Abstract

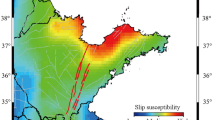

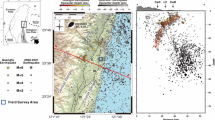

Thrust faults exist extensively in nature, and their activities often cause earthquakes and disasters involving underground engineering, such as the May 12, 2008 Wenchuan Earthquake; the April 20, 2013 Ya’an Earthquake; and the Nov. 3, 2011 Yima Qianqiu Coal-Mining Accident in China. In this paper, the initiation and propagation of a thrust are discussed from a mechanical viewpoint using fault mechanics and fault-slip analysis, taking as an example the Yima section of the Xiashi-Yima thrust (north side of the eastern Qinling Orogen, China). The research primarily focuses on the stress field and the formation trajectory of the thrust and the genesis of the large-scale inversion thrust sheet. The results show that the thrust results from failures in the compressive deformation state and that its stress state is entirely compressive shear. The rupture trajectory of the thrust develops upward, and the fault fracture zone forms similarly to a listric fault, up-narrow and down-wide. The model results and the genesis of the large-scale inversion thrust sheet are consistent with in situ exploration observations. This investigation can be extended to other thrust faults with similar characteristics, particularly for the design of mining operations in tectonic-active areas. Moreover, this research can be used to further study the mechanism of thrust faults and provide support for the feasibility of using fault-slip analysis to assess fault stability.

Similar content being viewed by others

Abbreviations

- \(\sigma_{1}\), \(\sigma_{3}\) :

-

The maximum and minimum principal stress (MPa)

- \(\bar{\sigma }_{x}\), \(\bar{\sigma }_{y}\), \(\bar{\tau }_{xz}\), \(\bar{\sigma }_{z}\) :

-

The effective stress components (MPa)

- \(\sigma_{t}\) :

-

The uniaxial tensile strength (MPa)

- \(n = c^{2} /\sigma_{t}\) :

-

The undetermined coefficient (MPa)

- \(c\) :

-

The cohesion in the parabolic Mohr failure criterion (MPa)

- \(\tilde{\sigma }_{z}\), \(\tilde{\tau }_{zx}\), \(\tilde{\sigma }_{x}\) :

-

The ultimate stress components (MPa)

- \(\tilde{\sigma }_{x}^{ + }\), \(\tilde{\sigma }_{x}^{ - }\) :

-

The two solutions for \(\tilde{\sigma }_{x}\) (MPa)

- \(\tilde{S}_{x}\), \(\tilde{S}_{z}\), \(\tilde{\tau }\), \(\tilde{\sigma }\) :

-

The external stress components acting on the fault plane (MPa)

- \(\tau_{\text{crit}}\), \(\bar{\tau }_{\text{crit}}\) :

-

The critical values of shear stress, also called static and dynamic friction stress, respectively (MPa)

- \(\tilde{\sigma }_{f}\), \(\tau_{0}\) :

-

The normal stress and cohesion in the Mohr–Coulomb law (MPa)

- \(\sigma_{\alpha }\), \(\tau_{\alpha }\) :

-

The normal and shear stress acting on cleavage boundaries (MPa)

- \(\sigma_{x}\), \(\sigma_{y}\), \(\tau_{xy}\), \(\sigma_{x1}\), \(\sigma_{y1}\), \(\tau_{xy1}\), \(\sigma_{x2}\), \(\sigma_{y2}\), \(\tau_{xy2}\) :

-

The stress components in the stress analysis of an overhanging beam with an asymmetrical crack (MPa)

- \(\sigma_{x(a)}\) :

-

The relative tension stress of the crack tip (MPa)

- \(\sigma_{r}\), \(\sigma_{{\bar{\theta }}}\), \(\tau_{{r\bar{\theta }}}\) :

-

The stress components in polar coordinates (MPa)

- \(\sigma\) :

-

The resultant stress of \(\sigma_{r}\) and \(\sigma_{x(a)}\) (MPa)

- \(\tau_{\text{eff}}\), \(M_{\text{eff}}\), \(M_{{G - {\text{eff}}}}\) :

-

The effective shear stress (MPa) and moments (MPa·m)

- P 1, P 2 :

-

Two opposite forces acting on the free end of an overhanging beam with an asymmetrical crack (N)

- F :

-

The force acting tangentially on the boundaries of the potential cleavage (N)

- \(K_{\text{I}}\) :

-

The stress intensity factor of the mode I crack (\(MPa \cdot \sqrt m\))

- \(\gamma\) :

-

The stress gradient of fluid-filled rocks (MPa/m)

- \(\lambda\) :

-

The ratio of the pore fluid pressure to the geostatic stress

- \(\mu\) :

-

The coefficient of friction

- \(\theta\) :

-

The gradient of the sliding system (°)

- \(\bar{\theta }\) :

-

The cleavage angle (°)

- \(\alpha\) :

-

The angle between \(\sigma_{1}\) and the potential deformation zone (°)

- \(\phi\) :

-

The angle between \(\sigma_{1}\) and the shear plane (°)

- \(\phi_{0}\) :

-

The shear angle under the pure shear state (°)

- \(\beta\) :

-

The angle between \(\sigma_{1}\) and the pre-existing cleavage (°)

- \(\eta\) :

-

The angle between \(\sigma_{1}\) and the normal to the cleavage (°)

- \(\delta\) :

-

The fault’s dip angle where the micro-unit is established (°)

- \(\psi\) :

-

The angle between the potential deformation zone and the pre-existing cleavage (°)

- \(z_{h}\) :

-

The critical depth as the mass of the sliding system reaches limit equilibrium (m)

- H :

-

The effective arm of the pre-existing cleavage (m)

- L :

-

The side of the unit square or H max in the \(\sigma_{1}\) direction (m)

- h, b :

-

The height and width of the overhanging beam (m)

- 2h 1, 2h 2 :

-

The distances from the crack to the lower and upper free surfaces, respectively (m)

- \(r\) :

-

The distance parameter in polar coordinates (m)

- \(k\) :

-

A correction factor

References

Anderson E (1905) The dynamics of faulting. Trans Edinb Geol Soc 8:387–402

Bott MHP (1959) The mechanics of oblique slip faulting. Geol Mag 96:109–117

Cai M, He M, Liu D (2002) Rock mechanics and engineering. Science Press, Beijing

Cai W, Dou LM, He J, Liu HS, Li ZL, Ding YL (2014) Mechanical genesis of Henan (China) Yima thrust nappe structure. J Cent South Univ 21:2857–2865. doi:10.1007/s11771-014-2251-6

Calamita F, Pace P, Satolli S (2012a) Coexistence of fault-propagation and fault-bend folding in curve-shaped foreland fold-and-thrust belts: examples from the Northern Apennines (Italy). Terra Nova 24:396–406. doi:10.1111/j.1365-3121.2012.01079.x

Calamita F, Satolli S, Turtù A (2012b) Analysis of thrust shear zones in curve-shaped belts: Deformation mode and timing of the Olevano-Antrodoco-Sibillini thrust (Central/Northern Apennines of Italy). J Struct Geol 44:179–187. doi:10.1016/j.jsg.2012.07.007

Cao D, Su S (1988) Evolution and occurrence characteristics of Yima coal basin. Coal Geol Explor 6:11–17

Cao D, Gao W, Wang C (1991) The thrust and nappe tectonics zone along the boundary of coal accumulation of north China. J China Univ Min Technol 20:28–35

Chatzaras V, Xypolias P, Kokkalas S, Koukouvelas I (2013) Tectonic evolution of a crustal-scale oblique ramp, Hellenides thrust belt, Greece. J Struct Geol 57:16–37. doi:10.1016/j.jsg.2013.10.003

Chen Q (1986) Mechanical research on gravitational structure: Mechanical analysis of listric faults. Seismol Geol 8:11–21

Chen WF (2007) Limit analysis and soil plasticity. J. Ross Publishing, Florida

Chen C, Cao Y (1989) The filling and deformation history of Cretaceous and Jurassic on Henan Yima basin. Henan Geol 7:37–43

Chen C, Cao Y (1991) The thrust nappe structure of Henan Yima coalfield. Henan Geol 9:31–36

Crans W, Mandl G, Haremboure J (1980) On the theory of growth faulting: A geomechanical delta model based on gravity sliding. J Petrol Geol 2:265–307

Cummings D (1976) Theory of plasticity applied to faulting, Mojave Desert, southern California. Geol Soc Am Bull 87:720–724

Di Domenica A, Turtu A, Satolli S, Calamita F (2012) Relationships between thrusts and normal faults in curved belts: New insight in the inversion tectonics of the Central-Northern Apennines (Italy). J Struct Geol 42:104–117. doi:10.1016/j.jsg.2012.06.008

Diwu C, Sun Y, Zhang H, Wang Q, Guo A, Fan L (2012) Episodic tectonothermal events of the western North China Craton and North Qinling Orogenic Belt in central China: Constraints from detrital zircon U-Pb ages. J Asian Earth Sci 47:107–122. doi:10.1016/j.jseaes.2011.07.012

Dong SW et al (2008) Jurassic tectonic revolution in China and new interpretation of the “Yanshan Movement”. Acta Geol Sin Engl Ed 82:334–347

Dong Y, Zhang G, Hauzenberger C, Neubauer F, Yang Z, Liu X (2011a) Palaeozoic tectonics and evolutionary history of the Qinling orogen: evidence from geochemistry and geochronology of ophiolite and related volcanic rocks. Lithos 122:39–56. doi:10.1016/j.lithos.2010.11.011

Dong Y, Zhang G, Neubauer F, Liu X, Genser J, Hauzenberger C (2011b) Tectonic evolution of the Qinling orogen, China: Review and synthesis. J Asian Earth Sci 41:213–237. doi:10.1016/j.jseaes.2011.03.002

Dou LM, He XQ (2001) Theory and technology of rockburst prevention. China University of Mining and Technology Press, Xuzhou

Gale WJ, Blackwood RL (1987) Stress distributions and rock failure around coal mine roadways. Int J Rock Mech Min Sci Geomech Abs 24:165–173. doi:10.1016/0148-9062(87)90524-9

Guo R, Pan C, Yu R (2003) Mining theory and technology for hard rock deposit with rockburst tendency. Metallurgical Industry Press, Beijing

Hafner W (1951) Stress distributions and faulting. Geol Soc Am 62:373–398

Hall J, Calon TJ, Aksu AE, Meade SR (2005) Structural evolution of the Latakia Ridge and Cyprus Basin at the front of the Cyprus Arc, Eastern Mediterranean Sea Marine. Geology 221:261–297. doi:10.1016/j.margeo.2005.03.007

Hansen JA (2013) Direct inversion of stress, strain or strain rate including vorticity: a linear method of homogenous fault–slip data inversion independent of adopted hypothesis. J Struct Geol 51:3–13. doi:10.1016/j.jsg.2013.03.014

He M, Qian Q (2010) The basis of deep rock mechanics. Science Press, Beijing

He H, Dou L, Fan J, Du T, Sun X (2012) Deep-hole directional fracturing of thick hard roof for rockburst prevention. Tunn Undergr Sp Tech 32:34–43. doi:10.1016/j.tust.2012.05.002

Hubbert MK, Rubey WW (1959) Role of fluid pressure in mechanics of overthrust faulting I. Mechanics of fluid-filled porous solids and its application to overthrust faulting. Geol Soc Am Bull 70:115–166. doi: 10.1130/0016-760670[115:ROFPIM]2.0.CO;2

Jadoon IAK, Khurshid A (1996) Gravity and tectonic model across the Sulaiman fold belt and the Chaman fault zone in western Pakistan and eastern Afghanistan. Tectonophysics 254:89–109. doi:10.1016/0040-1951(95)00078-X

Jaeger JC, Cook NG, Zimmerman R (2009) Fundamentals of rock mechanics. Wiley, New York

Kao H, Chen WP (2000) The Chi-Chi earthquake sequence: active, out-of-sequence thrust faulting in Taiwan. Science 288:2346–2349. doi:10.1126/science.288.5475.2346

Kassi AM, Kelling G, Kasi AK, Umar M, Khan AS (2009) Contrasting Late Cretaceous-Palaeocene lithostratigraphic successions across the Bibai Thrust, western Sulaiman Fold-Thrust Belt, Pakistan: their significance in deciphering the early-collisional history of the NW Indian Plate margin. J Asian Earth Sci 35:435–444. doi:10.1016/j.jseaes.2009.02.006

Konicek P, Soucek K, Stas L, Singh R (2013) Long-hole destress blasting for rockburst control during deep underground coal mining. Int J Rock Mech Min Sci 61:141–153. doi:10.1016/j.ijrmms.2013.02.001

Korneev VG (1980) On the approximate solution of problems of plastic-flow theory for media obeying Coulomb’s yield criterion. USSR Comput Maths Math Phys 20:165–181. doi:10.1016/0041-5553(80)90031-2

Kracke DW, Heinrich R (2004) Local seismic hazard assessment in areas of weak to moderate seismicity-case study from Eastern Germany. Tectonophysics 390:45–55. doi:10.1016/j.tecto.03.023

Leclère H, Fabbri O (2013) A new three-dimensional method of fault reactivation analysis. J Struct Geol 48:153–161. doi:10.1016/j.jsg.2012.11.004

Li HZ et al (2012a) Study on geochemistry and development mechanism of Proterozoic chert from Xiong’er Group in southern region of North China Craton. Acta Petrol Sin 28:3679–3691

Li Z, Liu S, Chen H, Deng B, Hou M, Wu W, Cao J (2012b) Spatial variation in Meso-Cenozoic exhumation history of the Longmen Shan thrust belt (eastern Tibetan Plateau) and the adjacent western Sichuan basin: Constraints from fission track thermochronology. J Asian Earth Sci 47:185–203. doi:10.1016/j.jseaes.2011.10.016

Lisle RJ (2013) A critical look at the Wallace-Bott hypothesis in fault-slip analysis. Bull Soc Geol Fr 184:299–306

Lisle RJ, Srivastava DC (2004) Test of the frictional reactivation theory for faults and validity of fault-slip analysis. Geology 32:569–572. doi:10.1130/G20408.1

Lisle RJ, Walker RJ (2013) The estimation of fault slip from map data: the separation-pitch diagram. Tectonophysics 583:158–163. doi:10.1016/j.tecto.2012.10.034

Lu R, He D, Suppe J, Ma Y, Liu B, Chen Y (2012) Along-strike variation of the frontal zone structural geometry of the Central Longmen Shan thrust belt revealed by seismic reflection profiles. Tectonophysics 580:178–191. doi:10.1016/j.tecto.2012.09.018

Ma RY, Peng JB, Men YM, Pan AF (2003) A study on mechanical mechanism on development of thrust fault. J Northwest Univ (Nat Sci Ed) 33:196–200

Mandl G, Shippam GK (1981) Mechanical model of thrust sheet gliding and imbrication, Special Publications, vol 9. Geological Society, London, pp 79–98. doi:10.1144/GSL.SP.1981.009.01.08

McFarland JM, Morris AP, Ferrill DA (2012) Stress inversion using slip tendency. Comput Geosci UK 41:40–46. doi:10.1016/j.cageo.2011.08.004

Mescua JF, Giambiagi LB (2012) Fault inversion vs. new thrust generation: A case study in the Malargüe fold-and-thrust belt, Andes of Argentina. J Struct Geol 35:51–63. doi:10.1016/j.jsg.2011.11.011

Moeck I, Kwiatek G, Zimmermann G (2009) Slip tendency analysis, fault reactivation potential and induced seismicity in a deep geothermal reservoir. J Struct Geol 31:1174–1182. doi:10.1016/j.jsg.2009.06.012

Morris AP, Ferrill DA (2009) The importance of the effective intermediate principal stress (σ’2) to fault slip patterns. J Struct Geol 31:950–959. doi:10.1016/j.jsg.2008.03.013

Mourgues R, Cobbold PR (2006) Sandbox experiments on gravitational spreading and gliding in the presence of fluid overpressures. J Struct Geol 28:887–901. doi:10.1016/j.jsg.2005.12.013

Mu Z, Dou L, He H, Fan J (2013) F-structure model of overlying strata for dynamic disaster prevention in coal mine. Int J Min Sci Technol 23:513–519. doi:10.1016/j.ijmst.2013.07.008

Neves M, Paiva LT, Luis J (2009) Software for slip-tendency analysis in 3D: a plug-in for Coulomb. Comput Geosci UK 35:2345–2352. doi:10.1016/j.cageo.2009.03.008

Nye JF (1951) The flow of glaciers and ice-sheets as a problem in plasticity. Proc R Soc Lond 207:554–572

Pan M, Li T (2002) Disaster geology. Peking University Press, Beijing

Paterson MS, Wong TF (2005) Experimental Rock Deformation-The Brittle Field. Springer, Heidelberg

Peng SS (2008) Coal mine ground control, 3rd edition edn. Society for Mining, Metallurgy, and Exploration, Inc. (SME), Englewood

Qi SW, Xu QA, Lan HX, Zhang B, Liu JY (2010) Spatial distribution analysis of landslides triggered by 2008.5.12 Wenchuan Earthquake, China. Eng Geol 116:95–108. doi:10.1016/j.enggeo.2010.07.011

Ramsay JG (1980) Shear zone geometry: A review. J Struct Geol 2:83–99. doi:10.1016/0191-8141(80)90038-3

Ratschbacher L et al (2003) Tectonics of the Qinling (Central China): tectonostratigraphy, geochronology, and deformation history. Tectonophysics 366:1–53. doi:10.1016/S0040-1951(03)00053-2

Shan B, Xiong X, Zheng Y, Jin BK, Liu CL, Xie ZJ, Hsu HT (2013) Stress changes on major faults caused by 2013 Lushan earthquake and its relationship with 2008 Wenchuan earthquake. Sci China Earth Sci 56:1169–1176. doi:10.1007/s11430-013-4642-1

Tang B, Zhang L (2013) Ya’an earthquake. Lancet 381:1984–1985. doi:10.1016/S0140-6736(13)61201-5

Tang DJ, Shi XY, Jiang GQ, Wang XQ (2012) Morphological association of microbially induced sedimentary structures (MISS) as a paleoenvironmental indicator: An example form the proterozoic succession of the southern north China platform. In: Noffke N, Chafetz H (eds) Microbial Mats in Siliciclastic Depositional Systems through Time, SEPM-Soc Sedimentary Geology, vol vol 101. Society for Sedimentary Geology Special Publication, Tulsa, pp 163–175

Tapponnier P, Molnar P (1976) Slip-line field theory and large-scale continental tectonics. Nature 264:319–324. doi:10.1038/264319a0

Tapponnier P, Molnar P (1977) Active faulting and tectonics in China. J Geophys Res 82:2905–2930. doi:10.1029/JB082i020p02905

Tong H (2012) Comment and some questions on “Puzzles and the maximum effective moment (MEM) criterion in structural Geology”. J Struct Geol 36:81–84. doi:10.1016/j.jsg.2011.12.003

Tranos MD (2012) Slip preference on pre-existing faults: a guide tool for the separation of heterogeneous fault-slip data in extensional stress regimes. Tectonophysics 544:60–74. doi:10.1016/j.tecto.2012.03.032

Turtù A, Satolli S, Maniscalco R, Calamita F, Speranza F (2013) Understanding progressive-arc-and strike-slip-related rotations in curve-shaped orogenic belts: the case of the Olevano-Antrodoco-Sibillini thrust (Northern Apennines, Italy). J Geophys Res: Solid Earth 118:459–473. doi:10.1002/jgrb.50096

Wallace RE (1951) Geometry of shearing stress and relation to faulting. J Geol 59:118–130

Wang X, Wang T, Zhang C (2013) Neoproterozoic, Paleozoic, and Mesozoic granitoid magmatism in the Qinling Orogen, China: Constraints on orogenic process. J Asian Earth Sci 72:129–151. doi:10.1016/j.jseaes.2012.11.037

Wobus C, Heimsath A, Whipple K, Hodges K (2005) Active out-of-sequence thrust faulting in the central Nepalese Himalaya. Nature 434:1008–1011. doi:10.1038/nature03499

Wu YB, Zheng YF (2013) Tectonic evolution of a composite collision orogen: an overview on the Qinling-Tongbai-Hong’an-Dabie-Sulu orogenic belt in central China. Gondwana Res 23:1402–1428. doi:10.1016/j.gr.2012.09.007

Xue F, Lerch MF, Kröner A, Reischmann T (1996) Tectonic evolution of the East Qinling Mountains, China, in the Palaeozoic: a review and new tectonic model. Tectonophysics 253:271–284. doi:10.1016/0040-1951(95)00060-7

Xu Q, Zhang S, Dong X (2013) Genetic Types of Large-Scale Landslides Induced by the Wenchuan Earthquake. In: Earthquake-Induced Landslides. Springer, pp 511–520. doi:10.1007/978-3-642-32238-9_54

Yin A, Oertel G (1993) Kinematics and strain distribution of a thrust-related fold system in the Lewis thrust plate, northwestern Montana (USA). J Struct Geol 15:707–719. doi:10.1016/0191-8141(93)90057-H

Zhao LH, Yang F (2013) Construction of improved rigid blocks failure mechanism for ultimate bearing capacity calculation based on slip-line field theory. J Cent South Univ 20:1047–1057. doi:10.1007/s11771-013-1583-y

Zheng Y, Wang T, Ma M, Davis GA (2004) Maximum effective moment criterion and the origin of low-angle normal faults. J Struct Geol 26:271–285. doi:10.1016/S0191-8141(03)00079-8

Zheng Y, Zhang J, Wang T (2011) Puzzles and the maximum-effective-moment (MEM) criterion in structural geology. J Struct Geol 33:1394–1405. doi:10.1016/j.jsg.2011.06.004

Zheng Y, Zhang J, Wang T (2012) Reply to comment and some questions on “Puzzles and the maximum-effective- moment (MEM) criterion in structural geology”. J Struct Geol 36:85–87. doi:10.1016/j.jsg.2011.12.004

Acknowledgments

The Institute of Rock Pressure (Henan Dayou Energy Limited Company) and the Yuejin, Qianqiu, and Yangcun coal mines provided the data for the local geology. In particular, we would like to extend special thanks to Prof. Richard J. Lisle, Dr. Alessandra Di Domenica, Dr. Sara Satolli, and another reviewer for their useful comments and constructive suggestions, which greatly improved the quality of this manuscript. We would never have completed this paper without the constant encouragement and patience of Prof. Joao Hippertt. We would also like to thank Dr. Guangyao Si from Imperial College for his discussions and language editing assistance. We gratefully acknowledge the financial support for this work provided by the National Basic Research Program of China (2010CB226805), the Research and Innovation Project for College Graduates of Jiangsu Province (CXLX13-949), the National Natural Science Foundation of China (51174285, 51404243), and Projects (SZBF2011-6-B35) supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Model of Material Mechanics-Linear Elastic Fracture Mechanics (MM-LEFM) (Ma et al. 2003)

Assuming an overhanging beam with an asymmetrical crack and two opposite forces (P 1 and P 2) at the free end (see Fig. 21), the section (B–C) can be approximated as an overhanging beam with equivalent force (P = P 2 − P 1) acting on the end region (B-B’), and thereby, the stresses can be described by material mechanics theory:

where b is the width of the beam and h is the height of the beam.

Let 2h 1 and 2h 2 be the distances from the crack to the lower and upper free surfaces, respectively. Accordingly, the upper and lower section of AB can be, respectively, approximated as the overhanging beam with end region (B-B’). Thus, the stresses can be expressed as follows:

By substituting \(y = H - 2h_{2}\) and \(h = H\) into Eq. (9), the shear stress (\(\tau_{xy}\)) of the crack tip can be expressed as follows:

The relative tension stress of the crack tip can be expressed as

The force (P 1) acting on the lower section is usually very small or approximately zero, and the thickness is usually very large. For this reason, the lower section can be equivalent to a large, thick basement that largely stretches downward. Therefore, \(\sigma_{y} = 0\), \(\tau_{xy} \approx 0\), and Eq. (13) is approximated as

According to the material mechanics theory, the maximum tension stress (or normal stress) exists around the outward surface on the fixed end of beam. If the stress (\(\sigma_{x(a)}\)) is considered only, a vertical crack developing upward will likely be generated in the crack end of the upper branch beam.

Additionally, the crack, under the stress state shown in Fig. 21, can be considered a mode I crack from the perspective of fracture mechanics. Therefore, the stress components are expressed as follows:

where \(K_{\text{I}}\) is the stress intensity factor of the mode I crack. \(r\) is the distance parameter in polar coordinates, in which the crack end is defined as the coordinate origin. \(\bar{\theta }\) is the cleavage angle (between the cleavage direction and the direction of the original crack).

Using the stress components as axes, the following coordinate system can be derived:

According to fracture mechanics theory, the cleavage direction of a mode I crack is in the direction of the original crack (\(\bar{\theta } = 0\)). In this context, the crack propagation is dominated by \(\sigma_{r}\) (see Eq. (17)) in the stress field of the crack end.

where \(k\) is a correction factor.

It should be noted that the stress values (\(\sigma_{r}\), \(\sigma_{{\bar{\theta }}}\), and \(\tau_{{r\bar{\theta }}}\)) are all zero near the crack end when \(\bar{\theta } = \pi\). However, the stress (\(\sigma_{x(a)}\)) is not zero (see Eq. 14). Therefore, crack propagation should be affected by the resultant stress (\(\sigma\)) of \(\sigma_{r}\) and \(\sigma_{x(a)}\), and the direction of crack propagation is the vertical direction of \(\sigma\), which can be expressed as follows:

By substituting Eqs. (14) and (17) into Eq. (18), and letting P 1 = 0, the cleavage angle (\(\bar{\theta }\)) can be expressed as

The parameter (b) can be regarded as the unit length, and r is not equal to zero. Irwin’s theory states that the radius of the plastic zone at the crack end can be considered as the value of r, and as such, it is usually constant for a given material. As a result, with the propagation of the crack, h 2 decreases, and in this context, the stratum on the crack face can be considered to be equivalent to a beam with the thickness gradually thinning. The foregoing discussion suggests that the cleavage angle (\(\bar{\theta }\)) becomes increasingly large, and ultimately, a listric trajectory with a steeply dipping shallow depth and a gently dipping deeper end can be formed.

It remains for these results to be applied to shear faults or inverse faults. Even if compressive stress is applied, shear fracture can still occur. In that case, the fracture and the propagation of the micro-crack occur simultaneously. The compressive stress in the end of the micro-crack is adjusted to the tensional stress, which makes the micro-crack develop similarly as a mode I crack. As shown in Fig. 22, a force (P 2) parallel to the fault plane is applied to the end of a shear fault. Consequently, bending deformation near the crack end will occur based on the buckling of struts theory. Ultimately, the stress state of Fig. 22 can be adjusted to the state shown in Fig. 21.

Appendix B: Maximum Effective Moment (MEM) Criterion

As shown in Fig. 23, a unit square from a potential cleavage zone, the foliation of which has not yet rotated, is cut to analyze the stress state. The normal stress \(\sigma_{\alpha }\) and the shear stress \(\tau_{\alpha }\) acting on cleavage boundaries are given, respectively, by

where \(\alpha\) is the angle between \(\sigma_{1}\) and the potential deformation zone.

To create a deformation band, there must be an effective moment \(M_{\text{eff}}\) that drives the foliation in the cleavage zone to rotate away from its initial orientation. The effective moment (\(M_{\text{eff}}\)) driving the foliation to rotate is given by the force (F) acting tangentially on the boundaries of the potential cleavage and its arm H: \(M_{\text{eff}} = FH\). Because F = stress × area, the stress is equivalent to the force if we substitute the stress for the force acting on the side of a unit area. The force is an effective shear stress \(\tau_{\text{eff}}\). Thus, (Zheng et al. 2004)

where L is the side of the unit square or H max in the \(\sigma_{1}\) direction (Fig. 23a). Substituting Eq. (21) into Eq. (22) thus yields

Recently, Tong (2012) developed the theoretical MEM criterion (Fig. 23b), and Eq. (23) was revised to

Appendix C: Stress Field and Distribution Derived by the Mechanical Model of a Gravitational Gliding Layer and the Parabolic Mohr Failure Criterion

Based on the mechanical model of a gravitational gliding layer (see Fig. 24) (Hubbert and Rubey 1959; Chen 1986), the analytical expression can be expressed by the effective stress as follows:

where \(\gamma\) is the stress gradient of fluid-filled rocks; \(\lambda\) is the ratio of the pore fluid pressure to the geostatic stress.

Herein, the parabolic Mohr failure criterion (Cai et al. 2002) is employed (see Fig. 25), which can be expressed as follows:

where \(\sigma_{t}\) is the uniaxial tensile strength; \(n = c^{2} /\sigma_{t}\) is the undetermined coefficient; and \(c\) is the cohesion.

An expression for the parabolic Mohr envelope using the stress components as axes can be derived:

By substituting Eq. (25) into Eq. (27), the ultimate stresses (\(\tilde{\sigma }_{z}\), \(\tilde{\tau }_{zx}\), and \(\tilde{\sigma }_{x}\)) can be obtained as follows:

Equation (28) shows that the sliding system can reach the state of ultimate stress only if \(n(\sigma_{t} + \tilde{\sigma }_{z} ) - \tilde{\tau }_{zx}^{2} \ge 0\). When \(n(\sigma_{t} + \tilde{\sigma }_{z} ) - \tilde{\tau }_{zx}^{2} = 0\), the mass of the sliding system reaches limit equilibrium at \(z = z_{h}\). Substituting \(n(\sigma_{t} + \tilde{\sigma }_{z} ) - \tilde{\tau }_{zx}^{2} = 0\) and \(z = z_{h}\) into Eq. (28) yields the following:

There are two solutions for \(\tilde{\sigma }_{x}\) (\(\tilde{\sigma }_{x}^{ + }\) and \(\tilde{\sigma }_{x}^{ - }\)) in Eq. (28); thus, there are two states of ultimate stress: \(\tilde{\sigma }_{x}^{ + } = (\tilde{\sigma }_{z} + n) + 2\sqrt {n(\sigma_{t} + \tilde{\sigma }_{z} ) - \tilde{\tau }_{zx}^{2} }\), \(\tilde{\sigma }_{x}^{ - } = (\tilde{\sigma }_{z} + n) - 2\sqrt {n(\sigma_{t} + \tilde{\sigma }_{z} ) - \tilde{\tau }_{zx}^{2} }\).

Rights and permissions

About this article

Cite this article

Cai, W., Dou, L., Li, Z. et al. Mechanical Initiation and Propagation Mechanism of a Thrust Fault: A Case Study of the Yima Section of the Xiashi-Yima Thrust (North Side of the Eastern Qinling Orogen, China). Rock Mech Rock Eng 48, 1927–1945 (2015). https://doi.org/10.1007/s00603-014-0666-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0666-x