Abstract

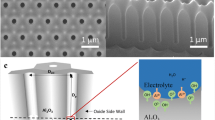

Anodic aluminum oxide (AAO) containing high-aspect ratio pore channels has been widely used as a template for fabricating nanowires or other 1D nanostructures. For AAO prepared in oxalic acid, the anodizing potential is set as 40 V in order to balance the oxidation and dissolution rates. In practice, a higher potential is beneficial in increasing the pore size. However, a higher potential increases the local electrolyte temperature and therefore damages the pore structure. In this article, this problem is resolved by means of a high-potential hybrid pulse anodization (HPA) technique, in which a period of small negative potential is applied to suppress the Joule heating effect during the AAO preparation process. The scanning electron microscope results showed that HPA with an anodizing potential of 60 V resulted in an intact pore structure on the AAO surface. By contrast, the AAO formed using conventional direct current anodization with the same anodizing potential contained many small irregular pores around each original pore. The present results suggest that HPA has significant potential for the fabrication of high-quality nanowires with various diameters for such applications as magnetic recording, super capacitors or field emission devices.

Similar content being viewed by others

References

Bai A, Hu C, Yang Y, Lin C (2008) Pore diameter control of anodic aluminum oxide with ordered array of nanopores. Electrochim Acta 53:2258–2264

Chung CK, Zhou RX, Liu TY, Chang WT (2009) Hybrid pulse anodization for the fabrication of porous anodic alumina films from commercial purity (99%) aluminum at room temperature. Nanotechnology 20:055301

Chung CK, Chang WT, Liao MW, Chang HC (2011) Effect of pulse voltage and aluminum purity on the characteristics of anodic aluminum oxide using hybrid pulse anodization at room temperature. Thin Solid Films 519:4754–4758

Chung CK, Chang WT, Liao MW, Chang HC (2012) Improvement of pore distribution uniformity of nanoporous anodic aluminum oxide with pulse reverse voltage on low-and-high-purity aluminum foils. Mater Lett 88:104–107

Diggle JW, Downie TC, Goulding CW (1969) Anodic oxide films on aluminum. Chem Rev 69:365–369

Goldberger J, He RR, Zhang YF, Lee SW, Yan HQ, Choi HJ, Yang PD (2003) Single-crystal gallium nitride nanotubes. Nature 422:599–602

Huczko A (2000) Template-based synthesis of nanomaterials. Appl Phys Mater Sci Process 70:365–376

Lee W, Ji R, Goesele U, Nielsch K (2006) Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat Mater 5:741–747

Li AP, Muller F, Birner A, Nielsch K, Gosele U (1998) Hexagonal pore arrays with a 50–420 nm interpore distance formed by self-organization in anodic alumina. J Appl Phys 84:6023–6026

Li D, Zhao L, Jiang C, Lu JG (2010) Formation of anodic aluminum oxide with serrated nanochannels. Nano Lett 10:2766–2771

Li Y, Ling ZY, Hu X, Liu YS, Chang Y (2011) Formation and microstructures of unique nanoporous AAO films fabricated by high voltage anodization. J Mater Chem 21:9661–9666

Masuda H, Fukuda K (1995) Ordered metal nanohole arrays made by a two-step replication of honeycomb structures of anodic alumina. Science 268:1466–1468

Ono S, Saito M, Asoh H (2004a) Self-ordering of anodic porous alumina induced by local current concentration: burning. Electrochem Solid State Lett 7:B21–B24

Ono S, Saito M, Ishiguro M, Asoh H (2004b) Controlling factor of self-ordering of anodic porous alumina. J Electrochem Soc 151:B473–B478

O’Sullivan JP, Wood GC (1970) The morphology and mechanism of formation of porous anodic films on aluminum. Proc R Soc Lond A 317:511–543

Piao Y, Lim H, Chang JY, Lee WY, Kim H (2005) Nanostructured materials prepared by use of ordered porous alumina membranes. Electrochim Acta 50:2997–3013

Rahman S, Yang H (2003) Nanopillar arrays of glassy carbon by anodic aluminum oxide nanoporous templates. Nano Lett 3:439–442

Shimizu T, Xie T, Nishikawa J, Shingubara S, Senz S, Goesele U (2007) Synthesis of vertical high-density epitaxial Si(100) nanowire arrays on a Si(100) substrate using an anodic aluminum oxide template. Adv Mater 19:917–920

Sulka GD, Stępniowski WJ (2009) Structural features of self-organized nanopore arrays formed by anodization of aluminum in oxalic acid at relatively high temperatures. Electrochim Acta 54:3683–3691

Wang XY, Wang XY, Huang WG, Sebastian PJ, Gamboa S (2005) Sol–gel template synthesis of highly ordered MnO2 nanowire arrays. J Power Sour 140:211–215

Yang SG, Zhu H, Yu DL, Jin ZQ, Tang SL, Du YW (2000) Preparation and magnetic property of Fe nanowire array. J Magn Magn Mater 222:97–100

Zaraska L, Sulka GD, Jaskuła M (2011) Porous anodic alumina formed by anodization of aluminum alloy (AA1050) and high purity aluminum. J Solid State Electrochem 15:2427–2436

Acknowledgments

This work is partially sponsored by National Science Council under contract No. NSC99-2221-E-006-032-MY3 and NSC101-2628-E-006-012-MY3. We also would like to thank the Centre for Micro/Nano Science and Technology in National Cheng Kung University for analysis instrument support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, C.K., Liao, M.W. & Khor, O.K. Fabrication of porous anodic aluminum oxide by hybrid pulse anodization at relatively high potential. Microsyst Technol 20, 1827–1832 (2014). https://doi.org/10.1007/s00542-013-1948-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-1948-z