Abstract

Unlike metals, rocks show bi-modularity (different Young’s moduli and Poisson’s ratios in compression and tension). Displacements monitored during the Brazilian test are used in this study to obtain the Young’s modulus and Poisson’s ratio in tension. New equations for the displacements in a Brazilian test are derived considering the bi-modularity in the stress–strain relations. The digital image correlation technique was used to monitor the displacements of the Brazilian disk flat surface. To validate the Young’s modulus and Poisson’s ratio obtained from the Brazilian test, the results were compared with the values from the direct tension tests. The results obtained from the Brazilian test were repetitive and within 3.5% of the value obtained from the direct tension test for the rock tested.

Similar content being viewed by others

Abbreviations

- OB:

-

Horizontal axis of reference

- OE:

-

Vertical axis of reference

- P :

-

Diametrical load

- D :

-

Disk diameter

- t :

-

Disk thickness

- σ xx :

-

Stress in x-direction

- σ yy :

-

Stress in y-direction

- σ tb :

-

Brazilian strength

- ε xx :

-

Strain in x-direction

- ε yy :

-

Strain in y-direction

- ν c :

-

Poisson’s ratio in compression

- ν t :

-

Poisson’s ratio in tension

- E c :

-

Young’s modulus in compression

- E t :

-

Young’s modulus in tension

- u :

-

Displacement in x-direction

- v :

-

Displacement in y-direction

- m x :

-

Slope of linear fit for u versus P plot

- m y :

-

Slope of linear fit for v versus P plot

- SD:

-

Standard deviation

- CoV:

-

Coefficient of variation

- n :

-

Sample size

References

Ambartsumyan SA (1969) Basic equations and relations in the theory of elasticity of anisotropic bodies with differing moduli in tension and compression. Inzh Zh Meth Tverd Tela 3:51–61

ASTM Standard D3967-08 (2008) Standard test method for splitting tensile strength of intact rock core specimens. ASTM International, West Conshohocken, pp 20–23. doi:10.1520/D3967-08.2. www.astm.org

Belrhiti Y et al (2017) Combination of Brazilian test and digital image correlation for mechanical characterization of refractory materials. J Eur Ceram Soc 37(5):2285–2293. doi:10.1016/j.jeurceramsoc.2016.12.032

Bieniawski ZT, Bernede MJ (1979) Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. Int J Rock Mech Min Sci Geomech Abstr 16(2): 137–140. http://www.scopus.com/scopus/inward/record.url?eid=2-s2.0-0018681945&partnerID=40&rel=R8.0.0%5Cnhttp://linkinghub.elsevier.com/retrieve/pii/0148906279914505

Collins DS (1997) Excavation induced seismicity in granitic rock: a case study at the underground research laboratory. Keele University, Keele

CorelatedSolutions (2010a) CSI Application Note AN-824. Columbia, SC, USA. www.CorrelatedSolutions.com

CorelatedSolutions (2010b) Vic-3D 2010 Reference Manual. Columbia, SC, USA. www.CorrelatedSolutions.com

Fairbairn EMR, Ulm F-J (2002) A tribute to Fernando L. L. B. Carneiro (1913–2001) engineer and scientist who invented the Brazilian test. Mater Struct 35(April):195–196

Fairhurst C (1961) Laboratory measurement of some physical properties of rock. In: The 4th U.S. symposium on rock mechanics (USRMS), 30 March–1 April, University Park, Pennsylvania, pp 106–17

Fuenkajorn Kittitep, Klanphumeesri Sippakorn (2011) Laboratory determination of direct tensile strength and deformability of intact rocks. Geotech Test J 34(1):1–6

Haimson BC, Tharp TM (1974) Stresses around boreholes in bilinear elastic rock. Soc Petrol Eng J 14(2):145–151. doi:10.2118/4241-PA

Hondros G (1959) The evaluation of Poisson’s ratio and the modulus of materials of low tensile resistance by the Brazilian (indirect tensile) test with particular reference to concrete. Aust J Appl Sci 10:243–268

Irani FK, Khan AS (1987) Failure behavior of rocks at ambient temperature. Mech Mater 6: 271–283. http://ac.els-cdn.com/0167663687900263/1-s2.0-0167663687900263-main.pdf?_tid=a6f41fc6-13e6-11e7-8486-00000aacb35e&acdnat=1490726882_5c43154feb5009a990c625e7ffb55825. 28 March 2017

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 15: 99–103. https://www.isrm.net

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. PhD Thesis. University of Manitoba, Winnipeg, Canada

Park G, Piasecki M (1993) Petrofabric assessment of samples from the Lac Du Bonnet Batholith. Keele University Internal Report, Canada

Patel S, Martin CD (2017) Application of digital image correlation technique for measurement of tensile elastic constants in Brazilian tests on a bi-modular crystalline rock. Manuscript Accepted, pp 1–20

Stirling RA, Simpson DJ, Davie CT (2013) The application of digital image correlation to Brazilian testing of sandstone. Int J Rock Mech Min Sci 60: 1–11. http://linkinghub.elsevier.com/retrieve/pii/S1365160912002547

Sundaram PN, Corrales JM (1980) Brazilian tensile strength of rocks with different elastic properties in tension and compression. Int J Rock Mech Min Sci Geomech Abstr 17(2): 131–133. http://www.sciencedirect.com/science/article/pii/014890628090265X. 30 Sept 2017

Sutton MA, Orteu J-J, Schreier H (2009) Image correlation for shape, motion and deformation measurements. Springer, Boston. http://link.springer.com/10.1007/978-0-387-78747-3

Wawersik WR (1968) Detailed analysis of rock failure in laboratory compression tests. PhD Thesis, University of Minnesota, Minneapolis, USA

Ye JH, Wu FQ, Sun JZ (2009) Estimation of the tensile elastic modulus using Brazilian disc by applying diametrically opposed concentrated loads. Int J Rock Mech Min Sci 46(3):568–576

Ye JH, Wu FQ, Zhang Y, Ji HG (2012) Estimation of the bi-modulus of materials through deformation measurement in a Brazilian disk test. Int J Rock Mech Min Sci 52: 122–131. http://linkinghub.elsevier.com/retrieve/pii/S1365160912000585

Acknowledgements

We acknowledge the Swedish Nuclear Fuel and Waste Management Co. (SKB) Sweden, the Canadian Nuclear Waste Management Organization (NWMO), and the Natural Sciences and Engineering Research Council of Canada (NSERC) who provided funding for this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

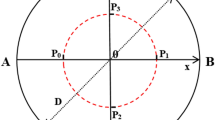

We used Cartesian coordinate system. The center of the Brazilian disk coincides with the origin O of the Cartesian system.

Sign convention: stress and strain values are +ve in tension; horizontal displacement +ve toward +ve x-direction; vertical displacement +ve toward +ve y-direction.

Appendix

Appendix

1.1 Displacement Along Horizontal and Vertical Line in a Brazilian Test

Figure 8 shows the Brazilian disk loaded along its vertical diameter EF. For a particular value of load (P), the horizontal displacement (u(x)) along the horizontal diameter (AB) and the vertical displacement (v(y)) along the vertical diameter (EF) are functions of x, y, E c, E t, ν c and ν t (due to symmetry, the vertical displacement along AB and the horizontal displacement along EF are zero). The derivations for u(x) and v(y) here follow the methodology that is adopted by Ye et al. (2012). However, the bi-modularity relation between the elastic constants as given by Ambartsumyan (1969) and Sundaram and Corrales (1980) is considered in the Brazilian stress–strain equations.

The horizontal and vertical stress along the horizontal diameter AB are:

and the horizontal and vertical stress along the vertical diameter EF are:

(Hondros 1959; Ye et al. 2012).

According to Ambartsumyan (1969) and the model adopted by Sundaram and Corrales (1980), the strain–stress relationships for a plane stress condition (σ zz = 0) with bi-modularity can be written as:

and

where

Considering a small segment dx at a distance x from the center of the disk along the horizontal diameter AB (Fig. 8), the small displacement of this segment is:

and the total horizontal displacement of the point at distance x is:

Substituting the value of σ xx and σ yy from Eqs. (6) and (7), u(x) can be written as:

where

and

Let’s assume w \(= 2x/D\) for the first part and \(x = \frac{D}{2} \tan z\) for the second part.

substituting the values of w and z

Assuming \(x = \frac{D}{2} {\text{tan }}w\)

Substituting the value of w,

Hence,

Substituting the vales for I 1 and I 2 and rearranging u(x) can be written as:

or in terms of du/dP

where \(m_{x} = {\text{d}}P/{\text{d}}u\) (slope of u-P plot, Fig. 7).

Similarly, considering a small segment dy at a distance y from the center of the disk along the vertical diameter EF (Fig. 8), the small displacement of this segment is:

and the total vertical displacement of the point at distance y is:

substituting the value of σ xx and σ yy from Eqs. (8) and (9), \(v\left( y \right)\) can be written as:

where,

Assuming 2y = t, i.e., 2dy = dt

substituting the value of I 3

or in terms of dv/dP

where \(m_{y} = {\text{d}}P/{\text{d}}v\) (slope of v-P plot, Fig. 7).

1.2 Calculation of Tensile Modulus from the Displacement Measurements

The horizontal displacement equation

can be written as:

where,

The vertical displacement equation

can be written as:

where,

substituting the value of \(\frac{1}{{E_{\rm c} }}\) in Eq. (17) and rearranging, Et can be expressed as:

The elastic constants are related by the equation (Ambartsumyan 1969):

Substituting the value of 1/E c and E t, ν t can be written as:

1.3 Sample Calculation for Young’s Modulus and Poisson’s Ratio in Tension form the Displacement Measurements

The typical value obtained for a sample and the parameters A, B, C, F, G, H, E c, E t and ν t as per the (18), (19), (20), (21) and (22) are shown in Table 5. The coefficient of variation for the tensile Young’s modulus and Poisson’s ratio are 6.0 and 3.7%, respectively. These variations within the sample are acceptable considering the different kinds of mineral grains present in the sample as discussed in Sect. 3 and because some plastic strain may have developed in the sample even at 50% of the peak load.

Rights and permissions

About this article

Cite this article

Patel, S., Martin, C.D. Evaluation of Tensile Young’s Modulus and Poisson’s Ratio of a Bi-modular Rock from the Displacement Measurements in a Brazilian Test. Rock Mech Rock Eng 51, 361–373 (2018). https://doi.org/10.1007/s00603-017-1345-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1345-5