Abstract

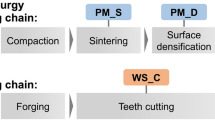

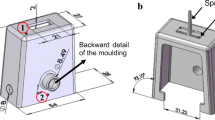

The presented investigations of material properties of micro-components have been carried out in one project of the DFG Collaborative Research Centre (SFB) 499 “Development, production and quality assurance of moulded micro-components made out of metallic and ceramic materials” [SFB01]. The aim of this SFB is to develop production methods for micro-components in large-, middle and short-batches, where the applied metallic and ceramic materials can sustain high stresses and are wear-resistant, e.g. in relation to plastics. A micro-turbine and a sun-and-planet gearing with three stages (outside diameter: 1.9 mm; already realised in plastic [THÜ99]) are planned as a demonstration device. However, for the design of such micro-components, no reliable data for material states in small dimensions are available. Therefore, bending-specimens made out of micro-cast Stabilor G and out of micro-powder-injection-moulded ZrO2 were investigated with respect to their behaviour under quasi-static as well as under cyclic loading.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 10 August 2001/Accepted: 24 September 2001

Rights and permissions

About this article

Cite this article

Auhorn, M., Beck, T., Schulze, V. et al. Quasi-static and cyclic testing of specimens with high aspect ratios produced by micro-casting and micro-powder-injection-moulding. Microsystem Technologies 8, 109–112 (2002). https://doi.org/10.1007/s00542-001-0131-0

Issue Date:

DOI: https://doi.org/10.1007/s00542-001-0131-0