Abstract

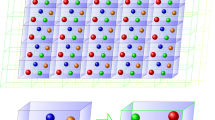

Architectured materials (or metamaterials) are constituted by a unit-cell with a complex structural design repeated periodically forming a bulk material with emergent mechanical properties. One may obtain specific macro-scale (or bulk) properties in the resulting architectured material by properly designing the unit-cell. Typically, this is stated as an optimal design problem in which the parameters describing the shape and mechanical properties of the unit-cell are selected in order to produce the desired bulk characteristics. This is especially pertinent due to the ease manufacturing of these complex structures with 3D printers. The proper generalized decomposition provides explicit parametic solutions of parametric PDEs. Here, the same ideas are used to obtain parametric solutions of the algebraic equations arising from lattice structural models. Once the explicit parametric solution is available, the optimal design problem is a simple post-process. The same strategy is applied in the numerical illustrations, first to a unit-cell (and then homogenized with periodicity conditions), and in a second phase to the complete structure of a lattice material specimen.

Similar content being viewed by others

References

Almgren RF (1985) An isotropic three-dimensional structure with Poisson’s ratio = \(-1\). J Elast 15(4):427–430

Amendola A, Smith CJ, Goodall R, Auricchio F, Feo L, Benzoni G, Fraternali F (2016) Experimental response of additively manufactured metallic pentamode materials confined between stiffening plates. Compos Struct 142:254–262

Ammar A, Chinesta F, Díez P, Huerta A (2010) An error estimator for separated representations of highly multidimensional models. Comput Methods Appl Mech Eng 199(25):1872–1880

Anthoine A (1995) Derivation of the in-plane elastic characteristics of masonry through homogenization theory. Int J Solids Struct 32(2):137–163

Banerjee D, Ji C, Iizuka H (2016) Invisibility cloak with image projection capability. Sci Rep 6:38,965 EP. https://doi.org/10.1038/srep38965

Bauchau OA, Craig JI (2009) Structural analysis: with applications to aerospace structures, vol 163. Springer, New York

Bertoldi K, Reis PM, Willshaw S, Mullin T (2010) Negative Poisson’s ratio behavior induced by an elastic instability. Adv Mater 22(3):361–366

Cadman JE, Zhou S, Chen Y, Li Q (2013) On design of multi-functional microstructural materials. J Mater Sci 48(1):51–66

Chinesta F, Ammar A, Cueto E (2010) Recent advances and new challenges in the use of the proper generalized decomposition for solving multidimensional models. Arch Comput Methods Eng 17(4):327–350

Christensen J, Kadic M, Kraft O, Wegner M (2015) Vibrant times for mechanical metamaterials. MRS Commun 5:453–462

Cook RD, Malkus DS, Plesha ME, Witt RJ (2002) Concepts and applications of finite element analysis, 4th edn. Wiley, New York

Elipe JCÁ, Lantada AD (2012) Comparative study of auxetic geometries by means of computer-aided design and engineering. Smart Mater Struct 21(10):105,004

Ergin T, Stenger N, Brenner P, Pendry JB, Wegener M (2010) Three-dimensional invisibility cloack at optical wavelengths. Science 328:337–339

Greaves GN, Greer AL, Lakes RS, Rouxel T (2011) Poisson’s ratio and modern materials. Nat Mater 10(11):823837

Hopkins JB, Lange KJ, Spadaccini CM (2013) Designing microstructural architectures with thermally actuated properties using freedom, actuation and constraint topologies. J Mech Des 135(6):061,004

Kadic M, Bückmann T, Schittny R, Wegener M (2013) Metamaterials beyond electromagnetism. Rep Prog Phys 76(12):126,501

Kadic M, Bückmann T, Stenger N, Thiel M, Wegener M (2012) On the practicability of pentamode mechanical metamaterials. Appl Phys Lett 100(19):191,901

Lantada AD, Muslija A, García-Ruíz JP (2015) Auxetic tissue engineering scaffolds with nanometric features and resonances in the megahertz range. Smart Mater Struct 24(5):055,013

Lempriere B (1968) Poissons ratio in orthotropic materials. AIAA J 6(11):2226–2227

Michel JC, Moulinec H, Suquet P (1999) Effective properties of composite materials with periodic microstructure: a computational approach. Comput Methods Appl Mech Eng 172:109–143

Milton GW, Cherkaev A (1995) Which elasticity tensors are realizable? J Eng Mater Technol 117:483–493

Modesto D, Zlotnik S, Huerta A (2015) Proper generalized decomposition for parameterized Helmholtz problems in heterogeneous and unbounded domains: application to harbor agitation. Comput Methods Appl Mech Eng 295:127–149. https://doi.org/10.1016/j.cma.2015.03.026

Rafsanjani A, Akbarzadeh A, Pasini D (2015) Snapping mechanical metamaterials under tension. Adv Mater 27(39):5931–5935

Rafsanjani A, Pasini D (2016) Bistable auxetic mechanical metamaterials inspired by ancient geometric motifs. Extreme Mech Lett 9:291–296

Reis PM (2015) A perspective on the revival of structural (in) stability with novel opportunities for function: from buckliphobia to buckliphilia. J Appl Mech Technol 82:111,001

Reis PM, Jaeger HM, van Hecke M (2015) Designer matter: a perspective. Extreme Mech Lett 5:25–29

Sigmund O (1994) Design of material structures using topology optimization. Ph.D. thesis, Technical University of Denmark

Sigmund O (1994) Materials with prescribed constitutive parameters: an inverse homogenization problem. Int. J. Solids Struct. 31(17):2313–2329

Sigmund O (1995) Tailoring materials with prescribed elastic properties. Mech Mater 20:351–368

Sigmund O, Torquato S (1996) Composites with extremal thermal expansion coefficients. Appl Phys Lett 69(21):3203–3205

Zlotnik S, Díez P, González D, Cueto E, Huerta A (2015) Effect of the separated approximation of input data in the accuracy of the resulting PGD solution. Adv Model Simul Eng Sci. https://doi.org/10.1016/j.cma.2015.03.026

Zlotnik S, Díez P, Modesto D, Huerta A (2015) Proper generalized decomposition of a geometrically parametrized heat problem with geophysical applications. Int J Numer Methods Eng 103(10):737–758

Acknowledgements

This work has been supported by Ministerio de Economía y Competitividad, Grant Numbers DPI2014-51844-C2-2-R and DPI2017-85139-C2-2-R, together with Generalitat de Catalunya, Grant Number 2014-SGR-1471 and European Education, Audiovisual and Culture Executive Agency (EACEA) under the Erasmus Mundus Joint Doctorate Simulation in Engineering and Entrepreneurship Development (SEED), FPA 2013-0043.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A. Proper generalized decomposition algorithms

Appendix B. Analytical solutions

Given the unit-cell global stiffness matrix built by Bernoulli beam elements, \(\mathbf {K}(\varvec{\mu })\), the equations

contain equilibrium and periodicity conditions, given a specific load case in the unit-cell. If the constraints are applied using a direct method [11], then the system unknowns can be split into released and constrained such as

in a way that the constrained unknowns can be solved in terms of the released

The system can be solved for the released unknowns only:

where

While \(\forall \varvec{\mu } \in \mathcal {D}=I_{1}\times I_{2}\times \ldots \times I_{\texttt {n}_{\texttt {p}}}\), \(\mathbf {K}(\varvec{\mu }) \in \mathbb {R}^{({\texttt {n}_{\texttt {dof}}}\times {\texttt {n}_{\texttt {dof}}})}\), \(\mathbf {K}_{\mathrm {R}}(\varvec{\mu }) \in \mathbb {R}^{({n_{\mathrm {R}}}\times {n_{\mathrm {R}}})}\). In the unit-cell problem, \({\texttt {n}_{\texttt {dof}}}=24\) is reduced to \({n_{\mathrm {R}}}=13\). Now the system can be solved symbolically with the parameters \(\varvec{\mu } = [ t \, \, a \,\, b\, \, \alpha ]^{\textsf {T}}\).

With this, the parametric solution for case XX results:

Figure 25 shows a scaled analytical solution for case XX, evaluated at parameters \(b=1\), \(t=\frac{1}{40}\), \(a=0.5\), \(\alpha =60^{\circ }\) as an example.

The solution for load case YY becomes:

Figure 26 shows a scaled analytical solution for case YY, evaluated at parameters \(b=1\), \(t=\frac{1}{40}\), \(a=0.5\), \(\alpha =60^{\circ }\).

Finally, for case XY:

Figure 27 shows a scaled analytical solution for case XY, evaluated at parameters \(b=1\), \(t=\frac{1}{40}\), \(a=0.5\), \(\alpha =60^{\circ }\).

At this point, it seems worth mentioning the parametric analytical solutions have the size of a unit-cell reduced by its periodic constraints. For a full structure done by repetitions of unit-cells, or a pattern with irregularities, the cost of obtaining such expressions becomes computationally unfeasible.

Finally, the components of the effective elasticity matrix are calculated from (37) and are shown in Eqs. (43)–(48). It is worth mentioning that these results are affected by a factor of E, the Young’s modulus of the constituent material, which is here omitted for the sake of clarity:

Using (43), (45) and (46) the orthotropic Poisson’s ratios can be calculated as follows, which assumes a state of plane stress ([6]):

Rights and permissions

About this article

Cite this article

Sibileau, A., García-González, A., Auricchio, F. et al. Explicit parametric solutions of lattice structures with proper generalized decomposition (PGD). Comput Mech 62, 871–891 (2018). https://doi.org/10.1007/s00466-017-1534-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-017-1534-9