Abstract

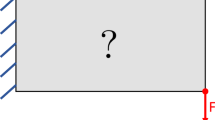

Mechanical science and engineering can use machine learning. However, data sets have remained relatively scarce; fortunately, known governing equations can supplement these data. This paper summarizes and generalizes three reduced order methods: self-consistent clustering analysis, virtual clustering analysis, and FEM-clustering analysis. These approaches have two-stage structures: unsupervised learning facilitates model complexity reduction and mechanistic equations provide predictions. These predictions define databases appropriate for training neural networks. The feed forward neural network solves forward problems, e.g., replacing constitutive laws or homogenization routines. The convolutional neural network solves inverse problems or is a classifier, e.g., extracting boundary conditions or determining if damage occurs. We will explain how these networks are applied, then provide a practical exercise: topology optimization of a structure (a) with non-linear elastic material behavior and (b) under a microstructural damage constraint. This results in microstructure-sensitive designs with computational effort only slightly more than for a conventional linear elastic analysis.

Similar content being viewed by others

References

Hashin Z, Shtrikman S (1963) A variational approach to the theory of the elastic behaviour of multiphase materials. J Mech Phys Solids 11(2):127

Hill R (1965) A self-consistent mechanics of composite materials. J Mech Phys Solids 13(4):213

Ghosh S, Lee K, Moorthy S (1996) Two scale analysis of heterogeneous elastic-plastic materials with asymptotic homogenization and Voronoi cell finite element model. Comput Methods Appl Mech Eng 132(1–2):63

Paley M, Aboudi J (1992) Micromechanical analysis of composites by the generalized cells model. Mech Mater 14(2):127

Dvorak GJ (1992) Transformation field analysis of inelastic composite materials. Proc R Soci London Series A Math Phys Sci 437(1900):311–327

Michel JC, Suquet P (2003) Nonuniform transformation field analysis. Int J Solids Struct 40(25):6937

Yvonnet J, He QC (2007) The reduced model multiscale method (R3M) for the non-linear homogenization of hyperelastic media at finite strains. J Comput Phys 223(1):341

Berkooz G, Holmes P, Lumley JL (1993) The proper orthogonal decomposition in the analysis of turbulent flows. Annu Rev Fluid Mech 25(1):539

Liu Z, Bessa M, Liu W (2016) Self-consistent clustering analysis: an efficient multi-scale scheme for inelastic heterogeneous materials. Comput Methods Appl Mech Eng 306:319

Shakoor M, Kafka OL, Yu C, Liu WK (2018) Data science for finite strain mechanical science of ductile materials. Comput Mech 1–13

Kafka OL, Yu C, Shakoor M, Liu Z, Wagner GJ, Liu WK (2018) Data-driven mechanistic modeling of influence of microstructure on high-cycle fatigue life of nickel titanium. JOM 70(7):1154

Yu C, Kafka OL, Liu WK (2019) Self-consistent clustering analysis for multiscale modeling at finite strains. Comput Methods Appl Mech Eng 349:339

Oishi A, Yagawa G (2017) Computational mechanics enhanced by deep learning. Comput Methods Appl Mech Eng 327:327

Kirchdoerfer T, Ortiz M (2016) Data-driven computational mechanics. Comput Methods Appl Mech Eng 304:81

Liu Z, Wu C, Koishi M (2018) A deep material network for multiscale topology learning and accelerated nonlinear modeling of heterogeneous materials. Comput Methods Appl Mech Eng 345:1138–1168

Tang S, Zhang L, Liu WK (2018) From virtual clustering analysis to self-consistent clustering analysis: a mathematical study. Comput Mech 1–18

Cheng G, Li X, Nie Y, Li H (2019) FEM-Cluster based reduction method for efficient numerical prediction of effective properties of heterogeneous material in nonlinear range. Comput Methods Appl Mech Eng 348:157–184

Kröner E (1972) Statistical continuum mechanics, vol 92. Springer, Berlin

Gan Z, Li H, Wolff SJ, Bennett JL, Hyatt G, Wagner GJ, Cao J, Liu WK (2019) Data-driven microstructure and microhardness design in additive manufacturing using self-organizing map. Engineering (in press)

Zhang L, Tang S, Yu C, Zhu X, Liu W K (2019) Fast calculation of interaction tensors in clustering-based homogenization. Comput Mech (in press)

Nie Y, Cheng G, Li X, Xu L, Li K (2019) Principle of cluster minimum complementary energy of FEM-cluster-based reduced order method: fast updating the interaction matrix and predicting effective nonlinear properties of heterogeneous material. Comput Mech. https://doi.org/10.1007/s00466-019-01710-6

Goodfellow I, Bengio Y, Courville A (2016) Deep learning. MIT Press. http://www.deeplearningbook.org. Accessed 28 Apr 2019

Haykin S (1994) Neural networks: a comprehensive foundation. Prentice Hall PTR, Upper Saddle River

Schmidhuber J (2015) Deep learning in neural networks: an overview. Neural Netw 61:85

Funahashi KI (1989) On the approximate realization of continuous mappings by neural networks. Neural Netw 2(3):183

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2(5):359

Ghaboussi J, Garrett J Jr, Wu X (1991) Knowledge-based modeling of material behavior with neural networks. J Eng Mech 117(1):132

Furukawa T, Yagawa G (1998) Implicit constitutive modelling for viscoplasticity using neural networks. Int J Numer Methods Eng 43(2):195

Qingbin L, Zhong J, Mabao L, Shichun W (1996) Acquiring the constitutive relationship for a thermal viscoplastic material using an artificial neural network. J Mater Process Technol 62(1–3):206

Yeh IC (1998) Modeling of strength of high-performance concrete using artificial neural networks. Cement Concrete Res 28(12):1797

Huber N, Tsakmakis C (2001) A neural network tool for identifying the material parameters of a finite deformation viscoplasticity model with static recovery. Comput Methods Appl Mech Eng 191(3–5):353

Pichler B, Lackner R, Mang HA (2003) Back analysis of model parameters in geotechnical engineering by means of soft computing. Int J Numer Methods Eng 57(14):1943

Kucerová A, Leps M, Zeman J (2009) Back analysis of microplane model parameters using soft computing methods. arXiv preprint arXiv:0902.1690

Feyel F, Chaboche JL (2000) FE2 multiscale approach for modelling the elastoviscoplastic behaviour of long fibre SiC/Ti composite materials. Comput Methods Appl Mech Eng 183(3–4):309

Kouznetsova V, Geers MG, Brekelmans WM (2002) Multi-scale constitutive modelling of heterogeneous materials with a gradient-enhanced computational homogenization scheme. Int J Numer Methods Eng 54(8):1235

Feyel F (2003) A multilevel finite element method (FE2) to describe the response of highly non-linear structures using generalized continua. Comput Methods Appl Mech Eng 192(28—-30):3233

Ghaboussi J, Pecknold DA, Zhang M, Haj-Ali RM (1998) Autoprogressive training of neural network constitutive models. Int J Numer Methods Eng 42(1):105

Shin H, Pande G (2000) On self-learning finite element codes based on monitored response of structures. Comput Geotech 27(3):161

Shin H, Pande G (2003) Identification of elastic constants for orthotropic materials from a structural test. Comput Geotech 30(7):571

Gawin D, Lefik M, Schrefler B (2001) ANN approach to sorption hysteresis within a coupled hygro-thermo-mechanical FE analysis. Int J Numer Methods Eng 50(2):299

Lefik M, Schrefler B (2002) One-dimensional model of cable-in-conduit superconductors under cyclic loading using artificial neural networks. Fusion Eng Des 60(2):105

Lefik M, Schrefler B (2003) Artificial neural network as an incremental non-linear constitutive model for a finite element code. Comput Methods Appl Mech Eng 192(28–30):3265

Le B, Yvonnet J, He QC (2015) Computational homogenization of nonlinear elastic materials using neural networks. Int J Numer Methods Eng 104(12):1061

Bhattacharjee S, Matouš K (2016) A nonlinear manifold-based reduced order model for multiscale analysis of heterogeneous hyperelastic materials. J Comput Phys 313:635

Cecen A, Dai H, Yabansu YC, Kalidindi SR, Song L (2018) Material structure-property linkages using three-dimensional convolutional neural networks. Acta Mater 146:76

Wang K, Sun W (2019) Meta-modeling game for deriving theory-consistent, microstructure-based traction-separation laws via deep reinforcement learning. Comput Methods Appl Mech Eng 346:216

Han J, Moraga C (1995) The influence of the sigmoid function parameters on the speed of backpropagation learning. In: International workshop on artificial neural networks. Springer, Berlin, pp 195–201

Matlab deep learning toolbox (2018b) MATLAB deep learning toolbox. The MathWorks, Natick

Levenberg K (1944) A method for the solution of certain non-linear problems in least squares. Q Appl Math 2(2):164

Marquardt DW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11(2):431

Goodfellow I, Bengio Y, Courville A (2017) Deep learning. MIT Press, Cambridge

Matsugu M, Mori K, Mitari Y, Kaneda Y (2003) Subject independent facial expression recognition with robust face detection using a convolutional neural network. Neural Netw 16(5–6):555

Lubbers N, Lookman T, Barros K (2017) Inferring low-dimensional microstructure representations using convolutional neural networks. Phys Rev E 96(5):052111

Kondo R, Yamakawa S, Masuoka Y, Tajima S, Asahi R (2017) Microstructure recognition using convolutional neural networks for prediction of ionic conductivity in ceramics. Acta Mater 141:29

DeCost BL, Francis T, Holm EA (2017) Exploring the microstructure manifold: image texture representations applied to ultrahigh carbon steel microstructures. Acta Mater 133:30

Ling J, Hutchinson M, Antono E, DeCost B, Holm EA, Meredig B (2017) Building data-driven models with microstructural images: generalization and interpretability. Mater Discov 10:19

Cang R, Li H, Yao H, Jiao Y, Ren Y (2018) Improving direct physical properties prediction of heterogeneous materials from imaging data via convolutional neural network and a morphology-aware generative model. Comput Mater Sci 150:212

Yang Z, Yabansu YC, Al-Bahrani R, Wk Liao, Choudhary AN, Kalidindi SR, Agrawal A (2018) Deep learning approaches for mining structure-property linkages in high contrast composites from simulation datasets. Comput Mater Sci 151:278

Yang Z, Yabansu YC, Jha D, Wk Liao, Choudhary AN, Kalidindi SR, Agrawal A (2019) Establishing structure-property localization linkages for elastic deformation of three-dimensional high contrast composites using deep learning approaches. Acta Mater 166:335

Abaqus V (2014) 6.14 Documentation. Dassault Systemes Simulia Corporation 651

Cheng G, Guo X (1997) \(\varepsilon \)-relaxed approach in structural topology optimization. Struct Optim 13(4):258

Duysinx P, Bendsøe MP (1998) Topology optimization of continuum structures with local stress constraints. Int J Numer Methods Eng 43(8):1453

Guo X, Cheng G, Yamazaki K (2001) A new approach for the solution of singular optima in truss topology optimization with stress and local buckling constraints. Struct Multidiscip Optim 22(5):364

Guo X, Zhang WS, Wang MY, Wei P (2011) Stress-related topology optimization via level set approach. Comput Methods Appl Mech Eng 200(47–48):3439

Sigmund O (2001) A 99 line topology optimization code written in MATLAB. Struct Multidiscip Optim 21(2):120

Acknowledgements

The authors thank Sourav Saha and Satyajit Mojumder for their helpful suggestions during the writing process. W.K.L. acknowledges the support of the National Science Foundation under Grant No. MOMS/CMMI-1762035. O.L.K. thanks the United States National Science Foundation (NSF) for their support through the NSF Graduate Research Fellowship Program under financial award number DGE-1324585. H. L. acknowledges the support by the Northwestern University Data Science Initiative (DSI) under Grant No. 171 4745002 10043324. L.Z. and SQ.T. were supported partially by the National Science Foundation of China under Grant numbers 11832001, 11521202, and 11890681.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Kafka, O.L., Gao, J. et al. Clustering discretization methods for generation of material performance databases in machine learning and design optimization. Comput Mech 64, 281–305 (2019). https://doi.org/10.1007/s00466-019-01716-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-019-01716-0