Abstract

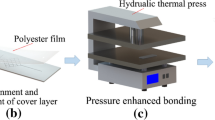

Micro channels from polyether ether ketone (PEEK), 1 mm in width and depth and 1.6 cm in length, have been fabricated by ultrasonic hot embossing and ultrasonic welding. Micro channels from PEEK enable constructing chemically inert microfluidic systems suitable for applications at temperatures of more than 200 °C. Besides this, a new design can be realized within one working day, investment costs are only a few 10,000 €, and the cycle time of fabricating a microfluidic system is a few seconds. Maximum temperature and pressure difference over a micro channel are not limited by the material properties of semicrystalline PEEK but by difficulties in producing them and by their change of morphology during manufacturing. To ultrasonically fabricate a microchannel two ultrasonic processes need to be combined. The channel itself is fabricated in a first ultrasonic hot embossing process and then sealed with a lid foil in a second ultrasonic welding step. This paper shows that, PEEK changes its morphology when it is ultrasonically hot embossed to produce a microfluidic channel. Moreover the degree of crystallinity varies according to the local position in the micro channel. It turned out that successful sealing of a micro channel by ultrasonic welding is facilitated by energy directors from semicrystalline PEEK. Therefore, semi-finished PEEK channels need being exposed to a temperature of at least 170 °C for 30 min before ultrasonic welding. This way, the amorphous PEEK is recrystallized resulting in hardened polymer micro structures. Such a heat treatment is also necessary after welding to achieve the desired stability at high temperatures. Tests show that the PEEK channels remain tight at a pressure difference of up to 700 kPa at a temperature of up to 220 °C.

Similar content being viewed by others

References

Altmann B, Ahrens R, Welle A, Dinglreiter H, Schneider M, Schober A (2012) Microstructuring of multiwell plates for three-dimensional cell culture applications by ultrasonic embossing. Biomed Microdevices 14(2):291–301. doi:10.1007/s10544-011-9605-8

Burlage K, Gerhardy C, Praefke H, Liauw MA, Schomburg WK (2013) Slug length monitoring in liquid–liquid Taylor-flow integrated in a novel PVDF micro channel. Chem Eng J 227:111–115. doi:10.1016/j.cej.2012.08.070

Diaz A, Casas MT, Puiggalí J (2015) Dispersion of functionalized silica micro- and nanoparticles into Poly (nonamethylene Azelate) by ultrasonic micro-molding. Appl Sci 5(4):1252–1271. doi:10.3390/app5041252

Hellerich W, Harsch G, Haenle S (2004) Werkstoff-Führer Kunststoffe, Eigenschaften Prüfungen, Kennwerte, 9th edn. Carl Hanser Verlag, München. ISBN 978-3-4462-2559-6

Khuntontong P, Blaser T, Schomburg WK (2008) Ultrasonic micro hot embossing of thermoplastic polymers. In: Proceeding of the 24th annual meeting of the Polymer Processing Society, PPS24, Salerno, Italy, 15–19 June, pp II.364

Kockmann N, Tollkötter A, Baldhoff T, Ovat N, Sackmann J, Schomburg WK (2014) Mikrofluidisches System aus Ultraschall-heißgeprägten PVDF-Modulen zur Untersuchung von Mehrphasenreaktionen. Chemie Ingenier Technik. WILEY-VCH Verlag, Weinheim, 86(9):1526. doi:10.1002/cite.201450118

Korte H (1996) Einfluß der Spritzgießbedingungen und Möglichkeiten der prozessnahen Qualitätssicherung mittels statistischer Methoden beim Ultraschallschweißen. Dissertation, RWTH Aachen University

Lee CH, Jung PG, Lee SM, Park SH, Shin BS, Kim J-H, Hwang K-Y, Kim KM, Ko JS (2010) Replictaion of polyethylene nano-micro hierachical structures using ultrasonic forming. J Micromech Microeng 20(3):035018. doi:10.1088/0960-1317/20/3/035018

Liao S, Gerhardy C, Sackmann J, Schomburg WK (2015a) Tools for ultrasonic hot embossing. Microsyst Technol 21(7):1533–1541. doi:10.1007/s00542-014-2232-6

Liao S, Sackmann J, Tollkötter A, Pasterny M, Kockmann N, Schomburg WK (2015b) Ultrasonic fabrication of micro nozzles from a stack of PVDF foils for generating and characterizing microfluidic dispersions. Microsyst Technol. doi:10.1007/s00542-015-2708-z

Liu S-J, Dung Y-T (2005) Hot embossing precise structure onto plastic plates by ultrasonic vibration. Polym Eng Sci 45(7):915–925. doi:10.1002/pen.20357

Maurer P, Gerhardy C, Gräber S, Jahnen-Dechent W, Schomburg WK (2015) Kalzifizierungsanalyse in einem Mikrofluidikchip. Proc. Mikrosystemtechnik-Kongress in Karlsruhe 26. bis 28. Oktober 226–229, VDE-Verlag GmbH, Berlin, Offenbach. ISBN 978-3-8007-4100-7

Mekaru H, Nakamura O, Maruyama O, Maeda R, Hattori T (2007a) Development of precision transfer technology of atmospheric hot embossing by ultrasonic vibration. Microsyst Technol 13(3):385–391. doi:10.1007/s00542-006-0203-2

Mekaru H, Goto H, Takahashi M (2007b) Development of ultrasonic micro hot embossing technology. Microelectron Eng 84(5-8):1282–1287. doi:10.1016/j.mee.2007.01.235

Menges G, Haberstroh E, Michaeli W, Schmachtenberg E (2011) Werkstoffkunde Kunststoffe, 6th edn. Carl Hanser Verlag, München. doi:10.3139/9783446443532

Osswald TA, Menges G (2012) Materials science of polymers for engineers, 3rd edn. Carl Hanser Verlag, München. doi:10.3139/9781569905241

Planellas M, Sacristán M, Rey L, Olmo C, Aymamí J, Casas MT, del Valle LJ, Franco L, Puiggalí J (2014) Micro-molding with ultrasonic vibration energy: new method to disperse nanoclays in polymer matrices. Ultrason Sonochem 21(4):1557–1569. doi:10.1016/j.ultsonch.2013.12.027

Potente H (2004) Fügen von Kunststoffen – Grundlagen, Verfahren, Anwendung. Carl Hanser Verlag, München. ISBN 3-446-22755-6

Runge T, Sackmann J, Schomburg WK, Blank LM (2016) Ultrasonically manufactured microfluidic device for yeast analysis. Microsyst Technol. doi:10.1007/s00542-016-3007-z

Sackmann J, Burlage K, Gerhardy C, Memering B, Liao S, Schomburg WK (2015) Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 56:189–200. doi:10.1016/j.ultras.2014.08.007 (ISSN: 0041-624X)

Sacristán M, Plantá X, Morell M, Puiggalí J (2014) Effects of ultrasonic vibration on the micro-molding processing of polylactide. Ultrason Sonochem 21(1):376–386. doi:10.1016/j.ultsonch.2013.07.007

Šakalys R, Janušas G, Palevičius A, Bendikienė R, Palevičius R (2015) Microstructure replication using high frequency vibroactive pad. Mechanika 21(2):134–140. doi:10.5755/j01.mech.21.2.8886 ISSN: 1392–1207

Tollkötter A, Sackmann J, Baldhoff T, Schomburg WK, Kockmann N (2015) Ultrasonic hot embossed polymer micro reactors for optical measurement of chemical reactions. Chem Eng Technol 38(7):1113–1121. doi:10.1002/ceat.201400522

Yu HW, Lee CH, Jung PG, Shin BS, Kim J-H, Hwang K-Y, Ko JS (2009) Polymer microreplication using ultrasonic vibration energy. J Micro/Nanolith MEMS MOEMS 8(2):021113. doi:10.1117/1.3129824

Acknowledgements

The results presented here were partly achieved with the support of Deutsche Forschungsgemeinschaft with the support code SCHO 850/14-1. The DSCs were carried out by the Institute of Textile Technology at RWTH Aachen University and Chair for Textile Machinery.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kosloh, J., Sackmann, J. & Schomburg, W.K. Ultrasonic fabrication of micro fluidic channels from polyether ether ketone (PEEK). Microsyst Technol 23, 5505–5513 (2017). https://doi.org/10.1007/s00542-017-3284-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-017-3284-1