Abstract

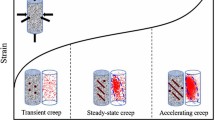

Triaxial creep tests were performed on diabase specimens from the dam foundation of the Dagangshan hydropower station, and the typical characteristics of creep curves were analyzed. Based on the test results under different stress levels, a new nonlinear visco-elasto-plastic creep model with creep threshold and long-term strength was proposed by connecting an instantaneous elastic Hooke body, a visco-elasto-plastic Schiffman body, and a nonlinear visco-plastic body in series mode. By introducing the nonlinear visco-plastic component, this creep model can describe the typical creep behavior, which includes the primary creep stage, the secondary creep stage, and the tertiary creep stage. Three-dimensional creep equations under constant stress conditions were deduced. The yield approach index (YAI) was used as the criterion for the piecewise creep function to resolve the difficulty in determining the creep threshold value and the long-term strength. The expression of the visco-plastic component was derived in detail and the three-dimensional central difference form was given. An example was used to verify the credibility of the model. The creep parameters were identified, and the calculated curves were in good agreement with the experimental curves, indicating that the model is capable of replicating the physical processes.

Similar content being viewed by others

Abbreviations

- A :

-

Parameter related to the material

- c :

-

The cohesive strength

- c ∞ :

-

The long-term cohesion

- E 0 :

-

Elastic parameter

- E 1 :

-

Visco-elastic parameter

- \(\langle F_{\infty } \rangle\) :

-

A switching function

- f ∞ :

-

The long-term yield function

- g ∞ :

-

The long-term plastic potential function

- G :

-

Shear modulus

- G 0 :

-

Three-dimensional elastic parameter

- G 1 :

-

Three-dimensional visco-elastic parameter

- I 1 :

-

The first invariant of the stress tensor

- J 2 :

-

The second invariant of the deviatoric stress tensor

- \(J_{2}^{'}\) :

-

The second invariant of the deviatoric visco-plastic strain tensor

- \(J_{2}^{\text{vp}}\) :

-

The onset of tertiary creep by the second invariant of the deviatoric visco-plastic strain tensor

- K :

-

Bulk modulus

- m :

-

Parameter related to the material

- n :

-

Parameter related to the material

- q :

-

The difference value of σ 1 and σ 3 (q = σ 1 − σ 3)

- S ij :

-

The deviatoric stress tensor

- (S ij )0 :

-

Constant value of the deviatoric stress tensor

- S ve :

-

Three-dimensional creep threshold

- S s :

-

Three-dimensional long-term strength

- \(S_{ij}^{N}\) :

-

New deviatoric stress for a time step

- \(S_{ij}^{O}\) :

-

Old deviatoric stress for a time step

- \(\hat{S}_{i}^{N}\) :

-

New trial stress of the deviatoric stress tensors

- t :

-

Creep time

- t s :

-

The time of the beginning of tertiary creep

- t un :

-

A constant time that is used to nondimensionalize the time

- \(\langle \rangle\) :

-

A switching function

- YAI:

-

Yield approach index

- YAIve :

-

YAI value corresponding to the creep threshold

- YAIs :

-

YAI value corresponding to the long-term strength

- σ :

-

Total stress

- \(\dot{\sigma }\) :

-

The derivative of σ

- \(\ddot{\sigma }\) :

-

The second derivative of σ

- σ 0 :

-

Instant stress

- σ 1, σ 2, σ 3 :

-

Principle stresses (\(\sigma_{1} \le \sigma_{2} \le \sigma_{3}\) compression negative)

- σ 1m, σ 2m, σ 3m :

-

Stresses for the first, second, and third parts of the proposed model

- σ ve :

-

The creep threshold

- σ s :

-

The long-term strength

- \(\sigma_{\infty }^{t}\) :

-

The long-term tensile strength

- σ un :

-

A constant stress that is used to nondimensionalize the stress

- σ ii :

-

The spherical stress tensors

- \(\hat{\sigma }_{0}^{N}\) :

-

New trial stress of the spherical stress tensors

- ε :

-

Total strain

- \(\dot{\varepsilon }\) :

-

The derivative of ε

- \(\ddot{\varepsilon }\) :

-

The second derivative of ε

- ε 1m, ε 2m, ε 3m :

-

Strains for the first, second, and third parts of the model

- ε ij :

-

The deviatoric strain tensors

- ε ii :

-

The spherical stain tensors

- \(\dot{\varepsilon }_{ij}\) :

-

Strain rate tensor

- \(\dot{\varepsilon }_{ij}^{\text{e}}\) :

-

Elastic strain rate tensor

- \(\dot{\varepsilon }_{ij}^{\text{p}}\) :

-

Plastic (time-independent) strain rate tensor

- \(\dot{\varepsilon }_{ij}^{\text{vp}}\) :

-

Visco-plastic (time-dependent) strain rate tensor

- \(\dot{\varepsilon }_{\text{vol}}^{3}\) :

-

The volume strain rate of the visco-plastic element

- ε acce :

-

Accelerated creep strain

- \(\varepsilon_{{t_{\text{s}} }}\) :

-

The cumulated irreversible shear strain at the beginning of tertiary creep

- e ij :

-

The deviatoric strain tensor

- \(\dot{e}_{{_{ij} }}^{3}\) :

-

The visco-plastic deviatoric strain rate tensor

- \(e_{ij}^{N}\) :

-

The new deviatoric strain tensor for a time step

- \(e_{ij}^{O}\) :

-

The old deviatoric strain tensor for a time step

- θ σ :

-

The Lode’s angle

- ϕ :

-

The angle of internal friction

- ϕ ∞ :

-

The angle of long-term internal friction

- ψ ∞ :

-

The material long-term dilation

- η 1 :

-

Visco-elastic parameter

- η 2 :

-

Visco-elastic parameter

References

Barla G, Debernardi D, Sterpi D (2012) Time-dependent modeling of tunnels in squeezing conditions. ASCE Int J Geomech 12(6):697–710

Bonini M, Debernardi D, Barla M, Barla G (2009) The mechanical behaviour of clay shales and implications on the design of tunnels. Rock Mech Rock Eng 42(2):361–388

Boukharov GN, Chanda MW, Boukharov NG (1995) The three processes of brittle crystalline rock creep. Int J Rock Mech Min Sci Geomech Abstr 32(4):325–335

Debernardi D, Barla G (2009) New viscoplastic model for design analysis of tunnels in squeezing conditions. Rock Mech Rock Eng 42(2):259–288

Fabre G, Pellet F (2006) Creep and time-dependent damage in argillaceous rocks. Int J Rock Mech Min Sci 43(6):950–960

Fujii Y, Kiyama T, Ishijima Y, Kodama J (1999) Circumferential strain behavior during creep tests of brittle rocks. Int J Rock Mech Min Sci 36(3):323–327

Gasc-Barbier M, Chanchole S, Bérest P (2004) Creep behavior of Bure clayey rock. Appl Clay Sci 26(1–4):449–458

Goodman RE (1989) Introduction to rock mechanics, 2nd edn. John Wiley and Sons, New York

Haupt M (1991) A constitutive law for rock salt based on creep and relaxation tests. Rock Mech Rock Eng 24(2):179–206

Itasca Consulting Group, Inc. (2005) FLAC3D (version 3.0) user manual. Itasca Consulting Group, Inc., Minneapolis, MN

Itô H, Sasajima S (1987) A ten year creep experiment on small rock specimens. Int J Rock Mech Min Sci Geomech Abstr 24(2):113–121

Jaeger JC, Cook NGW, Zimmerman RW (2007) Fundamentals of rock mechanics, 4th edn. Blackwell, Oxford

Korzeniowski W (1991) Rheological Model of Hard Rock Pillar. Rock Mech Rock Eng 24(3):155–166

Malan DF (1999) Time-dependent behaviour of deep level tabular excavations. Rock Mech Rock Eng 32(2):123–155

Malan DF (2002) Simulating the time-dependent behaviour of excavations in hard rock. Rock Mech Rock Eng 35(4):225–254

Maranini E, Brignoli M (1999) Creep behaviour of a weak rock: experimental characterization. Int J Rock Mech Min Sci 36(1):127–138

Miura K, Okui Y, Horii H (2003) Micromechanics-based prediction of creep failure of hard rock for long-term safety of high-level radioactive waste disposal system. Mech Mater 35(3–6):587–601

Nomikos P, Rahmannejad R, Sofianos A (2011) Supported axisymmetric tunnels within linear viscoelastic Burgers rocks. Rock Mech Rock Eng 44(5):553–564

Perzyna P (1966) Fundamental problems in viscoplasticity. Adv Appl Mech 9:243–377

Shao J-F, Zhu QZ, Su K (2003) Modeling of creep in rock materials in terms of material degradation. Comput Geotech 30(7):549–555

Shin K, Okubo S, Fukui K, Hashiba K (2005) Variation in strength and creep life of six Japanese rocks. Int J Rock Mech Min Sci 42(2):251–260

Song YH, Ooi PSK (2010) Interpretation of shakedown limit from multistage permanent deformation tests. In: Transportation Research Record: Journal of the Transportation Research Board, No. 2167, Transportation Research Board of the National Academies, Washington DC, pp 72–82

Song YH, Ooi PSK (2011) Examination of permanent deformation models for use on a recycled concrete aggregate, a virgin aggregate, and a blend of the two. In: Emerging Technologies for Material, Design, Rehabilitation, and Inspection of Roadway Pavements, Geotechnical Special Publication No. 218, GeoHunan International Conference 2011, Zhangjiajie, Hunan, China, June 2011, pp 166–173

Sterpi D, Gioda G (2009) Visco-plastic behaviour around advancing tunnels in squeezing rock. Rock Mech Rock Eng 42(2):319–339

Sun J (1999) Rheological behavior of geomaterials and its engineering applications. China Architecture and Building Press, Beijing

Sun J (2007) Rock rheological mechanics and its advance in engineering application. Chin J Rock Mech Eng 26(6):1081–1106

Tan T-K, Kang W-F (1980) Locked in stresses, creep and dilatancy of rocks, and constitutive equations. Rock Mech 13(1):5–22

Xu W-Y, Yang S-Q, Chu W-J (2006) Nonlinear viscoelasto-plastic rheological model (Hohai model) of rock and its engineering application. Chin J Rock Mech Eng 25(3):433–447

Yang WD (2011) Nonlinear damage rheological mechanical model for complex rock of high dam slope and its engineering application. Ph.D. thesis, Shandong University, China

Yang T-Q, Luo W-B, Xu P, Wei Y-T, Gang Q-G (2004) Viscoelastic theory and application. Science Press, Beijing

Zhang CQ, Zhou H, Feng XT (2011) An index for estimating the stability of brittle surrounding rock mass: FAI and its engineering application. Rock Mech Rock Eng 44:401–414

Zhang ZL, Xu WY, Wang W, Wang RB (2012) Triaxial creep tests of rock from the compressive zone of dam foundation in Xiangjiaba Hydropower Station. Int J Rock Mech Min Sci 50:133–139

Zhao YL, Cao P, Wen YD, Wang YX, Chai HB (2008) Elastovisco-plastic rheological experiment and nonlinear rheological model of rocks. Chin J Rock Mech Eng 27(3):477–486

Acknowledgments

The authors gratefully acknowledge the financial support of the National Science Foundation of China under grant nos. 51309238 and 51279093. The work in this paper is also supported by the Open Project of State Key Laboratory Breeding Base for Mining Disaster Prevention and Control (Shandong University of Science and Technology) with no. MDPC2012KF05.

Author information

Authors and Affiliations

Corresponding author

Appendix: Implementation of the Elasto-Visco-Plastic Model in FLAC3D

Appendix: Implementation of the Elasto-Visco-Plastic Model in FLAC3D

The three-dimensional finite difference model is developed and applied with FLAC3D. In order to program the creep model, the three-dimensional finite difference constitutive equation is derived (Itasca Consulting Group, Inc. 2005).

Equation 18 is written in the incremental form:

The second part of the model (Schiffman body) can be written in the central difference form as:

The first part of the model (Hook body) can also be written in the central difference form as:

where the overbar indicates the mean value over the time step Δt:

The superscripts N and O denote new and old values, respectively. \(S_{ij}^{N}\) and \(S_{ij}^{O}\) are the new and old deviatoric stress tensors for a time step, respectively. \(e_{ij}^{N}\) and \(e_{ij}^{O}\) are the new and old deviatoric strain tensors for a time step, respectively.

After substituting Eqs. (I.4) and (I.5) into Eq. (I.2) and solving for \(e_{ij}^{2,N} ,\) the Kelvin strain contribution may be expressed as:

where:

After substituting Eqs. (I.3) and (I.6) into Eq. (I.1) and solving for the new deviatoric stress component, we find [using the mean value definitions Eqs. (I.4) and (I.5)]:

where:

The volumetric deformation behavior is given by:

The failure criterion used in the FLAC3D model is a combination of the Mohr–Coulomb criterion with tension cutoff (Itasca 2005), which is also used in this study. However, the long-term parameters used in this study are different with FLAC3D. A function h(σ 1, σ 3) = 0, which is represented by the diagonal between the representation of \(f_{\infty }^{s} = 0\) and \(f_{\infty }^{t} = 0\) in the (σ 1, σ 3)-plane, is defined. The positive and negative domains are indicated by this function, which is shown in Fig. 15, and the function has the form:

where a P and σ P are constants defined as:

If the stress state falls within domain 1, shear failure occurs, and the stress state is placed on the curve \(f_{\infty }^{s} = 0\) using a flow rule derived using the potential function \(g_{\infty }^{s} ,\) as shown in Eq. 24.

If the point falls within domain 2, tensile failure takes place, and the new stress state conforms to \(f_{\infty }^{t} = 0\) using a flow rule derived using \(g_{\infty }^{t} ,\) as shown in Eq. 25. The flow rule specifies that the direction of the plastic strain increment vector is normal to the plastic potential surface. Equation 19 can be expressed as:

In the principal stress space, Eq. (I.13) is:

In the creep model implementation in FLAC3D, the new trial stress components \(\hat{S}_{i}^{N}\) and \(\hat{\sigma }_{0}^{N}\) are computed from Eqs. (I.8) and (I.10), assuming visco-elastic increments. The trial principal stress components are calculated and sorted, and the yield function is computed. As long as \(f \ge 0 ,\) the trial stresses are taken for new stresses. If \(f < 0 ,\) plastic flow takes place and the trial stresses must be corrected by a component due to the incremental plastic strain before their value is assigned to the new stresses and the evolution law is updated (Itasca Consulting Group, Inc. 2005). Expressing Eqs. (I.8) and (I.10) in principal axes, the definition of trial stresses can be written as follows:

The stress tensor can be decomposed as the deviatoric stress and the spherical stress tensor. Combining the two equations in Eq. (I.15) yields:

where:

Using the definition for deviatoric components, Eq. (I.16) can also be expressed as:

where:

for shear yielding:

Partial differentiation of Eq. 24 yields:

Substituting Eqs. (I.14) and (I.21) into Eq. (I.19), shear yielding takes the following form:

where:

and for tensile yielding:

Partial differentiation of Eq. 25 becomes:

Substituting Eqs. (I.14) and (I.24) into Eq. (I.19) gives:

where:

In summary, the stress–strain relationship of the complex nonlinear visco-elastic-plastic creep model can be expressed by using Eqs. (I.8) and (I.10). Visco-plastic correction is used by Eqs. (I.22) and (I.25), assuming that the principal directions have not been affected by the occurrence of plastic flow. The above equations are used to develop the model.

Rights and permissions

About this article

Cite this article

Yang, W., Zhang, Q., Li, S. et al. Time-Dependent Behavior of Diabase and a Nonlinear Creep Model. Rock Mech Rock Eng 47, 1211–1224 (2014). https://doi.org/10.1007/s00603-013-0478-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-013-0478-4