Abstract

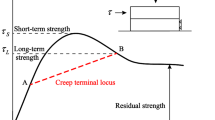

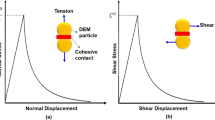

The dynamic shear behavior of rock joints is significant to both rock engineering and earthquake dynamics. With the discrete element method (DEM), the dynamic direct-shear tests on the rough rock joints with 3D (sinusoidal or random) surface morphologies are simulated and discussed. Evolution of the friction coefficient with the slip displacement shows that the 3D DEM joint model can accurately reproduce the initial strengthening, slip-weakening, and steady-sliding responses of real rock joints. Energy analyses show that the strengthening and weakening behavior of the rock joint are mainly attributed to the rapid accumulation and release of the elastic energy in the joint. Then, effects of the surface roughness and the normal stress on the friction coefficient and the micro shear deformation mechanisms, mainly volume change and asperity damage, of the rock joint are investigated. The results show that the peak friction coefficient increases logarithmically with the increasing surface roughness, but decreases exponentially with the increasing normal stress. In addition, the rougher rock joint exhibits both higher joint dilation and asperity degradation. However, high normal stress constrains the joint dilation, but promotes the degree of asperity degradation significantly. Lastly, the effects of the 3D surface morphology on the shear behavior of the rock joint are investigated with a directional roughness parameter. It is observed that the anisotropy of the surface roughness consequently results in the variation of the peak friction coefficient of the joint corresponding to different shearing directions as well as the micro shear deformation mechanisms, e.g., the extent of joint dilation.

Similar content being viewed by others

Abbreviations

- A :

-

Amplitude of the sinusoidal surface profile (m)

- A t/A n :

-

True/nominal area of the joint surface (m2)

- \(A_{{\theta^{*} }}\) :

-

Normalized asperity area (m2)

- A pψ :

-

Fitting parameter (rad)

- A c :

-

Fitting parameter (m)

- a p, b p, A p, A ss :

-

Dimensionless fitting parameters

- C :

-

Dimensionless shape parameter

- D c/D a :

-

The critical weakening/strengthening distance (m)

- d :

-

Slip displacement (m)

- E el :

-

Elastic energy (J)

- E d :

-

Dilation work (J)

- E br :

-

Breakage dissipation (J)

- E f :

-

Frictional dissipation (J)

- E k :

-

Kinetic energy (J)

- F f/F n :

-

Friction/normal force exerted in the upper rock block (N)

- F n/F s :

-

Normal/shear contact force (N)

- F w :

-

Wall force (N)

- H :

-

Total height of the joint (m)

- K n/K s :

-

Normal/shear contact stiffness (N/m)

- k n/k s :

-

Normal/shear particle stiffness (N/m)

- L :

-

Width of the lower rock block (m)

- N s :

-

Number of sliding contacts

- N t :

-

Total number of contacts

- R s :

-

3D non-directional surface roughness parameter

- U n/U s :

-

Normal/shear contact displacement (m)

- u n/u s :

-

Normal/shear joint displacement (m)

- z JS :

-

z-coordinate of the particles in the joint surface (m)

- \(\alpha\) :

-

Strengthening parameter

- \(\phi_{\text{r}}\) :

-

Residual friction angle (rad)

- λ :

-

Periodicity of the sinusoidal surface profile (m)

- μ :

-

Particle friction coefficient

- μ ini :

-

Initial joint friction coefficient

- μ i (i = 1, 2, 3, 4):

-

Energy decomposition terms of the joint friction coefficient

- μ ss :

-

Steady-state friction coefficient of the joint

- μ p :

-

Peak friction coefficient of the joint

- \(\theta^{*}\) :

-

Local dip angle of the surface asperities (rad)

- \(\theta_{\hbox{max} }^{*} /(C + 1)\) :

-

3D directional surface roughness parameter (rad)

- σ n :

-

Normal stress (MPa)

- \(\tau\) :

-

Peak shear strength of the joint (MPa)

References

Asadi MS, Rasouli V, Barla G (2012) A bonded particle model simulation of shear strength and asperity degradation for rough rock fractures. Rock Mech Rock Eng 45(5):649–675

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10(1–2):1–54

Beer G, Poulsen BA (1994) Efficient numerical modelling of faulted rock using the boundary element method. Int J Rock Mech Min Sci Geomech Abstr 31(5):485–506

Brace WF, Byerlee JD (1996) Stick–slip as a mechanism for earthquakes. Science 153(3739):990–992

Cheng YP, Nakata Y, Bolton MD (2003) Discrete element simulation of crushable soil. Geotechnique 53(7):633–641

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

De Moerlooze K, Al-Bender F, Van Brussel H (2010) A generalized asperity-based friction model. Tribol Lett 40(1):113–130

Di Toro G, Goldsby DL, Tullis TE (2004) Friction falls towards zero in quartz rock as slip velocity approaches seismic rates. Nature 427(6973):436–439

El-Soudani SM (1978) Profilometric analysis of fractures. Metallography 11(3):247–336

Greenwood JA, Williamson JBP (1966) Contact of nominally flat surfaces. Proc R Soc Lond 295(1442):300–319

Guo Y, Morgan JK (2004) Influence of normal stress and grain shape on granular friction: results of discrete element simulations. J Geophys Res 109(B12)

Guo Y, Morgan JK (2007) Fault gouge evolution and its dependence on normal stress and rock strength—results of discrete element simulations: gouge zone properties. J Geophys Res 112(B10)

Guo Y, Morgan JK (2008) Fault gouge evolution and its dependence on normal stress and rock strength—results of discrete element simulations: gouge zone properties. J Geophys Res 112(B10)

Han R, Hirose T, Shimamoto T (2010) Strong velocity weakening and powder lubrication of simulated carbonate faults at seismic slip rates. J Geophys Res 115(B3)

Hatano T (2009) Scaling of the critical slip distance in granular layers. Geophys Res Lett 36(18):L18304

Hazzard JF, Young RP, Maxwell SC (2000) Micromechanical modeling of cracking and failure in brittle rocks. J Geophys Res 105(B7):16683–16697

Huang TH, Chang CS, Chao CY (2002) Experimental and mathematical modeling for fracture of rock joint with regular asperities. Eng Fract Mech 69(17):1977–1996

Huang J, Xu S, Hu S (2013) Effects of grain size and gradation on the dynamic responses of quartz sands. Int J Impact Eng 59:1–10

Huang J, Xu S, Hu S (2014) Influence of particle breakage on the dynamic compression responses of brittle granular materials. Mech Mater 68:15–28

Kazerani T, Yang ZY, Zhao J (2012) A discrete element model for predicting shear strength and degradation of rock joint by using compressive and tensile test data. Rock Mech Rock Eng 45(5):695–709

Kulatilake PHSW (1985) Estimating elastic constants and strength of discontinuous rock. J Geotech Eng 111(7):847–864

Li JC, Ma GW (2009) Experimental study of stress wave propagation across a filled rock joint. Int J Rock Mech Min Sci 46(3):471–478

Mair K, Frye KM, Marone C (2002) Influence of grain characteristics on the friction of granular shear zones. J Geophys Res 107(B10)

Marone C (1998) The effect of loading rate on static friction and the rate of fault healing during the earthquake cycle. Nature 391(6662):69–72

Morgan JK (2004) Particle dynamics simulations of rate- and state-dependent frictional sliding of granular fault gouge. Pure Appl Geophys 161(9–10):1877–1891

Mutlu O, Bobet A (2005) Slip initiation on frictional fractures. Eng Fract Mech 72(5):729–747

Niemeijer AR, Spiers CJ (2006) Velocity dependence of strength and healing behaviour in simulated phyllosilicate-bearing fault gouge. Tectonophysics 427(1):231–253

Ohnaka M (2003) A constitutive scaling law and a unified comprehension for frictional slip failure, shear fracture of intact rock, and earthquake rupture. J Geophys Res 108(B2)

Park J-W, Song J-J (2009) Numerical simulation of a direct shear test on a rock joint using a bonded-particle model. Int J Rock Mech Min Sci 46(8):1315–1328

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41(8):1329–1364

Rasouli V, Harrison JP (2004) A comparison of linear profiling and an in-plane method for the analysis of rock surface geometry. Int J Rock Mech Min Sci 41(3):133–138

Reches ZE, Lockner DA (2010) Fault weakening and earthquake instability by powder lubrication. Nature 467(7314):452–455

Rozman MG, Urbakh M, Klafter J (1996) Origin of stick-slip motion in a driven two-wave potential. Phys Rev E 54(6):6485–6494

Schneider HJ (1976) The friction and deformation behaviour of rock joints. Rock Mech 8(3):169–184

Scholz CH (1998) Earthquakes and friction laws. Nature 391(6662):37–42

Sone H, Shimamoto T (2009) Frictional resistance of faults during accelerating and decelerating earthquake slip. Nat Geosci 2(10):705–708

Souley M, Homand F, Thoraval A (1997) The effect of joint constitutive laws on the modelling of an underground excavation and comparison with in situ measurements. Int J Rock Mech Min Sci 34(1):97–115

Tatone BS, Grasselli G (2009) A method to evaluate the three-dimensional roughness of fracture surfaces in brittle geomaterials. Rev Sci Instrum 80(12):125110

Tatone BS, Grasselli G (2013) An investigation of discontinuity roughness scale dependency using high-resolution surface measurements. Rock Mech Rock Eng 46(4):657–681

Wibberley CAJ, Shimamoto T (2005) Earthquake slip weakening and asperities explained by thermal pressurization. Nature 436(7051):689–692

Wilson B, Dewers T, Reches Z, Brune J (2005) Particle size and energetics of gouge from earthquake rupture zones. Nature 434(7034):749–752

Zhao J (1997a) Joint surface matching and shear strength part A: joint matching coefficient (JMC). Int J Rock Mech Min Sci 34(2):173–178

Zhao J (1997b) Joint surface matching and shear strength part B: JRC–JMC shear strength criterion. Int J Rock Mech Min Sci 34(2):179–185

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant Nos. 11272304 and 11102206) and the Research Fund for the Doctoral Program of Higher Education of China (Grant No. 20113402110008).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

According to Eq. (1), the elastic energy is calculated as:

where \(\sum\nolimits_{{N_{\text{c}} }} {}\) refers to summation over all contacts. Refer to Eq. (1) for the definition of the other parameters (the same as below).

The kinetic energy is calculated as:

where m, I, V, and ω are the mass, moment of inertial and translational velocity, and the rotational velocity of particles, respectively. \(\sum\nolimits_{{N_{\text{P}} }} {}\) refers to the summation over all particles.

The frictional dissipation is calculated as:

where \(V_{i}^{\text{s}}\) is the relative shear velocity of two contacting particles (i = 1, 2, 3), \(F_{j}^{\text{d}}\) is the damping force, and V j is the ball velocity. j = 1, 2, 3 represents the translational degrees of particles, while j = 4, 5, 6 represents the rotational degrees of particles. \(\Updelta t\) is the time step.

The breakage energy is calculated as the elastic energy lost in the bond-breakage process:

where \(F_{\hbox{max} }^{\text{n}}\) and \(F_{\hbox{max} }^{\text{s}}\) are the normal and the shear bond strengths, respectively.

Rights and permissions

About this article

Cite this article

Huang, J., Xu, S. & Hu, S. Numerical Investigations of the Dynamic Shear Behavior of Rough Rock Joints. Rock Mech Rock Eng 47, 1727–1743 (2014). https://doi.org/10.1007/s00603-013-0502-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-013-0502-8