, Zhang R, Wang M, Wei S, Zhang Z, Gao M, Zhang Z (2017) Physical properties coal from different depths. J China Coal Soc 42(8):2101–2109

Mojid MR, Negash BM, Abdulelah H, Jufar SR, Adewumi BK (2021) A state–of–art review on waterless gas shale fracturing technologies. J Pet Sci Eng 196:108048

McDaniel BW, Grundmann SR, Kendrick WD, Wilson DR, Jordan SW (1997) Field applications of cryogenic nitrogen as a hydraulic fracturing fluid. In SPE annual technical conference and exhibition. OnePetro

Palmer C, Sito Z (2013) Nitrogen and carbon dioxide fracturing fluids for the stimulation of unconventional shale plays. AGH Drilling Oil Gas 30(1):191–198

Qin L, Zhai C, Liu S, Xu J (2018) Mechanical behavior and fracture spatial propagation of coal injected with liquid nitrogen under triaxial stress applied for coalbed methane recovery. Eng Geol 233:1–10

Ren Q, Zhang Y, Arauzo I, Shan L, Xu J, Wang Y, Xiang J (2021) Roles of moisture and cyclic loading in microstructures and their effects on mechanical properties for typical Chinese bituminous coals. Fuel 293:120408

Song Y, Zou Q, Su E, Zhang Y, Sun Y (2020) Changes in the microstructure of low-rank coal after supercritical CO2 and water treatment. Fuel 279:118493

Shao Z, Wang Y, Tang X (2020) The influences of heating and uniaxial loading on granite subjected to liquid nitrogen cooling. Eng Geol 271:105614

Tao S, Chen S, Pan Z (2019) Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci Eng 7(4):1059–1074

Westaway R (2016) The importance of characterizing uncertainty in controversial geoscience applications: induced seismicity associated with hydraulic fracturing for shale gas in northwest England. Proc Geol Assoc 127(1):1–17

Xu J, Zhai C, Ranjith PG, Sun Y, Cong Y, Zheng Y, Yang W (2021) Investigation of non-isothermal effect of cyclic carbon dioxide on the petrography of coals for coal mine methane recovery. Fuel 290:120085

Xue Y, Liu J, Liang X, Wang S, Ma Z (2022a) Ecological risk assessment of soil and water loss by thermal enhanced methane recovery: numerical study using two-phase flow simulation. J Clean Prod 334:130183

Xue Y, Liu J, Ranjith PG, Gao F, Zhang Z, Wang S (2022b) Experimental investigation of mechanical properties, impact tendency, and brittleness characteristics of coal mass under different gas adsorption pressures. Geomech Geophys Geo-energ Geo-resour 8(5):131

Xie J, Xie J, Ni G, Sheik R, Sun Q, Wang H (2020) Effects of pulse wave on the variation of coal pore structure in pulsating hydraulic fracturing process of coal seam. Fuel 264:116906

Yang Y, Liu S, Chang X (2021) Fracture stiffness evaluation with waterless cryogenic treatment and its implication in fluid flowability of treated coals. Int J Rock Mech Min 142:104727

Yun Y, Shimin L, Xin C (2021) Fracture stiffness evaluation with waterless cryogenic treatment and its implication in fluid flowability of treated coals. Int J Rock Mech Min Sci 142:104727

Zhang J, Li Y, Pan Y, Wang X, Yan M, Shi X, Li H (2021a) Experiments and analysis on the influence of multiple closed cemented natural fractures on hydraulic fracture propagation in a tight sandstone reservoir. Eng Geol 281:105981

Zhou J, Yang K, Tian S, Zhou L, Xian X, Jiang Y, Cai J (2020) CO2-water-shale interaction induced shale microstructural alteration. Fuel 263:116642

Zhang G, Ranjith PG, Fu X, Li X (2021b) Pore-fracture alteration of different rank coals: implications for CO2 sequestration in coal. Fuel 289:119801

Zhao C, Xing J, Zhou Y, Shi Z, Wang G (2020) Experimental investigation on hydraulic fracturing of granite specimens with double flaws based on DIC. Eng Geol 267:105510

Zang A, Yoon JS, Stephansson O, Heidbach O (2013) Fatigue hydraulic fracturing by cyclic reservoir treatment enhances permeability and reduces induced seismicity. Geophys J Int 195(2):1282–1287

Zang A, Stephansson O, Stenberg L, Plenkers K, Specht S, Milkereit C, Weber M (2017) Hydraulic fracture monitoring in hard rock at 410 m depth with an advanced fluid-injection protocol and extensive sensor array. Geophys J Int 208(2):790–813

Zang A, Zimmermann G, Hofmann H, Stephansson O, Min KB, Kim KY (2019) How to reduce fluid-injection-induced seismicity. Rock Mech Rock Eng 52(2):475–493

Zang A, Zimmermann G, Hofmann H, Niemz P, Kim KY, Diaz M, Yoon JS (2021) Relaxation damage control via fatigue-hydraulic fracturing in granitic rock as inferred from laboratory-, mine-, and field-scale experiments. Sci Rep 11(1):1–16

Zhuang L, Zang A (2021) Laboratory hydraulic fracturing experiments on crystalline rock for geothermal purposes. Earth-Sci Rev 216:103580

Zhuang L, Jung SG, Diaz M, Kim KY, Hofmann H, Min KB, Zang A, Yoon JS (2020) Laboratory true triaxial hydraulic fracturing of granite under six fluid injection schemes and grain-scale fracture observations. Rock Mech Rock Eng 53(10):4329–4344

Acknowledgements

The authors are grateful to the financial support from the National Natural Science Foundation of China (12002270), the China Postdoctoral Science Foundation (2020M683686XB, 2020M673451, 2021T140553, 2021M692600), the Scientific Research Program Funded by Shaanxi Provincial Education Department (22JK0477) and the Youth Talent Promotion Project of the Xi’an Association for Science and Technology (095920211334).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xue, Y., Liu, J., Ranjith, P.G. et al. Changes in Microstructure and Mechanical Properties of Low-Permeability Coal Induced by Pulsating Nitrogen Fatigue Fracturing Tests. Rock Mech Rock Eng 55, 7469–7488 (2022). https://doi.org/10.1007/s00603-022-03031-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-03031-2