Abstract

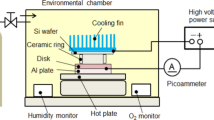

The formation of head smears during the heat-assisted magnetic recording is a significant problem that must be addressed to ensure the reliability of the head-disk interface. In this study, the formation of a head smear by diamond-like carbon (DLC) films on magnetic disks was analyzed through simulated heating experiments. DLC films with a thickness of 100 nm were prepared and heated on a hot plate in an environmental gas chamber. A smear was observed on a silicon wafer placed 3 mm above the DLC surface film after the heating of the film. The smear amount was quantified based on the intensity of the carbon peak of the smear, which was measured by X-ray photoelectron spectroscopy. In air, the carbon concentration decreased with the heating temperature, while in nitrogen, it increased. Further, the carbon concentration of the smear formed in air was lower than that in nitrogen. A comparison of the smears formed by DLC films with different hydrogen concentrations showed that a greater amount of the decomposition gases was generated from the DLC films with a higher hydrogen concentration and that this value increased at lower temperatures. This result suggests that DLC films with low hydrogen concentrations generate smaller amounts of the decomposition gases during heating than those with high hydrogen concentrations. In addition, the results of Raman spectroscopy suggested that the DLC films get degraded during heating, resulting in the generation of hydrocarbon gases because the films contain carbon and hydrogen. Moreover, since peaks related to fragments with atomic masses of 250–500 atomic mass units were observed in the time-of-flight secondary ion mass spectrometry spectra of the smears, it can be concluded that the smears consist of hydrocarbons with relatively higher molecular weights.

Similar content being viewed by others

References

Akasaka H, Kawaguchi S, Ohshio S, Saitoh H (2011) Estimation of thermal decomposition of amorphous carbon films. Trans Mat Res Soc Jpn 36:505–508

Akasaka H, Tunmee S, Rittihong U, Tomidokoro M, Euaruksakul C, Norizuki S, Supruangnet R, Nakajima H, Hirata Y, Ohtake N (2020) Thermal decomposition and structural variation by heating on hydrogenated amorphous carbon films. Diam Relat Mater 101:107609

Bourgoin D, Turgeon S, Ross GG (1999) Characterization of hydrogenated amorphous carbon films produced by plasma-enhanced chemical vapor deposition with various chemical hybridizations. Thin Solid Films 357:246–253

Challener WA, Peng C, Itagi AV, Karns D, Peng W, Peng Y, Yang XM, Zhu X, Gokemeijer NJ, Hsia YT, Ju G, Rottmayer RE, Seigler MA, Gage EC (2009) Heat-assisted magnetic recording by a near-field transducer with efficient optical energy transfer. Nat Photon 3:220–224

Kiely JD, Jones PM, Yang Y, Brand JL, Anaya-Dufresne M, Fletcher PC, Zavaliche F, Toivola Y, Duda JC, Johnson MT (2017) Write-induced head contamination in heat-assisted magnetic recording. IEEE Trans Magn 53:3300307

Ristein J, Stief RT, Ley L, Beyer W (1998) A comparative analysis of a-C:H by infrared spectroscopy and mass selected thermal effusion. J Appl Phys 84:3836–3847

Tagawa N, Tani H, Koganezawa S, Lu R (2020) Experimentalstudyonsmearcharacteristicsuponlaser heating in air and helium in heat heat-assisted magnetic recording. IEEE Trans Magn. https://doi.org/10.1109/TMAG.2020.3012979

Tani H, Uesaraie Y, Lu R, Koganezawa S, Tagawa N (2018a) Structural changes of perfluoropolyether lubricant accumulated on the pin surface during laser heating. IEEE Trans Magn 54:3300505

Tani H, Uesaraie Y, Lu R, Koganezawa S, Tagawa N (2018b) Smear growth on head slider surface from siloxane outgas on heat assisted magnetic recording. Microsyst Technol 26:4641–4648

Tani H, Shibahara Y, Lu R, Koganezawa S, Tagawa N (2019) TOF-SIMS analysis of perfluoropolyether lubricant smear transferred from disk surface following laser heating. Microsyst Technol 26:79–88

Tani H, Naito R, Lu R, Koganezawa S, Tagawa N (2020) Low friction of diamond-like carbon film due to liquid hydrocarbon generated by laser heating in a nitrogen gas environment. Tribol Lett. https://doi.org/10.1007/s11249-020-01333-6

Yakata K, Ichikawa S, Tani H, Lu R, Koganezawa S, Tagawa N (2020) Smear and decomposition mechanism of magnetic disk PFPE lubricant film by laser heating in air and helium conditions. Tribol Online 15:186–193

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tani, H., Lu, R., Koganezawa, S. et al. Investigation of mechanism of smear formation from diamond-like carbon films on heating. Microsyst Technol 27, 2243–2255 (2021). https://doi.org/10.1007/s00542-020-05041-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-05041-y