Abstract

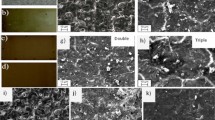

The objective of this study is to analyze the influence of substrate wettability and reflow conditions on the shape, lateral dimensions and optical properties of plano-convex lenses with nominal diameter of 16–28 µm fabricated by photolithographically patterning 7.5 µm thick layer of positive ma-P 1275 resist and subsequent thermal reflow. Five types of fused silica substrates modified by different plasma treatments and ion beam deposition of diamond like carbon (DLC) films were selected for the fabrication of microlens arrays in such a way that complete set of them could cover a wide range of wettability. At the same conditions of thermal reflow, defectivity of fabricated microlens arrays and resulting shape of the microlenses depended on the substrate treatment. Differences were especially marked for the lenses with smaller diameter. The best results were obtained for microlens arrays on DLC and SiOx doped DLC coated substrates. Minimal temperature required for complete reflow of the lenses with nominal diameter of 16–28 µm on SiOx doped DLC coated fused silica substrates depended on the lateral dimensions of the lenses and varied from 130 to 140 °C. Radius of curvature for the fabricated lenses could be somewhat tailored by the further increase of reflow temperature.

Similar content being viewed by others

References

Audran S, Faure B, Mortini B, Regolini J, Schlatter G, Hadziioannou G (2006) Study of mechanisms involved in photoresist microlens formation. Microelectron Eng 83:1087–1090

Butter RS, Waterman DR, Lettington AH, Ramos RT, Fordham EJ (1997) Production and wetting properties of fluorinated diamond-like carbon coatings. Thin Solid Films 311:107–113

Chen WC, Wu TJ, Wu WJ, Su GDJ (2013) Fabrication of inkjet-printed SU-8 photoresist microlenses using hydrophilic confinement. J Micromech Microeng 23:065008

del Campo A, Greiner C (2007) SU-8: a photoresist for high-aspect-ratio and 3D submicron lithography. J Micromech Microeng 17:R81–R95

Di S, Du R (2009) The controlling of microlens contour by adjusting developing time in thermal reflow method. Proc SPIE 7381:73811D

Galeotti F, Mroz W, Scavia G, Botta C (2013) Microlens arrays for light extraction enhancement in organic light-emitting diodes: a facile approach. Org Electron 14:212–218

Han MG, Park YJ, Kim SH, Yoo BS, Park HH (2004) Thermal and chemical stability of reflowed-photoresist microlenses. J Micromech Microeng 14:398–402

Hedsten K, Karlen D, Bengtsson J, Enoksson P (2006) Refractive lenses in silicon micromachining by reflow of amorphous fluorocarbon polymer. J Micromech Microeng 16:S88–S95

Ito H (2008) Rise of chemical amplification resists from laboratory curiosity to paradigm enabling Moore’s law. Proc SPIE 6923:692302

Jeon CW, Gu E, Liu C, Girkin JM, Dawson MD (2005) Polymer microlens arrays applicable to AlInGaN ultraviolet micro-light-emitting diodes. IEEE Photonic Tech L 17:1887–1889

Jin H, Xin Q, Li N, Jin J, Wang B, Yao Y (2013) The morphology and chemistry evolution of fused silica surface after Ar/CF4 atmospheric pressure plasma processing. Appl Surf Sci 286:405–411

Jucius D, Grigaliūnas V, Guobienė A (2004) Rapid evaluation of imprint quality using optical scatterometry. Microelectron Eng 71:190–196

Klopp JM, Pasini D, Byers JD, Willson CG, Frechet JMJ (2001) Microlithographic assessment of a novel family of transparent and etch-resistant chemically amplified 193-nm resists based on cyclopolymers. Chem Mater 13:4147–4153

Langridge MT, Cox DC, Webb RP, Stolojan V (2014) The fabrication of aspherical microlenses using focused ion-beam techniques. Micron 57:56–66

Lazauskas A, Grigaliūnas V, Meškinis Š, Ecarla F, Baltrusaitis J (2013) Surface morphology, cohesive and adhesive properties of amorphous hydrogenated carbon nanocomposite films. Appl Surf Sci 276:543–549

Lee SK, Kim MG, Jo KW, Shin SM, Lee JH (2008) A glass reflowed microlens array on a Si substrate with rectangular through-holes. J Opt A Pure Appl Opt 10:044003

Myers JD, Cao W, Cassidy V, Eom SH, Zhou R, Yang L, You W, Xue J (2012) A universal optical approach to enhancing efficiency of organic-based photovoltaic devices. Energy Environ Sci 5:6900–6904

Nieto D, Arines J, Gomez-Reino C, O’Connor GM, Flores-Arias MT (2011) Fabrication and characterization of microlens arrays on soda-lime glass using a combination of laser direct-write and thermal reflow techniques. J Appl Phys 110:023108

Nussbaum P, Volkel R, Herzig HP, Eisner M, Haselbeck S (1997) Design, fabrication and testing of microlens arrays for sensors and microsystems. Pure Appl Opt 6:617–636

O’Neill FT, Sheridan JT (2002) Photoresist reflow method of microlens production part I: background and experiments. Optik 113:391–404

Oh SS, Choi CG, Kim YS (2010) Fabrication of micro-lens arrays with moth-eye antireflective nanostructures using thermal imprinting process. Microelectron Eng 87:2328–2331

Ottevaere H, Cox R, Herzig HP, Miyashita T, Naessens K, Taghizadeh M, Volkel R, Woo HJ, Thienpont H (2006) Comparing glass and plastic refractive microlenses fabricated with different technologies. J Opt A Pure Appl Opt 8:407–429

Pan CT, Su CY (2008) Study of micro-lens array by reflow process. J Mod Opt 55:2843–2856

Pasini D, Klopp JM, Frechet JMJ (2001) Design, synthesis, and characterization of carbon-rich cyclopolymers for 193 nm microlithography. Chem Mater 13:4136–4146

Popovic ZD, Sprague RA, Connel GAN (1988) Technique for monolithic fabrication of microlens arrays. Appl Opt 27:1281–1284

Qin S, Shang J, Ma M, Zhang L, Lai C, Huang QA, Wong CP (2013) Fabrication of micro-polymer lenses with spacers using low-cost wafer-level glass-silicon molds. IEEE T Comp Pack Man 3:2006–2013

Roy E, Voisin B, Gravel JF, Peytavi R, Boudreau D, Veres T (2009) Microlens array fabrication by enhanced thermal reflow process: towards efficient collection of fluorescence light from microarrays. Microelectron Eng 86:2255–2261

Schilling A, Merz R, Ossmann C, Herzig HP (2000) Surface profiles of reflow microlenses under the influence of surface tension and gravity. Opt Eng 39:2171–2176

Sinzinger S, Jahns J (2003) Microoptics, 2nd edn. Wiley-VCH, Weinheim

Tamulevičienė A, Meškinis Š, Kopustinskas V, Tamulevičius S (2011) Multilayer amorphous hydrogenated carbon (a-C:H) and SiOx doped a-C:H films for optical applications. Thin Solid Films 519:4004–4007

Wen TT, Hocheng H (2009) Innovative rapid replication of microlens arrays using electromagnetic force-assisted UV imprinting. J Micromech Microeng 19:025012

Zappe H (2012) Micro-optics: a micro-tutorial. Adv Opt Technol 1:117–126

Acknowledgments

This research was funded by a Grant (No. MIP-67/2015) from the Research Council of Lithuania.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jucius, D., Grigaliūnas, V., Lazauskas, A. et al. Effect of fused silica surface wettability on thermal reflow of polymer microlens arrays. Microsyst Technol 23, 2193–2206 (2017). https://doi.org/10.1007/s00542-016-2975-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-2975-3