Abstract

This paper presents the development of a low temperature transient liquid phase bonding process for 8″ wafer-level packaging of micro-electro-mechanical systems. Cu/Sn and Au/Sn material systems have been investigated under varying bonding temperatures from 240 to 280 °C and different dwell times from 8 to 30 min. The used bond frame had a width of 80 μm and lateral dimensions of 1.5 mm × 1.55 mm. The sealing frame of the cap wafer consisted of Au and Cu, respectively, and Sn. The MEMS wafer only holds the parent metal of Au or Cu. High quality bonds were confirmed by shear tests, cleavage analysis, polished cross-section analysis using optical and electron microscope, energy dispersive X-ray spectroscopy and pressure cocker test. The samples showed high shear strength (>80 MPa), nearly perfect bond regions and no main failure mode in the cleavage analyses. Non-corroded Cu test structures confirmed the hermeticity.

Similar content being viewed by others

References

Agarwal R, Zhang W, Limaye P, Ruythooren W (2009) High Density Cu-Sn TLP Bonding for 3D Integration. Proc. IEEE 59th Electronic Components and Technology Conference pp 345–349

Baum M, Hofmann L, Wiemer M, Geßner T (2009) Solid-Liquid-Interdiffusion Bonding für 3D-Integration und Wafer-Level-Packaging. Proc. 3rd Mikrosystemtechnik Kongress

Bosco NS, Zok FW (2004) Critical interlayer thickness for transient liquid phase bonding in the Cu-Sn system. Acta Mat 52:2965–2972

Cain SR, Wilcox JR, Venkatraman R (1997) A diffusional model for transient liquid phase bonding. Acta Mater 45:701–707

Cao Y, Ning W, Luo L (2009) Wafer-level package with simultaneous tsv connection and cavity hermetic sealing by solder bonding for MEMS device. IEEE Trans Electron Packag Manuf 32:125–132

He P, Zhang J, Zhou R, Li X (1999) Diffusion bonding technology of titanium alloy to a stainless steel web with an Ni interlayer. Mater Charact 43:287–292

Hoivik N, Wang K, Aasmundtveit K, Salomonsen G, Lapadatu A, Kittilsland G et al (2010) Fluxless wafer-level Cu–Sn bonding for micro- and nanosystems packaging. Proc. 3rd Electronic System-Integration Technology Conference (ESTC)

Joint Committee on Powder Diffraction Standards (JCPDS), Ed. Swarthmore

Kim D, Kim J, Wang LG, Lee CC (2005) Nucleation and growth of intermetallics and gold clusters on thick tin layers in electroplating process. Mater Sci Eng A 393:315–319

Kim W, Wang Q, Hwang J, Lee M, Jung K, Ham S et al (2005) A low temperature, hermetic wafer level packaging method for RF MEMS switch. Proc. 55th electronic Components and Technology Conference Vol. 2: 1103–1108

Kumar S, Handwerker CA, Dayananda MA (2011) Intrinsic and Interdiffusion in Cu-Sn System. J Phase Equilib Diff 32:309–319

Lee C, Yu A, Yan L, Wang H, He J, Zhang QX et al (2009) Characterization of intermediate In/Ag layers of low TEmperature fluxless solder based Wafer bonding for MEMS packaging. Sensor Actuator A 154:85–91

Lindroos V, Tilli M, Lehto A, Motooka T (2010) Handbook of Silicon Based MEMS Materials and Technologies, 1st edn Elsevier (William Burlington), Butterworth

MacDonald WD, Eagar TW (1992) Transient liquid phase bonding. Annu Rev Mater Sci 23:23–46

Matijasevic G, Lee CC, Wang CY (1989) Void-free Au-Sn eutectic bonding of GaAs dice and its characterization using scanning acoustic microscopy. J Electron Mater 18:327–337

Okamoto H (2007) Au-Sn (Gold-Tin). J Phase Equilib Diff 28:490

Onuki J, Chonan Y, Komiyama T, Nihei M (2002) Imfluence of sodlering conditions on void formation in large-area solder joints. Mater Trans 43:1774–1777

Pham N, Limaye P, Czarnecki P, Olalla V, Cherman V, Tezcan D, Tilmans H (2010) Metal-bonded, hermetic 0-level package for MEMS. Proc. 12th electronics packaging Technology Conference pp 1–6

Schmid-Fetzer R (1996) Fundamentals of bonding by isothermal solidification for high temperature semiconductor applications. In: Lin RY, Chang YA, Reddy RG, Liu CT (eds) Design fundamentals of high temperature composites, intermetallics, and metal-ceramics systems, the minerals. The Minerals, Metals and Materials Society, Warrendale, pp 75–98

Shewmon PG (1989) Diffusion in solids. Metals and Materials Society Minerals, Warrendale

Theunis F, Lisec T, Reinert W, Bielen J, Yang D, de Jongh M (2007) A Novel And Efficient Packaging Technology For RF-MEMS Devices. Proc. 57th Electronic Components and Technology Conference pp 1239–1245

Tomlinson WJ, Rhodes HG (1987) Kinetics of intermetallic compound growth between nickel, electroless Ni-P, electroless Ni-B and tin at 453 to 493 K. J Mater Sci 22:1769–1772

Tu KN (1973) Interdiffusion and reaction in bimetallic Cu-Sn thin films. Acta Mat 21:347–354

Wang PJ, Kim JS, Kim D, Lee CC (2007) Fluxless bonding of silicon to molybdenum using Sn-rich solders. Proc. 57th Electronic Components and Technology Conference pp 1573–1578

Wang Q, Choa SH, Kim W, Hwang J, Ham S, Moon C (2006) Application of Au-Sn eutectic bonding in hermetic radio-frequency microelectromechanical system wafer level packaging. J Electron Mater 35:425–432

Welch WC, Najafi K (2007) Nickel-Tin transient liquid phase (TLP) wafer bonding for MEMS vacuum packaging. Proc. 14th International Conference on Solid-State Sensors, Actuators and Microsystems 1327–1328

Welch WC, Najafi K (2008) Gold-indium transient liquid phase (TLP) wafer bonding for MEMS vacuum packaging. Proc. 21st MEMS pp 806–809

Yu DQ, Thew ML (2010) Newly developed low cost, reliable Wafer level hermetic sealing using Cu/Sn system. Proc. 3rd electronic System-Integration Technology Conference pp 1–5

Yu DQ, Yan LL, Lee C, Choi WK, Thew S, Foo CK et al (2009) Wafer-level hermetic bonding using Sn/In and Cu/Ti/Au metallization. IEEE Trans Compon Packag Technol 32:926–934

Acknowledgments

This work has been supported by the DFG within the Collaborative Research Center SFB 855: Magnetoelectric Composites—Future Biomagnetic Interfaces, project C2.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

See Fig. 17.

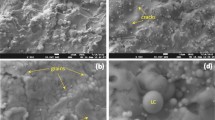

SEM micrographs (a, c, e) and corresponding EDX line scan measurements (b, d, f) for run A2, A3 and C from Table 2. The SEM micrographs show homogeneous and void free bond regions, which are confirmed by the EDX line scans. The measured 8wt % Sn corresponds to the targeted ζ/ζ′ phase

Appendix 2

See Fig. 18.

SEM micrographs (a, c, e) and corresponding EDX line scan measurements (b, d, f) for run D, F and G from Table 2. The SEM micrographs show Cu/Cu-Sn/Cu sandwiches, which are confirmed by the EDX line scan. The measured 32wt % Sn corresponds to the targeted ε phase

Rights and permissions

About this article

Cite this article

Marauska, S., Claus, M., Lisec, T. et al. Low temperature transient liquid phase bonding of Au/Sn and Cu/Sn electroplated material systems for MEMS wafer-level packaging. Microsyst Technol 19, 1119–1130 (2013). https://doi.org/10.1007/s00542-012-1708-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1708-5