Abstract

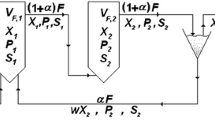

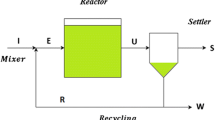

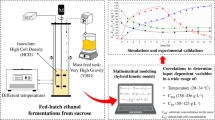

An unsegregated and unstructured model developed for a small-scale process of ethanol production in a tower reactor with cell recycle was applied to describe the experimental data obtained in a large-scale process. The model was developed considering the following points: reactor hydrodynamic behavior analogous to that of ideal CSTR, substrate limitation, inhibition phenomena linked both to ethanol and to biomass, absence of fermentation in the settler, and no loss of cell viability. The scale-up criterion consisted in maintaining an identical relation settler volume/fermentor volume on the two scales. All large-scale experiments were carried out using a flocculating yeast strain IR-2, isolated from fermented food, and identified as Saccharomyces cerevisiae. Sugarcane juice was used as the substrate source with sugar concentrations of 150 g/l. Different values of dilution rate and recycle ratio were employed (D = 0.11–0.33 h−1, α = 5.4–18.0) and the temperature was of 32 °C. The kinetic parameters were similar on both scales and the model predictions agreed well with the large-scale experimental data.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 25 June 1998

Rights and permissions

About this article

Cite this article

Oliveira, S., De Castro, H., Visconti, A. et al. Continuous ethanol fermentation in a tower reactor with flocculating yeast recycle: scale-up effects on process performance, kinetic parameters and model predictions. Bioprocess Engineering 20, 525–530 (1999). https://doi.org/10.1007/s004490050624

Issue Date:

DOI: https://doi.org/10.1007/s004490050624