Abstract

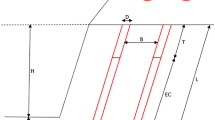

Backbreak is one of the unfavorable blasting results, which can be defined as the unwanted rock breakage behind the last row of blast holes. Blast pattern parameters, like stemming, burden, delay timing, stiffness ratio (bench height/burden) and rock mass conditions (e.g., geo-mechanical properties and joints), are effective in backbreak intensity. Till date, with the exception of some qualitative guidelines, no specific method has been developed for predicting the phenomenon. In this paper, an effort has been made to apply artificial neural networks (ANNs) for predicting backbreak in the blasting operation of the Chadormalu iron mine (Iran). Number of ANN models with different hidden layers and neurons were tried, and it was found that a network with architecture 10-7-7-1 is the optimum model. A comparative study also approved the superiority of the ANN modeling over the conventional regression analysis. Mean square error (MSE), variance account for (VAF) and coefficient of determination (R 2) between measured and predicted backbreak for the ANN model were calculated and found 89.46 %, 0.714 and 90.02 %, respectively. Also, for the regression model, MSE, VAF and R 2 were computed and found 66.93 %, 1.46 and 68.10 %, respectively. Sensitivity analysis was also carried out to find out the influence of each input parameter on backbreak results, and it was revealed that burden is the most influencing parameter on the backbreak, whereas water content is the least effective parameter in this regard.

Similar content being viewed by others

References

Ambrozic T, Turk G (2003) Prediction of subsidence due to underground mining by artificial neural networks. Comput Geosci 29:627–637. doi:10.1016/S0098-3004(03)00044-X

Bauer A (1982) Wall control blasting in open pits. CIM special, vol 30. In: 14th Canadian rock mechanics symposium. Canadian Institute of Mining and Metallurgy, pp 3–10

Badal R (1994) Controlled blasting in jointed rocks. Int J Rock Mech Min Sci 31:79–84. doi:10.1016/0148-9062(94)92317-5

Bhandari S (1997) Engineering rock blasting operations. A. A. Balkema, Rotterdam, pp 165–166

Bhandari S, Badal R (1990) Relationship of joints orientation with hole spacing parameters in multi-hole blasting. In: 3rd international symposium on rock fragmentation by blasting, Brisbane, Australia, pp 225–231

Demuth H, Beal M, Hagan M (1996) Neural network toolbox 5 user’s guide. The Math Work, Natick

Gate WC, Ortiz BLT, Florez RM (2005) Analysis of rockfall and blasting backbreak problems. Proc Am Rock Mech Conf 5:671–680

Hagan TN (1980) The effect of some structural properties of rock on the design and results of blasting. In: Proceedings of the 3rd Australian–New Zealand conference. Geomechanics, pp 205–213

Hafsaoui A, Talhi K (2009) Influence of joint direction and position of explosive charge on fragmentation. Arab J Sci Eng 34:125–134

Jenkins SS (1981) Adjusting blast design for best results. Pit and Quarry, Rotterdam

Jhanwar JC, Jethwa JL (2000) The use of air decks in production blasting in an open pit coal mine. Geotech Geol Eng 18:269–287. doi:10.1023/A:1016634231801

Jia Z, Chen G, Huang S (1998) Computer simulation of open pit bench blasting in jointed rock mass. Int J Rock Mech Min Sci 35:476–486. doi:10.1016/S0148-9062(98)00137-5

Jimeno CL, Jimeno EL, Carcedo FJA (1995) Drilling and blasting of rocks. Balkema, Rotterdam

Jong YH, Lee CI (2004) Influence of geological conditions on the powder factor for tunnel blasting. Int J Rock Mech Min Sci 41:533–538. doi:10.1016/j.ijrmms.2003.12.130

Kahraman S, Gunaydin O, Alber M, Fener M (2009) Evaluating the strength and deformability properties of Misis fault breccia using artificial neural networks. J Expert Syst Appl 36:6874–6878. doi:10.1016/j.eswa.2008.08.002

Khandelwal M, Singh TN (2006) Prediction of blast induced ground vibrations and frequency in opencast mine: a neural network approach. J Sound Vibrat 289:711–725. doi:10.1016/j.jsv.2005.02.044

Khandelwal M, Monjezi M (2012) Prediction of backbreak in open pit blasting operation using machine learning method. Rock Mech Rock Eng (online published)

Khandelwal M (2012) Prediction of safe charge to protect surrounding structures using support vector machine. Geotech Geol Eng (online published)

Khandelwal M (2010) Evaluation and prediction of blast induced ground vibration using support vector machine. Int J Rock Mech Min Sci 47(3):509–516

Khandelwal M, Singh TN (2009) Prediction of blast induced ground vibration using artificial neural network. Int J Rock Mech Min Sci 46:1214–1222

Khandelwal M, Singh TN (2007) Evaluation of blast induced ground vibration predictors. Soil Dyn Earthq Eng 27(2):116–125

Konya CJ, Walter EJ (1991) Rock blasting and over break control. Federal Highway Administration, FHWA-HI-92-001

Konya CJ, Walter EJ (2003) Rock blasting and over break control, 2nd edn. Federal Highway Administration, FHWA-HI-92-001

Kulatilake PHSW, Qiong Wu, Hudaverdi T, Kuzu C (2010) Mean particle size prediction in rock blast fragmentation using neural networks. Eng Geol 114:298–311. doi:10.1016/j.enggeo.2010.05.008

Lu Y (2005) Underground blast induced ground shock and its modeling using artificial neural network. Comput Geotech 32:164–178. doi:10.1016/j.compgeo.2005.01.007

Mandal SK, Singh MM, Dasgupta S (2008) Theoretical concept to understand plan and design smooth blasting pattern. Geotech Geol Eng 26:399–416. doi:10.1007/s10706-008-9177-4

Meulenkamp F, Alvarez Grima M (1999) Application of neural networks for the prediction of the unconfined compressive strength (UCS) from Equotip hardness. Int J Rock Mech Min Sci 36:29–39. doi:10.1016/S0148-9062(98)00173-9

Mohamed MT (2009) Artificial neural network for prediction and control of blasting vibrations in Assiut (Egypt) limestone quarry. Int J Rock Mech Min Sci 46:426–431. doi:10.1016/j.ijrmms.2008.06.004

Monjezi M, Bahrami A, YazdianVarjani A (2010) Simultaneous prediction of fragmentation and fly rock in blasting operation using artificial neural networks. Int J Rock Mech Min Sci 47:476–480. doi:10.1016/j.ijrmms.2009.09.008

Monjezi M, Dehghani H (2008) Evaluation of effect of blasting pattern parameters on backbreak using neural networks. Int J Rock Mech Min Sci 45:1446–1453. doi:10.1016/j.ijrmms.2008.02.007

Monjezi M, Ghafurikalajahia M, Bahrami A (2010) Prediction of blast-induced ground vibration using artificial neural networks. Tunn Undergr Sp Tech. doi:10.1016/j.tust.2010.05.002

Monjezi M, Rezaei M, Yazdian A (2010) Prediction of backbreak in open-pit blasting using fuzzy set theory. J Expert Syst Appl 37:2637–2643. doi:10.1016/j.eswa.2009.08.014

Ozgen Karacan C (2008) Modeling and prediction of ventilation methane emissions of U.S. longwall mines using supervised artificial neural networks. Int J Coal Geol 73:371–387. doi:10.1016/j.coal.2007.09.003

Santos OJ Jr, Celestino B (2008) Artificial neural networks analysis of Sao Paulo subway tunnel settlement data. Tunn Undergr Sp Tech 23:481–491. doi:10.1016/j.tust.2007.07.002

Scoble MJ, Lizotte YC, Paventi M, Mohanty BB (1997) Measurement of blast damage. Min Eng 49:103–108

Stegemann JA, Buenfeld NR (2003) Prediction of unconfined compressive strength of cement paste containing industrial wastes. Waste Manag 23:321–332. doi:10.1016/S0956-053X(02)00062-4

Singh SP (2000) The role of joints and rock mass quality in perimeter control. In: Proceedings of the 1st world conference on explosives and blasting technique, pp 371–375

Tiryaki B (2008) Application of artificial neural networks for predicting the cuttability of rocks by drag tools. Tunn Undergr Sp Tech 2:273–280. doi:10.1016/j.tust.2007.04.008

Levesque R (2007) SPSS programming and data management: a guide for SPSS and SAS users, 4th edn. SPSS, Chicago

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monjezi, M., Ahmadi, Z., Varjani, A.Y. et al. Backbreak prediction in the Chadormalu iron mine using artificial neural network. Neural Comput & Applic 23, 1101–1107 (2013). https://doi.org/10.1007/s00521-012-1038-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-1038-7