Abstract

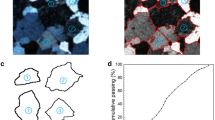

This paper presents a new procedure to create numerical models considering grain shape and size as well as pore size in an explicit and stochastic equivalent manner. Four shape factors are introduced to reproduce shape and size of grains and pores. Thin sections are used to analyze grain shape and pore size of rock specimen. First, a particle-based numerical model is set up by best fitted clumps from a shape library according to thin sections. Finally, an equivalent Voronoi-based discrete element model is set up based on the superimposed particle model. Uniaxial compression and tensile tests are simulated for validation. Both tests indicate that grain boundaries and pores provide preferred paths of weakness for crack propagation, but they also reveal significant differences in terms of intra- and inter-granular fracturing.

Similar content being viewed by others

References

Bass JD (2013) Elasticity of minerals, glasses, and melts. In: Ahrens TJ (ed) Mineral physics & crystallography: a handbook of physical constants. American Geophysical Union, Washington, DC, pp 45–63

Bolander JE, Sukumar N (2005) Irregular lattice model for quasistatic crack propagation. Phys Rev B 71(9):094106

Chao H, Jie B, Somnath G (2007) Micromechanical and macroscopic models of ductile fracture in particle reinforced metallic materials. Model Simul Mater Sci Eng 15(4):S377

Chen W, Konietzky H (2014) Simulation of heterogeneity, creep, damage and lifetime for loaded brittle rocks. Tectonophysics 633:164–175

Chen SG, Zhao J (1998) A study of UDEC modelling for blast wave propagation in jointed rock masses. Int J Rock Mech Min Sci 35(1):93–99

Chen W, Konietzky H, Abbas SM (2015) Numerical simulation of time-independent and -dependent fracturing in sandstone. Eng Geol 193:118–131

Christodoulou I, Tan PJ (2013) Crack initiation and fracture toughness of random Voronoi honeycombs. Eng Fract Mech 104:140–161

Correns CW (1969) Crystal physics. In: Introduction to mineralogy: crystallography and petrology, Springer, Berlin, pp 101–161. doi:10.1007/978-3-642-87134-4_3

Cox MR, Budhu M (2008) A practical approach to grain shape quantification. Eng Geol 96(1–2):1–16

Eberhardt E, Stimpson B, Stead D (1999) Effects of grain size on the initiation and propagation thresholds of stress-induced brittle fractures. Rock Mech Rock Eng 32(2):81–99

Fakhimi A, Alavi Gharahbagh E (2011) Discrete element analysis of the effect of pore size and pore distribution on the mechanical behavior of rock. Int J Rock Mech Min Sci 48(1):77–85

Fredrich JT, Evans B, Wong T-F (1990) Effect of grain size on brittle and semibrittle strength: implications for micromechanical modelling of failure in compression. J Geophys Res Solid Earth 95(B7):10907–10920

Groh U, Konietzky H, Walter K, Herbst M (2011) Damage simulation of brittle heterogeneous materials at the grain size level. Theor Appl Fract Mech 55(1):31–38

Itasca (2010) UDEC-manuals. Itasca Consulting Group Inc, Minneapolis

ImageJ (https://imagej.nih.gov/ij/) Image processing and analysis in Java, an open source soft by USA National Institutes of Health

Kazerani T (2013) Effect of micromechanical parameters of microstructure on compressive and tensile failure process of rock. Int J Rock Mech Min Sci 64:44–55

Lan H, Martin CD, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J Geophys Res Solid Earth 115(B1):B01202

Lindqvist JE, Åkesson U, Malaga K (2007) Microstructure and functional properties of rock materials. Mater Charact 58(11–12):1183–1188

Liu HY, Roquete M, Kou SQ, Lindqvist PA (2004) Characterization of rock heterogeneity and numerical verification. Eng Geol 72(1–2):89–119

Moorthy S, Ghosh S (1998) A Voronoi cell finite element model for particle cracking in elastic–plastic composite materials. Comput Methods Appl Mech Eng 151(3–4):377–400

Olsson WA (1974) Grain size dependence of yield stress in marble. J Geophys Res 79(32):4859–4862

Palchik V (1999) Influence of porosity and elastic modulus on uniaxial compressive strength in soft brittle porous sandstones. Rock Mech Rock Eng 32(4):303–309

Paterson MS (1958) Experimental deformation and faulting in Wombeyan marble. Bull Geol Soc Am 69:465–476

Rice RW (1989) Relation of tensile strength-porosity effects in ceramics to porosity dependence of Young’s modulus and fracture energy, porosity character and grain size. Mater Sci Eng A 112:215–224

Tan X, Konietzky H, Frühwirt T, Dan D (2015) Brazilian tests on transversely isotropic rocks: laboratory testing and numerical simulations. Rock Mech Rock Eng 48(4):1341–1351

Tan X, Konietzky H, Chen W (2016) Numerical simulation of heterogeneous rock using discrete element model based on digital image processing. Rock Mech Rock Eng 49(12):4957–4964

Wadell H (1935) Volume, shape, and roundness of quartz particles. J Geol 43(3):250–280

Wong TF (1982) Micromechanics of faulting in Westerly granite. Int J Rock Mech Min Sci Geomech Abstr 19(2):49–64

Wong RHC, Chau KT, Wang P (1996) Microcracking and grain size effect in Yuen Long marbles. Int J Rock Mech Min Sci Geomech Abstr 33(5):479–485

Xiao F, Yin X (2016) Geometry models of porous media based on Voronoi tessellations and their porosity-permeability relations. Comput Math Appl 72(2):328–348. doi:10.1016/j.camwa.2015.09.009

Zorlu K, Gokceoglu C, Ocakoglu F, Nefeslioglu HA, Acikalin S (2008) Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng Geol 96(3–4):141–158

Acknowledgements

The first author would like to thank the Chinese Scholarship Council for its financial support provided for his Ph.D study at TU Bergakademie Freiberg, Germany. Special thanks to Mr. Jörn Wichert and Mr. Martin Herbst for technical supporting. And thanks to Mr. Tom Weichmann, Mrs. Beatrice Tauch, and Mr. Gerd Münzberger for help during lab testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Konietzky, H. & Frühwirt, T. Voronoi-Based DEM Simulation Approach for Sandstone Considering Grain Structure and Pore Size. Rock Mech Rock Eng 50, 2749–2761 (2017). https://doi.org/10.1007/s00603-017-1257-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1257-4